EN 1011-3:2018

(Main)Welding - Recommendations for welding of metallic materials - Part 3: Arc welding of stainless steels

Welding - Recommendations for welding of metallic materials - Part 3: Arc welding of stainless steels

This document gives general recommendations for the fusion welding of stainless steels. Specific details relevant to austenitic, austenitic-ferritic, ferritic and martensitic stainless steels are given in Annexes A to D.

Schweißen - Empfehlungen zum Schweißen metallischer Werkstoffe - Teil 3: Lichtbogenschweißen von nichtrostenden Stählen

Dieses Dokument enthält allgemeine Anforderungen für das Schmelzschweißen von nichtrostenden Stählen. Besondere Hinweise, die sich auf austenitische, austenitisch ferritische, ferritische und martensitische nicht¬rostende Stähle beziehen, sind in den Anhängen A bis D wiedergegeben.

Soudage - Recommandations pour le soudage des matériaux métalliques - Partie 3: Soudage à l'arc des aciers inoxydables

Le présent document donne des recommandations générales pour le soudage par fusion des aciers inoxydables. Des détails spécifiques aux aciers inoxydables austénitiques, austéno-ferritiques, ferritiques et martensitiques sont donnés dans les Annexes A à D.

Varjenje - Priporočila za varjenje kovinskih materialov - 3. del: Obločno varjenje nerjavnih jekel

Ta evropski standard podaja splošna priporočila za talilno varjenje nerjavnega jekla. Posebne podrobnosti, ki se nanašajo na avstenitno, avstenitno-feritno, feritno in martenzitno nerjavno jeklo, so navedene v dodatkih A–D.

General Information

- Status

- Published

- Publication Date

- 04-Dec-2018

- Withdrawal Date

- 29-Jun-2019

- Technical Committee

- CEN/TC 121 - Welding

- Drafting Committee

- CEN/TC 121/SC 4 - Quality management in the field of welding

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 05-Nov-2024

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 11-Dec-2018

- Effective Date

- 11-Dec-2018

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 1011-3:2018 - "Welding - Recommendations for welding of metallic materials - Part 3: Arc welding of stainless steels" (CEN) provides practical, general recommendations for the fusion arc welding of stainless steels. The standard complements EN 1011-1 (general guidance) and contains four informative annexes (A–D) with specific guidance for austenitic, austenitic‑ferritic, ferritic, and martensitic stainless steels. It is intended to help produce satisfactory welds and to identify welding‑related problems and avoidance measures.

Key topics and requirements

EN 1011-3:2018 addresses the following technical topics:

- Scope and normative references - references include EN ISO 5817, EN ISO 14175, CEN ISO/TR 15608 and EN ISO 15609‑1.

- Terms and definitions relevant to stainless steel welding (e.g., passive layer).

- Parent metal, storage and handling recommendations to avoid contamination and embrittlement.

- Welding consumables - selection criteria and gas recommendations for fusion arc processes.

- Fabrication and weld details - joint design, backing, and practical welding details to control heat input and metallurgical effects.

- Quality requirements of welds - defect control and acceptance criteria (to be used with applicable testing/acceptance standards).

- Distortion control - methods to minimise thermal distortion during fabrication.

- Post‑weld cleaning and treatment - guidance on cleaning, pickling, passivation and heat treatment where applicable.

- Annexes A–D - specific guidance for each stainless steel family covering chemical composition, microstructure, welding consumables, cracking risks, mechanical properties, corrosion resistance, distortion and post‑weld treatments.

Applications and who should use it

This standard is intended for professionals involved in stainless steel fabrication and welding, including:

- Welding engineers and procedure developers

- Fabrication and workshop managers

- Quality and inspection personnel

- Designers and specifiers creating welded stainless steel components

- Training instructors and technical procurement staff

Typical practical uses:

- Developing welding procedure specifications (WPS) for stainless steel components

- Selecting appropriate consumables, shielding gases and post‑weld cleaning methods

- Mitigating welding defects (hot cracking, sensitisation, loss of corrosion resistance)

- Ensuring consistent weld quality across industries that use stainless steels

Related standards

- EN 1011‑1 (General guidance for arc welding)

- EN ISO 5817 (Quality levels for imperfections)

- EN ISO 14175 (Welding gases)

- CEN ISO/TR 15608 (Material grouping guidelines)

- EN ISO 15609‑1 (Welding procedure specification - arc welding)

EN 1011-3:2018 is a practical reference for aligning arc welding practices with the metallurgical and corrosion behaviour of different stainless steel families.

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

EN 1011-3:2018 is a standard published by the European Committee for Standardization (CEN). Its full title is "Welding - Recommendations for welding of metallic materials - Part 3: Arc welding of stainless steels". This standard covers: This document gives general recommendations for the fusion welding of stainless steels. Specific details relevant to austenitic, austenitic-ferritic, ferritic and martensitic stainless steels are given in Annexes A to D.

This document gives general recommendations for the fusion welding of stainless steels. Specific details relevant to austenitic, austenitic-ferritic, ferritic and martensitic stainless steels are given in Annexes A to D.

EN 1011-3:2018 is classified under the following ICS (International Classification for Standards) categories: 25.160.10 - Welding processes. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1011-3:2018 has the following relationships with other standards: It is inter standard links to EN 1011-3:2000, EN 1011-3:2000/A1:2003, EN 12952-14:2004, EN 1011-1:2009, EN 1090-2:2018, EN 1011-5:2003, EN 15085-4:2007, EN 1993-4-3:2007, EN 1090-2:2018+A1:2024, EN 1090-2:2008+A1:2011, EN 40-5:2002, EN 4632-004:2012, EN 15085-4:2023, EN 12899-1:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1011-3:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Schweißen - Empfehlungen zum Schweißen metallischer Werkstoffe - Teil 3: Lichtbogenschweißen von nichtrostenden StählenSoudage - Recommendations pour le soudage des matériaux métalliques - Partie 3 : Soudage à l'arc des aciers inoxydablesWelding - Recommendations for welding of metallic materials - Part 3: Arc welding of stainless steels77.140.20Visokokakovostna jeklaStainless steels25.160.10Varilni postopki in varjenjeWelding processesICS:Ta slovenski standard je istoveten z:EN 1011-3:2018SIST EN 1011-3:2019en,fr,de01-marec-2019SIST EN 1011-3:2019SLOVENSKI

STANDARDSIST EN 1011-3:2001/A1:2004SIST EN 1011-3:20011DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1011-3

December

t r s z ICS

t wä s x rä s r Supersedes EN

s r s sæ uã t r r rEnglish Version

Welding æ Recommendations for welding of metallic materials æ Part

uã Arc welding of stainless steels Soudage æ Recommandations pour le soudage des matßriaux mßtalliques æ Partie

uã Soudage à l 5arc des aciers inoxydables

Schweißen æ Empfehlungen zum Schweißen metallischer Werkstoffe æ Teil

uã Lichtbogenschweißen von nichtrostenden Stählen This European Standard was approved by CEN on

s y September

t r s zä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s z CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s r s sæ uã t r s z ESIST EN 1011-3:2019

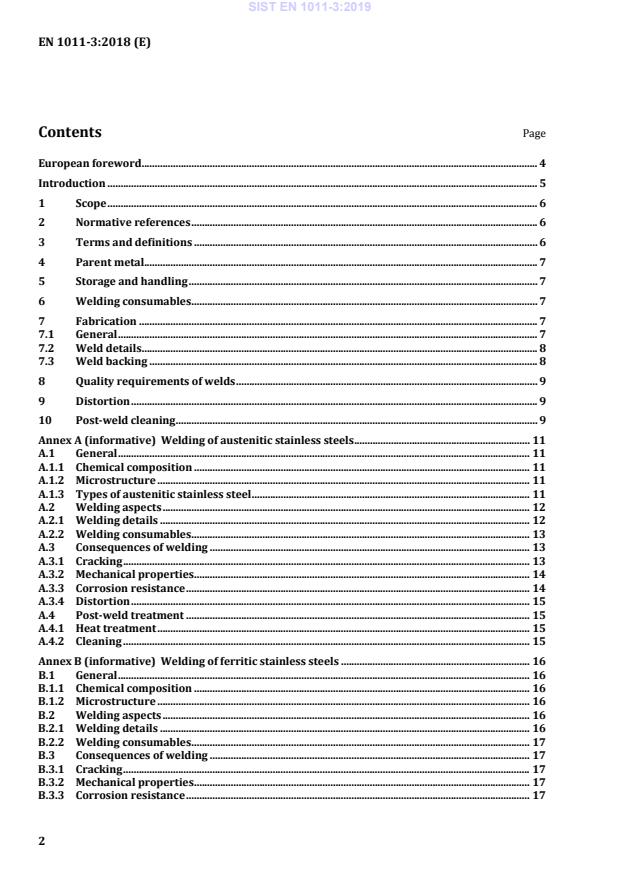

Welding of austenitic stainless steels . 11 A.1 General . 11 A.1.1 Chemical composition . 11 A.1.2 Microstructure . 11 A.1.3 Types of austenitic stainless steel . 11 A.2 Welding aspects . 12 A.2.1 Welding details . 12 A.2.2 Welding consumables . 13 A.3 Consequences of welding . 13 A.3.1 Cracking . 13 A.3.2 Mechanical properties . 14 A.3.3 Corrosion resistance . 14 A.3.4 Distortion . 15 A.4 Post-weld treatment . 15 A.4.1 Heat treatment . 15 A.4.2 Cleaning . 15 Annex B (informative)

Welding of ferritic stainless steels . 16 B.1 General . 16 B.1.1 Chemical composition . 16 B.1.2 Microstructure . 16 B.2 Welding aspects . 16 B.2.1 Welding details . 16 B.2.2 Welding consumables . 17 B.3 Consequences of welding . 17 B.3.1 Cracking . 17 B.3.2 Mechanical properties . 17 B.3.3 Corrosion resistance . 17 SIST EN 1011-3:2019

Welding of austenitic-ferritic stanless steels . 19 C.1 General . 19 C.1.1 General . 19 C.1.2 Chemical composition . 19 C.1.3 Microstructure . 19 C.1.4 Types of austenitic – ferritic stainless steel . 19 C.2 Welding aspects. 19 C.2.1 Welding details . 19 C.2.2 Welding consumables . 20 C.3 Consequences of welding . 21 C.3.1 General . 21 C.3.2 Cracking . 21 C.3.3 Mechanical properties . 21 C.3.4 Corrosion resistance. 21 C.3.5 Distortion. 21 C.3.6 Porosity . 21 C.4 Post-weld treatment . 22 C.4.1 Heat treatment . 22 C.4.2 Cleaning . 22 Annex D (informative)

Welding of martensitic and martensitic-austenitic stainles steels . 23 D.1 General . 23 D.1.1 Chemical composition . 23 D.1.2 Types of martensitic and martensitic-austenitic stainless steel . 23 D.2 Welding aspects. 23 D.3 Consequences of welding . 24 D.3.1 Cracking . 24 D.3.2 Mechanical properties . 24 D.3.3 Corrosion resistance. 24 D.3.4 Distortion. 24 D.4 Post-weld treatment . 25 D.4.1 Heat treatment . 25 D.4.2 Cleaning . 25 Bibliography . 26

IEC Electropedia: available at http://www.electropedia.org/

ISO Online browsing platform: available at http://www.iso.org/obp

3.1 passive layer thin, transparent and tightly adherent film on the surface of stainless steels which protects them against corrosive attack 3.2 stabilized/unstabilized stabilized steels contain additions of strong carbide/nitride forming elements, (usually titanium or niobium), which limit the formation of chromium carbides/nitrides, allowing the stainless steel to retain its corrosion resistance, particularly around grain boundaries 3.3 ferrite number number indicating magnetic attraction, relative to a series of reference samples and therefore, proportional to the ferro-magnetic phase content, approximately equal to ferrite (delta ferrite) content over the range 0 % to 10 % but more readily measured SIST EN 1011-3:2019

Welding of austenitic stainless steels A.1 General A.1.1 Chemical composition The chemical compositions of typical austenitic stainless steels are listed in EN 10088-1. These steels generally contain a minimum of 16,5 % chromium, with sufficient nickel and/or manganese, carbon and nitrogen to produce an austenitic microstructure. They may also contain additions of other elements such as molybdenum, nitrogen, titanium, niobium, copper, silicon, or sulphur to improve specific properties such as corrosion resistance, oxidation resistance, or for machinability, etc. A.1.2 Microstructure The microstructures of austenitic stainless steels are governed by the balance of ferrite and austenite stabilizing elements, the principal ferrite stabilizing elements are chromium, molybdenum and silicon, while the principal austenite stabilizing elements are nickel, manganese, carbon and nitrogen. The structure which will form in the weld metal may be predicted from the balance of ferrite and austenite stabilizing elements, using e.g. a Schaeffler, DeLong, W.R.C. or ESPY diagram. Austenitic stainless steels consist of an austenitic matrix which, in certain grades, may contain small quantities of delta ferrite, the amount of ferrite increasing during welding without the addition of a filler metal. Other grades are fully austenitic and contain no ferrite, even after welding. Austenitic stainless steels are usually supplied in the solution annealed condition, which involves heating to approximately 1 050 °C, or higher, followed by rapid cooling to room temperature. Annealing results in softening of the steel and minimizes the delta ferrite content, so that even steels which form delta ferrite during welding will generally contain virtually no ferrite in the annealed condition. A.1.3 Types of austenitic stainless steel A.1.3.1 Standard austenitic stainless steels Most of the standard austenitic stainless steels are not fully austenitic but may form a small amount of delta ferrite after welding without the addition of a filler metal. The standard stainless steels in this category are still referred to as austenitic stainless steels, even when a small amount of ferrite is present, e.g. EN 10088-1 grades 1.4301, 1.4401, 1.4436. The carbon content of the standard austenitic stainless steels is normally less than 0,06 %. In order to minimize the formation of chromium carbides during welding, low carbon (<0,03 %) versions of many standard grades are produced, which also after welding are resistant against corrosion, e.g. EN 10088-1 grades 1.4307, 1.4404, 1.4432. Similar high corrosion resistance of standard grades may be obtained either through the additions of titanium, or niobium/tantalum, which combine with carbon, preventing the formation of chromium carbides during welding. These grades are referred to as 'stabilized' austenitic stainless steel, e.g. EN 10088-1 grades 1.4541, 1.4550, 1.4571. SIST EN 1011-3:2019

· 3 FN and a reduced risk of solidification cracking (see EN ISO 8249 for measurement of ferrite content). SIST EN 1011-3:2019

%) or by using stabilized (titanium, niobium/tantalum) steels and consumables. Contamination of the weld and heat affected zone (HAZ) should be avoided, to eliminate the risk of carbon and nitrogen pickup. Shielding gases containing more than 2,5 % CO2 should, therefore, by avoided, unless specifically recommended by the consumable manufacturer/supplier. To reduce the risk of intermetallic precipitation during welding, the heat input and interpass temperature should be kept low. SIST EN 1011-3:2019

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...