EN 1440:2008

(Main)LPG equipment and accessories - Periodic inspection of transportable refillable LPG cylinders

LPG equipment and accessories - Periodic inspection of transportable refillable LPG cylinders

This European Standard specifies procedures for periodic inspection and testing, for transportable refillable LPG cylinders with a water capacity from 0,5 l up to and including 150 l.

This standard is applicable to the following:

welded and brazed steel LPG cylinders with a specified minimum wall thickness (see EN 1442 and EN 12807 or the equivalent standard);

welded steel LPG cylinders without specified minimum wall thickness (see EN 14140:2003+A1 or the equivalent standard);

welded aluminium LPG cylinders (see EN 13110 or the equivalent standard);

composite LPG cylinders (see EN 14427 or the equivalent standard).

This standard is intended to be applied to cylinders complying with RID/ADR (including pi marked cylinders) and also to existing non RID/ADR cylinder populations.

This standard does not apply to cylinders permanently installed in vehicles.

Flüssiggas-Geräte und Ausrüstungsteile - Wiederkehrende Prüfung von ortsbeweglichen, wiederbefüllbaren Flaschen für Flüssiggas (LPG)

Diese Europäische Norm legt Verfahren für die wiederkehrende Prüfung von ortsbeweglichen, wieder¬befüll¬baren Flaschen für Flüssiggas (LPG) mit einem Fassungsraum von 0,5 l bis einschließlich 150 l fest.

Diese Norm gilt für:

geschweißte und gelötete Flaschen aus Stahl für Flüssiggas (LPG) mit festgelegter Mindest-Wanddicke (siehe EN 1442 und EN 12807 oder gleichwertige Norm);

geschweißte Flaschen aus Stahl für Flüssiggas (LPG) ohne festgelegte Mindest-Wanddicke (siehe EN 14140:2003+A1 oder gleichwertige Norm);

geschweißte Flaschen aus Aluminium für Flüssiggas (LPG) (siehe EN 13110 oder gleichwertige Norm);

Flüssiggasflaschen aus Verbundwerkstoff (siehe EN 14427 oder gleichwertige Norm).

Diese Norm ist für Flaschen vorgesehen, die RID/ADR entsprechen (einschließlich Flaschen mit Pi Kenn¬zeichnung) sowie für bestehende Flaschengruppen, die nicht mit RID/ADR übereinstimmen.

Diese Norm gilt nicht für Flaschen, die dauerhaft in Fahrzeugen eingebaut sind.

Equipement et accessoires GPL - Contrôle périodique des bouteilles de GPL transportables et réutilisables

Cette Norme européenne spécifie des modes opératoires pour des contrôles et des essais périodiques pour des bouteilles pour GPL rechargeables et transportables d’une capacité en eau comprise entre 0,5 et 150 l.

Cette norme s’applique aux éléments suivants :

bouteilles pour GPL en acier soudées et brasées avec une épaisseur de paroi minimale précisée (voir l’EN 1442 et EN 12807 et norme équivalente) ;

bouteilles pour GPL en acier soudées et brasées sans épaisseur de paroi minimale précisée (voir l’EN 14140:2003+A1 ou une norme équivalente) ;

bouteilles pour GPL en aluminium soudées (voir l’EN 13110 ou une norme équivalente) ;

bouteilles pour GPL en matériaux composites (voir l’EN 14427 ou une norme équivalente).

Il est prévu d’appliquer cette norme à des bouteilles conformes au RID/ADR (y compris les bouteilles comportant un marquage pi), ainsi qu’aux familles de bouteilles existantes non-conformes aux RID/ADR

Cette norme ne s’applique pas aux bouteilles installées en permanence dans des véhicules.

Oprema in pribor za utekočinjeni naftni plin (UNP) - Periodični pregledi premičnih, ponovno polnljivih jeklenk za UNP

General Information

- Status

- Withdrawn

- Publication Date

- 26-Feb-2008

- Withdrawal Date

- 13-Mar-2012

- Technical Committee

- CEN/TC 286 - Liquefied petroleum gas equipment and accessories

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 14-Mar-2012

- Completion Date

- 14-Mar-2012

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 19-Jan-2023

- Effective Date

- 19-Jun-2010

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 1440:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "LPG equipment and accessories - Periodic inspection of transportable refillable LPG cylinders". This standard covers: This European Standard specifies procedures for periodic inspection and testing, for transportable refillable LPG cylinders with a water capacity from 0,5 l up to and including 150 l. This standard is applicable to the following: welded and brazed steel LPG cylinders with a specified minimum wall thickness (see EN 1442 and EN 12807 or the equivalent standard); welded steel LPG cylinders without specified minimum wall thickness (see EN 14140:2003+A1 or the equivalent standard); welded aluminium LPG cylinders (see EN 13110 or the equivalent standard); composite LPG cylinders (see EN 14427 or the equivalent standard). This standard is intended to be applied to cylinders complying with RID/ADR (including pi marked cylinders) and also to existing non RID/ADR cylinder populations. This standard does not apply to cylinders permanently installed in vehicles.

This European Standard specifies procedures for periodic inspection and testing, for transportable refillable LPG cylinders with a water capacity from 0,5 l up to and including 150 l. This standard is applicable to the following: welded and brazed steel LPG cylinders with a specified minimum wall thickness (see EN 1442 and EN 12807 or the equivalent standard); welded steel LPG cylinders without specified minimum wall thickness (see EN 14140:2003+A1 or the equivalent standard); welded aluminium LPG cylinders (see EN 13110 or the equivalent standard); composite LPG cylinders (see EN 14427 or the equivalent standard). This standard is intended to be applied to cylinders complying with RID/ADR (including pi marked cylinders) and also to existing non RID/ADR cylinder populations. This standard does not apply to cylinders permanently installed in vehicles.

EN 1440:2008 is classified under the following ICS (International Classification for Standards) categories: 23.020.30 - Pressure vessels, gas cylinders; 23.020.35 - Gas cylinders. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1440:2008 has the following relationships with other standards: It is inter standard links to EN 14795:2005, EN 14767:2005, EN 1440:2005, EN 14914:2005, EN 1440:2008+A1:2012, EN 1440:2008/FprA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1440:2008 is associated with the following European legislation: EU Directives/Regulations: 94/55/EC, 96/49/EC, 96/86/EC, 96/87/EC, TRRTP121; Standardization Mandates: M/086. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1440:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Flüssiggas-Geräte und Ausrüstungsteile - Wiederkehrende Prüfung von ortsbeweglichen, wiederbefüllbaren Flaschen für Flüssiggas (LPG)Bouteilles en acier soudé transportables et rechargeables pour gaz de pétrole liquéfié (GPL) - Requalification périodiqueLPG equipment and accessories - Periodic inspection of transportable refillable LPG cylinders23.020.30MHNOHQNHPressure vessels, gas cylindersICS:Ta slovenski standard je istoveten z:EN 1440:2008SIST EN 1440:2008en,fr,de01-junij-2008SIST EN 1440:2008SLOVENSKI

STANDARDSIST EN 14795:20061DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1440February 2008ICS 23.020.30Supersedes EN 1440:2005, EN 14767:2005, EN14795:2005, EN 14914:2005

English VersionLPG equipment and accessories - Periodic inspection oftransportable refillable LPG cylindersBouteilles en acier soudé transportables et rechargeablespour gaz de pétrole liquéfié (GPL) - RequalificationpériodiqueFlüssiggas-Geräte und Ausrüstungsteile - WiederkehrendePrüfung von ortsbeweglichen, wiederbefüllbaren Flaschenfür Flüssiggas (LPG)This European Standard was approved by CEN on 6 January 2008.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2008 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1440:2008: ESIST EN 1440:2008

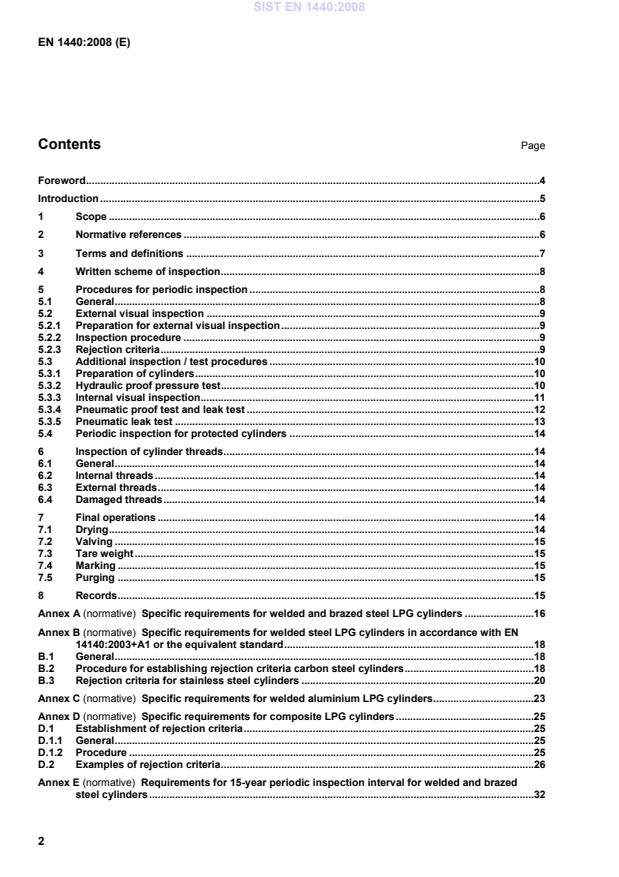

Specific requirements for welded and brazed steel LPG cylinders.16 Annex B (normative)

Specific requirements for welded steel LPG cylinders in accordance with EN 14140:2003+A1 or the equivalent standard.18 B.1 General.18 B.2 Procedure for establishing rejection criteria carbon steel cylinders.18 B.3 Rejection criteria for stainless steel cylinders.20 Annex C (normative)

Specific requirements for welded aluminium LPG cylinders.23 Annex D (normative)

Specific requirements for composite LPG cylinders.25 D.1 Establishment of rejection criteria.25 D.1.1 General.25 D.1.2 Procedure.25 D.2 Examples of rejection criteria.26 Annex E (normative)

Requirements for 15-year periodic inspection interval for welded and brazed steel cylinders.32 SIST EN 1440:2008

Guidance on requirements for 10-year periodic inspection interval on composite cylinders.34 Annex G (normative)

Periodic inspection procedure for a particular design of protected cylinder.35 G.1 Scope and cylinder description.35 G.2 Cylinders design and manufacturing requirements.36 G.2.1 Steel cylinder.36 G.2.2 External protection.36 G.2.3 Marking and recording requirements.36 G.3 Inspection at filling.36 G.4 Periodic destructive tests on batch sampling.36 G.4.1 Testing procedure.36 G.4.2 Destructive tests.37 G.4.3 Rejection criteria and batch sampling.37 G.4.4 Periodic inspection tests reports and records.37 Bibliography.38

Therefore the standards listed in the normative references and covering basic requirements of the RID/ADR not addressed within the present standard are normative only when the standards themselves are referred to in the RID and/or in the technical annexes of the ADR. The main changes between this version of the standard and the 2005 version is that this version combines EN 1440:2005, EN 14767:2005, EN 14795:2005 and EN 14914:2005 into a single standard. This European Standard supersedes EN 1440:2005, EN 14767:2005, EN 14795:2005 and EN 14914:2005. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom. SIST EN 1440:2008

For undated references, the latest edition of the referenced document (including any amendments) applies. EN 837-1, Pressure gauges - Part 1: Bourdon tube pressure gauges - Dimensions, metrology, requirements and testing EN 837-3, Pressure gauges - Part 3: Diaphragm and capsule pressure gauges - Dimensions, metrology, requirements and testing EN 1439, LPG equipment and accessories - Transportable refillable welded and brazed steel Liquefied Petroleum Gas (LPG) cylinders - Procedure for checking before, during and after filling EN 1442, LPG equipment and accessories - Transportable refillable welded steel cylinders for LPG - Design and construction EN 10028-7, Flat products made of steels for pressure purposes - Part 7: Stainless steels EN 12816, Transportable refillable steel and aluminium LPG cylinders – Disposal EN 13152, Specification and testing of LPG cylinder valves - Self closing EN 13153, Specification and testing of LPG cylinder valves - Manually operated EN 14140:2003+A1:2006, LPG equipment and accessories - Transportable refillable welded steel cylinders for LPG - Alternative design and construction EN 14427:2004, Transportable refillable fully wrapped composite cylinders for Liquefied Petroleum Gases (LPG) - Design and Construction EN 14894, LPG equipment and accessories - Cylinder and drum marking SIST EN 1440:2008

NOTE This is not a composite cylinder; see EN 14427 and Figure G.1 3.6 casing permanently attached sleeve covering part of, or the whole of the pressure containing envelope of a composite cylinder, usually incorporating a foot ring and a shroud NOTE Permanently attached means that casing cannot be removed during service without destruction, or by using special tools. 3.7 LPG (liquefied petroleum gas) mixture of predominantly butane or propane with traces of other hydrocarbon gases classified in accordance with UN number 1965, hydrocarbon gases mixture, liquefied, NOS or UN number 1075, petroleum gases, liquefied NOTE In some countries, UN number 1011, 1978 may also be designated LPG. SIST EN 1440:2008

For protected cylinders the interval is determined in accordance with G.4.1. For composite cylinders, the determination of the interval between periodic inspections shall depend on the content of a written scheme that shall be approved by a competent authority. Annex F gives guidance on conditions to obtain approval for 10-year interval.

The inspection procedures to be applied shall be selected from the alternatives given in Clause 5. 5 Procedures for periodic inspection 5.1 General Procedures for periodic inspection shall consist of inspections as described in Table 1. Table 1 —Procedures for periodic inspection Cylinders Procedures Welded and brazed steel LPG cylinders a - external visual inspection as described in 5.2

and,

- additionally, at least one of the tests described in 5.3. Welded aluminium LPG cylinders and composite LPG cylinders. - external visual inspection as described in 5.2,

- internal visual inspection as described in 5.3.3.2 b , and

- additionally, at least one of the following tests: - hydraulic test (see 5.3.2), - pneumatic proof and leak test (see 5.3.4). a

An alternative procedure for periodic inspection of protected cylinders is described in 5.4. b

For transparent composite cylinders, the internal visual inspection may be made from outside.

Periodic inspections/tests shall be carried out by a competent person under the control of a body approved by a competent authority. SIST EN 1440:2008

The decision to render a cylinder unserviceable may be taken at any stage during the periodic inspection procedure.

With agreement by the owner, a cylinder shall be rendered unserviceable in accordance with EN 12816 (where applicable), so that it cannot be re-issued into service as a pressure vessel. NOTE In some countries, render unserviceable means scrapping. 5.2 External visual inspection 5.2.1 Preparation for external visual inspection a) If required, the cylinder shall be cleaned and have all loose coatings or labels, corrosion products, tar, oil or other foreign matter removed from its external surface. b) Care shall be taken to avoid damaging the cylinder. c) When cylinders are treated by a process that might remove cylinder material, the competent body shall decide whether a thickness test is required, e.g. ultrasonic thickness check. NOTE Cleaning methods may be wire brushing, shot blasting (in accordance with EN ISO 8504 all parts and EN ISO 8501-1), water jet cleaning, chemical cleaning or other suitable methods. 5.2.2 Inspection procedure Welded steel, brazed steel and welded aluminium LPG cylinders, shall be inspected for: a) dents, cuts, gouges, bulges, cracks, laminations or punctures, applying the criteria for rejection in Annex A, Annex B and Annex C as appropriate; b) corrosion, giving special attention to areas where water can be trapped, at the base of the cylinder, the junction between the cylindrical shell and the foot-ring, the cylindrical shell and the valve guard or shroud, and in particular hidden corrosion (e.g. data plate) applying the criteria for rejection given in Annex A, Annex B and Annex C as appropriate; c) other defects (e.g. depressed bung or fire damage) applying the criteria for rejection given in Annex A, Annex B and Annex C as appropriate; d) integrity of all permanent attachments; e) integrity of all mandatory permanent markings. Composite cylinders shall be inspected for: f) cuts, gouges, bulges, cracks or de-laminations, applying the criteria for acceptance/rejection in Annex D; g) other defects e.g. depressed bung or fire damage applying to the criteria for acceptance/rejection in

Annex D; h) integrity of all permanent attachments; i) integrity of the mandatory permanent marking. 5.2.3 Rejection criteria Defects and rejection limits are described in: Annex A for specific requirements for welded and brazed steel LPG cylinders; SIST EN 1440:2008

a) Inspection, maintenance and scrapping of valves shall be in accordance with EN 14912. b) Cylinders with inoperative or blocked valves shall be brought to a place for safe valve removal. 5.3.2 Hydraulic proof pressure test 5.3.2.1 General A liquid shall be used as the test medium, e.g. water or kerosene. 5.3.2.2 Preparation of cylinders In addition to requirements in 5.3.1, the external surface of the cylinder shall be in such condition that any leak can be detected.

If the cleaning method involves the wetting of the outside surface, the outside surface shall be completely dried before commencing the test procedure.

5.3.2.3 Test equipment Pressure gauges that are used to read the cylinder test pressure shall be in accordance with EN 837-1 and EN 837-3 accuracy class 1,6 or better.

They shall be calibrated or checked for accuracy against a master gauge at regular intervals and in any case not less frequently than once a month.

The master gauge shall be re-calibrated in accordance with national requirements.

The design and installation of the equipment and the cylinders connected to it shall ensure that no air is trapped in the system. All joints within the system shall be leak tight. A device shall be fitted to the test equipment to ensure that no cylinder is subjected to pressure in excess of its test pressure by more than the tolerance given in 5.3.2.4. The test equipment shall not restrict the expansion of the cylinder. 5.3.2.4 Procedure a) Cylinder shall be positioned so that the welds are visible during the test. b) Pressure of the test shall be at least the test pressure marked on the cylinder. c) Pressure shall be increased gradually in the cylinder until the test pressure is reached.

Then the cylinder shall be isolated from the pumping system. d) Test pressure shall not be exceeded by more than 20 % or 6 bar, whichever is the least.

More than one cylinder may be tested at a time provided they all have a test pressure within the tolerance specified.

If SIST EN 1440:2008

Cylinders, showing visible defects, shall be examined by a competent person. h) Cylinders that fail shall be rejected.

NOTE If a cylinder leaks through a pinhole at the weld, it should be examined by a competent person to determine whether it can be repaired by welding or rendered unserviceable.

Welding or repairing should be carried out in accordance with the manufacturer’s requirements.

These types of repairs are not permitted by the ADR. 5.3.3 Internal visual inspection 5.3.3.1 Internal visual inspection for welded and brazed steel LPG cylinders and LPG cylinders of alternative design and construction 5.3.3.1.1 General Internal visual inspection is applicable to cylinders where the wall thickness is equal to or greater than the minimum calculated wall thickness and the design burst pressure is known, or can be shown to be at least: 35 bar for commercial butane cylinders, and

70 bar for commercial propane cylinders. 5.3.3.1.2 Preparation of cylinders a) Cylinders shall be depressurised in a safe and controlled manner before proceeding. b) Cylinders with inoperative or blocked valves shall be brought to a place for safe valve removal. c) Valves shall be removed from cylinders.

For inspection, maintenance and scrapping of cylinder valves see EN 14912. 5.3.3.1.3 Procedure a) After removing the residual liquid, where necessary, and any other foreign matter from the interior, cylinders shall be inspected internally for any sign of corrosion or other defects that may affect their integrity, using a safe inspection lighting system with appropriate internal illumination (e.g. an endoscope). b) Cylinders showing signs of internal corrosion, except those having only a film layer of surface rust, shall be removed for further detailed evaluation in accordance with Table A.2 and Table B.2 as appropriate.

c) If cleaning is required, care shall be taken to avoid damaging the cylinder walls.

Cylinders shall be re-inspected after cleaning. SIST EN 1440:2008

For inspection, maintenance and scrapping of cylinder valves see EN 14912. d) Care shall be taken when clamping composite cylinders in order to avoid damage. 5.3.3.2.3 Procedure a) After removing residual liquid, where necessary, and any other foreign matter from the interior, cylinders shall be inspected internally for any sign of corrosion or other defects that may affect its integrity, using a safe inspection lighting system with appropriate internal illumination (e.g. an endoscope). b) Cylinders showing signs of internal defects, e.g. cracks, damaged liner, internal corrosion or chemical attack, shall be scrapped.

c) If cleaning is required, care shall be taken to avoid damaging the cylinder walls.

Cylinders shall be re-inspected after cleaning. 5.3.4 Pneumatic proof test and leak test 5.3.4.1 Preparation of cylinders a) Cylinders shall be depressurised in a safe and controlled manner before proceeding. b) Cylinders with inoperative or blocked valves shall be brought to a place for safe valve removal. c) Valves shall be removed from cylinders.

For inspection, maintenance and scrapping of cylinder valves see EN 14912. NOTE 1 The valve may be fitted before the proof test or leak test, see 7.2. Repainting before the pneumatic test shall be limited to a primer coat.

The finishing coat shall be applied after the test in order not to mask potential leaks. NOTE 2 Consideration should be given to the need to avoid corrosion if full water immersion will be used. 5.3.4.2 Procedure 5.3.4.2.1 Proof test a) Cylinders shall be tested in a safe enclosure to protect against rupture under pneumatic pressure. b) Pressure of the test shall be at least the test pressure marked on the cylinder. SIST EN 1440:2008

If necessary, the pressure relief valve shall be removed and the port plugged for testing. d) After the cylinder has been placed in a safe enclosure, it shall be charged with the pneumatic test medium (e.g. natural gas, air, nitrogen) to the test pressure and held at that pressure for 5 s to 7 s.

The cylinder passes the proof test if it does not burst.

The cylinder shall then be isolated from the pressure source. 5.3.4.2.2 Leak test a) Pressure shall be reduced to a pressure not less than 6 bar. b) Reduced pressure shall be held for the time necessary to inspect the cylinder and checked it out for any leaks. c) Cylinders that do not leak or show any visible permanent distortion after the pressure has been released shall be deemed to have passed this test. d) Cylinders that fail shall be rejected. 5.3.5 Pneumatic leak test 5.3.5.1 General CAUTION — This test is only applicable to cylinders with less than 6,5 litres water capacity. The pneumatic leak test is applicable to cylinders where the wall thickness is equal to or greater than the minimum calculated wall thickness and the design burst pressure is known, or can be shown to be at least: 35 bar for commercial butane cylinders, and 70 bar for commercial propane cylinders. 5.3.5.2 Preparation of cylinder a) Cylinders shall be depressurised in a safe and controlled manner before proceeding. b) Cylinders with inoperative or blocked valves shall be brought to a place for safe valve removal. c) Valves shall be removed from cylinders.

For inspection, maintenance and scrapping of cylinder valves see EN 14912. NOTE Consideration should be given to the need to avoid corrosion, if full water immersion will be used. 5.3.5.3 Procedure a) Cylinder shall be filled with a pneumatic test medium (e.g. natural gas, air, nitrogen) in such a way that the internal pressure developed in the cylinders at the time they are checked for leakage shall not be less than 6 bar: NOTE 1 Propane vapour may also be used as the test medium.

b) Cylinder shall be isolated from the pressure source. NOTE 2 To achieve this pressure the ambient temperature should be at least 20 °C. SIST EN 1440:2008

The gas tightness check shall be capable of detecting any leak from any part of the cylinder.

d) Cylinders that do not leak or show any visible permanent distortion after the pressure has been released shall be deemed to have passed the test. e) Cylinders that fail shall be rejected. 5.4 Periodic inspection for protected cylinders An example of a periodic inspection procedure for a particular design of protected cylinder is given in Annex G. 6 Inspection of cylinder threads 6.1 General When the valve (and any other fitting) is removed during periodic inspection, the cylinder threads shall be inspected in accordance with 6.2 to 6.4. 6.2 Internal threads The internal threads of the cylinder shall be visually examined to ensure they are of full form and clean.

They shall be checked for burrs, cracks, and other thread damage. 6.3 External threads External neck threads, which are required for operational reasons, shall be examined for integrity and for thread damage. 6.4 Damaged threads Where necessary and where the design permits, damaged threads shall be repaired by a competent person or the cylinder shall be rendered unserviceable in accordance with EN 12816.

For composite cylinders, a cylinder shall be rendered unserviceable, so that it cannot be re-issued into service as a pressure vessel using one of the following methods by: crushing or shredding the cylinder using mechanical means; drilling two holes of approximately 20 mm in diameter in the cylinder wall; irregular cutting of the neck; irregular cutting of the cylinder in two or more pieces; bursting (in a controlled and safe manner); other suitable safe method. 7 Final operations 7.1 Drying After hydraulic testing, effective precautions shall be taken to prevent internal corrosion. SIST EN 1440:2008

The torque applied shall be consistent with both the cylinder and valve manufacturer’s recommendations. New valves shall be in accordance with EN 13152 or EN 13153. Inspection or refurbishing of valves shall be in accordance with EN 14912. 7.3 Tare weight The tare weight or indication of tare weight of the cylinder shall be re-established if any modification or re-valving has been made that affects the tare weight of the cylinder. If the new tare indication is different from the old tare indication, it shall be marked on the cylinder and the former tare shall be made unreadable. 7.4 Marking After successful completion of the periodic inspection, each cylinder shall be legibly and durably marked in accordance with EN 14894. NOTE In case of periodic inspection conducted in accordance with 5.4, special provisions for marking/registration may be defined and agreed by the competent authority. 7.5 Purging Air shall be removed from the cylinder, e.g. by evacuation or by displacement with LPG.

NOTE This may be performed at the test station or at the filling station. 8 Records The organisation operating the testing station shall maintain records of the quality system, inspection reports and test data, calibration data and reports concerning the qualifications or approvals of the competent persons. Inspection reports and test data for cylinders shall be kept and maintained by the organisation operating the testing station at least for the retest period plus 2 years. An inspection report or test data can cover one or more cylinders. SIST EN 1440:2008

Specific requirements for welded and brazed steel LPG cylinders Rejection limits for physical, material and other defects on the cylinder shell are given in Table A.1, Table A.2 and Table A.3.

Table A.1 — Physical defects in the cylinder wall Defect Description Rejection limit Bulge Visible swelling of the cylinder All

Dent A depression in the cylinder that has neither penetrated nor removed metal, when its width at any point is greater than 2 % of the external cylinder diameter. When the depth of the dent exceeds 25 % of its width at any point a. Cut or gouge A sharp impression where metal has been removed or redistributed. Where the original calculated wall thickness is known:

depth of cut or gouge is such that the undamaged (remaining) wall is less than the minimum calculated wall thickness. Where the original calculated wall thickness is not known:

all. Dent containing cut or gouge A depression in the cylinder within which there is a cut or gouge. When the size of the dent or cut or gouge exceeds the dimensions for rejection as an individual defect. Crack A split or rift in the cylinder shell. All Lamination Layering of the material within the cylinder wall appearing as a discontinuity, crack, lap or bulge at the surface. All a Appearance (e.g. sharp dent) and location (e.g. on shoulder of the cylinder) also play a part in the evaluation of dent severity.

A greater depth can be accepted providing that the depth of corrosion does not reduce the wall thickness below the minimum calculated wall thickness. Chain pitting or line or channel corrosion A series of pits or corroded cavities of limited width along the length or around the cylinder circumference. 1) When the total length of corrosion in any direction exceeds 50 % of the circumference of the cylinder; or 2) When the depth of penetration exceeds 0,4 mm. A greater depth can be accepted providing that the depth of corrosion does not reduce the wall thickness below the minimum calculated wall thickness; or

3) When the depth of corrosion cannot be measured. Crevice corrosion Crevice corrosion occurs in the area of the intersection of the foot-ring or shroud with the cylinder. When the depth of penetration exceeds 0,4 mm or when the depth of corrosion cannot be measured Table A.3 — Other defects

Defect Description Rejection limit Depressed bung Damage to the bung which has altered the profile of the cylinder. A limited level of depression/alignment deviation, as agreed by the competent body Otherwise, all Arc or torch burns Burning of the cylinder base metal, a hardened heat affected zone, the addition of extraneous weld metal, or the removal of metal by scarfing or cratering. All Fire damage a Excessive general or localized heating of a cylinder usually indicated by: – charring or burning of paint; – fire damage of the metal; – distortion of the cylinder; – melting of metallic valve parts; – melting of any plastic components, e.g. date ring, plug or cap. All Not firmly attached foot-ring

All Damaged foot-ring Badly deformed foot-ring unstable or unbalanced cylinder Damaged shroud Loose or badly deformed shroud Preventing proper operation or protection of valve a If paint is only superficially charred, a cylinder may be accepted by a competent person. SIST EN 1440:2008

Specific requirements for welded steel LPG cylinders in accordance with EN 14140:2003+A1 or the equivalent standard

B.1 General The owner of the cylinder (or their authorized representative) shall provide the testing station with rejection criteria for the physical and material defects and heat damage to the cylinder. The rejection/ acceptance criteria will be established at the time of the type approval. These criteria will be established by the manufacturer, taking into account the design conditions of the cylinder (e.g. wall thickness, material). See EN 14140. The descriptions for defects on carbon steel cylinders are shown in Table B.1, Table B.2 and Table B.3.

The completed tables for stainless steel cylinders are shown in Table B.4, Table B.5 and Table B.6. B.2 Procedure for establishing rejection criteria carbon steel cylinders The rejection criteria for the defects described in Table B.1, Table B.2 and Table B.3 shall be established in accordance with the following procedure for each design of cylinder as defined in EN 14140:2003+A1: for each defect, four cylinders with the same defect shall be tested.

The size of this defect is recorded.

If the defects of the cylinders are different sizes, the size of the smaller defect shall be recorded; two cylinders shall be submitted to the burst test as described in EN 14140:2003+A1 and two cylinders shall be submitted to the fatigue test as described in EN 14140:2003+A1. if the cylinders pass the tests, the defect is acceptable.

The rejection limit can then be defined by the size of that defect; when all rejection criteria have been established for a design of cylinder as defined in EN 14140:2003+A1:2006, Table B.1, Table B.2 and Table B.3 shall be completed by the owner/manufacturer of the cylinder.

Appearance (e.g. sharp dent) and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...