EN ISO 15641:2001

(Main)Milling cutters for high speed machining - Safety requirements (ISO 15641:2001)

Milling cutters for high speed machining - Safety requirements (ISO 15641:2001)

This standard deals with the principle hazards arising from use of milling cutters, e.g. milling cutters according to ISO 3855, used for high speed machining (chip removal machining at increased peripheral speeds) on metal working machine tools and prescribes safety requirements.

It specifies design methods, centrifugal force test procedures, operational limits and the provision of information that will lead to minimisation or elimination of these hazards.

The standard is applicable to milling cutters which are intended for operation at speeds in accordance with figures 1 and 2.

These figures respectively define the rotational speed limits and peripheral speed limits for specific cutter diameters.

NOTE A detailed explanation is provided in annex B.

Fräswerkzeuge für die Hochgeschwindigkeitsbearbeitung - Sicherheitstechnische Anforderungen (ISO 15641:2001)

Diese Norm behandelt die grundsätzlichen Gefährdungen, die beim Einsatz von Fräswerkzeugen (z.B. Fräswerkzeuge entsprechend ISO 3855) für die Hochgeschwindigkeitsbearbeitung (spanende Be-arbeitung mit erhöhten Umfangsge-schwindigkeiten) auf Metall-bearbei-tungs-maschinen auftreten und legt die Sicherheitsanforderungen fest.

Sie gibt Hinweise zu Konstruktionsmethoden, Fliehkraft-Typ-prüfungsver-fahren, Bearbeitungsgrenzen und zur Bereitstellung von Informationen, die zur Mini-mierung oder Beseiti-gung dieser Gefährdungen führen.

Diese Norm ist anwendbar für Fräswerkzeuge, die für den Gebrauch bei Geschwindigkeiten/Betriebsdrehzahlen ent-sprechend den Bildern 1 und 2 vorgesehen sind.

Diese Bilder definieren die Drehzahl- und Umfangsgeschwindigkeitsgrenzen für bestimmte Fräserdurchmesser.

ANMERKUNG Eine detaillierte Erläuterung wird in Anhang B gegeben.

Fraises pour usinage à grande vitesse - Prescriptions de sécurité (ISO 15641:2001)

La présente norme traite des phénomènes dangereux principaux se produisant lors de l'utilisation des fraises (par exemple fraises selon l'ISO 3855) pour usinage à grande vitesse (enlèvement de copeaux à des vitesses périphériques élevées) sur des machines pour le travail du métal et donne les prescriptions de sécurité. Elle spécifie les méthodes de conception, les procédures d'essai de force centrifuge, les limites fonctionnelles et les informations à fournir qui conduiront à la réduction ou à l'élimination de ces phénomènes dangereux. La norme s'applique aux fraises qui sont prévues pour fonctionner aux vitesses spécifiées aux figures 1 et 2. Ces figures définissent respectivement les limites de la vitesse de rotation et les limites de la vitesse périphérique pour des diamètres de fraise spécifiques.

NOTE : Une explication détaillée est fournie en annexe B.

Milling cutters for high speed machining - Safety requirements (ISO 15641:2001)

General Information

- Status

- Published

- Publication Date

- 31-Aug-2001

- Withdrawal Date

- 30-Mar-2002

- Technical Committee

- CEN/TC 143 - Machine tools - Safety

- Drafting Committee

- CEN/TC 143/WG 7 - Rotating cutting tools for high speed machining

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 10-Jul-2006

- Completion Date

- 10-Jul-2006

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 09-Feb-2026

- Referred By

EN 13128:2001+A2:2009 - Safety of machine tools - Milling machines (including boring machines) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN ISO 15641:2001 - Milling cutters for high speed machining - Safety requirements specifies safety requirements for milling cutters used in high speed machining (chip removal at increased peripheral speeds) on metalworking machine tools. The standard addresses principle hazards from high rotational energy, prescribes design methods, centrifugal force test procedures, operational limits, and the required information for use to minimise or eliminate risks. It applies to cutters intended to operate within the rotational speed and peripheral speed limits shown in the standard’s figures (see figures 1 and 2). Informative annexes provide design guidance (Annex A) and scope explanation (Annex B).

Key topics and technical requirements

- Scope & applicability: Covers solid (one‑piece), composite (bonded), and complex (mechanically fastened) milling cutters intended for high speed machining.

- Hazard analysis: Identifies primary hazards (centrifugal forces, burst risk, released component energies) and handling hazards (mounting, dismounting, transport).

- Design principles: Tools must be designed to resist centrifugal loads; calculation is allowed for geometrically similar product lines if validated by testing.

- Speed safety factor: Manufacturer’s maximum rotational speed (nmax) must be verified with a rotational speed safety factor of 2, giving a centrifugal force safety factor of 4:1 (with reference to clause 5.4.3).

- Centrifugal force type testing: Specifies general test requirements and separate test procedures for solid/composite and complex cutters, including test duration and test rotational speed determination.

- Key parameters and terminology: Defines terms like maximum diameter (D), critical diameter for bending (d), protruding length (lp), tool mass (mw), component masses (mt), and nmax.

- Balance and manufacturing integrity: Emphasises balance quality, manufacturing integrity and correct fixing types (bonding, friction lock, form lock, separable).

- Marking & documentation: Requires marking, user instructions, and application information (limits, mounting, drive/clamping, coolant/air considerations).

Applications and users

EN ISO 15641:2001 is intended for:

- Tool designers and manufacturers - to design and validate milling cutters for high speed use.

- Suppliers and distributors - to provide correct marking and documentation.

- Machine builders and safety engineers - to assess tool compatibility with machine speed limits and guarding.

- Shop floor managers and machinists - to select compliant cutters and follow operational limits and mounting instructions.

Note: This tool standard addresses tool safety but does not alone ensure complete machine safety - machine-specific safety standards must also be followed.

Related standards

- EN 1070 - Safety of machinery: Terminology

- ISO 1940-1 - Balance quality of rigid rotors

- ISO 3002-1 - Cutting tool geometry terms

- ISO 3855 - Milling cutters nomenclature

Keywords: EN ISO 15641:2001, ISO 15641:2001, milling cutters, high speed machining, centrifugal force testing, rotational speed, peripheral speed, safety requirements.

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

EN ISO 15641:2001 is a standard published by the European Committee for Standardization (CEN). Its full title is "Milling cutters for high speed machining - Safety requirements (ISO 15641:2001)". This standard covers: This standard deals with the principle hazards arising from use of milling cutters, e.g. milling cutters according to ISO 3855, used for high speed machining (chip removal machining at increased peripheral speeds) on metal working machine tools and prescribes safety requirements. It specifies design methods, centrifugal force test procedures, operational limits and the provision of information that will lead to minimisation or elimination of these hazards. The standard is applicable to milling cutters which are intended for operation at speeds in accordance with figures 1 and 2. These figures respectively define the rotational speed limits and peripheral speed limits for specific cutter diameters. NOTE A detailed explanation is provided in annex B.

This standard deals with the principle hazards arising from use of milling cutters, e.g. milling cutters according to ISO 3855, used for high speed machining (chip removal machining at increased peripheral speeds) on metal working machine tools and prescribes safety requirements. It specifies design methods, centrifugal force test procedures, operational limits and the provision of information that will lead to minimisation or elimination of these hazards. The standard is applicable to milling cutters which are intended for operation at speeds in accordance with figures 1 and 2. These figures respectively define the rotational speed limits and peripheral speed limits for specific cutter diameters. NOTE A detailed explanation is provided in annex B.

EN ISO 15641:2001 is classified under the following ICS (International Classification for Standards) categories: 25.100.20 - Milling tools. The ICS classification helps identify the subject area and facilitates finding related standards.

EN ISO 15641:2001 has the following relationships with other standards: It is inter standard links to EN 393:1993, EN ISO 11608-1:2000, HD 384.5.52 S1:1995, EN 13128:2001+A2:2009, EN 1359:1998, EN 357:2004, EN 12417:2001+A2:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN ISO 15641:2001 is associated with the following European legislation: EU Directives/Regulations: 98/37/EC; Standardization Mandates: M/079. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN ISO 15641:2001 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Milling cutters for high speed machining - Safety requirements (ISO 15641:2001)Fräswerkzeuge für die Hochgeschwindigkeitsbearbeitung - Sicherheitstechnische Anforderungen (ISO 15641:2001)Fraises pour usinage a grande vitesse - Prescriptions de sécurité (ISO 15641:2001)Milling cutters for high speed machining - Safety requirements (ISO 15641:2001)25.100.20Orodja za frezanjeMilling toolsICS:Ta slovenski standard je istoveten z:EN ISO 15641:2001SIST EN ISO 15641:2002en01-januar-2002SIST EN ISO 15641:2002SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN ISO 15641September 2001ICS 25.100.20English versionMilling cutters for high speed machining - Safety requirements(ISO 15641:2001)Fraises pour usinage à grande vitesse - Prescriptions desécurité (ISO 15641:2001)Fräswerkzeuge für die Hochgeschwindigkeitsbearbeitung -Sicherheitstechnische Anforderungen (ISO 15641:2001)This European Standard was approved by CEN on 7 March 2001.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2001 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN ISO 15641:2001 ESIST EN ISO 15641:2002

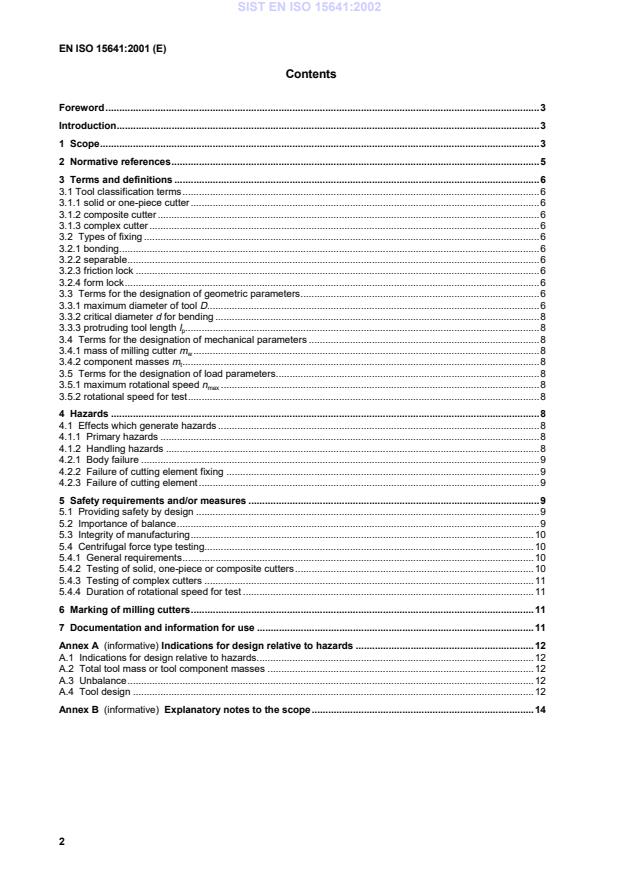

Scope.32

Normative references.53

Terms and definitions.63.1 Tool classification terms.63.1.1 solid or one-piece cutter.63.1.2 composite cutter.63.1.3 complex cutter.63.2

Types of fixing.63.2.1 bonding.63.2.2 separable.63.2.3 friction lock.63.2.4 form lock.63.3

Terms for the designation of geometric parameters.63.3.1 maximum diameter of tool D.63.3.2 critical diameter d for bending.83.3.3 protruding tool length lp.83.4

Terms for the designation of mechanical parameters.83.4.1 mass of milling cutter mw.83.4.2 component masses mt.83.5

Terms for the designation of load parameters.83.5.1 maximum rotational speed nmax.83.5.2 rotational speed for test.84

Hazards.84.1

Effects which generate hazards.84.1.1

Primary hazards.84.1.2

Handling hazards.84.2.1

Body failure.94.2.2

Failure of cutting element fixing.94.2.3

Failure of cutting element.95

Safety requirements and/or measures.95.1

Providing safety by design.95.2

Importance of balance.95.3

Integrity of manufacturing.105.4

Centrifugal force type testing.105.4.1

General requirements.105.4.2

Testing of solid, one-piece or composite cutters.105.4.3

Testing of complex cutters.115.4.4

Duration of rotational speed for test.116

Marking of milling cutters.117

Documentation and information for use.11Annex A

(informative) Indications for design relative to hazards.12A.1

Indications for design relative to hazards.12A.2

Total tool mass or tool component masses.12A.3

Unbalance.12A.4

Tool design.12Annex B

(informative)

Explanatory notes to the scope.14SIST EN ISO 15641:2002

ScopeThis standard deals with the principle hazards arising from use of milling cutters, e.g. milling cutters according toISO 3855, used for high speed machining (chip removal machining at increased peripheral speeds) on metal workingmachine tools and prescribes safety requirements.It specifies design methods, centrifugal force test procedures, operational limits and the provision of information thatwill lead to minimisation or elimination of these hazards.The standard is applicable to milling cutters which are intended for operation at speeds in accordance with figures 1and 2.These figures respectively define the rotational speed limits and peripheral speed limits for specific cutter diameters.NOTE

A detailed explanation is provided in annex B.SIST EN ISO 15641:2002

Maximum diameter of tool D in mmb

Rotational speed n in min-1Figure 1 - Rotational speed n vs maximum diameter of tool DSIST EN ISO 15641:2002

Maximum diameter of tool D in mmb

Velocity at D (speed vD at maximum diameter of tool D) inminmFigure 2 - Velocity at D (speed vD) vs maximum diameter of tool D2

Normative referencesThis European Standard incorporates by dated or undated reference provisions from other publications. Thesenormative references are cited at the appropriate places in the text and the publications are listed hereafter. For datedreferences, subsequent amendments to or revisions of any of these publications apply to this European Standard onlywhen incorporated in it by amendment or revision. For undated references the latest edition of the publication referredto applies (including amendments).EN 1070Safety of machinery – TerminologyISO 1940-1:1986Mechanical vibration – Balance quality requirements of rigid rotors – Part 1: Determination of permissibleresidual unbalanceISO 3002-1Basic quantities in cutting and grinding – Part 1: Geometry of the active part of cutting tools – General terms,reference systems, tool and working angles, chip breakersISO 3855Milling cutters – NomenclatureSIST EN ISO 15641:2002

Terms and definitionsFor the purposes of this standard the terms and definitions given in EN 1070, ISO 3002-1 and the following apply:3.1 Tool classification terms3.1.1solid or one-piece cuttermilling cutter which has no detachable parts. Its body and cutting part or parts are one piece.3.1.2composite cuttermilling cutter in which the cutting part or parts (e.g. tips) are attached to the body by material bonding (e.g. by brazing).3.1.3complex cuttermilling cutter in which one or more parts (e.g. indexable inserts, cartridges, clamping elements) are attached to thebody by mechanical fastening (e.g. key bolt, screw bolt or clamp bolt fixing which operate by friction lock or form lockprinciples).3.2

Types of fixing3.2.1bondingsecuring of cutter parts with material bonding such as brazing, welding or gluing.3.2.2separablesecuring of cutter parts by detachable fastening(s). Examples are friction lock and form lock fixings, or a combinationof these, which can be mounte

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...