EN 13483:2013

(Main)Rubber and plastic hoses and hose assemblies with internal vapour recovery for measured fuel dispensing systems - Specification

Rubber and plastic hoses and hose assemblies with internal vapour recovery for measured fuel dispensing systems - Specification

This European Standard specifies the requirements and test methods for verification for hose assemblies with vapour recovery for delivery systems on petrol filling stations.

The hose assemblies with vapour recovery for delivery systems on petrol filling stations need to be capable of withstanding anticipated mechanical, thermal and chemical stressing and be resistant to the combustible liquids used in these applications as well as their vapour and vapour air mixtures. It is imperative that the assemblies be constructed in such a way that actions during normal operation cannot give rise to dangerous electrostatic charges nor that there will be any reduction in the performance of the vapour recovery.

The assemblies are intended for use at ambient temperatures between –30 °C and +55 °C for normal temperature class and –40 °C and +55 °C for low temperature class at a working pressure 16 bar ).

Hoses can be constructed from rubber or thermoplastic elastomer (TPE) and this document specifies the requirements for three types of hoses in two grades and two classes of hose assemblies for measured fuel dispensing systems, including oxygenated fuels ( 15 % oxygenated compounds) with internal vapour recovery tubing or hose.

NOTE This European Standard is not applicable to multi chamber fuel dispensing hoses.

As part of the certification of a new dispenser, testing of fuel samples in accordance with EN 228 should be carried out at least eight weeks after the first use of the equipment to avoid unrepresentative sulphur content results.

Gummi- und Kunststoffschläuche und -schlauchleitungen mit innenliegender Gasrückführung für Zapfsäulen an Tankstellen - Anforderungen

Diese Europäische Norm legt Anforderungen und Prüfverfahren an Schlauchleitungen mit Gasrückführung für Zapfsäulen an Tank¬stellen fest.

Die Schlauchleitungen mit Gasrückführung für Zapfsäulen an Tankstellen müssen den zu erwartenden mecha-nischen, thermischen und chemischen Beanspruchungen widerstehen können und gegen die bei diesen Anwendungen auftretenden brennbaren Flüssigkeiten sowie deren Gase und Gas-Luft-Gemische be¬ständig sein. Die Schlauchleitungen müssen so ausgeführt sein, dass das Arbeiten bei Normal¬betrieb keine gefährlichen elektrostatischen Aufladungen erzeugen oder die Leistung der Gasrückführung verringern kann.

Die Leitungen sind für den Einsatz bei Umgebungstemperaturen vorgesehen, die für die Normal¬temperatur-klasse zwischen 30 °C und 55 °C und für die Tieftemperaturklasse zwischen -40 °C und 55 °C bei einem Betriebsdruck 16 bar ) liegen.

Die Schläuche können aus Gummi oder einem thermoplastischen Elastomer (TPE) hergestellt werden, und in dem vorliegenden Dokument werden Anforderungen an drei Schlauchtypen festgelegt und zwar für zwei Kate-gorien und zwei Klassen von Schlauchleitungen für Zapfsäulen, einschließlich von Schläuchen mit innen-liegender Gasrückführung, ohne oder mit Einlage, die für mit sauerstoffhaltigen Verbindungen angereicherte Kraftstoffe vorgesehen sind ( 15 % sauerstoffhaltige Verbindungen).

ANMERKUNG Dieses Dokument gilt nicht für Mehrkammer Zapfsäulenschläuche.

Als Teil der Zertifizierung einer neuen Zapfsäule sollten Kraftstoffproben nach EN 228 mindestens acht Wochen nach der ersten Verwendung der Ausrüstung geprüft werden, um unrepräsentative Ergebnisse in Zusammen¬hang mit dem Schwefelgehalt zu vermeiden.

Tuyaux et flexibles en caoutchouc et en plastique à récupération interne de vapeur pour systèmes de livraison mesurée de carburant - Spécification

La présente Norme européenne spécifie les exigences et les méthodes d’essai pour la vérification des assemblages flexibles à récupération de vapeur des systèmes de distribution équipant les stations-service.

Il est nécessaire que les assemblages flexibles à récupération de vapeur pour les systèmes de distribution équipant les stations-service supportent les contraintes mécaniques, thermiques et chimiques prévues et soient résistant aux combustibles liquides utilisés dans ces applications ainsi qu'à leur vapeur et aux mélanges air-vapeur. Il est impératif que les assemblages soient construits de manière à ce que des actions effectuées en fonctionnement normal ne puissent pas provoquer des charges électrostatiques dangereuses, ni réduire les performances de récupération de vapeur.

Les assemblages sont destinés à être utilisés à des températures ambiantes comprises entre – 30 °C et + 55 °C pour une classe de températures normales et entre – 40 °C et + 55 °C pour une classe de basses températures à une pression de service 16 bar ).

Les tuyaux peuvent être fabriqués à partir de caoutchouc ou d'élastomères thermoplastiques (TPE) et le présent document spécifie les exigences pour trois types de tuyaux avec deux catégories et deux classes d’assemblages flexibles pour les systèmes de livraison mesurée de carburant, y compris les carburants oxygénés ( 15 % composés oxygénés) avec tube ou tuyau interne de récupération de vapeur.

NOTE La présente Norme européenne ne s’applique pas aux tuyaux multi-chambres pour distribution de carburants.

Dans le cadre de la certification d’un nouveau distributeur, il convient qu’un essai d’échantillons de carburant selon l’EN 228 soit réalisé au moins huit semaines après la première utilisation de l'équipement afin d'éviter des résultats en teneur en soufre peu représentatifs.

Gumene in polimerne cevi ter cevni priključki z notranjim sistemom za rekuperiranje hlapov za sisteme za merjeno točenje goriva na bencinskih črpalkah - Specifikacija

Ta evropski standard določa preskusne metode za preverjanje cevnih priključkov s sistemom za rekuperiranje hlapov za sisteme dovajanja na bencinskih črpalkah. Cevni priključki s sistemom za rekuperiranje hlapov za sisteme dovajanja na bencinskih črpalkah morajo vzdržati pričakovane mehanske, toplotne in kemijske obremenitve ter biti odporni na gorljive tekočine, s katerimi se uporabljajo, ter na njihove hlape in njihove mešanice z zrakom. Nujno je, da so ti priključki zasnovani tako, da njihovi vplivi med običajnim delovanjem ne povzročajo nevarnega elektrostatičnega naboja in zmanjšanega delovanja pri rekuperiranju hlapov. Priključki so namenjeni uporabi pri temperaturi okolice med -30 °C in +55 °C za običajni temperaturni razred ter -40 °C in +55 °C za nizki temperaturni razred pri delovnem tlaku ≤ 16 barov1). Cevi so lahko izdelane iz gume ali plastomernih elastomerov (TPE); ta dokument določa zahteve za tri vrste cevi v dveh tipih in dva razreda cevnih priključkov za sisteme za merjeno točenje goriva, vključno z oksigeniranimi gorivi (≤ 15 % kisikovih spojin), z notranjim priključkom ali cevjo za rekuperiranje hlapov.

General Information

- Status

- Withdrawn

- Publication Date

- 18-Jun-2013

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 218 - Rubber and plastics hoses and hose assemblies

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 12-Oct-2022

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 03-Jul-2010

- Effective Date

- 10-Mar-2020

- Effective Date

- 09-Feb-2026

- Refers

ISO 188:2011 - Rubber, vulcanized or thermoplastic - Accelerated ageing and heat resistance tests - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

EN 13483:2013 is a standard published by the European Committee for Standardization (CEN). Its full title is "Rubber and plastic hoses and hose assemblies with internal vapour recovery for measured fuel dispensing systems - Specification". This standard covers: This European Standard specifies the requirements and test methods for verification for hose assemblies with vapour recovery for delivery systems on petrol filling stations. The hose assemblies with vapour recovery for delivery systems on petrol filling stations need to be capable of withstanding anticipated mechanical, thermal and chemical stressing and be resistant to the combustible liquids used in these applications as well as their vapour and vapour air mixtures. It is imperative that the assemblies be constructed in such a way that actions during normal operation cannot give rise to dangerous electrostatic charges nor that there will be any reduction in the performance of the vapour recovery. The assemblies are intended for use at ambient temperatures between –30 °C and +55 °C for normal temperature class and –40 °C and +55 °C for low temperature class at a working pressure 16 bar ). Hoses can be constructed from rubber or thermoplastic elastomer (TPE) and this document specifies the requirements for three types of hoses in two grades and two classes of hose assemblies for measured fuel dispensing systems, including oxygenated fuels ( 15 % oxygenated compounds) with internal vapour recovery tubing or hose. NOTE This European Standard is not applicable to multi chamber fuel dispensing hoses. As part of the certification of a new dispenser, testing of fuel samples in accordance with EN 228 should be carried out at least eight weeks after the first use of the equipment to avoid unrepresentative sulphur content results.

This European Standard specifies the requirements and test methods for verification for hose assemblies with vapour recovery for delivery systems on petrol filling stations. The hose assemblies with vapour recovery for delivery systems on petrol filling stations need to be capable of withstanding anticipated mechanical, thermal and chemical stressing and be resistant to the combustible liquids used in these applications as well as their vapour and vapour air mixtures. It is imperative that the assemblies be constructed in such a way that actions during normal operation cannot give rise to dangerous electrostatic charges nor that there will be any reduction in the performance of the vapour recovery. The assemblies are intended for use at ambient temperatures between –30 °C and +55 °C for normal temperature class and –40 °C and +55 °C for low temperature class at a working pressure 16 bar ). Hoses can be constructed from rubber or thermoplastic elastomer (TPE) and this document specifies the requirements for three types of hoses in two grades and two classes of hose assemblies for measured fuel dispensing systems, including oxygenated fuels ( 15 % oxygenated compounds) with internal vapour recovery tubing or hose. NOTE This European Standard is not applicable to multi chamber fuel dispensing hoses. As part of the certification of a new dispenser, testing of fuel samples in accordance with EN 228 should be carried out at least eight weeks after the first use of the equipment to avoid unrepresentative sulphur content results.

EN 13483:2013 is classified under the following ICS (International Classification for Standards) categories: 23.040.70 - Hoses and hose assemblies; 75.200 - Petroleum products and natural gas handling equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13483:2013 has the following relationships with other standards: It is inter standard links to EN 13483:2005, EN 13483:2022, ISO 37:2011, ISO 188:2011, ISO 527-1:2012, ISO 1817:2011, ISO 4649:2010, EN ISO 8330:2008, EN ISO 8033:2017, EN ISO 7326:2016, EN 915:1996, EN ISO 4671:2022, EN ISO 1307:2008, EN ISO 1402:2021, EN ISO 10619-1:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13483:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Gummi- und Kunststoffschläuche und -schlauchleitungen mit innenliegender Gasrückführung für Zapfsäulen an Tankstellen - AnforderungenTuyaux et flexibles à récupération interne de vapeur pour un système de livraison mesurée carburant - SpécificationRubber and plastic hoses and hose assemblies with internal vapour recovery for measured fuel dispensing systems - Specification83.140.40Gumene ceviHoses75.200Petroleum products and natural gas handling equipmentICS:Ta slovenski standard je istoveten z:EN 13483:2013SIST EN 13483:2013en,de01-september-2013SIST EN 13483:2013SLOVENSKI

STANDARDSIST EN 13483:20051DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13483

June 2013 ICS 23.040.70; 75.200 Supersedes EN 13483:2005English Version

Rubber and plastic hoses and hose assemblies with internal vapour recovery for measured fuel dispensing systems - Specification

Tuyaux et flexibles en caoutchouc et en plastique à récupération interne de vapeur pour systèmes de livraison mesurée de carburant - Spécification

Gummi- und Kunststoffschläuche und -schlauchleitungen mit innenliegender Gasrückführung für Zapfsäulen an Tankstellen - Anforderungen This European Standard was approved by CEN on 25 April 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13483:2013: ESIST EN 13483:2013

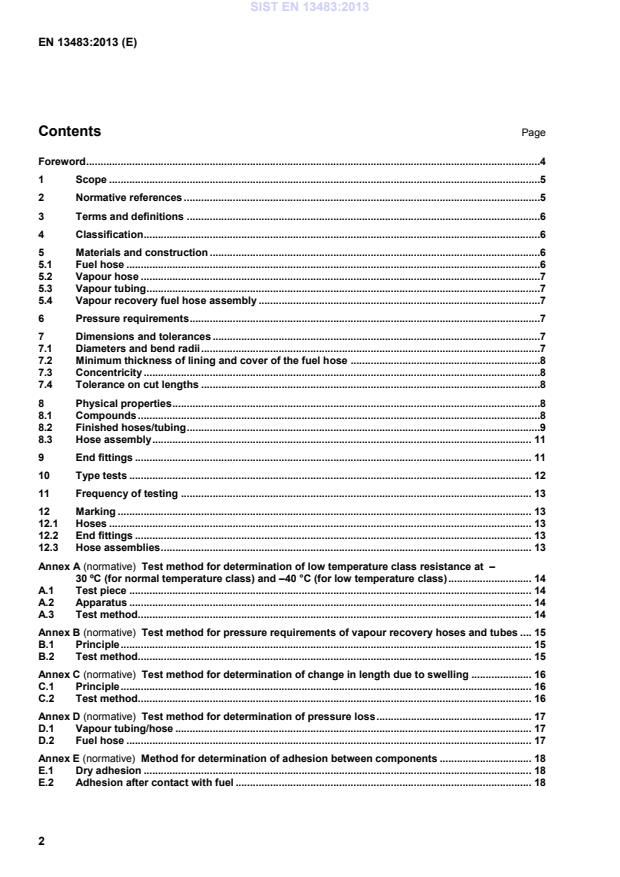

Test method for determination of low temperature class resistance at

–30 ºC (for normal temperature class) and –40 °C (for low temperature class) . 14 A.1 Test piece . 14 A.2 Apparatus . 14 A.3 Test method . 14 Annex B (normative)

Test method for pressure requirements of vapour recovery hoses and tubes . 15 B.1 Principle . 15 B.2 Test method . 15 Annex C (normative)

Test method for determination of change in length due to swelling . 16 C.1 Principle . 16 C.2 Test method . 16 Annex D (normative)

Test method for determination of pressure loss . 17 D.1 Vapour tubing/hose . 17 D.2 Fuel hose . 17 Annex E (normative)

Method for determination of adhesion between components . 18 E.1 Dry adhesion . 18 E.2 Adhesion after contact with fuel . 18 SIST EN 13483:2013

Test method for the determination of low temperature flexibility . 19 F.1 Test piece . 19 F.2 Apparatus . 19 F.3 Test method . 19 Annex G (normative)

Test method for the determination of rate of fuel permeation . 21 G.1 Test piece . 21 G.2 Apparatus . 21 G.3 Test method . 21 Annex H (normative)

Test method for flammability . 22 H.1 Test piece . 22 H.2 Apparatus . 22 H.3 Test method . 22 Annex I (normative)

Test method for the determination of leakage (leak test) . 24 Annex J (normative)

Test method for fatigue strength under reversed bending stresses (flex test) . 25 J.1 Apparatus and test piece . 25 J.2 Test method . 25 J.3 Test observations and report . 26 Annex K (normative)

End-fitting pull-off test . 27 K.1 Test piece . 27 K.2 Apparatus . 27 K.3 Test method . 27 Annex L (normative)

Test frequency for type tests and routine tests. 28 Annex M (informative)

Test frequency for production acceptance tests . 30 Bibliography . 32

1) 1 bar = 0,1 MPa SIST EN 13483:2013

Type 3, fine wire reinforced. Each type of hose shall be divided into two grades: Grade M: electrically bonded; Grade Ω: electrically conductive. Each type of hose shall be divided into two temperature classes: normal temperature class with an ambient working temperature of −30 °C to +55 °C; low temperature class (LT) with an ambient working temperature of −40 °C to +55 °C. 5 Materials and construction 5.1 Fuel hose The fuel hose shall consist of the following: a) a smooth, fuel resistant lining of rubber or thermoplastic elastomer (TPE); b) a suitable reinforcement, related to type; c) a non-corrugated fuel and weather resistant rubber or TPE cover. Hose assemblies shall be capable of conducting an electrical charge from coupling to coupling. SIST EN 13483:2013

Proof test pressure 24 b

Minimum burst pressure 48 18 a The vapour tubing/hose shall be designed for an absolute pressure of 0,2 bar (vacuum) with an external pressurisation of 8 bar. b See Annex B. 7 Dimensions and tolerances 7.1 Diameters and bend radii Diameters and bend radii shall conform to the values given in Table 2. SIST EN 13483:2013

min. Vapour tubing/hose 8,4 — 75 Fuel hose — 32,6 130 Assembly — — 130

7.2 Minimum thickness of lining and cover of the fuel hose When measured in accordance with EN ISO 4671, the thickness of the lining shall be not less than 1,6 mm and the thickness of the cover shall be not less than 1,0 mm. 7.3 Concentricity When determined in accordance with EN ISO 4671, the concentricity, based on a total indicator reading between the internal diameter and the outside diameter, shall not exceed 0,5 mm for the vapour tubing or hose, and shall not exceed 1,0 mm for the fuel hose. 7.4 Tolerance on cut lengths For cut lengths, the tolerances on length shall be in accordance with EN ISO 1307. The length of a hose assembly shall be measured from sealing face to sealing face of the end fittings with a tolerance from the nominal length of ± 1 %. 8 Physical properties 8.1 Compounds When tested in accordance with the methods in Table 3, the physical properties of the compounds used for the lining and cover shall conform to the values given in Table 3. Tests shall be performed either on samples taken from the hose or from moulded vulcanised sheets at a thickness of 2 mm or moulded test pieces vulcanised to the same cured state as the production hoses. SIST EN 13483:2013

Rubber TPE Thermo-plastic

Tensile strength,

min.

Lining and cover of fuel hose

and vapour tubing and hose

MPa

12 Test piece cut from hose or from test sheet

ISO 37

ISO 527-1 (Thermoplastic) Elongation at break,

min.

Lining and cover of fuel hose

and vapour tubing and hose

%

150 Accelerated ageing

Tensile strength change,

Lining and cover fuel hose and

vapour tubing and hose,

max.

ISO 188

(air oven method) 14 days at (70 ± 1) °C

Elongation at break change,

Lining and cover of fuel hose

and vapour tubing and hose,

max.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...