EN 815:1996+A2:2008

(Main)Safety of unshielded tunnel boring machines and rodless shaft boring machines for rock - Safety requirements

Safety of unshielded tunnel boring machines and rodless shaft boring machines for rock - Safety requirements

1.1 Field of application

This standard is applicable to unshieldsed tunnel boring machines, TBM's, and rodless shaft boring machines, SBM's, and their towed or attached back-up equipment for driving tunnels or shafts in rock where the whole area is excavated in one or more steps by mechanical means. It specifies essential safety requirements for the design, construction and maintenance of such machines when used in non-explosive atmosphere together with the methods of verification. The standard specifies monitoring for hazardous atmosphere.

For TBM's and SBM's which are to be used continuously in explosive atmosphere, additional relevant standards also apply.

This European Standard deals with all significant hazards pertinent to unshielded tunnel boring machines and rodless shaft boring machines for rock, when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). This European Standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards.

1.2 Description of the machines

The general term "unshielded tunnel boring machines" encompasses various kinds of machines for mechanical excavation of underground openings such as tunnels and inclined shafts. This is done in a continuous process, without blasting, using a rotating cutter head.

Depending on the hardness of the material being excavated, tools of different types are used to cut the rock. Normally, rolling discs are employed in medium to very hard rock. All tunnel boring machines, TBM's, and rodless shaft boring machines, SBM's, have the tools mounted on a cutter head which rotates under thrust against the rock. The torque required to rotate the cutter head is developed by electric or hydraulic motors and the thrust is normally delivered by hydraulically powered cylinders.

The torque and thrust reactions created by a TBM or SBM have to be resisted by anchoring the complete machine inside the bore itself by means

Sicherheit von Tunnelbohrmaschinen ohne Schild und gestängelosen Schachtbohrmaschinen zum Einsatz in Fels - Sicherheitsanforderungen

1.1 Anwendungsbereich

Diese Norm gilt für Tunnelbohrmaschinen ohne Schild, TBM genannt, gestängelose Schachtbohrmaschinen, SBM genannt, und deren gezogene oder mit ihnen verbundene Nachläufer, zum Vortrieb von Tunneln oder Schächten in Fels, bei denen der gesamte Querschnitt in einem oder mehreren Schritten mechanisch abgebaut wird. Die Norm spezifiziert notwendige Sicherheitsanforderungen in Bezug auf Konstruktion, Fertigung und Wartung solcher Maschinen, wenn sie in nicht explosionsgefährdeten Bereichen eingesetzt werden, zusammen mit den Methoden der Verifizierung. Die Norm spezifiziert die Überwachung gefährlicher Atmosphären.

Für TBM und SBM, die kontinuierlich in explosionsgefährdeten Bereichen eingesetzt werden sollen, gelten entsprechende Normen zusätzlich.

Diese Europäische Norm behandelt alle signifikanten Gefährdungen, die auf Tunnelbohrmaschinen ohne Schild und gestängelose Schachtbohrmaschinen zum Einsatz in Fels zutreffen, wenn sie bestimmungsgemäß und entsprechend den Empfehlungen des Herstellers verwendet werden (siehe Abschnitt 4). Diese Euro-päische Norm spezifiziert die entsprechenden technischen Maßnahmen zur Eliminierung oder Reduzierung der Risiken, die von den signifikanten Gefährdungen ausgehen.

1.2 Beschreibung der Maschinen

Der allgemeine Begriff „Tunnelbohrmaschinen ohne Schild“ umfasst unterschiedliche Arten von Maschinen für mechanisches Auffahren unterirdischer Hohlräume, wie z. B. Tunnel oder Schrägschächte. Dies wird in einem praktisch kontinuierlichen Vorgang ohne Sprengarbeit erreicht durch Verwendung eines rotierenden Bohr-kopfes.

Abhängig von der Härte des abzutragenden Gesteins werden unterschiedliche Werkzeuge verwendet um das Gestein zu schneiden. Normalerweise werden in mittelhartem bis sehr hartem Gestein Schneidrollen verwendet. (....)

Sécurité de tunneliers sans bouclier et des machines foreuses pour puits sans tige de traction - Exigences de sécurité

La présente Norme européenne s'applique aux tunneliers sans bouclier (TBM), aux machines foreuses pour puits sans tige de traction (SBM) et aux trains suiveurs remorqués ou attelés ou à leurs composants, pour creuser dans le rocher des tunnels ou des puits dont la pleine section est excavée en une ou plusieurs phases par des moyens mécaniques. Elle précise les prescriptions essentielles de sécurité pour la conception, la construction et la maintenance de telles machines lorsqu'elles ne sont pas utilisées en atmosphère explosible, en même temps que les méthodes de vérification. La norme spécifie la surveillance des atmosphères dangereuses.

Pour les TBM et SBM utilisés en permanence en atmosphère explosible, les normes pertinentes s'appliquent complémentairement.

La présente Norme européenne traite tous les phénomènes dangereux significatifs relatifs aux tunneliers sans bouclier et aux machines foreuses pour puits sans tige de traction, lorsqu’elles sont utilisées normalement et dans les conditions prévues par le constructeur (voir Article 4). Cette Norme européenne spécifie les mesures techniques appropriées pour éliminer ou réduire les risques dus aux phénomènes dangereux significatifs.

Varnost strojev za vrtanje predorov (TBM) in jaškov (SBM) v kamnini - Varnostne zahteve

General Information

- Status

- Withdrawn

- Publication Date

- 09-Sep-2008

- Withdrawal Date

- 20-May-2014

- Technical Committee

- CEN/TC 151 - Construction equipment and building material machines - Safety

- Drafting Committee

- CEN/TC 151/WG 4 - Tunnelling machines - Safety

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 21-May-2014

- Completion Date

- 21-May-2014

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 214, C 214, C 214, C 214, C 214, C 214, C 214, C OJ Date: 08-Sep-2009

Not Harmonized98/37/EC - MachineryOJ Ref: C 22, C 22, C 22, C 22, C 22, C 22, C 22, C 22, C, OJ Date: 28-Jan-2009

Relations

- Effective Date

- 19-Jan-2023

- Merged From

EN 815:1996 - Safety of unshielded tunnel boring machines and rodless shaft boring machines for rock - Effective Date

- 18-Jan-2023

- Effective Date

- 10-Oct-2009

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN 50014:1992 - Electrical apparatus for potentially explosive atmospheres - General requirements - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 815:1996+A2:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of unshielded tunnel boring machines and rodless shaft boring machines for rock - Safety requirements". This standard covers: 1.1 Field of application This standard is applicable to unshieldsed tunnel boring machines, TBM's, and rodless shaft boring machines, SBM's, and their towed or attached back-up equipment for driving tunnels or shafts in rock where the whole area is excavated in one or more steps by mechanical means. It specifies essential safety requirements for the design, construction and maintenance of such machines when used in non-explosive atmosphere together with the methods of verification. The standard specifies monitoring for hazardous atmosphere. For TBM's and SBM's which are to be used continuously in explosive atmosphere, additional relevant standards also apply. This European Standard deals with all significant hazards pertinent to unshielded tunnel boring machines and rodless shaft boring machines for rock, when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). This European Standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards. 1.2 Description of the machines The general term "unshielded tunnel boring machines" encompasses various kinds of machines for mechanical excavation of underground openings such as tunnels and inclined shafts. This is done in a continuous process, without blasting, using a rotating cutter head. Depending on the hardness of the material being excavated, tools of different types are used to cut the rock. Normally, rolling discs are employed in medium to very hard rock. All tunnel boring machines, TBM's, and rodless shaft boring machines, SBM's, have the tools mounted on a cutter head which rotates under thrust against the rock. The torque required to rotate the cutter head is developed by electric or hydraulic motors and the thrust is normally delivered by hydraulically powered cylinders. The torque and thrust reactions created by a TBM or SBM have to be resisted by anchoring the complete machine inside the bore itself by means

1.1 Field of application This standard is applicable to unshieldsed tunnel boring machines, TBM's, and rodless shaft boring machines, SBM's, and their towed or attached back-up equipment for driving tunnels or shafts in rock where the whole area is excavated in one or more steps by mechanical means. It specifies essential safety requirements for the design, construction and maintenance of such machines when used in non-explosive atmosphere together with the methods of verification. The standard specifies monitoring for hazardous atmosphere. For TBM's and SBM's which are to be used continuously in explosive atmosphere, additional relevant standards also apply. This European Standard deals with all significant hazards pertinent to unshielded tunnel boring machines and rodless shaft boring machines for rock, when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). This European Standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards. 1.2 Description of the machines The general term "unshielded tunnel boring machines" encompasses various kinds of machines for mechanical excavation of underground openings such as tunnels and inclined shafts. This is done in a continuous process, without blasting, using a rotating cutter head. Depending on the hardness of the material being excavated, tools of different types are used to cut the rock. Normally, rolling discs are employed in medium to very hard rock. All tunnel boring machines, TBM's, and rodless shaft boring machines, SBM's, have the tools mounted on a cutter head which rotates under thrust against the rock. The torque required to rotate the cutter head is developed by electric or hydraulic motors and the thrust is normally delivered by hydraulically powered cylinders. The torque and thrust reactions created by a TBM or SBM have to be resisted by anchoring the complete machine inside the bore itself by means

EN 815:1996+A2:2008 is classified under the following ICS (International Classification for Standards) categories: 91.220 - Construction equipment; 93.060 - Tunnel construction. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 815:1996+A2:2008 has the following relationships with other standards: It is inter standard links to EN 815:1996/A1:2005, EN 815:1996, EN 16191:2014, EN 60204-1:1992, EN 61310-1:1995, EN 60529:1991, EN 60439-1:1994, EN 50014:1992, ISO 3287:1999, EN 547-2:1996, EN 20594-1:1993, EN 418:1992, EN 1060-1:1995/A1:2002, EN 547-1:1996, EN 894-3:2000. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 815:1996+A2:2008 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 815:1996+A2:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2008

Varnost strojev za vrtanje predorov (TBM) in jaškov (SBM) v kamnini - Varnostne

zahteve

Safety of unshielded tunnel boring machines and rodless shaft boring machines for rock -

Safety requirements

Sicherheit von Tunnelbohrmaschinen ohne Schild und gestängelosen

Schachtbohrmaschinen zum Einsatz in Fels - Sicherheitsanforderungen

Sécurité de tunneliers sans bouclier et des machines foreuses pour puits sans tige de

traction - Exigences de sécurité

Ta slovenski standard je istoveten z: EN 815:1996+A2:2008

ICS:

91.220 Gradbena oprema Construction equipment

93.060 Gradnja predorov Tunnel construction

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN 815:1996+A2

NORME EUROPÉENNE

EUROPÄISCHE NORM

September 2008

ICS 91.220; 93.060 Supersedes EN 815:1996

English Version

Safety of unshielded tunnel boring machines and rodless shaft

boring machines for rock - Safety requirements

Sécurité de tunneliers sans boucliers et des machines Sicherheit von Tunnelbohrmaschinen ohne Schild und

foreuses pour puits sans tige de traction - Exigences de gestängelosen Schachtbohrmaschinen zum Einsatz in Fels

sécurité - Sicherheitsanforderungen

This European Standard was approved by CEN on 5 August 1996 and includes Amendment 1 approved by CEN on 22 December 2004

and Amendment 2 approved by CEN on 9 July 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the

official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,

Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2008 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 815:1996+A2:2008: E

worldwide for CEN national Members.

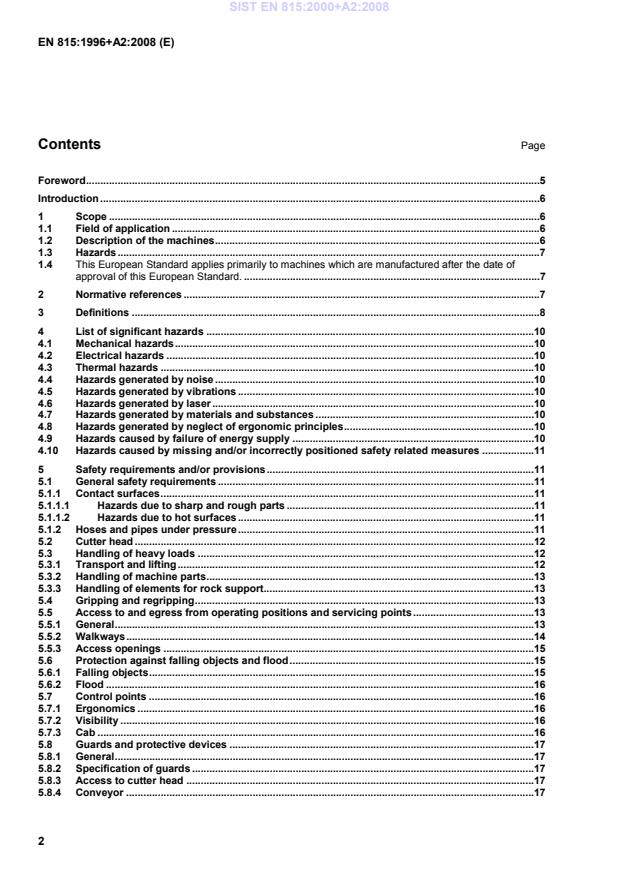

Contents Page

Foreword.5

Introduction .6

1 Scope .6

1.1 Field of application .6

1.2 Description of the machines.6

1.3 Hazards .7

1.4 This European Standard applies primarily to machines which are manufactured after the date of

approval of this European Standard. .7

2 Normative references .7

3 Definitions .8

4 List of significant hazards .10

4.1 Mechanical hazards.10

4.2 Electrical hazards .10

4.3 Thermal hazards .10

4.4 Hazards generated by noise .10

4.5 Hazards generated by vibrations .10

4.6 Hazards generated by laser .10

4.7 Hazards generated by materials and substances .10

4.8 Hazards generated by neglect of ergonomic principles.10

4.9 Hazards caused by failure of energy supply .10

4.10 Hazards caused by missing and/or incorrectly positioned safety related measures .11

5 Safety requirements and/or provisions.11

5.1 General safety requirements .11

5.1.1 Contact surfaces.11

5.1.1.1 Hazards due to sharp and rough parts .11

5.1.1.2 Hazards due to hot surfaces .11

5.1.2 Hoses and pipes under pressure.11

5.2 Cutter head .12

5.3 Handling of heavy loads .12

5.3.1 Transport and lifting.12

5.3.2 Handling of machine parts.13

5.3.3 Handling of elements for rock support.13

5.4 Gripping and regripping.13

5.5 Access to and egress from operating positions and servicing points.13

5.5.1 General.13

5.5.2 Walkways.14

5.5.3 Access openings .15

5.6 Protection against falling objects and flood.15

5.6.1 Falling objects.15

5.6.2 Flood .16

5.7 Control points .16

5.7.1 Ergonomics .16

5.7.2 Visibility .16

5.7.3 Cab .16

5.8 Guards and protective devices .17

5.8.1 General.17

5.8.2 Specification of guards .17

5.8.3 Access to cutter head .17

5.8.4 Conveyor .17

5.9 Control systems and devices.17

5.9.1 General .17

5.9.2 Control systems .17

5.9.3 Control devices.18

5.9.4 Starting, warning systems, stopping and emergency stopping.19

5.9.4.1 Starting.19

5.9.4.2 Warning systems .19

5.9.4.3 Stopping.20

5.9.4.4 Emergency stopping .20

5.9.5 Failure of the power supply.21

5.10 Towing connection.21

5.11 Laser guidance .21

5.12 Ventilation, control of dust and gas .22

5.12.1 General .22

5.12.2 Dust suppression .22

5.12.3 Dedusting .22

5.12.4 Atmospheric changes.22

5.12.4.1 General.22

5.12.4.2 Methane monitoring.22

5.12.4.3 Monitoring for other gases .23

5.13 Noise.23

5.14 Electrical equipment .23

5.14.1 General .23

5.14.2 Protective measures .24

5.14.3 Cables and leads .24

5.14.4 Transformers .24

5.14.5 Bonding .24

5.14.6 Switch gear .24

5.14.7 Lighting.25

5.14.8 Emergency lighting .25

5.15 Isolation of power supply .25

5.16 Energy supply other than electricity .25

5.17 !Fire protection".26

5.17.1 Fire extinguishing system .26

5.17.2 Fixed fire extinguishing systems.26

5.17.3 Installation of portable fire extinguishers.27

5.17.4 Water sprays .27

5.18 Storage of safety equipment for personnel.27

5.19 Indicators.27

5.19.1 Marking.27

5.19.2 Warning signs.28

5.19.3 Warning devices .28

5.19.4 Symbols.28

5.20 Maintenance.28

6 Verification of safety measures and/or provisions.28

7 Information for use.29

7.1 General .29

7.2 Instruction handbooks.29

7.2.1 General .29

7.2.2 Identification of handbooks.29

7.2.3 Content of operator's handbook.30

7.2.4 Content of maintenance handbook .31

7.2.5 Spare parts list.32

Annex A (normative) Protective measures for electrical accessories and lighting.33

Annex B (informative) Bibliography.34

Annex C (informative) Figures.35

Annex ZA (informative) #Relationship between this European Standard and the Essential

Requirements of EU Directive 98/37/EC$.39

Annex ZB (informative) #Relationship between this European Standard and the Essential

Requirements of EU Directive 2006/42/EC$.40

Foreword

This document (EN 815:1996+A2:2008) has been prepared by Technical Committee CEN/TC 151

“Construction equipment and building material machines - Safety”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an identical

text or by endorsement, at the latest by March 2009, and conflicting national standards shall be withdrawn at

the latest by December 2009.

This document includes Amendment 1, approved by CEN on 2004-12-22 and Amendment 2, approved by

CEN on 2008-07-09.

This document supersedes EN 815:1996.

The start and finish of text introduced or altered by amendment is indicated in the text by tags ! " and

# $.

This European Standard has been prepared under a mandate given to CEN by the European Commission

and the European Free Trade Association, and supports essential requirements of EU Directive(s).

#For relationship with EU Directive(s), see informative Annexes ZA and ZB, which are integral parts of this

document.$

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech

Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia,

Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain,

Sweden, Switzerland and United Kingdom.

Introduction

This European Standard is a Type C-standard as defined in EN 292-1:1991.

The machinery concerned and the extent to which hazards are covered is indicated in the scope of this

standard.

1 Scope

1.1 Field of application

This standard is applicable to unshieldsed tunnel boring machines, TBM's, and rodless shaft boring machines,

SBM's, and their towed or attached back-up equipment for driving tunnels or shafts in rock where the whole

area is excavated in one or more steps by mechanical means. It specifies essential safety requirements for

the design, construction and maintenance of such machines when used in non-explosive atmosphere together

with the methods of verification. The standard specifies monitoring for hazardous atmosphere.

For TBM's and SBM's which are to be used continuously in explosive atmosphere, additional relevant

standards also apply.

This European Standard deals with all significant hazards pertinent to unshielded tunnel boring machines and

rodless shaft boring machines for rock, when they are used as intended and under the conditions foreseen by

the manufacturer (see clause 4). This European Standard specifies the appropriate technical measures to

eliminate or reduce risks arising from the significant hazards.

1.2 Description of the machines

The general term "unshielded tunnel boring machines" encompasses various kinds of machines for

mechanical excavation of underground openings such as tunnels and inclined shafts. This is done in a

continuous process, without blasting, using a rotating cutter head.

Depending on the hardness of the material being excavated, tools of different types are used to cut the rock.

Normally, rolling discs are employed in medium to very hard rock. All tunnel boring machines, TBM's, and

rodless shaft boring machines, SBM's, have the tools mounted on a cutter head which rotates under thrust

against the rock. The torque required to rotate the cutter head is developed by electric or hydraulic motors and

the thrust is normally delivered by hydraulically powered cylinders.

The torque and thrust reactions created by a TBM or SBM have to be resisted by anchoring the complete

machine inside the bore itself by means of a gripping system which is reset after each boring stroke and

allows the machine to be steered in the desired direction.

TBM's normally operate in a near to horizontal direction but can also be used to drive inclined tunnels. When

the incline becomes too steep, a second anchoring system will be provided to prevent the machine from

sliding down while the primary grippers are reset.

In most cases TBM's work the full face of the tunnel. However, in some cases the tunnel is driven in two or

more phases, by starting with a pilot hole which is enlarged in one or more steps. This method is called

reaming. The machines used are in principle the same as a TBM driving the whole tunnel area in one step.

SBM's resemble closely TBM's but operate in vertical direction. The shaft is in many cases sunk in a

multistage operation, that is (i.e.), first a pilot hole is bored using a raise bore machine and the pilot hole is

reamed by using the SBM. Normally for this method, the shaft bottom is already undercut to provide adequate

room for the muck and its removal. The full face of the shaft can also be bored in one step. In this case the

muck is transported to the top of the shaft.

TBM's and SBM's intended for work in unstable rock are provided with equipment for the erection and

handling of rock reinforcement and/or lining.

The specified requirements of this standard conform to the European Standards EN 292-1 and EN 292-2.

1.3 Hazards

This standard deals with all identified significant hazards caused by TBM's and SBM's, when they are used

under the conditions stated by the manufacturer in the operator's handbook.

NOTE When TBM's and SBM's are to be used in explosive atmospheres the additional relevant standards apply.

1.4 This European Standard applies primarily to machines which are manufactured after the date of

approval of this European Standard.

2 Normative references

This European Standard incorporates by dated or undated references, provisions from other publications.

These normative references are cited at the appropriate places in the text and the publications are listed

hereafter. For dated references, subsequent amendments to or revisions of any of these publications apply to

this European Standard only when incorporated in it by amendment or revision. For undated references the

latest edition of the publication referred to applies.

EN 3:1975, Portable fire extinguishers.

EN 292-1:1991, Safety of machinery - Basic concepts, general principles for design - Part 1: Basic

terminology, methodology.

EN 292-2:1991/A1:1995, Safety of machinery - Basic concepts, general principles for design - Part 2:

Technical principles and specifications.

EN 418:1992, Safety of machinery - Emergency stop equipment, functional aspects - Principles for design.

prEN 547-1:1994, Safety of machinery – Human body measurements – Part 1: Principles for determining the

dimensions required for openings for whole body access into machinery.

prEN 547-2:1994, Safety of machinery – Human body measurements – Part 2: Principles for determining the

dimensions required for access openings.

EN 563:1994, Safety of machinery - Temperatures of touchable surfaces – Ergonomics data to establish

temperature limit values for hot surfaces.

prEN 894-1:1992, Safety of machinery – Ergonomic requirements for the design of displays and control

actuators – Part 1: Human interactions with displays and control actuators.

prEN 894-2:1992, Safety of machinery – Ergonomic requirements for the design of displays and control

actuators – Part 2: Displays.

prEN 894-3:1993, Safety of machinery – Ergonomic requirements for the design of displays and control

actuators – Part 3: Control actuators.

prEN 953:1992, Safety of machinery – General requirements for the design and construction of guards (fixed,

moveable).

EN 954-1, Safety of machinery - Safety related parts of control systems - Part 1: General principles for design.

EN 981:1995, Safety of machinery – System of danger and non-danger signals with sound and light.

EN 982:1996, Safety requirements for fluid power systems and components - Hydraulics

EN 983:1996, Safety requirements for fluid power systems and components - Pneumatics

ENV 1070:1993, Safety of machinery – Terminology.

EN 23411:1988, Earth-moving machinery – Human physical dimensions of operators and minimum operator

space envelope.

EN 50014:1992, Electric apparatus for potentially explosive atmospheres – General requirements.

EN 61310-1:1995, Safety of machinery – Indicating, marking and actuating principles – Part 1: Visual, audible

and tactile signals.

EN 61310-2:1995, Safety of machinery – Indicating, marking and actuating principles – Part 2: Marking.

EN 60204:1993, Safety of machinery – Electrical equipment of machines – Part 1: General requirements.

EN 60439-1:1993, Low voltage switch gear and control gear assemblies – Part 1: Requirements for type-

tested and partially type-tested assemblies.

EN 60529:1991, Classification of degrees of protection provided by enclosures.

EN 60825:1994, Laser – Radiation safety of laser products, equipment classification, requirements and user's

guide.

EN 60947-1:1991, Low voltage switch gear and control gear – Part 1: General rules.

EN ISO 3457:1995, Earth-moving machinery – Guards and shields – Definitions and specifications.

ISO 3795:1989, Road vehicles, tractors and machinery for agriculture and forestry – Determination of burning

behaviour of interior materials.

ISO 3864:1984, Safety colours and safety signs.

EN ISO 11202:1996, Acoustics – Noise emitted by machinery and equipment – Measurement of emission

sound pressure levels at the work-station and at other specified positions – Survey method in situ.

3 Definitions

For the purposes of this European Standard the definitions stated in ENV 1070:1993 apply.

3.1

unshielded tunnel boring machine, TBM

machine for full face mechanical excavation of underground openings such as tunnels and inclined shafts

using a rotating cutter head. The machine has no shield for tunnel support but can have a shield for the

protection of the cutter head. See figure C.2.

3.2

reaming TBM

tunnel boring machine that enlarges a pilot hole in one or more steps.

3.3

shaft boring machine, SBM

Rodless shaft boring machine operating downwards in a vertical direction. The SBM may ream a pilot hole in

one or more steps in which case the muck is falling down to an undercut space. See figure C.1. The full face

can also be bored in one step (blind boring). In this case the muck is removed up to the top of the shaft.

3.4

BM

Abbreviation for boring machines, covering all machines according to 3.1 – 3.3 for which common

specifications apply.

3.5

back-up equipment

Assembly of equipment, normally towed behind or attached to a BM to provide the BM with services for the

operation and its crew with facilities for their work and comfort. See figure C.2.

3.6

erecting device

Tunnel support erection and handling equipment situated within a TBM and its back-up equipment which is

used to install any tunnel support which acts structurally to maintain the tunnel void.

3.7

main control point

The control point from where the boring operation and advance of the BM is controlled.

3.8

control point

Any location from where one or more functions of the BM or its separate working units are controlled by an

operator.

3.9

exposed person

Any person wholly or partially in a danger zone.

3.10

walkway

part of the access system that permits walking or crawling between locations on a BM and its back-up

equipment.

3.11

walkway surface

The footpath within the walkway.

3.12

access opening

Opening within a BM and its back-up equipment, for example (e.g.) in the bulkhead or the cutter head through

which man access may be made to servicing points.

3.13

servicing point

Any location on a BM and its back-up equipment where maintenance or servicing is normally carried out.

4 List of significant hazards

This clause contains all hazards, as far as they are dealt with in this European Standard, identified by risk

assessments significant for this type of machinery and which require action to eliminate or reduce risk.

See clause

4.1 Mechanical hazards

a) Crushing hazard 5.2, 5.3, 5.5, 5.6, 5.8.3, 5.8.4, 7.2.3, 7.2.4

b) Friction or abrasive hazard 5.1.1.1

c) High pressure fluid ejection hazard 5.1.2

d) Loss of stability 5.4, 7.2.3

e) Slip, trip and fall hazards 5.5

4.2 Electrical hazards

a) Electrical contact, direct or indirect 5.14, 5.15

b) External influences on electrical equipment 5.14

4.3 Thermal hazards 5.1.1.2, 7.2.3

5.13

4.4 Hazards generated by noise

5.7.1, 5.7.3

4.5 Hazards generated by vibrations

4.6 Hazards generated by laser 5.11

4.7 Hazards generated by materials and substances

a) Dust and gas 5.12

b) Fire or explosion 5.7.3, 5.12, 5.16, 5.17, 7.2.3

c) Falling objects and flood 5.6

4.8 Hazards generated by neglect of ergonomic

principles

a) Unhealthy posture or excessive efforts 5.7.1, 5.7.2, 5.7.3

b) Neglected use of personal protection equipment 5.13, 5.18, 7.2.3

c) Inadequate local lighting 5.14.7, 5.14.8

4.9 Hazards caused by failure of energy supply

a) Failure of energy supply 5.9.5, 5.16

b) Failure of control system 5.9

See clause

4.10 Hazards caused by missing and/or incorrectly

positioned safety related measures

a) All kinds of guards 5.8

b) All kinds of safety related devices 5.9, 5.10, 5.12

c) Starting and stopping devices 5.9.3, 5.9.4

d) Safety signs and tags 5.19.2

e) All kinds of information or warning devices 5.9.4.2, 5.19, 7.2.3

f) Emergency stop devices 5.9.4.4

g) Safe handling of machinery and parts 5.3

h) Essential equipment and accessories for safe 7.2.3, 7.2.4

adjusting and/or maintaining

i) Equipment for evacuating gases 5.12

5 Safety requirements and/or provisions

Machinery shall comply with the safety requirements and/or technical provisions of this clause and in addition

with EN 292-2:1991 and EN 292-2:1991 for hazards relevant but not significant which are not covered by this

standard.

5.1 General safety requirements

This clause gives the requirements and measures for those hazards, for which particular action appears

necessary. So for applicable requirements and measures which are already contained in other standards,

specifically in EN 292 in its annex A or in type B – standards, reference is made to them, to relevant

subclauses and to the applicable performance category.

Unless stipulated otherwise in this standard, the BM shall satisfy the general safety requirements – as

appropriate – set down in type A or B standards and particularly in EN 292 with special reference to annex A

of part 2.

5.1.1 Contact surfaces

5.1.1.1 Hazards due to sharp and rough parts

Accessible parts of a BM shall be designed and manufactured to avoid an exposed person's contact with

sharp edges, angles or rough surfaces which are likely to cause injury. See 3.1 of EN 292-2.

5.1.1.2 Hazards due to hot surfaces

Where there is a risk of human contact with hot surfaces, protective covers for cases of normal access shall

be provided. For other cases warning signs shall be provided. See EN 563.

5.1.2 Hoses and pipes under pressure

Hoses, pipes and fittings shall be able to withstand the stresses from the pressure. The hoses shall be marked

with the rated working pressure. The requirements of prEN 982 and prEN 983 shall be complied with.

Where there is a risk that a rupture of a hose or pipe at a control point could cause a hazard to the operator,

the hoses and pipes shall be firmly secured and be provided with protective guards in accordance with 4.9 of

EN ISO 3457:1995.

5.2 Cutter head

In order to carry out inspection and maintenance work in safety, e.g. replacement of cutters, depending on the

size of the BM and the rock conditions for which the BM is designed one of the following alternative measures

shall be taken:

For stable rock conditions no action is required;

For unstable rock conditions and where the size of the cutter head allows, the cutter head shall be so

designed that replacement of cutters can be done without entering the area in front of the cutter head,

e.g. back loaded cutters;

For unstable rock conditions, where access to the area in front of the cutter head is required, the user

shall provide protective measures, e.g. temporary rock support or pre-treatment of the rock for the area in

front of the cutter head.

The following two additional requirements for SBM's apply:

The cutter head shall be equipped with hydraulically extendable and mechanically lockable supports to

hold the cutter head in place during maintenance;

Adequate anchoring points for safety harnesses shall be provided for personnel working on the cutter

head.

The measures foreseen above, the rock conditions for which the BM has been designed and warnings against

residual risks shall be listed in the operator's handbook as required in 7.2.3.

To gain access through a bulkhead or a dust shield to the area behind a cutter head and similarly through a

cutter head to the area in front of it, access openings of adequate size shall be provided. See 5.5.3.

Access shall be prevented during normal working operation by an interlocking barrier or door, e.g. by a key

trapped exchange system interlocked with the main control. See also 5.9.2.

The cutter head of the TBM shall be equipped with a holding brake system to prevent unintentional rotational

movement of the head. This system shall be actuated prior to access being made to the cutter head, e.g.

initiated by the access interlock. The brake shall be capable of holding an unbalanced mass of at least 500 kg

at maximum radius.

Verification of the holding brake system shall be by test.

Regarding work on the cutter head, see also 7.2.3.

5.3 Handling of heavy loads

5.3.1 Transport and lifting

Systems for the transport and lifting of heavy loads in the BM and its back-up area shall be provided to

minimise the need for manual handling.

Equipment shall be provided for lifting of such parts which require regular replacement, e.g. cutters.

All hydraulic and pneumatic rams and motors which sustain load shall hold the load in the event of a circuit

failure. See EN 982 and EN 983.

In all cases, winches and drive motors shall be fitted with brakes which are released during operation.

Due to the varied designs of BM's, no specific requirements can be given for the design of lifting equipment.

5.3.2 Handling of machine parts

Where the weight of parts exceeds 25 kg the parts shall be either:

Fitted with attachments for lifting gear;

Or so designed that they can be fitted with such attachments;

Or shaped in such a way that standard lifting gear can easily be attached.

See also 7.2.4.

5.3.3 Handling of elements for rock support

When a rock support system requires the lifting of units weighing more than 50 kg an erecting or lifting device

shall be fitted.

Such devices may be either stationary, with winch wires and levers moving the elements, or rotary where the

elements can be lifted directly to any position around the circumference of the tunnel.

5.4 Gripping and regripping

To prevent rotation or sliding backwards of the BM the gripping system shall ensure that the cutter head

rotation can be activated and the thrust force applied only when the minimum gripping pressure required has

been reached.

If the gripping pressure falls below this minimum, the cutter head rotation and the thrust force shall be shut off

automatically.

For duty in tunnels and inclined shafts with an inclination of 25 % or more to the horizontal, a device shall be

provided to prevent the TBM and its back-up equipment from sliding backwards during regripping or in the

case of failure of the gripping device, e.g. a spring loaded gripping system. This device shall be independent

of the hydraulic system and of external power sources. In the case of regripping or loss of power to the TBM, it

shall be activated automatically.

This additional gripping device shall be able to hold the TBM with a force equal to at least 1,25 times the

component of the dead weight of the TBM which is parallel to the shaft. This device shall, when operating, not

cause any additional risk.

Verification shall be by calculation and by inspection during manufacture.

5.5 Access to and egress from operating positions and servicing points

5.5.1 General

Tunnelling can involve work in very confined spaces. During tunnelling operations, access to a BM can only

be gained through the tunnel which is being driven and the available space is therefore limited. The

specification of walkways, access and egress openings in 5.5.2 and 5.5.3 give minimum requirements.

Wherever feasible the dimensions prescribed by prEN 547 shall be respected, see in particular figure 4.5 of

prEN 547-1:1991.

The BM shall be provided with stairs, ladders and walkways to allow safe access to and egress from all

working areas. Parts of BM where personnel are able to move about or stand shall be designed and

constructed to minimise risk of falls and to prevent crushing.

The areas of a BM and its back-up equipment where transfer of materials to and from the tunnel transport

system takes place shall be designed and constructed to ensure that safe access and egress for personnel is

possible.

The requirement for rescue by stretchers and supply of fresh air to emergency personnel shall be taken into

account.

5.5.2 Walkways

Walkways within the BM and between the BM and the tunnel wall shall have a minimum cross sectional area

of at least 0,5 m within which there shall be a rectangular clear body opening with a vertical dimension of at

least 700 mm and a horizontal dimension of at least 450 mm. Walkway surfaces should be at least 300 mm

wide but if they are less than 300 mm or where injury can be caused by falling then handrails and toeboards

shall be provided. See figure 1.

Storage areas for materials and equipment shall not be situated so that walkways and access openings can

be obstructed.

Whenever possible, changes in level and alignment of the walkway shall be avoided. Where ramps and

stairways are necessary, handrails or handholds to at least one side of the walkway shall be fitted. Small BM's

without stairs or ladders shall be equipped with handrails, footsteps, non-slip surfaces and anchoring points

for safety wires. ISO 2867 clauses 6 and 7 and EN 22860 are referred to for guidance but the above

requirements shall prevail.

Verification shall be by measurement during manufacture.

Dimensions in millimetres

Key

1 conveyor

Figure 1 — Walkway clearances

(Examples of the application of the requirements of 5.5.2)

3 2

NOTE Areas within broken lines 0,5 m

Areas hatched = 700 mm x 450 mm

5.5.3 Access openings

Access openings, e.g. to bulkheads and cutter head, shall have a clear body opening with a minimum

sectional dimension of 400 mm and a minimum area of 0,2 m .

Verification shall be by measurement during manufacture.

5.6 Protection against falling objects and flood

5.6.1 Falling objects

The main control point of the BM shall be provided with a cab or protective roof to protect against falling rock

and other falling objects such as tools and spare parts. The roof of the cab or the protective roof shall be able

to carry a point load of at least 2000 N at any position.

The main control point shall be located in areas where the risk of falling objects is minimised.

Space for extra equipment for rock stabilisation shall be provided. This standard does not cover the extra

equipment needed, but their interaction to the BM shall be considered. See also 7.2.3.

This extra equipment shall be mounted as close to the tunnel face as practicable. The manufacturer shall

inform the user in the operator's handbook regarding the intended use and limits of the BM and also warn

against residual risks if any, and of protective measures recommended.

When driving inclined shafts of 25 % inclination or more to the horizontal, the main control point shall be

protected from rolling or falling objects by

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...