EN 14466:2005+A1:2008

(Main)Fire-fighting pumps - Portable pumps - Safety and performance requirements, tests

Fire-fighting pumps - Portable pumps - Safety and performance requirements, tests

This document applies to portable pumps using fire-fighting centrifugal pumps as defined in EN 1028, driven

by an internal combustion engine and not intended to be permanently installed in fire-fighting and rescue

service vehicles and not intended for prolonged unattended operation.

NOTE 1 If use of the portable pump is foreseen for prolonged unattended operation, this should be agreed between the

purchaser and the manufacturer or the manufacturer‘s authorized representative at the time of ordering. In this case an

additional risk analysis should be carried out.

This document deals with all significant hazards, hazardous situations and events relevant to portable firefighting

pumps as described above, when they are used as intended and under the conditions foreseen by the

manufacturer (see Clause 4). It addresses the design, setting up, and operation of the portable pump.

This document also specifies performance requirements for portable pumps in its scope.

This document applies to portable pumps used in ambient temperatures between –15 °C and + 35 °C.

NOTE 2 Additional measures may be necessary for ambient temperatures beyond the limits –15 °C and + 35 °C

This document does not cover the effect on performance of water inlet temperatures above + 20°C.

This document does not contain any requirements for inlet and outlet connection couplings.

NOTE 3 For inlet and outlet connection couplings national regulations apply. The design should be agreed at the time

of ordering between purchaser and the manufacturer or manufacturer‘s authorized representative.

This document does not contain specific requirements for the driving engine but deals with the hazards related

to the interface between engine and pump.

Feuerlöschpumpen - Tragkraftspritzen - Sicherheits- und Leistungsanforderungen, Prüfungen

Dieses Dokument gilt für Tragkraftspritzen mit Feuerlöschkreiselpumpen nach EN 1028, die von einem

Verbrennungsmotor angetrieben werden und weder dafür vorgesehen sind, dauerhaft in Feuerwehr- und

Rettungsfahrzeugen eingebaut zu sein noch längere Zeit unbeaufsichtigt betrieben zu werden.

ANMERKUNG 1 Sofern die Tragkraftspritze für längeren unbeaufsichtigten Betrieb vorgesehen ist, sollte dies bei der

Bestellung zwischen dem Käufer und dem Hersteller oder dessen autorisiertem Vertreter vereinbart werden. In diesem

Fall sollte eine zusätzliche Risikoanalyse ausgeführt werden.

Dieses Dokument behandelt alle signifikanten Gefährdungen, Gefährdungssituationen und -ereignisse, die

sich beim bestimmungsgemäßen Einsatz der oben beschriebenen Tragkraftspritzen und unter den vom

Hersteller (siehe Abschnitt 4) vorhersagbaren Bedingungen ergeben. Es behandelt die Konstruktion, die

Einstellung und den Betrieb der Tragkraftspritze.

Dieses Dokument legt ferner die Leistungsanforderungen an Tragkraftspritzen im Anwendungsbereich fest.

Dieses Dokument gilt für Tragkraftspritzen, die unter Umgebungstemperaturen zwischen – 15 °C und + 35 °C

eingesetzt werden.

ANMERKUNG 2 Für Umgebungstemperaturen außerhalb des Bereiches von – 15 °C und + 35 °C können zusätzliche

Maßnahmen erforderlich sein.

Dieses Dokument berücksichtigt nicht den Einfluss von Wasserzulauftemperaturen oberhalb von + 20 °C auf

die Leistung des Geräts.

Dieses Dokument enthält keine Anforderungen an Eintritts- und Austritts-Anschlusskupplungen.

Pompes à usage incendie - Motopompes portables - Prescriptions de sécurité et de performance, essais

Le présent document s’applique aux motopompes portables utilisant des pompes centrifuges à usage incendie telles

que définies dans l'EN 1028, entraînées par un moteur à combustion, non destinées à un montage permanent sur

les véhicules de lutte contre l’incendie et des services de secours et non prévues pour un fonctionnement sans

surveillance prolongé.

NOTE 1 Si l'utilisation de la motopompe est prévue pour des fonctionnement sans surveillance prolongés, il convient que

ceci fasse l'objet d'un accord entre l’acquéreur et le fabricant ou son représentant autorisé au moment de la commande.

Dans ce cas, il convient d'effectuer une évaluation des risques complémentaire.

Le présent document traite de tous les phénomènes dangereux significatifs, des situations dangereuses et des

événements dangereux provoqués par les motopompes portables tel que décrit ci-dessus, lorsqu'elles sont utilisées

normalement et dans les conditions prévues par le constructeur (voir Article 4). Elle aborde les questions relatives à

la construction, au réglage et au fonctionnement des motopompes portables.

Le présent document spécifie également les prescriptions de performance auxquelles doivent satisfaire les

motopompes portables de ce domaine d’application.

Le présent document s’applique aux motopompes portables utilisées dans une plage de température ambiante

comprise entre – 15 °C et + 35 °C.

NOTE 2 Des mesures complémentaires peuvent être nécessaires pour les températures ambiantes situées au delà des

limites – 15 °C et + 35 °C.

Le présent document ne couvre pas les effet sur la performance pour des températures d'entrée supérieures

à + 20 °C.

Le présent document ne contient aucune prescription relative aux raccords d’aspiration et de refoulement.

Gasilske črpalke - Prenosne črpalke - Zahteve za varnost in obnašanje v uporabi, preskusi

General Information

- Status

- Published

- Publication Date

- 08-Jul-2008

- Withdrawal Date

- 27-Dec-2009

- Technical Committee

- CEN/TC 192 - Fire service equipment

- Drafting Committee

- CEN/TC 192 - Fire service equipment

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 04-Jun-2021

- Completion Date

- 04-Jun-2021

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 214, C 214, C 214, C 214, C 214, C 214, C 214, C OJ Date: 08-Sep-2009

Not Harmonized98/37/EC - MachineryOJ Ref: C 22, C 22, C 22, C 22, C 22, C 22, C 22, C 22, C, OJ Date: 28-Jan-2009

Relations

- Merged From

EN 14466:2005 - Fire fighting pumps - Portable pumps - Safety and performance requirements, tests - Effective Date

- 19-Jan-2023

- Effective Date

- 09-Feb-2026

- Refers

ISO 9244:1995 - Earth-moving machinery — Safety signs and hazard pictorials — General principles - Effective Date

- 09-Feb-2026

- Refers

EN 60254-1:2005 - Lead acid traction batteries - Part 1: General requirements and methods of tests - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 12639:2000 - Liquid pumps and pump units - Noise test code - Grade 2 and grade 3 of accuracy - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 14466:2005+A1:2008 - Fire-fighting pumps - Portable pumps - Safety and performance requirements, tests (CEN) - is a Type C European standard for portable fire-fighting centrifugal pumps (as defined in EN 1028) driven by an internal combustion engine. It specifies safety measures, performance requirements and verification tests for portable pump units that are not permanently installed in fire-and-rescue vehicles and are not intended for prolonged unattended operation. The standard applies to ambient temperatures between −15 °C and +35 °C and excludes requirements for inlet/outlet couplings and engine design beyond the pump–engine interface.

Key Topics

- Scope & hazards: identification of significant hazards for portable firefighting pumps and their intended use.

- Safety requirements: mechanical guards, thermal protection, electrical facilities, noise control, ergonomics, overspeed protection, stopping devices and pressure limit indication.

- Performance requirements: hydraulic performance, vibration limits, inclination (operation and transport), cold-start behavior, priming time, cooling and fuel system performance, clutch and generator criteria, corrosion resistance.

- Verification & testing: procedures for validating safety measures and performance (hydraulic tests, noise test code, inclination tests, vibration, cold start, priming).

- Documentation & marking: requirements for test reports, information for use, non-text safety signs, warnings and marking for safe operation.

- Annexes: normative and informative annexes including noise test code, inclination tests, signage guidance and EU Directive relationship (Annex ZA/ZB).

Applications

EN 14466 is used to:

- Develop and design portable fire-fighting pumps meeting recognised safety and performance benchmarks.

- Create procurement specifications and acceptance criteria for fire services and civil protection procurement.

- Guide manufacturers and authorized representatives in risk assessment, testing and CE-related documentation.

- Support test laboratories conducting verification of hydraulic performance, noise, vibration and durability.

- Inform maintenance organizations and end-users about safe operation, markings and required documentation.

Note: If a pump is intended for prolonged unattended operation, purchaser and manufacturer should agree this at ordering time and carry out an additional risk analysis.

Who should use this standard

- Pump manufacturers and OEMs

- Test and certification laboratories

- Fire and rescue services (procurement and technical teams)

- Regulatory bodies and national standards organizations

- Maintenance and safety engineers

Related Standards

- EN 1028 (centrifugal fire-fighting pumps) - defines pump types referenced by EN 14466.

- Relevant EU machinery directives (relationship documented in Annex ZA/ZB) for conformity and CE marking.

Keywords: EN 14466:2005+A1:2008, portable fire-fighting pumps, safety requirements, performance tests, centrifugal pump, priming time, noise test code, EN 1028, CEN.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 14466:2005+A1:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Fire-fighting pumps - Portable pumps - Safety and performance requirements, tests". This standard covers: This document applies to portable pumps using fire-fighting centrifugal pumps as defined in EN 1028, driven by an internal combustion engine and not intended to be permanently installed in fire-fighting and rescue service vehicles and not intended for prolonged unattended operation. NOTE 1 If use of the portable pump is foreseen for prolonged unattended operation, this should be agreed between the purchaser and the manufacturer or the manufacturer‘s authorized representative at the time of ordering. In this case an additional risk analysis should be carried out. This document deals with all significant hazards, hazardous situations and events relevant to portable firefighting pumps as described above, when they are used as intended and under the conditions foreseen by the manufacturer (see Clause 4). It addresses the design, setting up, and operation of the portable pump. This document also specifies performance requirements for portable pumps in its scope. This document applies to portable pumps used in ambient temperatures between –15 °C and + 35 °C. NOTE 2 Additional measures may be necessary for ambient temperatures beyond the limits –15 °C and + 35 °C This document does not cover the effect on performance of water inlet temperatures above + 20°C. This document does not contain any requirements for inlet and outlet connection couplings. NOTE 3 For inlet and outlet connection couplings national regulations apply. The design should be agreed at the time of ordering between purchaser and the manufacturer or manufacturer‘s authorized representative. This document does not contain specific requirements for the driving engine but deals with the hazards related to the interface between engine and pump.

This document applies to portable pumps using fire-fighting centrifugal pumps as defined in EN 1028, driven by an internal combustion engine and not intended to be permanently installed in fire-fighting and rescue service vehicles and not intended for prolonged unattended operation. NOTE 1 If use of the portable pump is foreseen for prolonged unattended operation, this should be agreed between the purchaser and the manufacturer or the manufacturer‘s authorized representative at the time of ordering. In this case an additional risk analysis should be carried out. This document deals with all significant hazards, hazardous situations and events relevant to portable firefighting pumps as described above, when they are used as intended and under the conditions foreseen by the manufacturer (see Clause 4). It addresses the design, setting up, and operation of the portable pump. This document also specifies performance requirements for portable pumps in its scope. This document applies to portable pumps used in ambient temperatures between –15 °C and + 35 °C. NOTE 2 Additional measures may be necessary for ambient temperatures beyond the limits –15 °C and + 35 °C This document does not cover the effect on performance of water inlet temperatures above + 20°C. This document does not contain any requirements for inlet and outlet connection couplings. NOTE 3 For inlet and outlet connection couplings national regulations apply. The design should be agreed at the time of ordering between purchaser and the manufacturer or manufacturer‘s authorized representative. This document does not contain specific requirements for the driving engine but deals with the hazards related to the interface between engine and pump.

EN 14466:2005+A1:2008 is classified under the following ICS (International Classification for Standards) categories: 13.220.10 - Fire-fighting. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14466:2005+A1:2008 has the following relationships with other standards: It is inter standard links to EN 14466:2005, EN 61310-3:2008, ISO 9244:1995, EN 60254-1:2005, EN 61310-1:1995, EN 60204-1:1997, EN 61310-2:2008, EN IEC/IEEE 82079-1:2020, EN 60529:1991, EN 894-2:1997+A1:2008, EN 1028-1:2002, EN 547-2:1996+A1:2008, EN ISO 13732-1:2008, EN 12639:2000, EN ISO 11102-2:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14466:2005+A1:2008 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14466:2005+A1:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.SUHVNXVLFeuerlöschpumpen - Tragkraftspritzen - Sicherheits- und Leistungsanforderungen, PrüfungenPompes à usage incendie - Motopompes portables - Prescriptions de sécurité et de performance, essaisFire-fighting pumps - Portable pumps - Safety and performance requirements, tests13.220.10Gašenje požaraFire-fightingICS:Ta slovenski standard je istoveten z:EN 14466:2005+A1:2008SIST EN 14466:2005+A1:2009en,fr,de01-januar-2009SIST EN 14466:2005+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14466:2005+A1

July 2008 ICS 13.220.10 Supersedes EN 14466:2005 English Version

Fire-fighting pumps - Portable pumps - Safety and performance requirements, tests

Pompes à usage incendie - Motopompes portables - Prescriptions de sécurité et de performance, essais

Feuerlöschpumpen - Tragkraftspritzen - Sicherheits- und Leistungsanforderungen, Prüfungen This European Standard was approved by CEN on 17 December 2004 and includes Amendment 1 approved by CEN on 6 June 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2008 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 14466:2005+A1:2008: ESIST EN 14466:2005+A1:2009

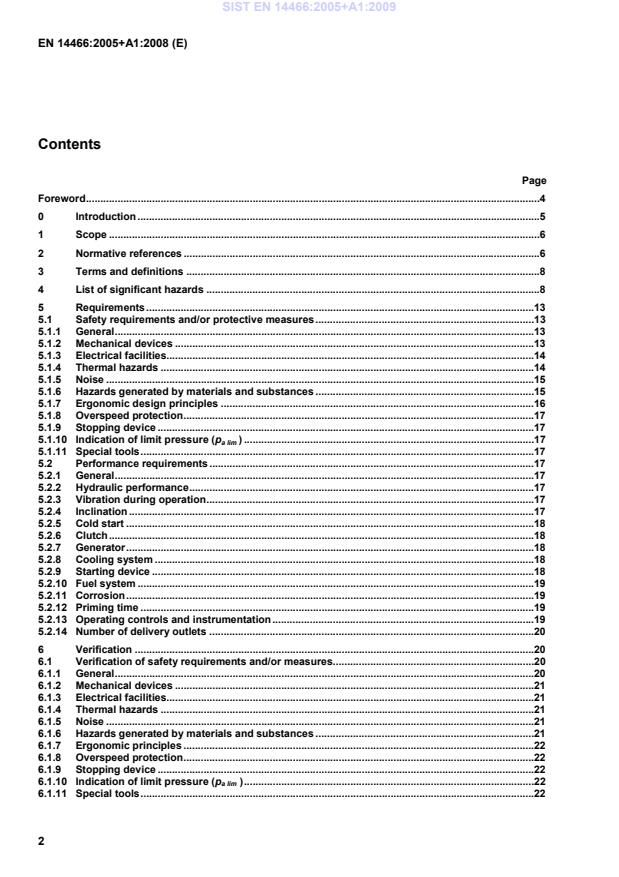

Example of the dimension of contour of a transporting device.31 Annex B (informative)

Examples of technical measures for noise reduction.32 Annex C (informative)

Example of an exhaust tail pipe (coupling).33 Annex D (informative)

Guidance for acceptance tests on delivery.34 Annex E (normative)

Noise test code.35 E.1 General.35 E.2 Grade of accuracy.35 E.3 Installation and mounting conditions.35 E.4 Operating conditions.35 E.5 Measurement uncertainties.35 E.6 Declaration.36 Annex F (normative)

Test of inclination during operation.37 Annex G (normative)

Test of inclination during transport (out of operation).38 Annex H (normative)

Requirements for non-text safety signs for use on portable pumps.39 H.1 General.39 H.2 Safety alert symbol (see figure H.1).39 H.3 Non-text hazard pictorials.39 H.4 Dimensions.39 H.5 Colours of safety signs.39 H.6 Location.39 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC.41 Annex ZB

(informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC"""".42 Bibliography.43

This document does not apply to portable pumps that are manufactured before the date of publication by CEN of this document. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 294, Safety of machinery — Safety distances to prevent danger zones being reached by the upper limbs. EN 349, Safety of machinery — Minimum gaps to avoid crushing of parts of the human body. EN 547-2, Safety of machinery — Human body measurements — Part 2: Principles for determining the dimensions required for access openings. EN 547-3, Safety of machinery — Human body measurements — Part 3: Anthropometric data. SIST EN 14466:2005+A1:2009

a) mass and stability; (potential energy of elements which may move under the effect of gravity); 1) mass and velocity (kinetic energy of elements in controlled or uncontrolled motion); 2) inadequacy of mechanical strength. b) accumulation of energy inside the machine, e.g. 1) liquids and gases under pressure.

Medium

Medium

Medium

Medium

Weight No rough external parts

High pressures, high velocity, (e.g. impeller) e.g. breaking off of handle

Sufficient handles, ergonomic design,

nearly same loading for every porter Choice of materials Specification of choice of materials, test pressures, and max. working pressures 5.1.1 5.1.2.1,

5.1.2.3,

5.1.10 1.2 Shearing hazard Medium Impeller; operation without suction screen Operating instructions 5.1.2.2,

5.1.7.4 1.3 Cutting or severing hazard Medium Edges, burrs Accurate processing, burring of parts 5.1.2.2 1.5 Drawing-in or trapping hazard Medium Fan wheel; connection between drive assembly and pump; other rotating parts Protective grating or other forms of covering 5.1.2.2 1.6 Impact hazard High Kick back of hand starter/freewheel Devices to avoid dangerous operation 5.1.2.3 1.9 High pressure fluid injection or ejection hazard Medium

Specification of test pressures 5.1.8,

5.1.10 SIST EN 14466:2005+A1:2009

Table 1 — List of significant hazards (continued) No. Hazard identification Risk evaluation Remarks Solution Clause reference in this document

2 Electrical hazards due to: 2.1 Contact of persons with live parts (direct contact) Medium Extra low voltage only Electrical installations corresponding to state of the art; engine with declaration of the manufacturer 5.1.3 2.2 Contact of persons with parts which have become live under faulty conditions (indirect contact) Medium Extra low voltage only

5.1.3 2.3 Approach to live parts under high voltage Medium Ignition

5.1.3 3 Thermal hazards, resulting in: 3.1 Burns, scalds and other injuries by a possible contact of persons with objects or materials with an extreme high or low temperature, by flames or explosions and also by the radiation of heat sources Medium Exhaust area Engine parts such as cylinder heads Handles Shielding or covering 5.1.4 4 Hazards generated by noise, resulting in: 4.1 Hearing loss (deafness) other physiological disorders (e.g. loss of balance, loss of awareness) Medium Noise at operating position

5.1.5 4.2 Interference with speech communication, acoustic signals, etc. Medium Communications and acoustic signals not audible at operating position

No signals (work, warning, information) that are audible only 5.1.5, 9.2.1 SIST EN 14466:2005+A1:2009

7 Hazards generated by materials and substances

7.1 Hazards from contact with or inhalation of harmful fluids, gases, mists, fumes and dusts Medium Exhaust gases, gasoline vapours, battery acid Exhaust pipe outlet should not be within the working area; operating instructions; operation in enclosed spaces only with precautions

5.1.6 7.2 Fire or explosion hazard

Medium Fuel system, explosive atmosphere

5.1.6.3 8 Hazards generated by neglecting ergonomic principles in machinery design e.g. hazards from: 8.1 Unhealthy postures or excessive effort High Carrying of the portable pump

Maintenance Suitable and ergonomic handles

Adequate tools 5.1.2.1,

5.1.7.1,

5.1.7.3,

5.1.7.5 5.1.11 8.2 Inadequate consideration of hand-arm or foot-leg anatomy Medium

5.1.7.4, 5.1.7.5 8.4 Inadequate local lighting Medium

5.1.7.2 8.6 Human error, human behaviour Medium Superheated steam caused by pumping against closed shut off valve; spilling of fuel whilst refuelling

exhaust pipe Temperature indicators or control Design: overflowing fuel shall not drop on hot exhaust parts 5.1.6.3 a), 5.1.7.3 SIST EN 14466:2005+A1:2009

8.8 Inadequate design or location of visual display units Medium e.g. temperature indicator All controls and warning and signalling indicators shall be easily visible from the operating position

5.1.7.3 10 Unexpected start-up, unexpected overrun/ overspeed (or any similar malfunction) from: 10.6 Errors made by the operator (due to mismatch of machinery with human characteristics and abilities, see 8.6) Medium See 8.6 The indication of the limit pressure pa lim shall be easily visible from the operator position 5.1.7.3,

5.1.10 11 Impossibility of stopping the machine in the best possible conditions Medium Engine shall be disengageable Stopping device 5.1.9 18 Loss of stability/overturning of machinery Medium Overturning of the pump during transportation and use Operating instructions: correct installation and securing of the pump 5.1.2.1 24 Due to the power source and to the transmission of power 24.1 Hazards from the engine and the batteries Medium

Secure fixing of the battery 5.1.6.4

5.1.1 General 5.1.1.1 Portable pumps shall comply with the safety requirements and/or protective measures of this clause and of EN 1028. In the event of conflict, the requirements of this clause shall take precedence. In addition, the portable pump shall be designed according to the principles of EN ISO 12100-1 and EN ISO 12100-2 for hazards relevant but not significant, which are not dealt with by this document. 5.1.1.2 For hazards which are to be reduced by the application of type B-standards referred to in this document (EN 294, EN 349, EN 547-2, EN 547-3, EN 563, EN 953, EN 60204-1, EN ISO 3744, EN ISO 11688-1, EN ISO 11688-2), the manufacturer shall carry out a risk assessment to establish the requirements of this type B-standards which are to be applied. This specific risk assessment shall be part of the general risk assessment of the portable pump. 5.1.1.3 Where the means of reducing the risk is by a safe system of operating the portable pump, the manufacturer shall include in the information for use, details of the system and of the elements of training required by the operating personnel. 5.1.1.4 Where the means of reducing the risk is by the physical arrangement or positioning of the portable pump, the manufacturer shall include in the information for use, a reference to the reduction means to be provided. Any limiting value of the requirement, and, if appropriate, the means of verification shall be notified. 5.1.1.5 The requirements of 5.1 shall be verified according to 6.1. The portable pump shall be fully operational after the tests. 5.1.1.6 For safety requirements related to electromagnetic phenomena the following paragraphs apply. The portable pump shall have sufficient immunity to electromagnetic disturbances to enable them to operate safely as intended and not fail to danger when exposed to the levels and types of disturbances intended by the manufacturer. The manufacturer of the portable pump shall design, install and wire the equipment and sub-assemblies taking into account the recommendations of the suppliers of these sub-assemblies. NOTE General requirements regarding electromagnetic compatibility (for the EEA the EMC Directives) can be covered by the application of European harmonized standards. For example the relevant clauses of either EN 55012 (CISPR 12) for emission, if the equipment includes only internal combustion engines, or by the generic standard EN 61000-6-3 for emission and by EN 61000-6-2 for immunity. 5.1.2 Mechanical devices 5.1.2.1 Transporting devices and loss of stability 5.1.2.1.1 The portable pump shall have lifting points or an adequate frame design to transport it according to the manufacturers manual. The handles/frame shall be designed to withstand at least 2,5 times the mass lifted divided by the number of lifting points according to 5.1.7.1. NOTE The handles should be fixed higher than the centre of gravity. 5.1.2.1.2 The transporting device shall withstand all expected mechanical loads and be designed for dragging and sliding the portable pump in terrain in an operational condition. NOTE An example of the dimension of contour of a transporting device is given in Annex A. SIST EN 14466:2005+A1:2009

Fixed guards for reducing risks from contact with moving parts of a pump, except for the pump inlet screen (see 9.3.2.5), shall be removable only by using a tool. It shall not be necessary to remove the guard in order for the pump to function normally.

Covers giving access for adjustment or setting of controls or sensors whilst the pump is in operation shall be secured against unintended opening both when open and closed, and as far as possible remain attached to the pump when open but shall not be required to be interlocked. Machined or cut parts exposed, or likely to be exposed, at any stage during installation, operation, or servicing of the pump shall be treated to remove burrs, rags and sharp edges by radiusing or chamfering. 5.1.2.3 Manual starting device If a manual starting device is used it shall be safe from kick back. Handle starting equipment shall be according to EN ISO 11102-1 and EN ISO 11102-2. Re-coil starting equipment shall be according to EN ISO 14314. 5.1.3 Electrical facilities Only extra low voltage as specified in EN 60204-1:1997, 6.4.1 shall be used, except ignition system.

The protection against direct contact shall be at least IP 2X as specified in EN 60529.

The portable pump shall be so designed and constructed that the battery, if a battery is part of the system, can be disconnected with the aid of an easily accessible device provided for that purpose. 5.1.4 Thermal hazards For maximum surface temperatures during operation and transport EN 563 and EN 13202 applies with following limits: a) For handles a contact duration of 1 min shall be applied. b) For unintentionally contactable surfaces, a contact duration of 0,5 s shall be applied. c) For intentionally contactable surfaces, e.g. controls, a contact duration of 4 s shall be applied. SIST EN 14466:2005+A1:2009

NOTE

EN ISO 14163 gives guidelines for noise control by silencers and EN ISO 11820 gives a method for measuring the acoustical performance of silencers. 5.1.5.3 Noise control by information The declared dual-number noise emission values shall be given in the information for use (see 9.3.2.3 n).

If consideration of noise reduction at the design stage shows that noise emission levels, after taking all possible technical measures, will be so high that further protection of the operator will be necessary, the information for use shall contain additional information (see 9.3.2.3 o). 5.1.6 Hazards generated by materials and substances 5.1.6.1 General Harmful materials shall not be used as part of the portable pump. NOTE For harmful materials see also Directive 67/548/EEC and its amendments. 5.1.6.2 Exhaust The exhaust system shall be designed and installed to avoid exhaust emission in the direction of the operator's position and combustible parts of the portable pump.

The end of the exhaust pipe(s) shall be designed and located so that a detachable exhaust hose can be used. Detachable exhaust hoses shall be offered by the manufacturer of the portable pump as accessories. NOTE An example of exhaust tail pipe (coupling) is given in Annex C.

5.1.6.3 Fuel system The design shall consider hazards from flammable fuels with regard to fuel pipes, tank location, leakage, filling and draining. The fuel system shall be designed in such a way that no leakage occurs at permitted incline of 15° from the horizontal during operation.

NOTE Inclines of more than 15° may be agreed upon between user and manufacturer. In this case additional measures can be necessary. If the fuel is gravity fed to the engine, a fuel tap is required. For fuel tanks the following additional requirements apply:

For markings see 9.4.2. 5.1.6.4 Battery If a battery is part of the system, the battery housing shall be constructed and located and the battery installed so as to avoid as far as possible the chance of electrolyte being ejected on to the operator in the event of rollover and/or to avoid the accumulation of vapours in places occupied by operators. 5.1.7 Ergonomic design principles 5.1.7.1 Lifting points Lifting points shall be provided for at least two persons for portable pumps up to 100 kg, and for at least four persons up to 200 kg. NOTE Additional transportation means are subject to agreement between manufacturer and user. 5.1.7.2 Lighting Means shall be provided to allow illumination, at least when the engine is running, of

a) control elements and instruments; b)

at least punctual around the portable pump of at least 5 lx over a distance of 1 m from the portable pump at ground level; c) the fuel tank for filling and checking the fuel level. 5.1.7.3 Displays and controls Displays and controls shall conform to the design principles specified in relevant parts of EN 894. EN 61310 (all parts) also applies. All instruments shall be visible for the operator standing in an upright position 1 m away from the operating panel. For markings see 9.4.2. 5.1.7.4 Maintenance Portable pumps shall be designed in accordance with the maintainability requirements in EN ISO 12100-2. Portable pumps shall be designed in accordance with EN 547-2 and EN 547-3 so that maintenance can be carried out without unreasonable efforts. 5.1.7.5 Handling and Mass Handling of the portable pump shall be possible with protective gloves for firefighters according to EN 659. SIST EN 14466:2005+A1:2009

5.1.10 Indication of limit pressure (pa lim ) Whenever pa lim according to EN 1028-1:2002, 5.2.1.2.3 is reached it shall be indicated visually. 5.1.11 Special tools Special tools for maintenance of the portable pump or replacement of spare parts/wear parts shall be supplied with the portable pump if the customer so desires. 5.2 Performance requirements 5.2.1 General If in the following no deviations to EN 1028 are required, the requirements in accordance with EN 1028 apply. The requirements of 5.2 shall be verified according to 6.2. The portable pump shall be fully operational after the tests. 5.2.2 Hydraulic performance The portable pump shall meet the guarantee points specified in EN 1028-1:2002, 6.17. 5.2.3 Vibration during operation Vibrations shall not impair the proper function of the portable pump. 5.2.4 Inclination 5.2.4.1 Inclination during operation At nominal delivery rate the portable pump shall be fully operational in all directions up to an inclination of 15° from the horizontal. NOTE Inclines of more than 15° may be agreed upon between user and manufacturer. 5.2.4.2 Inclination during transport (out of operation) The portable pump shall be fully operational after being inclined at a transport angle of at least 35° for (10 ± 1) s in all directions according to Figure G.1.

NOTE If a transport angle of more than 35° is feasible this should be indicated by the manufacturer in the information for use. SIST EN 14466:2005+A1:2009

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...