EN 13870:2015

(Main)Food processing machinery - Portion cutting machines - Safety and hygiene requirements

Food processing machinery - Portion cutting machines - Safety and hygiene requirements

1.1 General

This European Standard covers portion cutting machines and accessories.

This European Standard does not apply to automatic industrial slicing machines (see prEN 16743) and band saw machines (see EN 12268).

This European Standard defines requirements for the design and manufacture of portion cutting machines.

The machines covered by this European Standard are used for continuous portioning of fresh, smoked or frozen meat with and without bones or of similar products by separation by means of a blade.

This European Standard deals with all significant hazards, hazardous situations and events relevant to machines, appliances and machinery, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4).

This European Standard deals with the hazards which can arise during commissioning, operation, maintenance and decommissioning of the machine.

The European Standard does not deal with the specific hazards of loading devices.

This European Standard is not applicable to portion cutting machines which are manufactured before the date of publication of this document by CEN.

1.2 Types of machinery

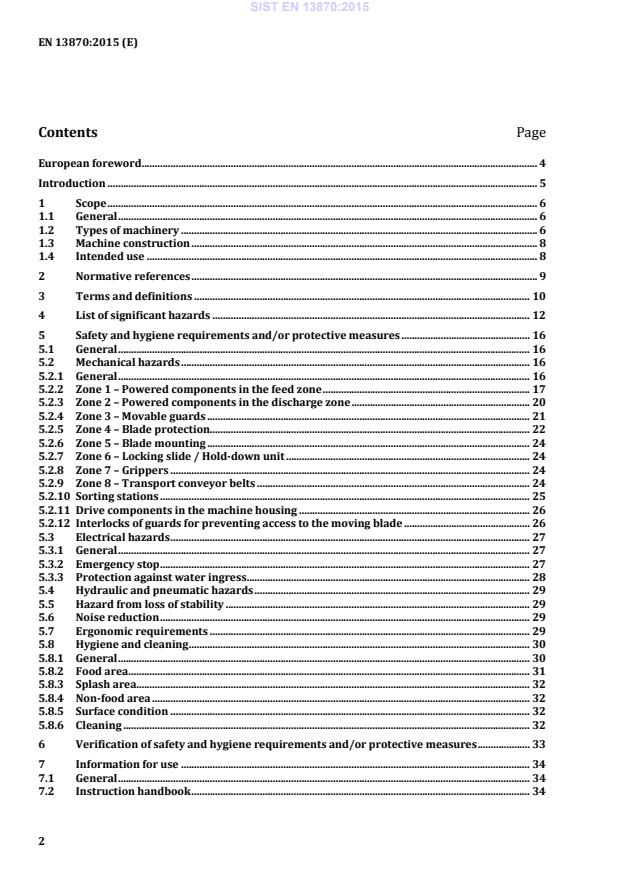

This European Standard covers the following types of machinery:

- Portion cutting machines with manual loading (see Figure 1);

- Portion cutting machines with automatic loading (see Figure 2).

1.3 Machine construction

Portion cutting machines depending on the construction consist of: machine housing (machine frame), fixed or moving product bases, automatic or manually operated grippers, hold-down unit, blade housing, blade, discharge device, associated drives, electrical, hydraulic or pneumatic components.

Portion cutting machines in the scope of this document may be equipped with the following auxiliary components:

- loading aid;

- discharge conveyor belt;

- laying unit;

- measurement or scanning devices;

- scales;

- sorting station (e.g. rocker, pusher);

- movement devices (e.g. castors).

1.4 Intended use

The intended use (as defined in EN ISO 12100:2010, 3.23) of portion cutting machines as dealt with in this document is described in 1.1.

The product is manually placed on the product base or automatically fed to the product base with a loading device. The product is supplied to the blade by automatic or manually operated grippers or conveyor slide or belt and the cutting process begins. The portion falls onto a discharge conveyor or a laying unit.

Nahrungsmittelmaschinen - Portionsschneidemaschinen - Sicherheits- und Hygieneanforderungen

1.1 Diese Europäische Norm legt Anforderungen an die Konstruktion und Herstellung von Wölfen (siehe Bilder 1a und 1b), die stationär betrieben werden, fest.

Die von dieser Europäischen Norm erfassten Maschinen werden für die Zerkleinerung von frischem oder gefrorenem Fleisch, Fleischprodukten und Fisch (nachfolgend als Produkt bezeichnet) durch Zerschneiden in einem Schneidsatz verwendet.

Wölfe für den Hausgebrauch werden von dieser Europäischen Norm nicht erfasst. Füllwölfe werden in EN 12463 „Nahrungsmittelmaschinen — Füllmaschinen und Vorsatzmaschinen — Sicherheits und Hygiene¬anforderungen“ behandelt.

Diese Europäische Norm gilt nur für Maschinen, die nach dem Ausgabedatum dieser Europäischen Norm hergestellt werden.

Wölfe mit einem Fußschalter mit selbsttätiger Rückstellung werden in dieser Europäischen Norm nicht behandelt.

Diese Europäische Norm behandelt:

- Wölfe für Läden und Vorbereitungsräume;

- Wölfe in Wurstküchen;

- Wölfe für den industriellen Einsatz;

- Zubehör.

In welchem Maße Gefährdungen erfasst sind, wird in dieser Europäischen Norm angegeben. Bei anderen Gefährdungen, die nicht in dieser Europäischen Norm behandelt werden, sollten die Maschinen, sofern zutreffend, EN ISO 12100:2010 entsprechen.

Diese Europäische Norm enthält keine speziellen Anforderungen an die Steuerung von Wölfen mittels Fußschalter.

1.2 Diese Norm umfasst folgende Bauarten:

- Wolf mit Einfüllschale, Einfüllschacht und Stopfer, Durchmesser 52 mm am Einfüllschacht (siehe Bild 3);

- Wolf mit Einfüllschale, Einfüllschacht, Schutzplatte und Stopfer, Durchmesser 52 mm am Einfüllschacht (siehe Bild 4);

- Wolf mit Einfülltrog und Deckel, Transportschnecke, mit ) oder ohne Mengwelle im Einfülltrog (siehe Bild 5);-

- Wolf mit Einfülltrog, mit oder ohne Deckel, Transportschnecke, mit1) oder ohne Mengwelle im Einfülltrog, mit Beschickungseinrichtung (kontinuierlich oder diskontinuierlich).

Wölfe bestehen aus einem Maschinenständer, einem Schneckengehäuse mit Arbeitsschnecke, einer Einfüllschale (mit Einfüllschacht) oder einem Einfülltrog, einer Transportschnecke (und manchmal einer zusätzlichen Mengwelle im Einfülltrog), einem Schneidsatz, einer Verschlussmutter, einer Beschickungs-einrichtung, einem Antriebsmotor und — abhängig von der Maschinenart — aus elektrischen, hydraulischen und pneumatischen Elementen. Sie besitzen auch verschiedene Schutzeinrichtungen, wie in Abschnitt 5 beispielhaft erläutert.

Machines pour les produits alimentaires - Portionneuses - Prescriptions relatives à la sécurité et à l'hygiène

1.1 Généralités

Le présent document couvre les portionneuses, ainsi que les accessoires.

Le présent document ne s'applique pas aux trancheuses industrielles automatiques (voir prEN 16743), ni aux scies à ruban (voir EN 12268).

Le présent document définit les prescriptions relatives à la conception et la fabrication des portionneuses.

Les machines couvertes par le présent document sont utilisées pour le portionnement continu de viandes fraîches, fumées ou congelées, désossées ou non, ou de produits similaires séparés au moyen d'une lame.

Le présent document traite tous les phénomènes dangereux significatifs, situations et événements dangereux significatifs associés aux machines, aux appareillages et aux mécanismes lorsque ceux-ci sont utilisés normalement et dans les conditions de mauvaises utilisations raisonnablement prévisibles par le fabricant (voir l'Article 4).

Le présent document traite des phénomènes dangereux qui peuvent se produire pendant la mise en service, le fonctionnement, l’entretien et la mise hors service de la machine.

Le présent document ne traite pas des phénomènes dangereux spécifiques liés aux dispositifs de chargement.

Le présent document ne s’applique pas aux portionneuses et trancheuses fabriquées avant la date de publication du présent document par le CEN.

1.2 Types de machines

Le présent document couvre les types de machines suivants :

- les portionneuses et trancheuses à chargement manuel (voir Figure 1) ;

- les portionneuses et trancheuses à chargement automatique (voir Figure 2).

1.3 Construction de la machine

Les portionneuses et trancheuses disposent, selon la construction du bâti de la machine (châssis), d'embases de produit fixes ou déplaçables, d'outils de préhension à action manuelle ou automatique, d'un dispositif de maintien, d'un bâti pour la lame, d'une lame, d'un dispositif d'évacuation, de commandes associées, et de composants électriques, hydrauliques ou pneumatiques.

Les portionneuses et trancheuses couvertes par le domaine d’application du présent document peuvent être équipées des composants auxiliaires suivants :

- un dispositif d'aide pour le chargement ;

- un tapis transporteur d'évacuation ;

- une unité de pose ;

- des dispositifs de mesurage ou scanners ;

- des cadrans ;

- un poste de tri (par exemple un basculeur, un poussoir) ;

- des dispositifs de déplacement (par exemple des roulettes).

1.4 Utilisation prévue

L’utilisation normale (telle que définie dans l’EN ISO 12100:2010, 3.23) des portionneuses et trancheuses traitées par le présent document est décrite au paragraphe 1.1.

Le produit est placé manuellement sur son embase ou automatiquement au moyen d'un dispositif de chargement. Le produit est acheminé vers la lame grâce à des outils de préhension à action manuelle ou automatique, ou un tapis transporteur et le processus de coupe commence. La portion tombe dans un convoyeur d'évacuation ou une unité de pose.

Stroji za predelavo hrane - Stroji za razrezovanje/razkosavanje na zrezke/zarebrnice - Varnostne in higienske zahteve

Ta dokument zajema stroje za razrezovanje/razkosavanje in pribor. Ta dokumentu določa obseg vključenosti nevarnosti. Ta dokument določa zahteve za načrtovanje in izdelavo strojev za razrezovanje/razkosavanje. Stroji, ki jih zajema ta dokument, se uporabljajo za neprekinjeno razkosavanje svežega, dimljenega ali zamrznjenega mesa s kostmi ali brez ali podobnih proizvodov z rezilom. Ta dokument obravnava vse velike nevarnosti, nevarne situacije in primere, povezane s stroji in napravami, kadar se uporabljajo, kot je predvideno, in pod pogoji, ki jih predvidi proizvajalec. Ta dokument določa nevarnosti, do katerih lahko pride pri začetku uporabe, delovanju, vzdrževanju in izločitvi stroja iz uporabe. Ta dokument ne obravnava posebnih nevarnosti nalagalnikov. Ta dokument se ne uporablja za stroje za razrezovanje/razkosavanje, ki so bili izdelani pred datumom, ko je CEN objavil ta dokument. Ta dokument zajema naslednje vrste strojev: – stroje za razrezovanje/razkosavanje z odvodno držo; – stroje za razrezovanje/razkosavanje z odvodnim koritom;

General Information

- Status

- Withdrawn

- Publication Date

- 08-Sep-2015

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 153 - Food processing machinery - Safety and hygiene specifications

- Drafting Committee

- CEN/TC 153/WG 2 - Meat processing machinery

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 17-Nov-2021

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 28-Dec-2011

- Effective Date

- 19-Jan-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

EN 13870:2015 is a standard published by the European Committee for Standardization (CEN). Its full title is "Food processing machinery - Portion cutting machines - Safety and hygiene requirements". This standard covers: 1.1 General This European Standard covers portion cutting machines and accessories. This European Standard does not apply to automatic industrial slicing machines (see prEN 16743) and band saw machines (see EN 12268). This European Standard defines requirements for the design and manufacture of portion cutting machines. The machines covered by this European Standard are used for continuous portioning of fresh, smoked or frozen meat with and without bones or of similar products by separation by means of a blade. This European Standard deals with all significant hazards, hazardous situations and events relevant to machines, appliances and machinery, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). This European Standard deals with the hazards which can arise during commissioning, operation, maintenance and decommissioning of the machine. The European Standard does not deal with the specific hazards of loading devices. This European Standard is not applicable to portion cutting machines which are manufactured before the date of publication of this document by CEN. 1.2 Types of machinery This European Standard covers the following types of machinery: - Portion cutting machines with manual loading (see Figure 1); - Portion cutting machines with automatic loading (see Figure 2). 1.3 Machine construction Portion cutting machines depending on the construction consist of: machine housing (machine frame), fixed or moving product bases, automatic or manually operated grippers, hold-down unit, blade housing, blade, discharge device, associated drives, electrical, hydraulic or pneumatic components. Portion cutting machines in the scope of this document may be equipped with the following auxiliary components: - loading aid; - discharge conveyor belt; - laying unit; - measurement or scanning devices; - scales; - sorting station (e.g. rocker, pusher); - movement devices (e.g. castors). 1.4 Intended use The intended use (as defined in EN ISO 12100:2010, 3.23) of portion cutting machines as dealt with in this document is described in 1.1. The product is manually placed on the product base or automatically fed to the product base with a loading device. The product is supplied to the blade by automatic or manually operated grippers or conveyor slide or belt and the cutting process begins. The portion falls onto a discharge conveyor or a laying unit.

1.1 General This European Standard covers portion cutting machines and accessories. This European Standard does not apply to automatic industrial slicing machines (see prEN 16743) and band saw machines (see EN 12268). This European Standard defines requirements for the design and manufacture of portion cutting machines. The machines covered by this European Standard are used for continuous portioning of fresh, smoked or frozen meat with and without bones or of similar products by separation by means of a blade. This European Standard deals with all significant hazards, hazardous situations and events relevant to machines, appliances and machinery, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). This European Standard deals with the hazards which can arise during commissioning, operation, maintenance and decommissioning of the machine. The European Standard does not deal with the specific hazards of loading devices. This European Standard is not applicable to portion cutting machines which are manufactured before the date of publication of this document by CEN. 1.2 Types of machinery This European Standard covers the following types of machinery: - Portion cutting machines with manual loading (see Figure 1); - Portion cutting machines with automatic loading (see Figure 2). 1.3 Machine construction Portion cutting machines depending on the construction consist of: machine housing (machine frame), fixed or moving product bases, automatic or manually operated grippers, hold-down unit, blade housing, blade, discharge device, associated drives, electrical, hydraulic or pneumatic components. Portion cutting machines in the scope of this document may be equipped with the following auxiliary components: - loading aid; - discharge conveyor belt; - laying unit; - measurement or scanning devices; - scales; - sorting station (e.g. rocker, pusher); - movement devices (e.g. castors). 1.4 Intended use The intended use (as defined in EN ISO 12100:2010, 3.23) of portion cutting machines as dealt with in this document is described in 1.1. The product is manually placed on the product base or automatically fed to the product base with a loading device. The product is supplied to the blade by automatic or manually operated grippers or conveyor slide or belt and the cutting process begins. The portion falls onto a discharge conveyor or a laying unit.

EN 13870:2015 is classified under the following ICS (International Classification for Standards) categories: 67.260 - Plants and equipment for the food industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13870:2015 has the following relationships with other standards: It is inter standard links to EN 13870:2005+A1:2010, EN 13870:2015+A1:2021, EN 60204-1:2006, EN 60529:1991, EN ISO 3744:2010, EN 1672-2:2020, EN 1005-2:2003+A1:2008, EN ISO 11688-1:2009, EN ISO 4871:2009, EN ISO 11201:2010, EN 1005-1:2001+A1:2008, EN 953:1997+A1:2009, EN ISO 14119:2013, EN ISO 13857:2008, EN ISO 13855:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13870:2015 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13870:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stroji za predelavo hrane - Stroji za razrezovanje/razkosavanje na zrezke/zarebrnice - Varnostne in higienske zahteveNahrungsmittelmaschinen - Portionsschneidemaschinen - Sicherheits- und HygieneanforderungenMachines pour les produits alimentaires - Portionneuses - Prescriptions relatives à la sécurité et à l'hygièneFood processing machinery - Portion cutting machines - Safety and hygiene requirements67.260Tovarne in oprema za živilsko industrijoPlants and equipment for the food industryICS:Ta slovenski standard je istoveten z:EN 13870:2015SIST EN 13870:2015en,fr,de01-november-2015SIST EN 13870:2015SLOVENSKI

STANDARDSIST EN 13870:2005+A1:20101DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13870

September

t r s w ICS

x yä t x r Supersedes EN

s u z y rã t r r w ªA sã t r s rEnglish Version

Food processing machinery æ Portion cutting machines æ Safety and hygiene requirements Machines pour les produits alimentaires æ Portionneuses æ Prescriptions relatives à la sécurité et à l 5hygiène

Nahrungsmittelmaschinen æ Portionsschneidemaschinen æ Sicherheitsæ und Hygieneanforderungen This European Standard was approved by CEN on

s August

t r s wä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey andUnited Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s w CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s u z y rã t r s w ESIST EN 13870:2015

Noise test code for portion cutting machines (grade 2) . 38 Annex B (normative)

Design principles to ensure cleanability of portion cutting machines and their auxiliary components . 40 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC . 45 Bibliography . 46

Key 1 loading protection hood 7 discharge conveyor belt (optional) 2 product base 8 discharge chute 3 round/sickle blade 9 discharge chute hood 4 blade protection hood/cutting space 10 feed protection hood 5 cutting zone 11 machine housing 6 cutting material holder/feeding carriage 12 locking slide/hold-down unit (depending on machine type) Figure 1 — Portion cutting machine with manual loading (exemplary embodiment) SIST EN 13870:2015

Key 1 product base 6 discharge conveyor belt 2 blade 7 discharge chute hood 3 blade protection hood/cutting space 8 hold-down unit 4 machine housing 9 pre-weighing unit (optional) 5 cutting material holder/feeding carriage

Figure 2 — Portion cutting machine with automatic loading (exemplary embodiment) 1.3 Machine construction Portion cutting machines depending on the construction consist of: machine housing (machine frame), fixed or moving product bases, automatic or manually operated grippers, hold-down unit, blade housing, blade, discharge device, associated drives, electrical, hydraulic or pneumatic components. Portion cutting machines in the scope of this document may be equipped with the following auxiliary components: — loading aid; — discharge conveyor belt; — laying unit; — measurement or scanning devices; — scales; — sorting station (e.g. rocker, pusher); — movement devices (e.g. castors). 1.4 Intended use The intended use (as defined in EN ISO 12100:2010, 3.23) of portion cutting machines as dealt with in this document is described in 1.1. SIST EN 13870:2015

Key 1 zone 1 3 zone 3 5 zone 5 7 zone 7 2 zone 2 4 zone 4 6 zone 6 8 zone 8 Figure 3 — Portion cutting machine with manual loading – hazard zones

Key 1 zone 1 3 zone 3 5 zone 5 7 zone 7 2 zone 2 4 zone 4 6 zone 6 8 zone 8 Figure 4 — Portion cutting machine with automatic loading – hazard zones SIST EN 13870:2015

a) Example with rocker b) Example with pusher Key 1 rocker/pusher 2 downstream component, e.g. transport conveyor A hazard point Figure 5 — Hazard points at the sorting station 5 Safety and hygiene requirements and/or protective measures 5.1 General Machinery shall comply with the safety requirements and/or protective/risk reduction measures of this clause. In addition, the machine shall be designed according to the principles of EN ISO 12100 for relevant but not significant hazards which are not dealt with by this document. Where the means of reducing the risk is by the physical arrangement or positioning of the machine the manufacturer shall include in the Information for use a reference to these means, and to any limiting value of the requirement, and, if appropriate, to the means of verification. Where the means of reducing the risk is by a safe system of work, the manufacturer shall include in the Information for use details of the system and of the elements of training required by the operating personnel. 5.2 Mechanical hazards 5.2.1 General Portion cutting machines shall be designed and constructed in accordance with Annex C and the conditions mentioned below. The guards shall comply with EN 953:1997+A1:2009. Fixing devices for fixed guards shall remain on the guards or on the machine if the guard is removed. Unless otherwise stipulated in other sub-clauses, the interlocking systems of guards shall comply with EN ISO 14119:2013, 4.2, and the safety related components of the control system shall present at least a performance level “c” of EN ISO 13849-1. SIST EN 13870:2015

· 1 600 mm to < 2 000 mm the safety distance up to the first hazard point can be

· 850 mm. — If the guard is at a height of

· 2 000 mm, a protective guard (e.g. photoelectric barrier,

20 mm on the guard, the safety distance from the protective guard (in operated position) to the first hazard point can be

· 130 mm (see Figure 6). SIST EN 13870:2015

Key 1 hazard zone 2 guard 3 protective guard 4 reference level Figure 6 — Reaching over the guard – safety dimensions 5.2.2.1.3. If non-contact protective equipment (e.g. active optoelectronic protective device (AOPD)) is used to prevent access to the hazard zone, it shall correspond to EN ISO 13855. 5.2.2.1.4. Inlet opening or inlet tunnel An unclosed inlet opening or an inlet opening closable with an interlocking or protective guard can be implemented at the supply side for the automatic loading. A special form of the unclosed inlet opening is the inlet tunnel. Unclosed inlet openings or inlet tunnels shall be designed so that the dimensions shown in Table 2 are complied with (see also Figure 7). SIST EN 13870:2015

·

1000 1000 1000 850 850 850 550 230 B

¶

280 250 230 200 180 150 120 30 C

¶

300 280 250 230 200 180 150 50 D

¶

330 300 280 250 230 200 180 50 E

¶

¶ 300

¶ 500 n.r.*

¶ 300

¶ 500 n.r.* n.r.* n.r.*

*n.r. = no requirements (dimensions in mm) A safety distance to the hazard point B opening height of the inlet opening C opening height of the inlet opening in combination with a terminal strip D opening height of the inlet opening in combination with one or more photoelectric barriers E opening width of the inlet opening Dimensions in mm

a) Unclosed opening b) Inlet tunnel Key 1 safeguard 2 electronic or mechanical trip device 3 photoelectric barrier(s) A safety distance up to the hazard point B opening height of the inlet opening C opening height of the inlet opening in combination with a terminal strip D opening height of the inlet opening in combination with one or more photoelectric barriers Figure 7 — Feed zone – Safety dimensions of inlet opening If the inlet opening is closed by an interlocking guard (with or without guard locking), inspection openings and gaps in and around the guard shall correspond to the requirements of EN ISO 13857:2008, Table 4. The requirements from 5.2.4 (zone 3) shall be complied with for the interlocking guard. 5.2.2.2 Manual loading If the loading protection hood is opened during the manual loading, access to the moving components in the feed zone (e.g. product base, grippers, hold-down unit) shall be protected. This is achieved by e.g. one of the following measures: SIST EN 13870:2015

·

1000 850 550 230 B

¶

200 150 85 30 (dimensions in mm) A safety distance to the hazard point B opening height at the front edge of the protection hood

Key A safety distance to the hazard point B opening height at the front edge of the protection hood Figure 8 — Discharge zone – Safety dimensions 5.2.3.2. If the arm is supported by a limiting obstruction of minimum 300 mm during the side intervention into the protection hood, the following safety distances are necessary (see Figure 9): SIST EN 13870:2015

¶ 170 mm and — safety distance (A) to the hazard point

· 550 mm. Dimensions in mm

Key A safety distance to the hazard point D opening width on the front of the protection hood Figure 9 — Discharge zone – Safety distance with limitation of the movement If the outlet-side intervention from the underside cannot be protected by a guard (e.g. protective sheet), the discharge conveyor, laying unit or the downstream auxiliary component shall be designed so that the intervention is prevented. The openings and safety distances shall correspond to EN ISO 13857:2008, Table 4. If the intervention is prevented by the downstream auxiliary component, it shall be ensured that the protection function of the auxiliary component is retained. This can be achieved e.g. by side guide plates, limit stops or interlocks. 5.2.4 Zone 3 – Movable guards 5.2.4.1 Manually operated guards A handle shall be provided on the manually operated guard. A handle can be dispensed with if the guard is designed so that it can be securely held and operated. The force required for lifting or lowering a guard may not exceed 250 N. Movable guards shall be secured against falling down. This is achieved by e.g. the following measures: — The movable guard shall be located far behind the dead centre in the open position. — If the movable guard is not far enough behind its dead centre in the open position, e.g. a counterweight, a spring or a mechanical latching device shall prevent falling. Guards that can assume their protection position without guard locking shall be locked with the mechanical drive. Normally, fixed guards, also those that are mobile in design for ergonomic reasons and only have to be opened for maintenance or repair and are not intended to be opened by the operator, are excepted from this. 5.2.4.2 Force-operated guards As long as the hazards cannot be prevented by the design (e.g. advancing deflector), the risk of crushing in force-operated guards shall be protected e.g. by the following methods: SIST EN 13870:2015

¶ 6 mm, is the guard locking (see 5.2.12.3) released. When locking with a locking force, this shall be minimum 200 N. — The guard closes with a crushing force of maximum 135 N or an impact force of maximum 180 N and a speed of maximum 200 mm/s. Only in the work position, if the distance from the guard to the closing edge is

¶ 25 mm, is the guard locking (see 5.2.12.3) released. When locking with a locking force, this shall be minimum 300 N. The distance up to the first hazard point shall be minimum 450 mm. — The guard closes with a speed of maximum 50 mm/s, if the distance from the guard to the closing edge is

¶ 200 mm. The closing speed shall not be more than 50 mm/s up to a minimum distance of 200 mm. — No handle may be mounted on force-operated guards that are locked by a retaining force. — If the drive energy fails (e.g. power failure, tube or hose breakage), the movement of the force-operated guard shall be interrupted if a crushing force of 135 N is exceeded. Safety relevant parts of the control shall correspond to the requirements from EN ISO 13849-1. — Non-contact protective device as closing edge protection. — In the case of safety guards that swivel upwards and under which the operator has to enter, the minimum height under the opened guard shall be 1 800 mm. Impact edges and corners may not have sharp edges. — Information in the instruction handbook: The manufacturer shall describe the safety working procedures which the operator has to follow in the instruction handbook. These methods of working shall be a component of the training that the operator shall fulfil. 5.2.5 Zone 4 – Blade protection 5.2.5.1 General Cutting tools have to be removed periodically. Cutting tools are sharp and special protective measures shall be taken. For such blades, designers shall provide means of attaching a tool to the blade to avoid hand contact: and a box, or surround guard, to protect against the sharp edges of the blade during handling and transportation. Explanations on the use of these protective means shall be included in the instruction handbook. Injuries due to cutting or piercing when working with the blade or when the blade is stationary shall be prevented. This is achieved by e.g. the following measures: — A blade protection shall be used for installation, removal and transport of the blade. — The manufacturer shall describe the residual risks when working with the blade and during all work in the area of the blade, especially during cleaning and maintenance, in the instruction handbook. The use and handling of the blade protection shall be described in the instruction handbook. SIST EN 13870:2015

Data on the safe storage, transport, maintenance, cleaning and use of the blades shall be contained in the instruction handbook. — The stationary blade may not move unintentionally when the housing is open and closed, e.g. by a braking device. 5.2.5.2 Cutting device and automatic loading Access into the active area of the powered blade shall be prevented during cutting operation and during automatic loading. This is achieved by e.g. the following measures: — The inlet-side access shall be prevented by the guards (e.g. loading protection hood, loading protection door). — For safety requirements, see 5.2.2.1 Zone 1. — The movable guards shall be locked with the machine drive. The interlocks shall correspond to the requirements from 5.2.12. — The inlet-side access is prevented by non-contact protective device, e.g. active optoelectronic protective device (AOPD). These shall correspond to EN ISO 13855. — The blade shall be installed in a blade housing with an interlocked blade protection hood. The interlocks shall correspond to the requirements from 5.2.12. — The outlet-side access into the active range of the blade shall be prevented by guards. — Requirements for the guards, see 5.2.3 Zone 2. — The movable guards shall be locked with the machine drive. The interlocks shall correspond to the requirements from 5.2.12. 5.2.5.3 Manual loading for powered blade Access to the active area of the powered blade shall be prevented during manual loading. This is achieved by e.g. the following measures: — A locking slide separates the blade from the feed area during loading. The locking slide may only be opened if the loading protection hood/loading protection door is closed. The loading protection hood/loading protection door can only be opened if the locking slide is closed. The interlock shall correspond to the requirements of EN ISO 14119:2013. — Openings in the locking slide (e.g. for hold-down unit) shall correspond to the requirements of EN ISO 13857:2008, Table 4. 5.2.5.4 Manual loading while blade is stationary Access to the active area of the stationary blade shall be prevented during manual loading. This is achieved by e.g. the following measures: — The blade shall be stopped with the normal stopping device before manual loading. The blade shall come to a standstill in a position in which direct access to the cutter is not possible. The requirements of EN ISO 13857:2008 apply in respect to this. The loading protection door shall be locked with the blade drive. The interlock shall correspond to the requirements from EN ISO 14119:2013, 4.2. SIST EN 13870:2015

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...