EN 14140:2003+A1:2006

(Main)LPG equipment and accessories - Transportable refillable welded steel cylinders for LPG - Alternative design and construction

LPG equipment and accessories - Transportable refillable welded steel cylinders for LPG - Alternative design and construction

This European Standard specifies the minimum requirements for the design, construction and testing during manufacture of transportable refillable welded steel Liquefied Petroleum Gas (LPG) cylinders, of water capacity from 0,5 l up to and including 150 l, exposed to ambient temperatures. It allows alternative design and construction methods to those required in EN 1442.

This European Standard applies only to cylinders with a circular cross-section.

All pressures are gauge unless otherwise stated.

Flüssiggas-Geräte und Ausrüstungsteile - Ortsbewegliche, wiederbefüllbare, geschweißte Flaschen aus Stahl für Flüssiggas (LPG) - Alternative Gestaltung und Konstruktion

Diese Europäische Norm legt Mindestanforderungen an Werkstoff, Gestaltung, Konstruktion und Ausführung, Herstellungsverfahren und Prüfung während der Herstellung ortsbeweglicher, wiederbefüllbarer, geschweißter Flüssiggasflaschen (LPG) aus Stahl mit einem Fassungsraum von 0,5 l bis einschließlich 150 l fest, die der Umgebungstemperatur ausgesetzt werden, um die in EN 1442 geforderten alternativen Gestaltungs- und Konstruktionsverfahren zu ermöglichen.

Diese Europäische Norm gilt nur für Flaschen mit rundem Querschnitt.

Alle Drücke sind Überdrücke, falls nicht anders angegeben.

Equipements pour GPL et leurs accessoires - Bouteilles en acier soudé transportables et rechargeables pour gaz de pétrole liquéfié (GPL) - Autres solutions en matière de conception et construction

La présente Norme européenne spécifie les exigences minimales concernant la conception, la construction et les essais lors de la fabrication des bouteilles en acier soudées, transportables et rechargeables pour le gaz de pétrole liquéfié (GPL) d’une capacité en eau comprise entre 0,5 l et 150 l inclus, soumises à la température ambiante. Elle autorise, en matière de conception et de fabrication, l’utilisation de solutions différentes de celles requises dans l’EN 1442.

La présente Norme européenne s’applique uniquement aux bouteilles de section transversale circulaire.

Sauf indication contraire, toutes les pressions sont des pressions relatives.

Oprema in pribor za utekočinjeni naftni plin (UNP) – Premične, ponovno polnljive varjene jeklene jeklenke za UNP – Alternativni način konstruiranja in izdelave

General Information

- Status

- Withdrawn

- Publication Date

- 05-Dec-2006

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 286 - Liquefied petroleum gas equipment and accessories

- Drafting Committee

- CEN/TC 286/WG 1 - Design and manufacture of LPG pressure vessels

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 03-Dec-2014

- Completion Date

- 11-Feb-2026

- Directive

- Not Harmonized94/55/EC - Transport of dangerous goods by road

Not Harmonized96/49/EC - Transport of dangerous goods by rail

Relations

- Effective Date

- 10-Dec-2014

- Effective Date

- 18-Jan-2023

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 14140:2003+A1:2006 is a standard published by the European Committee for Standardization (CEN). Its full title is "LPG equipment and accessories - Transportable refillable welded steel cylinders for LPG - Alternative design and construction". This standard covers: This European Standard specifies the minimum requirements for the design, construction and testing during manufacture of transportable refillable welded steel Liquefied Petroleum Gas (LPG) cylinders, of water capacity from 0,5 l up to and including 150 l, exposed to ambient temperatures. It allows alternative design and construction methods to those required in EN 1442. This European Standard applies only to cylinders with a circular cross-section. All pressures are gauge unless otherwise stated.

This European Standard specifies the minimum requirements for the design, construction and testing during manufacture of transportable refillable welded steel Liquefied Petroleum Gas (LPG) cylinders, of water capacity from 0,5 l up to and including 150 l, exposed to ambient temperatures. It allows alternative design and construction methods to those required in EN 1442. This European Standard applies only to cylinders with a circular cross-section. All pressures are gauge unless otherwise stated.

EN 14140:2003+A1:2006 is classified under the following ICS (International Classification for Standards) categories: 23.020.30 - Pressure vessels, gas cylinders; 23.020.35 - Gas cylinders. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14140:2003+A1:2006 has the following relationships with other standards: It is inter standard links to EN 14140:2014, EN 14140:2003, EN 1440:2008+A1:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14140:2003+A1:2006 is associated with the following European legislation: EU Directives/Regulations: 94/55/EC, 96/49/EC, TRRTP121; Standardization Mandates: M/086. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14140:2003+A1:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.LPG equipment and accessories - Transportable refillable welded steel cylinders for LPG - Alternative design and constructionEquipements pour GPL et leurs accessoires - Bouteilles en acier soudé transportables et rechargeables pour gaz de pétrole liquéfié (GPL) - Autres solutions en matiere de conception et constructionFlüssiggas-Geräte und Ausrüstungsteile - Ortsbewegliche, wiederbefüllbare, geschweißte Flaschen aus Stahl für Flüssiggas (LPG) - Alternative Gestaltung und KonstruktionTa slovenski standard je istoveten z:EN 14140:2003+A1:2006SIST EN 14140:2004+A1:2007en23.020.30MHNOHQNHPressure vessels, gas cylindersICS:SLOVENSKI

STANDARDSIST EN 14140:2004+A1:200701-april-2007

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14140:2003+A1

December 2006 ICS 23.020.30 English Version

LPG equipment and accessories - Transportable refillable welded steel cylinders for LPG - Alternative design and construction

Equipements pour GPL et leurs accessoires -Bouteilles en acier soudé transportables et rechargeables pour gaz de pétrole liquéfié (GPL) - Autres solutions en matière de conception et construction

Flüssiggas-Geräte und Ausrüstungsteile - Ortsbewegliche, wiederbefüllbare, geschweißte Flaschen aus Stahl für Flüssiggas (LPG) - Alternative Gestaltung und KonstruktionThis European Standard was approved by CEN on 10 July 2003 and includes Amendment 1 approved by CEN on 2 November 2006.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the Central Secretariat or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2006 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 14140:2003+A1:2006: E

Manufacturers marking.39 Bibliography.40

(ISO 15614-1:2004)."

1% proof stress for stainless steels, Rp1,0

3.1.2 normalised condition resulting from heat treatment in which a finished cylinder is heated to a uniform temperature above the upper critical point (Ac3) of the steel and then cooled under controlled conditions 3.1.3 stress relieved condition resulting from heat treatment in which a finished cylinder is heated to a uniform temperature below the lower critical point (Ac1) of the steel and cooled in a still atmosphere, the object of which is to reduce the residual stresses without altering the metallurgical structure of the steel 3.2 Symbols a Calculated minimum thickness of the cylindrical shell, in millimetres. A Percentage elongation after fracture. b Calculated minimum thickness of the end of the cylinder, in millimetres. C Shape factor for ends (see Table 1 and Figure 2). D Outside diameter of the cylinder as given in the design drawing (see Figure 1), in millimetres. Dp Outside diameter of a bend tests former (see Figure 8), in millimetres. e Actual thickness of the material used, in millimetres. h Height, in millimetres, of the cylindrical part of the end (see Figure 1). H Outside height, in millimetres, of the domed part of the end (see Figure 1). J Stress reduction factor. l Length of the cylinder, in millimetres. Lo Original gauge length of the test piece, in accordance with EN 10002-1, in millimetres. n Ratio of diameter of bend test former to the thickness of the test piece, (see Table 5).

Ptmin Minimum permissible test pressure, in bar. r Inside knuckle radius of the end, in millimetres. R Inside dishing radius of the end, in millimetres. Rg Guaranteed tensile strength guaranteed by the cylinder manufacturer for the finished cylinder, in newtons per square millimetre. Ro Minimum value of yield stress guaranteed by the cylinder manufacturer for the finished cylinder, in newtons per square millimetre. Rm Actual value of tensile strength determined by the tensile test specified in 7.4, in newtons per square millimetre. 4 Materials 4.1 Materials for shells and end pressings shall be: a) Carbon steel in accordance with EN 10120 or other appropriate standard providing they comply with the tests results described in this standard, or b) Stainless steel in accordance with EN 10028-7. 4.2 All parts welded to the cylinder shall be made of material compatible with the cylinder material. 4.3 The welding consumables shall be such that they are capable of giving consistent welds. The strength characteristics of the welds in the finished cylinder shall fulfil all requirements for the design and calculation of the cylinder.

4.4 !deleted text" !The cylinder manufacturer shall obtain certificates showing the chemical analysis and details of the mechanical properties of the steel supplied for the construction of the pressure retaining parts. The certificates shall be in accordance with EN 10204:2004, certificate Type 3.1 for shells and ends and Type 2.2 for the valve boss." 4.5 The manufacturer shall maintain a system of identification for the materials used in the fabrication in order that all materials for pressure parts in the completed cylinder can be traced to their origin. 5 Design 5.1 General requirements 5.1.1 The calculation of the wall thickness of the pressure parts shall be based on the yield stress of the material. 5.1.2 For calculation purposes, the value of the yield stress Ro is limited to a maximum of 0,85 Rg. 5.1.3 The calculation pressure (Pc) shall be: for cylinders restricted to LPG with a vapour pressure not exceeding 16 bar absolute at 70 °C:

For cylinders with a longitudinal weld: J = 0,9 For cylinders without a longitudinal weld: J = 1,0 5.3 Design of torispherical and semi-ellipsoidal ends concave to pressure 5.3.1 The shape of ends shall be such that the following conditions are fulfilled: for torispherical ends

R < D ; r

>

0,1 D ; h

>

4b (see Figure 1), for semi-ellipsoidal ends H > 0,192 D ; h

>

4b

(see Figure 1),

Key 1 Torispherical end 2 Semi-ellipsoidal end NOTE For torispherical ends the height H can be calculated using:

)](2) [(])[()(22b r

b R

b R

b R HDD+−++×−+−+= Figure 1 — Illustration of cylinder ends concave to pressure

5.3.2 The wall thickness (b) shall be not less than: cocP)R(C DPb+×××=15

In this formula, C is a shape factor, the value of which depends on the ratio H/D. The value of C shall be obtained from Figure 2 and Table 1 or Figure 3.

Figure 2 — Values of shape factor C for H/D between 0,2 and 0,25

Figure 3 — Values of shape factor C for H/D between 0,25 and 0,5

5.4 Ends of other shapes Ends of shapes other than those covered by 5.3 may be used provided that the adequacy of their design is demonstrated by a fatigue test in accordance with 7.11 or by appropriate stress analysis. 5.5 Minimum wall thickness The minimum wall thickness of each pressure part shall be the greater of that required by: for cylindrical shells, 5.2 or that required to meet the tests described in 8.1, for ends, 5.3 or 5.4, as appropriate, or that required to meet the tests described in 8.1. 5.6 Design of openings !deleted text" !5.6.1 All openings shall be located in one end of the cylinder. 5.6.2 Each opening in the cylinder shall be reinforced, either by a valve boss or pad securely attached by welding.

The suitability of the design of the reinforcement or design changes within an approved type of cylinder shall be confirmed by design calculations or a fatigue test in accordance with 7.11. 5.6.3 The welds of the opening reinforcement shall be not less than bD2,5 mm from any circumferential joints. 5.6.4 Unless otherwise specified, valve boss threads shall conform to a recognised specification. NOTE Suitable thread specifications include ISO 10920 for 25E thread and EN ISO 11116-1 for the 17E thread."

Otherwise the cylinder should be fitted with valves that have demonstrated, by impact tests in accordance with EN 13152 or EN 13153, that the valve can withstand damage without leakage of the contents. 5.8 Non-pressure containing attachments 5.8.1 Attachments shall be designed so as to avoid trapping water and to permit external inspection of the attachment welds. They shall be clear of longitudinal and circumferential joints. 5.8.2 Where a footring is fitted, it shall be of adequate strength to provide stability and be attached so that it does not prevent inspection of any pressure containing welds.

Any footring shall be suitably drained and the space enclosed by the footring suitably ventilated e.g. by means of openings." 6 Construction and workmanship 6.1 Welding qualification 6.1.1 Welding associated with the pressure envelope including non pressure-containing parts shall: !deleted text" !— have welding procedure specifications for all joints in accordance with EN ISO 15609-1, qualified in accordance with EN ISO 15614-1 or EN ISO 15613;" be done by welders approved in accordance with EN 287-1 and welding personnel in accordance with

EN 1418. The manufacturer shall maintain records. 6.1.2 Welding procedure approval tests shall be on welds that are representative of those made in production. 6.1.3 Welders shall have passed the approval tests for the specific type of work and procedure to be performed. 6.2 Plates and pressed parts The manufacturer shall ensure that pressure parts of the cylinders are of uniform quality and free from visible defects, which may ultimately affect the cylinder integrity. In the case of cylinders manufactured from stainless steel, care shall be taken to avoid contamination from other manufacturing materials. 6.3 Welded joints 6.3.1 The welding of the longitudinal and circumferential joints shall be a fully mechanised or automatic process so as to provide consistent and reproducible welds.

Key 1 Bevel optional 2 As desired 3 Depth of offset = e1 4 Inside of cylinder – avoid sharp break e Thickness of metal which is offset e1 Thickness of metal which is not offset w Width of weld Figure 4 — Illustration of a typical circumferential joggled weld butt joint 6.3.4 Before the cylinders are closed, longitudinal welds shall be visually examined from both sides in accordance with EN 970. 6.3.5 The fusion of the welded metal with the parent metal shall be smooth and free from overlapping, undercutting or abrupt irregularity.

There shall be no cracks, notching or porous patches in the welded surface and the surface adjacent to the weld.

The welded surface shall be regular and even without concavity. 6.3.6 Butt welds and joggled butt welds shall have full penetration. The excess thickness shall not exceed one fourth of the width of the weld. 6.4 Tolerances 6.4.1 Out-of-roundness The out-of-roundness of the cylindrical shell shall be limited so that the difference between the maximum and the minimum outside diameter in the same cross-section is not more than 1% of the mean of these diameters for two piece cylinders and 1,5% for three piece cylinders. 6.4.2 Straightness The maximum deviation of the cylindrical part of the shell from a straight line shall not exceed 0,3% of the cylindrical length.

Heat treatment 6.6.1 Cylinders manufactured using steel in accordance with EN 10120 shall be heat treated (normalised or stress relieved), unless the requirements of 6.6.3 have been satisfied. When using other steels, the manufacturer shall specify and carry out any heat treatment necessary to achieve the material properties required by the design. 6.6.2 The cylinder manufacturer shall maintain records of heat treatment carried out. 6.6.3 Cylinders manufactured using steel in accordance with EN 10120, need not be heat treated provided all the following requirements are met: cylinders are of three-piece construction, ends are semi ellipsoidal or torispherical in accordance with Figure 1 and the depth of pressing is limited such that:

0,26

≤−DbH and

b h8≤ cylinders are made from a fine grain steel with maximum grain size of 8, in the delivery condition, when tested in accordance with EN ISO 643 and three samples of each type, are subject to a fatigue test in accordance with 7.11.

Any subsequent change in design, material thickness, material specification or weld procedure shall require a further set of fatigue tests." !deleted text"

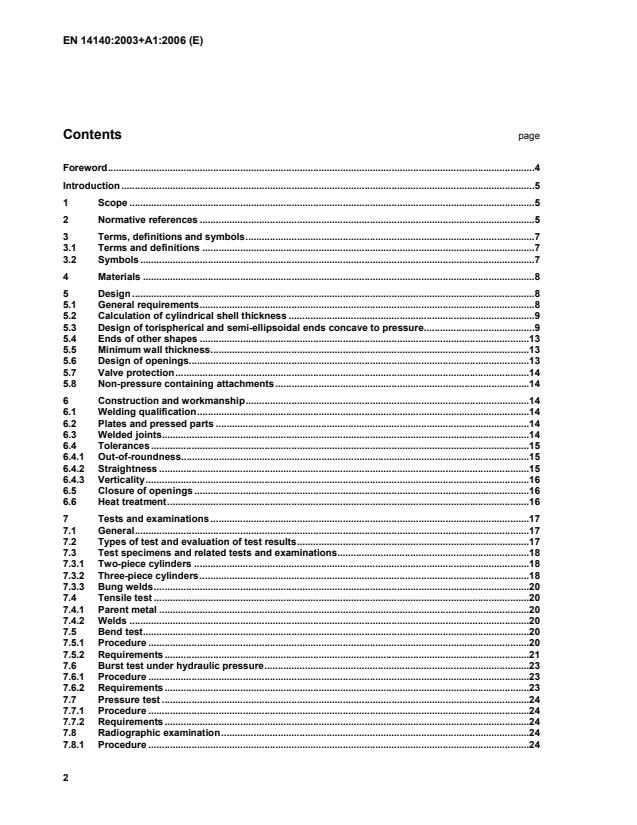

Specified in subclause

Specified in subclause Tensile 7.4 X 8.1 b) X 9.2 Mechanical Bend 7.5 X 8.1 b) X 9.2 Burst 7.6 X 8.1 c) X 9.7, 9.4, 9.8 Pressure 7.7 - - X 9.1.2 Radiographic 7.8 O 8.1 O X Y 9.2.2, 9.4, 9.5 9.2.1, 9.2.3 9.6.2 Macro 7.9 O 8.1 O X Y 9.2.2, 9.4, 9.5 9.3.1 9.6.2 Visual 7.10 X 8.1 d) X 6.3.4, 9.1.1, 9.1.2 Fatigue 7.11 X 8.1 a) - - Corrosion 7.12 X 8.1 f) - - Impact 7.13 X 8.1 g) - - Drop 7.14 X 8.1 h) - - O This allows for an option of a radiograph or macro

X No option permitted – test to be performed Y Retest required under certain circumstances "

EN 10002-1 1 Parent metal in the geometric longitudinal direction of the cylinder or, if it is not possible, in the circumferential direction, or the centre of one dished end. 1 bend test

EN 910 2 On the topside of the circumferential weld. 1 tensile test

EN 895 3 Perpendicular to the circumferential weld.

1 bend test

EN 910 4 On the underside of the circumferential weld. 1 macro examination

EN 1321

On a randomly selected location on the circumferential weld.

Test pieces that are not sufficiently flat, shall be flattened by cold pressing. In all bend test specimens, the weld shall be machined flush with the parent metal surface including any joggled material (see Figure 8 b)). 3411215 Key 1 Alternative locations of test specimen for tensile test 2 Test specimen for bend test (topside of the weld)

3 Test specimen for cross-weld tensile test

4 Test specimen for bend test (underside of the weld) 5 Circumferential weld Figure 5 — Test specimens taken from two-piece cylinders 7.3.2 Three-piece cylinders 7.3.2.1 For cylinders with longitudinal and circumferential welds (three-piece cylinders), test specimens (as detailed in Table 4) shall be taken from the places shown in Figure 6.

Table 4 — Types of tests and details (three-piece cylinders) Type In accordance with Key See Figure 6 Details 1 tensile test

EN 10002-1 1 Parent metal of cylindrical part in the longitudinal direction or, if this is not possible, in a circumferential direction. 1 tensile test

EN 10002-1 2 Parent metal from one dished end. 1 bend test

EN 910 3 On the topside of longitudinal weld. 1 bend test

EN 910 4 On the topside of a circumferential weld. 1 tensile test

EN 895 5 Perpendicular to the longitudinal weld.

1 bend test

EN 910 6 On the underside of the longitudinal weld. 1 tensile test

EN 895 7 Perpendicular to a circumferential weld.

1 bend test

EN 910 8 On the underside of a circumferential weld. 1 macro examination

EN 1321

On a randomly selected location on a circumferential weld.

9478106532191 Key 1 Alternative locations of test specimens for tensile test 2 Test specimen for tensile test 3 Test specimen for bend test (topside of the weld) 4 Test specimen for bend test (topside of the weld) 5 Test specimen for tensile test

6 Test specimen for bend test (underside of the weld) 7 Test specimen for tensile test

8 Test specimen for bend test (underside of the weld) 9 Circumferential weld 10 Longitudinal weld Figure 6 — Test specimens taken from three-piece cylinders

EN 10002-1. The two faces of the test specimen representing the inside and outside walls of the cylinder respectively shall not be machined. 7.4.1.2 Requirements The values obtained for yield stress, tensile strength and elongation shall be not less than those guaranteed by the cylinder manufacturer in the finished cylinder. 7.4.2 Welds 7.4.2.1 Procedure The tensile test perpendicular to the weld shall be carried out in accordance with EN 895 on a test specimen having a reduced cross section of 25 mm in width for a length extending up to 15 mm beyond the edges of the weld (see Figure 7).

Beyond this central part the width of the test specimen shall increase progressively. 7.4.2.2 Requirements The tensile strength value obtained, Rm, shall not be less than that guaranteed by the cylinder manufacturer Rg and in no case less than those given in the material specification, irrespective of where the fracture occurs in the cross section of the central part of the test specimen. Dimensions in millimetres 251515 Figure 7 — Test specimen for tensile test perpendicular to the weld 7.5 Bend test 7.5.1 Procedure 7.5.1.1 The preparation of test specimens and procedure for carrying out a bend test shall be in accordance with EN 910. 7.5.1.2 The bend test specimens shall be 25 mm in width.

A mandrel shall be placed in the centre of the weld while the test is being performed (see Figure 8).

7.5.2 Requirements No cracks shall be visible in the test specimen after bending.

Key a) Dimensions of test specimen b) Transverse guided bend test specimen preparation c) Illustration of bend test 1 Butt weld specimen 2 Joggle weld specimen 3 Weld dressed flush 4 Joggled portion to be removed Figure 8 — Bend tests

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...