EN 13674-2:2019

(Main)Railway applications - Track - Rail - Part 2: Switch and crossing rails used in conjunction with Vignole railway rails 46 kg/m and above

Railway applications - Track - Rail - Part 2: Switch and crossing rails used in conjunction with Vignole railway rails 46 kg/m and above

This document specifies switch and crossing rails that carry railway wheels. These are used in conjunction with Vignole railway rails.

This document is not applicable for the check rails that do not carry railway wheels.

Nine pearlitic steel grades are specified covering a hardness range of 200 HBW to 410 HBW and include non-heat treated non-alloy steels, non-heat treated alloy steels, heat treated non-alloy steels, heat treated low alloy steels and heat treated alloy steels.

There are 33 rail profiles specified in this standard, but they may not all be available in all steel grades.

Rails specified in EN 13674-1 can also be used as switch and crossing rails and if so used they will comply with the requirements of EN 13674-1.

Bahnanwendungen - Oberbau - Schienen - Teil 2: Schienen für Weichen und Kreuzungen, die in Verbindung mit Vignolschienen ab 46 kg/m verwendet werden

Dieser Teil dieses Dokuments enthält Festlegungen für radtragende Schienen für Weichen und Kreuzungen, die in Verbindung mit Vignolschienen eingesetzt werden.

Dieser Teil dieses Dokuments gilt nicht für Radlenkerschienen, die nicht von Eisenbahnrädern befahren werden.

Neun perlitische Stahlsorten in einem Härtebereich zwischen 200 HBW und 410 HBW sind festgelegt für Schienen aus nicht wärmebehandeltem unlegiertem Stahl, nicht wärmebehandeltem legiertem Stahl, wärmebehandeltem unlegiertem Stahl, wärmebehandeltem niedrig legiertem Stahl und wärmebehandeltem legiertem Stahl.

In dieser Norm sind 33 Schienenprofile festgelegt, aber nicht alle Profile müssen in jeder Stahlsorte verfügbar sein.

Die in EN 13674-1 festgelegten Schienen können auch als Schienen für Weichen und Kreuzungen verwendet werden und werden dann die Anforderungen nach EN 13674-1 erfüllen.

Applications ferroviaires - Voie - Rails - Partie 2 : Rails pour appareils de voie utilisés avec des rails Vignole de masse supérieure ou égale à 46 kg/m

Le présent document spécifie les rails d'appareils de voie qui supportent les roues du train. Ceux-ci sont utilisés en association avec les rails Vignole.

Ce document n'est pas applicable pour les contre-rails qui ne supportent pas les roues.

9 nuances d'acier perlitique sont spécifiées représentant une fourchette de dureté comprise entre 200 HBW et 410 HBW. Ces nuances d'acier comprennent : les aciers non alliés non traités thermiquement, les aciers alliés non traités thermiquement, les aciers non alliés traités thermiquement, les aciers faiblement alliés traités thermiquement et les aciers alliés traités thermiquement.

33 profils de rails sont spécifiés dans la présente norme, mais ils peuvent ne pas être disponibles dans toutes les nuances d'acier.

Les rails spécifiés dans l'EN 13674-1 peuvent aussi être utilisés pour les appareils de voie et, dans le cas d'une telle utilisation, ils doivent être conformes aux exigences de l'EN 13674-1.

Železniške naprave - Zgornji ustroj proge - Tirnice - 2. del: Tirnice za kretnice in križišča, ki se uporabljajo skupaj z Vignolovo tirnico z maso 46 kg/m ali več

Ta del standarda EN 13674 določa tirnice za kretnice in križišča, ki nosijo železniška kolesa. Uporabljajo se skupaj z Vignolovo tirnico. Ta del tega standarda se ne uporablja za kontrolne tirnice, ki ne nosijo železniških koles. Določenih je osem perlitnih razredov jekla z razponom trdote od 200 do 390 HBW, ki vključujejo nelegirana jekla, ki niso toplotno obdelana, legirana jekla, ki niso toplotno obdelana, toplotno obdelana nelegirana jekla in toplotno obdelana nizko legirana jekla. V tem standardu je opredeljenih »34 profilov tirnic«, vendar morda vsi niso na voljo v vseh razredih jekla. Tirnice, določene v standardu EN 13674-1, se prav tako lahko uporabljajo kot kretnice in križišča in morajo biti v tem primeru v skladu z zahtevami standarda EN 13674-1.

General Information

- Status

- Published

- Publication Date

- 01-Oct-2019

- Withdrawal Date

- 29-Apr-2020

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 1/WG 4 - Rails

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 02-Oct-2019

- Due Date

- 07-Dec-2018

- Completion Date

- 02-Oct-2019

Relations

- Effective Date

- 09-Oct-2019

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 13232-9:2006+A1:2011 - Railway applications - Track - Switches and crossings - Part 9: Layouts - Effective Date

- 28-Jan-2026

- Referred By

EN 15594:2009 - Railway applications - Track - Restoration of rails by electric arc welding - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 13674-2:2019 - Railway applications - Track - Rail - Part 2: Switch and crossing rails used in conjunction with Vignole railway rails 46 kg/m and above - defines technical and quality requirements for switch and crossing rails that carry wheels (not applicable to check rails that do not carry wheels). The standard covers material grades, profiles, manufacturing, identification, testing and acceptance criteria to ensure safe, durable components for turnout and crossing assemblies.

Key topics and technical requirements

- Steel grades & hardness: Nine pearlitic steel grades are specified, spanning a hardness range of 200 HBW to 410 HBW, including non‑heat treated and heat‑treated, alloy and low‑alloy variants (e.g., R370CrHT introduced).

- Rail profiles: The standard specifies 33 switch and crossing rail profiles (availability may vary by steel grade). Rails compliant with EN 13674‑1 may also be used as switch and crossing rails if they meet EN 13674‑1 requirements.

- Manufacture & product integrity: Includes factory production control, best‑practice manufacturing notes, requirements for blooms and rails, and identification methods (branding, hot and cold stamping, other marking).

- Qualification of manufacturer: Prerequisites for manufacturer qualification and evidence of capability for producing compliant rails.

- Acceptance tests and laboratory checks: Detailed acceptance testing including chemical composition, microstructure, decarburization, oxide cleanness, sulfur prints, hardness, tensile tests, and retest procedures.

- Dimensional tolerances & mechanical properties: Definitions for profile geometry, straightness, surface flatness, twist, linear mass, cutting/drilling tolerances and static properties.

- Inspection for internal & surface quality: Rules for non‑destructive inspection, internal defect acceptance and surface defect classification.

- Quality management: Requires manufacturers to operate quality systems at least equivalent to EN ISO 9001.

Practical applications

- Use for procurement, specification and acceptance of switch and crossing rails in new build, refurbishment and heavy‑duty turnout installations where Vignole rails ≥46 kg/m are used.

- Ensures compatibility of materials, welding and installation practices with interoperable European requirements.

- Guides testing laboratories, welders and contractors on acceptance sampling, mechanical testing and dimensional checks.

Who should use this standard

- Railway infrastructure owners and operators

- Rail manufacturers and foundries

- Track engineers, designers and consultants

- Procurement/specification teams and testing laboratories

- Welding contractors involved in turnout construction

Related standards

- EN 13674‑1 (Vignole railway rails ≥46 kg/m)

- EN 13674‑3 (Check rails)

- EN 13674‑4 (Vignole rails <46 kg/m)

- Welding and joining standards: EN 14587 series, EN 14730 series, EN 15594

- Other related: EN 14811, EN 16273

Keywords: EN 13674-2:2019, switch and crossing rails, Vignole railway rails 46 kg/m, rail steel grades, rail hardness, acceptance tests, rail manufacturing, turnout rails.

Get Certified

Connect with accredited certification bodies for this standard

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 13674-2:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Track - Rail - Part 2: Switch and crossing rails used in conjunction with Vignole railway rails 46 kg/m and above". This standard covers: This document specifies switch and crossing rails that carry railway wheels. These are used in conjunction with Vignole railway rails. This document is not applicable for the check rails that do not carry railway wheels. Nine pearlitic steel grades are specified covering a hardness range of 200 HBW to 410 HBW and include non-heat treated non-alloy steels, non-heat treated alloy steels, heat treated non-alloy steels, heat treated low alloy steels and heat treated alloy steels. There are 33 rail profiles specified in this standard, but they may not all be available in all steel grades. Rails specified in EN 13674-1 can also be used as switch and crossing rails and if so used they will comply with the requirements of EN 13674-1.

This document specifies switch and crossing rails that carry railway wheels. These are used in conjunction with Vignole railway rails. This document is not applicable for the check rails that do not carry railway wheels. Nine pearlitic steel grades are specified covering a hardness range of 200 HBW to 410 HBW and include non-heat treated non-alloy steels, non-heat treated alloy steels, heat treated non-alloy steels, heat treated low alloy steels and heat treated alloy steels. There are 33 rail profiles specified in this standard, but they may not all be available in all steel grades. Rails specified in EN 13674-1 can also be used as switch and crossing rails and if so used they will comply with the requirements of EN 13674-1.

EN 13674-2:2019 is classified under the following ICS (International Classification for Standards) categories: 93.100 - Construction of railways. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13674-2:2019 has the following relationships with other standards: It is inter standard links to EN 13674-2:2006+A1:2010, EN 13674-1:2011+A1:2017, EN ISO 6506-1:2014, EN ISO 6892-1:2019, EN 10276-1:2000, EN ISO 7827:1995, EN 10027-1:2016, EN 10027-2:2015, EN 10163-1:2004, EN 13232-9:2006+A1:2011, EN 15594:2009, EN 13232-6:2005+A1:2011, EN 13232-7:2023, EN 13232-5:2023, EN 14587-3:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13674-2:2019 is associated with the following European legislation: EU Directives/Regulations: 2008/57/EC, 2016/797/EU; Standardization Mandates: M/024, M/334, M/483. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13674-2:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2019

Nadomešča:

SIST EN 13674-2:2006+A1:2010

Železniške naprave - Zgornji ustroj proge - Tirnice - 2. del: Tirnice za kretnice in

križišča, ki se uporabljajo skupaj z Vignolovo tirnico z maso 46 kg/m ali več

Railway applications - Track - Rail - Part 2: Switch and crossing rails used in conjunction

with Vignole railway rails 46 kg/m and above

Bahnanwendungen - Oberbau - Schienen - Teil 2: Schienen für Weichen und

Kreuzungen, die in Verbindung mit Vignolschienen ab 46 kg/m verwendet werden

Applications ferroviaires - Voie - Rails - Partie 2 : Rails pour appareils de voie utilisés

avec des rails Vignole de masse supérieure ou égale à 46 kg/m

Ta slovenski standard je istoveten z: EN 13674-2:2019

ICS:

45.080 Tračnice in železniški deli Rails and railway

components

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13674-2

EUROPEAN STANDARD

NORME EUROPÉENNE

October 2019

EUROPÄISCHE NORM

ICS 93.100 Supersedes EN 13674-2:2006+A1:2010

English Version

Railway applications - Track - Rail - Part 2: Switch and

crossing rails used in conjunction with Vignole railway

rails 46 kg/m and above

Applications ferroviaires - Voie - Rails - Partie 2 : Rails Bahnanwendungen - Oberbau - Schienen - Teil 2:

pour appareils de voie utilisés avec des rails Vignole de Schienen für Weichen und Kreuzungen, die in

masse supérieure ou égale à 46 kg/m Verbindung mit Vignolschienen ab 46 kg/m verwendet

werden

This European Standard was approved by CEN on 2 January 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13674-2:2019 E

worldwide for CEN national Members.

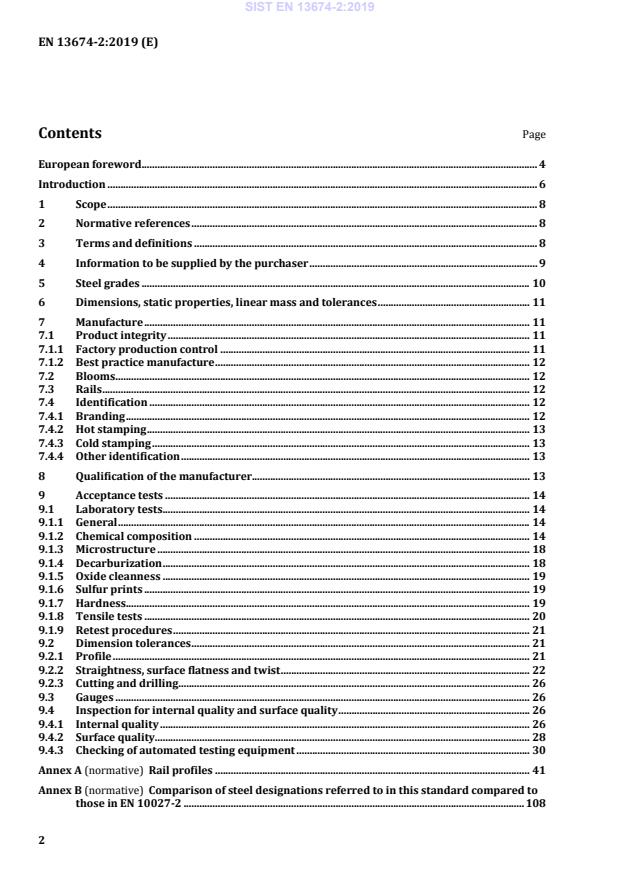

Contents Page

European foreword . 4

Introduction . 6

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 8

4 Information to be supplied by the purchaser . 9

5 Steel grades . 10

6 Dimensions, static properties, linear mass and tolerances . 11

7 Manufacture . 11

7.1 Product integrity . 11

7.1.1 Factory production control . 11

7.1.2 Best practice manufacture . 12

7.2 Blooms . 12

7.3 Rails . 12

7.4 Identification . 12

7.4.1 Branding . 12

7.4.2 Hot stamping . 13

7.4.3 Cold stamping . 13

7.4.4 Other identification . 13

8 Qualification of the manufacturer. 13

9 Acceptance tests . 14

9.1 Laboratory tests . 14

9.1.1 General . 14

9.1.2 Chemical composition . 14

9.1.3 Microstructure . 18

9.1.4 Decarburization . 18

9.1.5 Oxide cleanness . 19

9.1.6 Sulfur prints . 19

9.1.7 Hardness . 19

9.1.8 Tensile tests . 20

9.1.9 Retest procedures . 21

9.2 Dimension tolerances . 21

9.2.1 Profile . 21

9.2.2 Straightness, surface flatness and twist . 22

9.2.3 Cutting and drilling . 26

9.3 Gauges . 26

9.4 Inspection for internal quality and surface quality . 26

9.4.1 Internal quality . 26

9.4.2 Surface quality. 28

9.4.3 Checking of automated testing equipment . 30

Annex A (normative) Rail profiles . 41

Annex B (normative) Comparison of steel designations referred to in this standard compared to

those in EN 10027-2 . 108

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive 2008/57/EC aimed to be covered . 109

Bibliography . 111

European foreword

This document (EN 13674-2:2019) has been prepared by Technical Committee CEN/TC 256 “Railway

applications”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an identical

text or by endorsement, at the latest by April 2020, and conflicting national standards shall be withdrawn at

the latest by April 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 13674-2:2006+A1:2010.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive 2008/57/EC.

For relationship with EU Directive 2008/57/EC, see informative Annex ZA, which is an integral part of this

document.

The most significant change which was made in this new edition are the following ones:

1) suppression of Profile 60E2A3 as Figure A.20 in Table A.1, and update of numbering of Tables A.1 and

A.2 accordingly;

2) introduction of Grade R370CrHT in Table 3, and modifications of the relevant clauses and tables;

3) modification of the calculation formula for hardness in 9.1.7;

4) clean up of figures and editorial errors.

This part of EN 13674 is the second of the EN 13674 series, Railway applications – Track – Rail, which

consists of the following parts:

— Part 1: Vignole railway rails 46 kg/m and above;

— Part 2: Switch and crossing rails used in conjunction with Vignole railway rails 46 kg/m and above;

— Part 3: Check rails;

— Part 4: Vignole railway rails from 27 kg/m to, but excluding 46 kg/m.

Other published standards include the following:

— EN 14587-1, Railway applications - Infrastructure - Flash butt welding of new rails - Part 1: R220, R260,

R260Mn, R320Cr, R350HT, R350LHT, R370CrHT and R400HT grade rails in a fixed plant;

— EN 14587-2, Railway applications – Track - Flash butt welding of rails – Part 2: New R220, R260, R260Mn

and R350HT grade rails by mobile welding machines at sites other than a fixed plant;

— EN 14587-3, Railway applications – Track - Flash butt welding of rails – Part 3: Welding in association

with crossing construction;

— EN 14730-1, Railway applications – Track - Aluminothermic welding of rails – Part 1: Approval of welding

processes;

— EN 14730-2, Railway applications – Track - Aluminothermic welding of rails – Part 2: Qualification of

aluminothermic welders, approval of contractors and acceptance of welds;

— EN 14811, Railway applications – Track – Special purpose rail – Grooved rails and associated construction

profiles;

— EN 15594, Railway applications – Track – Restoration of rails by electric arc welding;

— EN 16273, Railway applications – Track – Forged rail transitions.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech

Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia,

Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North Macedonia,

Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom.

Introduction

This Introduction provides an explanation of the concepts and reasoning used in the drafting of this

document. Its inclusion also ensures that during future revisions, restrictions are removed where technology

progresses and held where it does not, thus ensuring continued safety as new manufacturers, products and

technologies are introduced.

The most commonly used standards of the world for the supply of railway rails have been reviewed during

the preparation of this document. However, modern rail production technology within the European Union

has demanded a completely new look at the philosophy and content of this part of EN 13674.

Whenever possible this part of EN 13674 is performance based, recognizes the European Quality System

standard EN ISO 9001 and requires manufacturers to offer the latest proven technology to consistently

satisfy the demanding quality of the required product.

Rail grading is based on hardness rather than tensile strength.

The acceptance tests have been designed to control those characteristics of the rail steel and rail that are of

relevance to the production of high quality rails and the demands of the railway.

The steel grades covered by this part of EN 13674 reflect trends in railway usage and heat-treated rails are

included. This document includes rail profiles for switch and crossing rails used in conjunction with Vignole

rails having a linear mass 46 kg/m and above.

To ensure the supply of high quality rails, some restrictions on production processes have been imposed.

This document supersedes other standards covered by the scope. In addition CEN required, where possible,

a performance based standard, taking into account safety implications and at the same time addressing

modern production technology. It was recognized that there would be few opportunities (and these would

have to be for transparent safety considerations) for derogation from this document to operate between the

user and the manufacturer.

This document reflects this change in philosophy from the traditional content of rail standards. A review was

undertaken of the most commonly used rail standards of the world. All relevant aspects important to both

user and manufacturer were considered with the aim of ensuring that all of the content had specific

usefulness and relevance. For example rail grading and much of this European Standard has been based on

hardness rather than tensile strength. While the two are directly related, hardness is very quick and cheap to

carry out and provides more relevant guidance to the user particularly where properties vary in different

parts of the profile.

Since many rail manufacturers would not have previously carried out proving trials, the document includes a

prerequisite for all manufacturers to prove conformity against a set of qualifying test criteria at the time of

tendering. The qualifying tests include all “normal” acceptance test results plus new ‘type-casting’ features

such as fracture toughness, fatigue and residual stress (see EN 13674-1). To provide users with the

necessary confidence, acceptance limits have been based on results from rail known to have performed well

in demanding track installations.

One aspect of this document, which is a complete break from tradition, is the inclusion of quality assurance

and inspection clause as part of product integrity.

So that quality management systems are consistent across all manufacturers and that users have the best

assurance for the consistency of required product quality on this safety critical component of the track, the

rail standard requires that the manufacturers’ quality assurance systems are at least equivalent to the

requirements of a quality management standard such as EN ISO 9001. The inclusion of this requirement also

reduces the need to incorporate detailed method and calibration descriptions on items such as normal

chemical composition determination and the need to define more extensive testing.

Ideally, manufacturing techniques should not be referenced in a product standard. However, some rail

attributes are either not known in an exact manner or are not measurable with satisfactory statistical

significance. In such cases best practice manufacturing techniques have been included as a last resort. The

equipment specified is that which gives the best probability of achieving the required product for use in

track. In the future new technology can add to, but preferably will reduce or delete such items.

Examples of areas where the technological state of the art renders the standard less than complete include:

— oxide/oxygen relationships;

— hydrogen test techniques;

— roller straightening effects on residual stresses;

— roller straightening effects on contact scrub;

— measurement and effect of residual stresses throughout the rail.

1 Scope

This document specifies switch and crossing rails that carry railway wheels. These are used in conjunction

with Vignole railway rails.

This document is not applicable for the check rails that do not carry railway wheels.

Nine pearlitic steel grades are specified covering a hardness range of 200 HBW to 410 HBW and include non-

heat-treated non-alloy steels, non-heat-treated alloy steels, heat-treated non-alloy steels, heat-treated low

alloy steels and heat-treated alloy steels.

There are 33 rail profiles specified in this standard, but they may not all be available in all steel grades.

Rails specified in EN 13674-1 can also be used as switch and crossing rails and if so used they will comply

with the requirements of EN 13674-1.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

EN 10027-1, Designation systems for steels – Part 1: Steel names

EN 10027-2, Designation systems for steels – Part 2: Numerical system

EN 10163-1, Delivery requirements for surface condition of hot-rolled steel plates, wide flats and sections –

Part 1: General requirements

EN 10276-1, Chemical analysis of ferrous materials – Determination of oxygen in steel and iron – Part 1:

Sampling and preparation of steel samples for oxygen determination

EN 13674-1:2011+A1:2017, Railway applications – Track – Rail – Part 1: Vignole railway rails 46 kg/m and

above

EN ISO 6506-1, Metallic materials – Brinell hardness test – Part 1: Test method (ISO 6506-1)

EN ISO 6892-1, Metallic materials – Tensile testing – Part 1: Method of test at room temperature (ISO 6892-1)

ISO 4968, Steel – Macrographic examination by sulfur print (Baumann method)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

heat

one liquid steel melt tapped out of a converter or electric arc furnace which includes after continuous casting

a given number of blooms relating to the weight of the heat and the extension of the mixing zone

Note 1 to entry: In the case of sequence casting the blooms belonging to the mixing zone should be clearly defined.

3.2

sequence

number of heats, of the same steel grade, which undergo continuous casting in tundishes

Note 1 to entry: Tundishes may be used in parallel if the caster has many strands.

3.3

heat-treated rail

rail that has undergone accelerated cooling from austenitizing temperature during the metallurgical

transformation period

3.4

re-heated rail

rolled rail that has undergone re-austenitization for heat treatment purposes

3.5

mill heat-treated rail

heat-treated rail that has not undergone re-austenitization after rolling

3.6

rolling process

process between the blooms leaving the heating furnace and exiting the finishing pass

3.7

isothermal treatment process

process whereby blooms are held for a period of time at an elevated temperature for diminishing the

hydrogen content

Note 1 to entry: For maximum efficiency this is as near to (but below) the pearlite to austenite transformation

temperature as is practically possible.

Note 2 to entry: This process is sometimes referred to as sub-critical diffusion annealing.

3.8

qualifying tests

special tests and criteria which are relevant to some aspects of the service performance of rails

Note 1 to entry: Acceptance tests also form part of the qualifying tests.

3.9

acceptance tests

tests carried out as part of the process and product control system, normally on a heat, sequence or tonnage

basis

3.10

rail running surface

curved surface of the rail head, and area between both gauge corners (transition points of the head

inclination and the first head radius)

4 Information to be supplied by the purchaser

The purchaser shall provide the supplier with the following information when inviting tenders to supply:

a) rail profiles (see Annex A);

b) steel grades (see Table 1);

c) length (or lengths) of rail (see 9.2.3 and Table 8);

d) paint code requirements (see 7.4.4);

e) undrilled or drilled rail ends to take fish plate bolts, and the location and dimensions of holes when

required (see 9.2.3 and Table 8);

f) any special treatments to be applied and corresponding tolerances for bolt holes (see 9.2.3);

g) cold stamping on the cut surface, if applicable (see 7.4.3).

5 Steel grades

The applicable steel grades are given in Table 1. The hardness ranges of the steel grades shall conform to

those given in Table 1.

The steel grade designations referred to in this standard are compared to those in EN 10027-1 and

EN 10027-2 in Annex B.

Table 1 — Steel grades

a

Grade Hardness range (HBW) Description Branding lines

R200 200 to 240 Non-alloy (C-Mn)

No branding lines

R220 220 to 260 Non-alloy (C-Mn)

______

___

R260 260 to 300 Non-alloy (C-Mn)

______

______

R260Mn 260 to 300 Non-alloy (C-Mn)

______

___

R260Cr 260 to 300 Alloy (0,5 % Cr) ______

______

______

R320Cr 320 to 360 Alloy (1 % Cr) ______

______

___

b

R350HT 350 to 390 Non-alloy (C-Mn) heat-treated

______ ______

___

b

R350LHT 350 to 390 Non-alloy (C-Mn) heat-treated ______ ______

___

b

R370CrHT 370 to 410 Alloy (C-Mn) heat-treated ___

______ ______

______

a

See Table 3 for chemical composition/mechanical properties.

b

See Table 5 for hardness requirements.

6 Dimensions, static properties, linear mass and tolerances

Rail profiles, dimensions, static properties and linear masses shall be in accordance with Annex A. The

tolerances of certain dimensions shall be given in Table 6. All other quantities are informative only.

NOTE Linear masses have been calculated based on the density of steel of 7,85 g/cm .

7 Manufacture

7.1 Product integrity

7.1.1 Factory production control

Rails shall be produced under a comprehensive system of factory production control, which shall ensure

confidence in the conformity of the finished product. The system shall address this European Standard to

ensure that the finished products consistently comply with requirements to achieve the product integrity

necessary to provide assurance of product safety in track.

Manufacturers shall demonstrate continuing compliance, including documented evidence, with the factory

production control system required.

NOTE Manufacturers having a factory production control system, such as EN ISO 9001, are recognized as satisfying

the minimum requirements specified by this clause.

7.1.2 Best practice manufacture

The product shall be manufactured to the best practices as defined in 7.1.1.

NOTE This is to ensure that the rail attributes, described in the Introduction, which are not known in an exact

manner or are not practically measurable, achieve the required high level of product integrity in track.

7.2 Blooms

Blooms made from basic oxygen steel or electric arc furnace steel that has been secondary ladle arc refined,

vacuum degassed and continuously cast, shall be used for the manufacture of rails.

7.3 Rails

The manufacturer shall operate a procedure for the effective removal of scale during the rolling and

straightening processes.

The cross-sectional area of the rail shall not exceed one seventh that of the bloom from which the rail is

rolled, except for full web rails (Figures A.27 to A.33), where this value shall not exceed one fifth.

Rail straightening shall be by a two stage roller straightening process which straightens the rail about its xx

and yy axes as defined in the rail profiles shown in Annex A. End deviations or a localized deviation on the

rail may be corrected using pressing.

NOTE Other mandatory processes are described in the relevant clauses within the standard.

7.4 Identification

7.4.1 Branding

Brand marks shall be rolled in relief on one side and in the middle of the web (see Annex A) of each rail at

least once every 4 m. The brand marks on the rails shall be clearly legible and shall be 15 mm to 25 mm high,

raised between 0,6 mm and 1,3 mm. For asymmetric rails, except 50E6A2, the brand shall be on the gauge

side of the rail profile. For 50E6A2 rail the brand shall be on the non-gauge side.

The branding line(s) to denote grade shall be 50 mm in length for the long branding line and 25 mm in

length for the short branding line.

The brand marks shall include:

a) identification of the mill;

b) steel grade as shown in Table 1;

c) last two figures of the year of manufacture;

d) rail profile identification as shown in Annex A.

EXAMPLES

__

ROLLING MILL 99 60 E1A5

______

(60 E1A5 profile rail rolled 1999, non-alloy rail steel grade R260)

__ ______

ROLLING MILL 99 60 E1T2

______

(60 E1T2 profile rail rolled 1999, non-alloy heat-treated rail steel grade R350HT).

7.4.2 Hot stamping

In addition to the branding requirements of 7.4.1 each rail shall be identified by a numerical and/or

alphabetical code system hot stamped on the non-branded side of the rail web by machine, except 50E6A2,

and each rail shall be hot stamped at least once every 5 m. If for asymmetric rails hot stamping every 5 m is

not practical, the identification of the rail shall be secured by hot stamping or rotary burr near one end of the

rail.

NOTE 1 A rail can display different indications of position of the rail in the blooms (A,B…Y) along its length.

NOTE 2 Subsequent cutting could result in more than one rail length having the same identity.

The figures and letters used shall be clearly legible and shall be 16 mm high. The stamped characters shall

have a flat or radius face (1 mm to 1,5 mm wide) with bevels on each side. The letters and numbers shall be

on a 10° angle from vertical and shall have rounded corners. The stamping shall be between 0,5 mm and

1,5 mm in depth along the centre of the web. The design shall be as shown in Figure 1.

The identification system employed shall be such as to enable the hot stamped marking to be collated with:

a) number of the heat from which the rail has been rolled;

b) number of the strand and position of bloom within the strand;

c) position of the rail in the bloom (A, B . Y).

In the event of identification marks having been removed, omitted or requiring alteration, re-identification

of such marks shall be made by rotary burr.

7.4.3 Cold stamping

Cold stamping shall only be used on the cut face of the rail within the central portion of the head, at the

request of the purchaser.

7.4.4 Other identification

The steel grade may additionally be identified using paint. The purchaser shall specify the colour and

position of the paint application.

8 Qualification of the manufacturer

The manufacturer shall qualify under EN 13674-1:2011+A1:2017, Clause 8 and shall then be qualified for all

profiles of this part of EN 13674, provided the qualification was for the profile 60E1, 60E2 or the heaviest

produced for the same grade.

NOTE The qualifying criteria specified in EN 13674-1 cannot be achieved using the rail grades and profiles

specified in this part of the standard.

For the R260Cr grade, the qualifying criteria may be agreed between the manufacturer and the purchaser.

9 Acceptance tests

9.1 Laboratory tests

9.1.1 General

Laboratory tests shall be performed, during production, at frequencies as stipulated in Table 2. Results for

each laboratory test shall comply with the limiting values shown in Table 3. Additional information and

other acceptance tests not covered by Table 3 shall comply with the requirements of 9.1.2 to 9.1.8 inclusive.

All rails supplied shall meet the requirements of Clause 9.

9.1.2 Chemical composition

9.1.2.1 General

The liquid chemical composition shall be determined for each heat. When the solid chemical composition is

checked, this shall be carried out at the position of the tensile test piece. The chemical composition shall

conform to the requirements of Table 3 and Table 4.

9.1.2.2 Hydrogen

The hydrogen content of the liquid steel shall be measured by determining pressure of hydrogen in the steel

using an online immersion probe system.

At least two liquid samples shall be taken from the first heat of any sequence using a new tundish and one

from each of the remaining heats and analysed for hydrogen content (see Table 2). The first sample from the

first heat in a sequence shall be taken from the tundish at the time of the maximum hydrogen concentration.

The heats shall be assessed for hydrogen content in accordance with Table 3.

If the hydrogen contents of the first samples of a first heat or the heat sample of a second or further heat do

not comply with the requirements of Table 3 then the blooms made before those samples are taken shall be

slowly cooled or isothermally treated. This applies also to all blooms made before the hydrogen content

eventually complies with the requirements in Table 3; in these cases, all heats shall be tested in the rail form,

or the manufacturer shall calculate the hydrogen content with a documented model of hydrogen diffusion

taking into account the time – temperature evolution of the blooms during the isothermal treatment process.

In case of dispute, the hydrogen content shall be tested in the rail form.

When testing of rails is required rail samples shall be taken at the hot saw at a frequency of one per heat at

random. However on the first heat in a sequence, the rail sample shall be from the last part of a first bloom

teemed on any strand. Hydrogen determination shall be carried out on samples taken from the centre of the

rail head.

If any test result after corrective treatment fails to meet the requirements stated in Table 3, the heat shall be

rejected.

Table 2 — Testing frequency

Test (on) Relevant Steel grades

subclause

R200, R220, R260, R260Mn, R260Cr, R320Cr R350HT, R350LHT, R370CrHT

Chemical composition 9.1.2 One per heat One per heat

Hydrogen 9.1.2.2 One per heat (2 tests from first heat in sequence) One per heat (2 from first heat in sequence)

a a

Total oxygen 9.1.2.3 One per sequence One per sequence

a,c

Microstructure 9.1.3 Not required for grades R200, R220 and R260 One per 100 t

One per 1 000 t or part thereof for grades

a,b

R260Mn, R260Cr and R320Cr

a,b

Decarburization 9.1.4 One per 1 000 t or part thereof One per 500 t

a,b a,b or c

Oxide cleanness 9.1.5 One per sequence One per sequence

a,b a,b or c

Sulfur print 9.1.6 One per 500 t or part thereof One per 500 t or part thereof

a,b a,c

Hardness 9.1.7 One per heat One per 100 t

a,b a,c

Tensile 9.1.8 One calculation per heat/one test per 2 000 t One per 1 000 t (test)

a

Samples shall be taken at random but only rails from blooms outside the mixing zone between heats when continuously cast in sequence.

b

Samples shall be cut after rolling.

c

Samples shall be cut from heat-treated rails.

Table 3 — Chemical composition/mechanical properties

−4

Steel grade % by mass 10 % Tensile Elongation after Hardness of the running

c

(ppm) strength R fracture A surface, Centre line

m

Max. Min. Min.

Steel Sample C Si Mn P S Cr Al V N a b MPa % HBW

O H

name max. max. max. max. max.

R200 Liquid 0,40 to 0,15 to 0,70 to 0,035 0,035 ≤ 0,15 0,004 0,030 0,009 20 3,0

0,60 0,58 1,20

Solid 0,38 to 0,13 to 0,65 to 0,040 0,040 ≤ 0,15 0,004 0,030 0,010 20 3,0 680 14 200 to 240

0,62 0,60 1,25

R220 Liquid 0,50 to 0,20 to 1,00 to 0,025 0,025 ≤ 0,15 0,004 0,030 0,009 20 3,0

0,60 0,60 1,25

Solid 0,50 to 0,20 to 1,00 to 0,025 0,025 ≤ 0,15 0,004 0,030 0,010 20 3,0 770 12 220 to 260

0,60 0,60 1,25

R260 Liquid 0,62 to 0,15 to 0,70 to 0,025 0,025 ≤ 0,15 0,004 0,030 0,009 20 2,5

0,80 0,58 1,20

Solid 0,60 to 0,13 to 0,65 to 0,030 0,030 ≤ 0,15 0,004 0,030 0,010 20 2,5 880 10 260 to 300

0,82 0,60 1,25

R260 Liquid 0,55 to 0,15 to 1,30 to 0,025 0,025 ≤ 0,15 0,004 0,030 0,009 20 2,5

0,75 0,60 1,70

Mn Solid 0,53 to 0,13 to 1,25 to 0,030 0,030 ≤ 0,15 0,004 0,030 0,010 20 2,5 880 10 260 to 300

0,77 0,62 1,75

R260 Liquid 0,40 to 0,20 to 1,20 to 0,025 0,025 0,40 to 0,004 0,060 0,009 20 2,5

0,60 0,45 1,60 0,60

Cr Solid 0,40 to 0,20 to 1,20 to 0,030 0,030 0,40 to 0,004 0,060 0,010 20 2,5 880 10 260 to 300

0,60 0,45 1,60 0,60

R320 Liquid 0,60 to 0,50 to 0,80 to 0,020 0,025 0,80 to 0,004 0,18 0,009 20 2,5

0,80 1,10 1,20 1,20

Cr Solid 0,58 to 0,48 to 0,75 to 0,025 0,030 0,75 to 0,004 0,20 0,010 20 2,5 1080 9 320 to 360

0,82 1,12 1,25 1,25

R350 Liquid 0,72 to 0,15 to 0,70 to 0,020 0,025 ≤ 0,15 0,004 0,030 0,009 20 2,5

0,80 0,58 1,20

HT Solid 0,70 to 0,13 to 0,65 to 0,025 0,030 ≤ 0,15 0,004 0,030 0,010 20 2,5 1175 9 350 to 390

0,82 0,60 1,25

R350 Liquid 0,72 to 0,15 to 0,70 to 0,020 0,025 ≤ 0,30 0,004 0,030 0,009 20 2,5

0,80 0,58 1,20

LHT Solid 0,70 to 0,13 to 0,65 to 0,025 0,030 ≤ 0,30 0,004 0,030 0,010 20 2,5 1175 9 350 to 390

0,82 0,60 1,25

R370 Liquid 0,70 to 0,40 to 0,70 to 0,020 0,020 0,40 to 0,004 0,030 0,009 20 1,5 1.280 9 370 to 410

0,82 1,00 1,10 0,60

CrHT Solid 0,025 0,025 0,004 0,030 0,010 20 1,5

0,68 to 0,38 to 0,65 to 0,35 to

0,84 1,02 1,15 0,65

a

See 9.1.2.3.

b

See 9.1.2.2.

c

See Figure 8.

Table 4 — Maximum residual elements, % by mass

Cu +

Mo Ni Cu Sn Sb Ti Nb Others

10 Sn

R200, R220, R260, R260Mn 0,02 0,10 0,15 0,030 0,020 0,025 0,01 0,35 Cr + Mo + Ni + Cu + V : 0,35

R260Cr, R320Cr 0,02 0,10 0,15 0,030 0,020 0,025 0,01 0,35 Ni + Cu : 0,16

R350HT 0,02 0,10 0,15 0,030 0,020 0,025 0,04 0,35 Cr + Mo + Ni + Cu + V : 0,25

R350LHT; R370CrHT 0,02 0,10 0,15 0,030 0,020 0,025 0,04 0,35 Mo + Ni + Cu + V : 0,20

9.1.2.3 Determination of total oxygen content

9.1.2.3.1 General

Total oxygen content shall be determined in the liquid steel, following solidification of the sample, or

from the solid rail head, in the positions shown in Figure 2, and at the frequency shown in Table 2.

The results obtained shall comply with the values given in Table 3.

9.1.2.3.2 Preparation of the sample

The thickness of the transverse rail slice shall be 4 mm.

Samples shall be prepared in accordance with EN 10276-1.

9.1.2.3.3 Measurement

The measurement of total oxygen shall be made using an automatic machine.

9.1.3 Microstructure

9.1.3.1 General

Microstructures shall be determined at a magnification of x 500.

The microstructure shall be verified for R260Mn, R260Cr, R320Cr and heat-treated rails at the

frequency given in Table 2.

The testing position in the rail head shall be as shown in Figure 3.

9.1.3.2 Grades R200, R220

The microstructure shall be a mixture of pearlite and grain boundary ferrite. There shall be no

martensite, bainite or grain boundary cementite.

9.1.3.3 Grade R260, R260Mn, R260Cr

The microstructure shall be pearlitic but grain boundary ferrite may occur in these grades. The

maximum grain boundary ferrite permitted is shown in Figure 4. There shall be no martensite, bainite

or grain boundary cementite.

9.1.3.4 Grade R320Cr

The microstructure shall be fully pearlitic with no martensite, bainite or grain boundary cementite.

9.1.3.5 Grades R350HT, R350LHT, R370CrHT

The microstructure shall be pearlitic with no martensite, bainite or grain boundary cementite. The

maximum grain boundary ferrite permitted is shown in Figure 4.

9.1.4 Decarburization

The decarburization shall be checked at the frequency shown in Table 2. The decarburization depth

shall be assessed by means of a hardness test. After a minimum of preparation of the rail surface

(polishing) a hardness test according to the method indicated in 9.1.7 will be performed in three points.

None of the results of hardness obtained shall be lower than the minimum value specified of the grade,

reduced by 7 HBW (example: 253 HBW for grade R260).

If there are any doubts regarding the conformity with the requirements on decarburization,

alternatively to the hardness test, at the discretion of the manufacturer or on request of the purchaser,

metallographic investigations shall be carried out.

Photomicrographs showing the depth of decarburization allowed are shown in Figure 5. Figure 6

defines the rail head surface for decarburization checks.

No closed ferrite network shall be observed below 0,5 mm depth measured anywhere on the rail head

surface.

9.1.5 Oxide cleanness

Samples shall be prepared and assessed in accordance with EN 13674-1. Samples shall be taken from

one of the last blooms of the last heat of the sequence but from each sample 2 specimens shall be tested.

The total index K3 shall be less than 10.

The testing position in the rail head is shown in Figure 7.

9.1.6 Sulfur prints

Sulfur prints of transverse rail sections shall be prepared in accordance with ISO 4968 at the frequency

shown in Table 2.

All samples, including those intended for repeat test, shall be taken from outside the mixing zones of the

heat. When part or all of an adjacent heat has been withdrawn due to non-conformance, tests shall be

made in the mixing zones to determine the first conforming blooms.

The sulfur prints shall correspond to the requirements specified in EN 13674-1:2011+A1:2017,

Annex D.

NOTE EN 13674-1:2011+A1:2017, Figure D.13 does not apply to the profiles of EN 13674-2.

9.1.7 Hardness

Brinell hardness tests shall be carried out in accordance with EN ISO 6506-1 at the frequency shown in

Table 2. The test conditions shall be as follows:

— tungsten carbide ball;

— ball diameter 2,5 mm;

— load 1,839 kN;

— period of application 15 s.

Other measurement techniques, for example Rockwell or Vickers hardness testing, may be used, but in

case of dispute Brinell hardness testing in accordance with EN ISO 6506-1 shall be used.

The hardness values measured shall meet the requirements given in Table 5 for the relevant grade.

In the case of heat-treated rails, the following shall apply:

HBW > HBW + 0,3(HBW – HBW )

2 3 1 3

where

HBW , HBW and HBW are the mean hardness values at position 1, 2 or 3 respectively. Also the

1 2 3

difference between any of the three positions shall be no more than 30 HBW. The testing positions

are shown in Figure 8.

The hardness on the centre line of the head crown shall not vary by more than 30 HBW on any

individual rail.

For the steel grades R200, R220, R260, R260Cr, R260Mn and R320Cr the hardness shall only be tested

for position RS. For heat-treated rails hardness shall be tested at the positions 1 to 4 as shown in

Figure 8.

0,5 mm shall be removed from the running surface before a hardness impression is made.

Table 5 — Hardness testing positions and requirements

Rail steel grade

Position

R200 R220 R260, R260Mn, R320Cr R350HT R350LHT R370CrHT

R260Cr

Hardness (HBW)

a b b c

RS 200 to 240 220 to 260 260 to 300 320 to 360 350 to 390 350 to 390 370 to 410

1 ≥ 340 ≥ 340 ≥ 360

2 ≥ 331 ≥ 331 ≥ 350

d d d d

3 ≥ 321 ≥ 321 ≥ 340

4 ≥ 340 ≥ 340 ≥ 360

a

RS = Point on the centre line running surface.

b

If the hardness exceeds 390 HBW, the rail is acceptable provided the microstructure is confirmed to be pearlitic, and the

hardness does not exceed 405 HBW.

c

If the hardness exceeds 410 HBW, the rail is acceptable provided the microstructure is confirmed to be pearlitic, and the

hardness does not exceed 425 HBW.

d

Not relevant.

9.1.8 Tensile tests

9.1.8.1 General

The tensile test shall be carried out with the test frequency specified in Table 2. Test samples from the

rail shall be taken as given in Figure 3. Results obtained shall comply with the values given in Table 3.

9.1.8.2 Method of test

The manufacturer shall determine the tensile properties in accordance with EN ISO 6892-1 using a

proportional circular test piece of 10 mm diameter.

Before test

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...