prEN 18205

(Main)Qualification of Welding Procedures for Plastic Materials

Qualification of Welding Procedures for Plastic Materials

This document specifies a procedure to qualify a preliminary welding procedure specification (pWPS) by welding procedure tests to produce a qualified welding procedure specification (WPS).

This document applies to the following thermoplastic welding processes: hot gas welding: round nozzle, speed, wedge; extrusion welding; heated tool welding: butt, socket, wedge. The document applies to the welding of the following products: sheet, pipe (unreinforced, solid wall only); fittings (unreinforced only); lining membrane.

This document covers the welding of the following groups of materials:

a) for sheets, pipes and fittings: PVC (including all kinds of PVC-U, PVC-C) and ABS; PP; PE; PVDF; ECTFE, PFA and FEP;

b) for lining membranes: PVC-P; PE; ECB;PP;

c) for pipes and fittings only: PA-U 11 and PA-U 12

Qualifizierung von Schweißverfahren für Kunststoffe

Qualification des modes opératoires de soudage des matières plastiques

Le présent document spécifie un mode opératoire pour qualifier un descriptif de mode opératoire de soudage préliminaire (DMOS-P) à l’aide d’épreuves de qualification d’un mode opératoire de soudage afin de produire un descriptif de mode opératoire de soudage (DMOS) qualifié.

NOTE 1 L’application du présent document garantit que la qualification du DMOS-P se déroule selon une procédure d’épreuve uniforme.

NOTE 2 L’objectif principal de la qualification du mode opératoire de soudage est de démontrer que le procédé d’assemblage proposé pour la construction est capable de produire des assemblages ayant les propriétés mécaniques requises pour l’application prévue.

Le présent document s’applique aux procédés de soudage de matières thermoplastiques suivants :

— soudage au gaz chaud : buse ronde, vitesse, coin chauffant ;

— soudage par extrusion ;

— soudage par élément chauffant : bout à bout, emboîture, coin chauffant.

Le présent document s’applique au soudage des produits suivants :

— feuilles ;

— tubes (sans renfort, à paroi compacte uniquement) ;

— raccords (sans renfort uniquement) ;

— membranes de revêtement.

Le présent document couvre le soudage des groupes de matériaux suivants :

a) pour les feuilles, tubes et raccords :

— PVC (incluant tous les types de PVC-U, PVC-C) et ABS ;

— PP ;

— PE ;

— PVDF ;

— ECTFE, PFA et FEP ;

b) pour les membranes de revêtement :

— PVC-P ;

— PE ;

— ECB ;

— PP ;

c) pour les tubes et raccords seulement :

— PA-U 11 et PA-U 12.

Kvalifikacija postopkov varjenja za polimerne materiale

General Information

- Status

- Not Published

- Publication Date

- 06-Jan-2027

- Technical Committee

- CEN/TC 249 - Plastics

- Drafting Committee

- CEN/TC 249/WG 16 - Welding of thermoplastics

- Current Stage

- 4060 - Closure of enquiry - Enquiry

- Start Date

- 18-Sep-2025

- Due Date

- 13-Nov-2025

- Completion Date

- 18-Sep-2025

Overview

prEN 18205 (CEN draft) establishes a uniform procedure to qualify a preliminary welding procedure specification (pWPS) by means of welding procedure tests so that a qualified welding procedure specification (WPS) can be issued. The standard applies to common thermoplastic welding processes - hot gas welding (round nozzle, speed, wedge), extrusion welding, and heated-tool welding (butt, socket, wedge) - and to products such as sheet, unreinforced solid-wall pipe, fittings (unreinforced) and lining membranes.

Key thermoplastic families addressed include PVC (PVC-U, PVC-C), ABS, PP, PE, PVDF, fluoropolymers (ECTFE, PFA, FEP), and specific materials for membranes and some pipe materials (PVC-P, ECB, PA-U11/12).

Key Topics

- Preliminary WPS (pWPS): pWPS shall be prepared according to CEN/TS 16892 and provide the basis for test execution.

- Test piece preparation: Test pieces must be welded per the pWPS; shapes and specimen locations are defined to avoid damaging the weld and heat-affected zones.

- Examination and testing: Visual examination (per EN 13100-1 and EN 14728) during welding and testing stages; mechanical (destructive) tests follow EN 12814 series (bend, tensile, peel, crush as applicable).

- Welding Procedure Qualification Record (WPQR): A documented record of procedure variables, visual observations, and mechanical test results used to demonstrate qualification.

- Acceptance criteria: Visual imperfections are assessed against EN 16296; mechanical test acceptance refers to EN 12814-8 and the specific test standards in the EN 12814 series.

- Range of qualification: The standard defines how qualification applies across organization, parent material, material thickness, welding process and position, joint type, and quality level.

Applications

prEN 18205 is intended for manufacturers, welding coordinators, testing laboratories and specifiers who need to:

- Validate welding procedures for pipelines, tanks, membranes and fabricated plastic assemblies.

- Produce a documented WPS that ensures consistent joint performance for service conditions.

- Support compliance and quality assurance programs in building, industrial, and utility applications where thermoplastic welded joints are used.

Benefits include improved repeatability of welds, clear acceptance criteria for imperfections and mechanical properties, and a harmonized foundation for personnel qualification and production control.

Related Standards

Relevant referenced documents include:

- CEN/TS 16892 - Specification of welding procedures

- EN 12814 series - Testing of welded joints of thermoplastics (bend, tensile, peel, crush)

- EN 13100-1 - Visual NDT of thermoplastic welds

- EN 14728 / EN 16296 - Imperfections and quality levels

- EN 13067 - Qualification of welding personnel

This guidance helps organizations translate a pWPS into a certified WPS by combining prescribed test specimens, visual and destructive testing, and a formal WPQR to demonstrate that the defined process produces joints fit for their intended application.

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

prEN 18205 is a draft published by the European Committee for Standardization (CEN). Its full title is "Qualification of Welding Procedures for Plastic Materials". This standard covers: This document specifies a procedure to qualify a preliminary welding procedure specification (pWPS) by welding procedure tests to produce a qualified welding procedure specification (WPS). This document applies to the following thermoplastic welding processes: hot gas welding: round nozzle, speed, wedge; extrusion welding; heated tool welding: butt, socket, wedge. The document applies to the welding of the following products: sheet, pipe (unreinforced, solid wall only); fittings (unreinforced only); lining membrane. This document covers the welding of the following groups of materials: a) for sheets, pipes and fittings: PVC (including all kinds of PVC-U, PVC-C) and ABS; PP; PE; PVDF; ECTFE, PFA and FEP; b) for lining membranes: PVC-P; PE; ECB;PP; c) for pipes and fittings only: PA-U 11 and PA-U 12

This document specifies a procedure to qualify a preliminary welding procedure specification (pWPS) by welding procedure tests to produce a qualified welding procedure specification (WPS). This document applies to the following thermoplastic welding processes: hot gas welding: round nozzle, speed, wedge; extrusion welding; heated tool welding: butt, socket, wedge. The document applies to the welding of the following products: sheet, pipe (unreinforced, solid wall only); fittings (unreinforced only); lining membrane. This document covers the welding of the following groups of materials: a) for sheets, pipes and fittings: PVC (including all kinds of PVC-U, PVC-C) and ABS; PP; PE; PVDF; ECTFE, PFA and FEP; b) for lining membranes: PVC-P; PE; ECB;PP; c) for pipes and fittings only: PA-U 11 and PA-U 12

prEN 18205 is classified under the following ICS (International Classification for Standards) categories: 25.160.10 - Welding processes. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 18205 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2025

Kvalifikacija postopkov varjenja za polimerne materiale

Qualification of Welding Procedures for Plastic Materials

Qualifizierung von Schweißverfahren für Kunststoffe

Qualification des modes opératoires de soudage des matières plastiques

Ta slovenski standard je istoveten z: prEN 18205

ICS:

25.160.10 Varilni postopki in varjenje Welding processes

83.080.01 Polimerni materiali na Plastics in general

splošno

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

June 2025

ICS 25.160.10

English Version

Qualification of Welding Procedures for Plastic Materials

Qualification des modes opératoires de soudage des Qualifizierung von Schweißverfahren für Kunststoffe

matières plastiques

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 249.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 18205:2025 E

worldwide for CEN national Members.

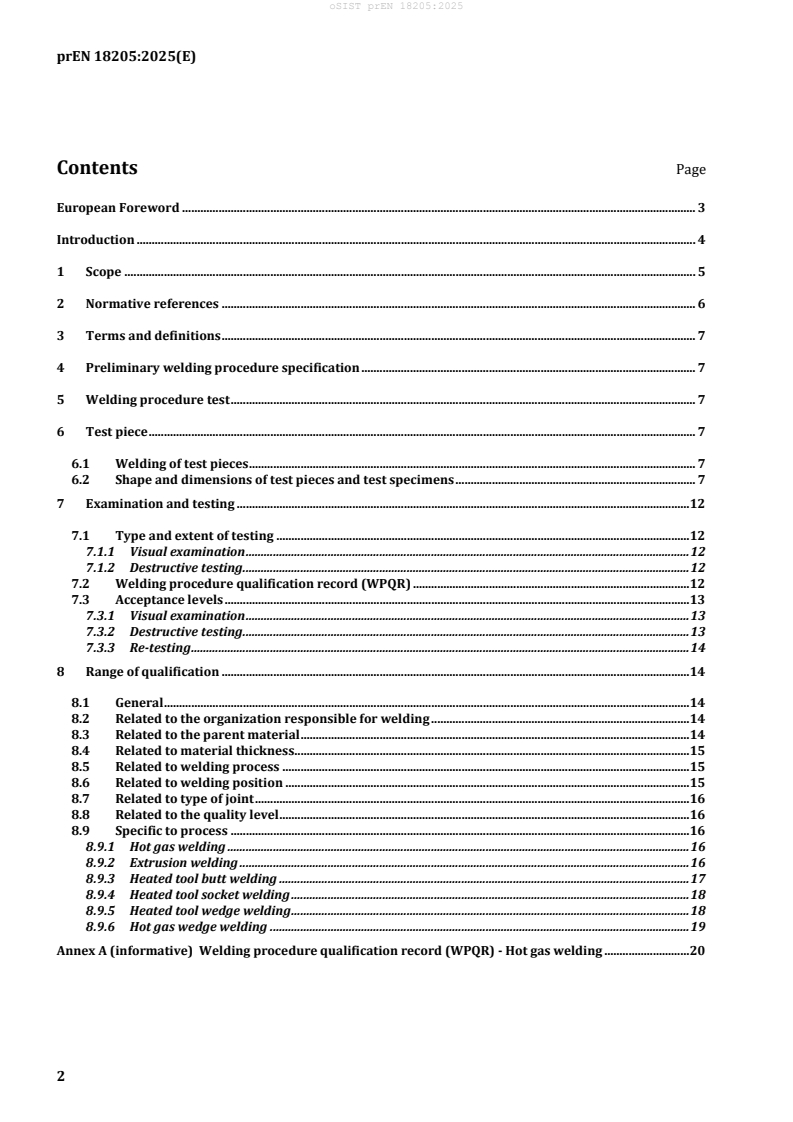

Contents Page

European Foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 6

3 Terms and definitions . 7

4 Preliminary welding procedure specification . 7

5 Welding procedure test . 7

6 Test piece . 7

6.1 Welding of test pieces . 7

6.2 Shape and dimensions of test pieces and test specimens . 7

7 Examination and testing . 12

7.1 Type and extent of testing . 12

7.1.1 Visual examination . 12

7.1.2 Destructive testing. 12

7.2 Welding procedure qualification record (WPQR) . 12

7.3 Acceptance levels . 13

7.3.1 Visual examination . 13

7.3.2 Destructive testing. 13

7.3.3 Re-testing . 14

8 Range of qualification . 14

8.1 General . 14

8.2 Related to the organization responsible for welding . 14

8.3 Related to the parent material . 14

8.4 Related to material thickness. 15

8.5 Related to welding process . 15

8.6 Related to welding position . 15

8.7 Related to type of joint . 16

8.8 Related to the quality level . 16

8.9 Specific to process . 16

8.9.1 Hot gas welding . 16

8.9.2 Extrusion welding . 16

8.9.3 Heated tool butt welding . 17

8.9.4 Heated tool socket welding . 18

8.9.5 Heated tool wedge welding . 18

8.9.6 Hot gas wedge welding . 19

Annex A (informative) Welding procedure qualification record (WPQR) - Hot gas welding . 20

European Foreword

This document (prEN 18205:2025) has been prepared by Technical Committee CEN/TC 249 “Plastics”,

the secretariat of which is held by SIS.

This document is currently submitted to the CEN Enquiry.

Introduction

This document covers the principles to be observed in the qualification testing of welding procedures for

thermoplastic materials.

1 Scope

This document specifies a procedure to qualify a preliminary welding procedure specification (pWPS) by

welding procedure tests to produce a qualified welding procedure specification (WPS).

NOTE 1 The application of this document ensures that the qualification of the pWPS is carried out according to

a uniform test procedure.

NOTE 2 The primary purpose of welding procedure qualification is to demonstrate that the joining process

proposed for construction is capable of producing joints having the required mechanical properties for the intended

application.

This document applies to the following thermoplastic welding processes:

— hot gas welding: round nozzle, speed, wedge;

— extrusion welding;

— heated tool welding: butt, socket, wedge;

This document applies to the welding of the following products:

— sheet

— pipe (unreinforced, solid wall only);

— fittings (unreinforced only);

— lining membrane;

This document covers the welding of the following groups of materials:

a) for sheets, pipes and fittings:

— PVC (including all kinds of PVC-U, PVC-C) and ABS;

— PP;

— PE;

— PVDF;

— ECTFE, PFA and FEP;

b) for lining membranes:

— PVC-P;

— PE;

— ECB;

— PP;

c) for pipes and fittings only:

— PA-U 11 and PA-U 12.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 12814-1, Testing of welded joints of thermoplastics semi-finished products - Part 1: Bend test

EN 12814-2, Testing of welded joints of thermoplastics semi-finished products - Part 2: Tensile test

EN 12814-4, Testing of welded joints of thermoplastics semi-finished products - Part 4: Peel test

EN 12814-7, Testing of welded joints of thermoplastics semi-finished products - Part 7: Tensile test with

waisted test specimens

EN 12814-8, Testing of welded joints of thermoplastics semi-finished products - Part 8: Requirements

EN 13100-1, Non destructive testing of welded joints of thermoplastics semi-finished products - Part 1:

Visual examination

EN 14728, Imperfections in thermoplastic welds - Classification

EN 16296, Imperfections in thermoplastics welded joints - Quality levels

EN 13067, Plastics welding personnel - Qualification of welders - Thermoplastics welded assemblies

CEN/TS 16892, Plastics - Welding of thermoplastics - Specification of welding procedures

EN ISO 23936-1, Oil and gas industries including lower carbon energy - Non-metallic materials in contact

with media related to oil and gas production - Part 1: Thermoplastics (ISO 23936-1)

ISO/TR 20118, Plastics – Guidance on fire characteristics and fire performance of PVC materials used in

building applications

ISO/TR 25901-1, Welding and allied processes — Vocabulary — Part 1: General terms

ISO 13953, Polyethylene (PE) pipes and fittings — Determination of the tensile strength and failure mode

of test pieces from a butt-fused joint

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 13067, ISO 23936-1,

ISO/TR 20118, ISO/TR 25901-1 and the following apply.

ISO and IEC maintain terminoloy databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at http://www.iso.org/obp

— IEC Electropedia: available at http://www.electropedia.org/

3.1

standard welding procedure specification

sWPS

welding procedure specification that contains acceptable welding variables based on standard industry

practice and is specified in national or international standards or specifications

4 Preliminary welding procedure specification

The preliminary welding procedure specification shall be prepared in accordance with CEN/TS 16892.

5 Welding procedure test

The welding and testing of test pieces shall be in accordance with Clauses 6 and 7.

6 Test piece

6.1 Welding of test pieces

Preparation and welding of the test pieces shall be carried out in accordance with the pWPS.

6.2 Shape and dimensions of test pieces and test specimens

The dimensions of the test piece and the number of test specimens to be cut from the test piece are

specified in Figures 1 to 7.

The shapes, dimensions and conditioning of the test specimens are specified in the relevant test

standards.

Cutting the test specimens shall be carried out without significant damage to the welds and their heat

affected zones.

Minimum dimensions in millimetres

Key

1 discard

2 6 bend test specimens cut from within this area

Figure 1 — Test piece for a butt weld on sheet (for bend test specimens)

Key

1 4 test specimens, 1 in each location (x1, x2, y1, y2)

l ≥ 350 or 2 dn, whichever is longer

Figure 2 — Test piece for a butt weld on pipe (for bend or tensile test specimens)

Minimum dimensions in millimetres

Key

1 discard

2 5 tensile test specimens cut from within this area

3 tensile test specimens (for reference)

Figure 3 —Test piece for a butt weld on sheet (for tensile test specimens)

Key

1 socket

2 pipe

l ≥ 5 dn

Figure 4 — Test piece for a socket weld

Minimum dimensions in millimetres

a) Test piece for lining membranes b) Lap seam without testing channel

Key

1 discard

2 5 peel test specimens cut from within this area

3 welding zone

Figure 5 — Test piece for lining membranes - Lap seam without testing channel

Minimum dimensions in millimetres

a) Test piece for lining membranes b) Lap seam with testing channel

Key

1 discard

2 5 peel test specimens cut from within this area

3 welding

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...