CEN/TS 16892:2015

(Main)Plastics - Welding of thermoplastics - Specification of welding procedures

Plastics - Welding of thermoplastics - Specification of welding procedures

This Technical Specification provides guidance for the minimum content of welding procedure specifications for the following welding processes:

- hot gas welding: round nozzle, high speed nozzle, wedge;

- extrusion welding;

- heated tool welding: butt, socket, wedge;

- solvent welding: socket;

- electrofusion welding: socket, saddle.

This Technical Specification applies to the welding of the following products and semi-finished products made of thermoplastic materials:

- sheet;

- pipe;

- fittings;

- lining membrane.

Kunststoffe - Schweißen von thermoplastischen Kunststoffen - Anforderung an Schweißverfahren

Diese Technische Spezifikation enthält Hinweise zu den Mindestangaben von Schweißanweisungen für folgende Schweißverfahren:

Warmgasschweißen: Runddüse, Schnellschweißdüse, Breitschlitzdüse;

Extrusionsschweißen;

Heizelementschweißen: Stumpfstoß, Muffe, Breitschlitzdüse;

Quellschweißen: Muffe;

Heizwendelschweißen: Muffe, Sattel.

Diese Technische Spezifikation gilt für das Schweißen folgender Produkte und Halbzeuge aus thermoplastischen Materialien:

Tafeln;

Rohre;

Formstücke;

Dichtungsbahnen.

Plastiques - Soudage des matériaux termoplastiques - Spécification de modes opératoires de soudage

Polimerni materiali - Varjenje plastomerov - Specifikacija varilnih postopkov

Ta tehnična specifikacija podaja smernice glede minimalne vsebine v specifikacijah postopkov varjenja za naslednje postopke varjenja:

– varjenje z vročim plinom: okrogla šoba, šoba za hitro varjenje, klini;

– ekstrudersko varjenje;

– varjenje z vročimi ploščami: soležni zvari, obojni zvari, klini;

– varjenje s topilom: obojni zvari;

– elektrofuzijsko varjenje: obojni zvari;

Ta tehnična specifikacija se uporablja za varjenje naslednjih izdelkov in polizdelkov iz plastomernih materialov:

– plošče;

– cevi;

– spojniki;

– obložne membrane

General Information

- Status

- Published

- Publication Date

- 15-Dec-2015

- Technical Committee

- CEN/TC 249 - Plastics

- Drafting Committee

- CEN/TC 249/WG 16 - Welding of thermoplastics

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 02-Sep-2025

- Completion Date

- 02-Sep-2025

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

CEN/TS 16892:2015 - Plastics: Welding of thermoplastics - Specification of welding procedures is a CEN Technical Specification that defines the minimum content of Welding Procedure Specifications (WPS) for common thermoplastic welding processes. It covers welding of thermoplastic products and semi‑finished products such as sheet, pipe, fittings and lining membranes, and provides informative WPS templates in annexes for consistent documentation and repeatability.

Keywords: CEN/TS 16892:2015, welding procedure specification, thermoplastics, WPS, WPQR

Key Topics

This Technical Specification prescribes the essential elements that a WPS must contain and organizes them into general, common and process‑specific requirements:

General WPS requirements

- Identification of the welding organization, WPS number and approval signature

- Scope of application and WPQR reference (when applicable)

- Range limits for essential and non‑essential variables

Parent material information

- Material designation/reference standards (or alternative identification)

- Thickness, SDR and nominal diameters for pipes and fittings

Common welding data

- Joint preparation (cutting, cleaning, jigging/clamping)

- Joint design and sketches or references

- Welding position (per EN ISO 6947 where applicable)

- Ambient temperature range and interpass cleaning

Process‑specific parameters

- Hot gas welding (round/high‑speed nozzle, wedge): nozzle diameter, gas type, gas temperature, gas flow, torch and rod angles, welding speed, filler geometry, backing and backing method

- Extrusion welding: welding shoe design, extrudate temperature/output, gas and hot gas temperature, welding speed, filler form (wire/pellet)

- Heated tool welding (butt, socket, wedge): heater plate temperature, bead‑up pressures/times, cooling times, joining pressure

- Solvent socket welding: cement/primer details, application and curing times, insertion depth and chamfering

- Electrofusion (socket, saddle): fitting manufacturer, voltage/current type, heating and cooling times, insertion depth, coil type, data input method

Informative annexes

- Example WPS templates (Annexes A–I) for each process to aid consistent documentation.

Applications

CEN/TS 16892:2015 is practical for:

- Welding organizations and fabricators who prepare or qualify WPS and WPQR

- Quality managers, welding supervisors and inspectors ensuring repeatable, auditable welding practice

- Designers and engineers specifying welding requirements for thermoplastic piping, linings and membrane systems

- Installers and contractors performing hot gas, extrusion, heated tool, solvent or electrofusion welding

Use this specification to standardize procedure documentation, improve process control, and support training and conformity assessment for thermoplastic welding.

Related Standards

- Normative reference: EN ISO 6947 (Welding positions) is referenced for welding position designation.

- CEN members may consider this CEN/TS for conversion to an EN standard; consult national standards bodies for adoption status.

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

CEN/TS 16892:2015 is a technical specification published by the European Committee for Standardization (CEN). Its full title is "Plastics - Welding of thermoplastics - Specification of welding procedures". This standard covers: This Technical Specification provides guidance for the minimum content of welding procedure specifications for the following welding processes: - hot gas welding: round nozzle, high speed nozzle, wedge; - extrusion welding; - heated tool welding: butt, socket, wedge; - solvent welding: socket; - electrofusion welding: socket, saddle. This Technical Specification applies to the welding of the following products and semi-finished products made of thermoplastic materials: - sheet; - pipe; - fittings; - lining membrane.

This Technical Specification provides guidance for the minimum content of welding procedure specifications for the following welding processes: - hot gas welding: round nozzle, high speed nozzle, wedge; - extrusion welding; - heated tool welding: butt, socket, wedge; - solvent welding: socket; - electrofusion welding: socket, saddle. This Technical Specification applies to the welding of the following products and semi-finished products made of thermoplastic materials: - sheet; - pipe; - fittings; - lining membrane.

CEN/TS 16892:2015 is classified under the following ICS (International Classification for Standards) categories: 25.160.10 - Welding processes. The ICS classification helps identify the subject area and facilitates finding related standards.

CEN/TS 16892:2015 has the following relationships with other standards: It is inter standard links to EN ISO 6947:2019, EN 13067:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

CEN/TS 16892:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2016

Polimerni materiali - Varjenje plastomerov - Specifikacija varilnih postopkov

Plastics - Welding of thermoplastics - Specification of welding procedures

Kunststoffe - Schweißen von thermoplastischen Kunststoffen - Anforderung von

Schweißverfahren

Plastiques - Soudage des matériaux termoplastiques - Spécification de modes

opératoires de soudage

Ta slovenski standard je istoveten z: CEN/TS 16892:2015

ICS:

25.160.10 Varilni postopki in varjenje Welding processes

83.080.01 Polimerni materiali na Plastics in general

splošno

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

CEN/TS 16892

TECHNICAL SPECIFICATION

SPÉCIFICATION TECHNIQUE

December 2015

TECHNISCHE SPEZIFIKATION

ICS 25.160.10

English Version

Plastics - Welding of thermoplastics - Specification of

welding procedures

Plastiques - Soudage des matériaux termoplastiques - Kunststoffe - Schweißen von thermoplastischen

Spécification de modes opératoires de soudage Kunststoffen - Anforderung von Schweißverfahren

This Technical Specification (CEN/TS) was approved by CEN on 13 November 2015 for provisional application.

The period of validity of this CEN/TS is limited initially to three years. After two years the members of CEN will be requested to

submit their comments, particularly on the question whether the CEN/TS can be converted into a European Standard.

CEN members are required to announce the existence of this CEN/TS in the same way as for an EN and to make the CEN/TS

available promptly at national level in an appropriate form. It is permissible to keep conflicting national standards in force (in

parallel to the CEN/TS) until the final decision about the possible conversion of the CEN/TS into an EN is reached.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2015 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TS 16892:2015 E

worldwide for CEN national Members.

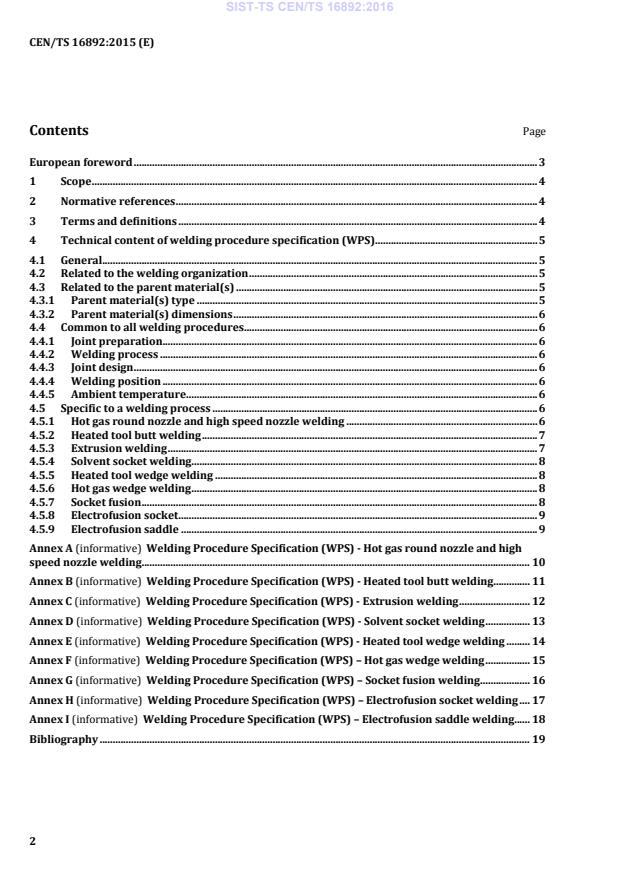

Contents Page

European foreword . 3

1 Scope . 4

2 Normative references . 4

3 Terms and definitions . 4

4 Technical content of welding procedure specification (WPS) . 5

4.1 General . 5

4.2 Related to the welding organization . 5

4.3 Related to the parent material(s) . 5

4.3.1 Parent material(s) type . 5

4.3.2 Parent material(s) dimensions . 6

4.4 Common to all welding procedures. 6

4.4.1 Joint preparation . 6

4.4.2 Welding process . 6

4.4.3 Joint design . 6

4.4.4 Welding position . 6

4.4.5 Ambient temperature . 6

4.5 Specific to a welding process . 6

4.5.1 Hot gas round nozzle and high speed nozzle welding . 6

4.5.2 Heated tool butt welding . 7

4.5.3 Extrusion welding . 7

4.5.4 Solvent socket welding. 8

4.5.5 Heated tool wedge welding . 8

4.5.6 Hot gas wedge welding . 8

4.5.7 Socket fusion . 8

4.5.8 Electrofusion socket . 9

4.5.9 Electrofusion saddle . 9

Annex A (informative) Welding Procedure Specification (WPS) - Hot gas round nozzle and high

speed nozzle welding. 10

Annex B (informative) Welding Procedure Specification (WPS) - Heated tool butt welding. 11

Annex C (informative) Welding Procedure Specification (WPS) - Extrusion welding . 12

Annex D (informative) Welding Procedure Specification (WPS) - Solvent socket welding . 13

Annex E (informative) Welding Procedure Specification (WPS) - Heated tool wedge welding . 14

Annex F (informative) Welding Procedure Specification (WPS) – Hot gas wedge welding . 15

Annex G (informative) Welding Procedure Specification (WPS) – Socket fusion welding . 16

Annex H (informative) Welding Procedure Specification (WPS) – Electrofusion socket welding . 17

Annex I (informative) Welding Procedure Specification (WPS) – Electrofusion saddle welding . 18

Bibliography . 19

European foreword

This document (CEN/TS 16892:2015) has been prepared by Technical Committee CEN/TC 249 “Plastics”,

the secretariat of which is held by NBN.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent

rights.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to announce this Technical Specification: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey

and the United Kingdom.

1 Scope

This Technical Specification provides guidance for the minimum content of welding procedure

specifications for the following welding processes:

— hot gas welding: round nozzle, high speed nozzle, wedge;

— extrusion welding;

— heated tool welding: butt, socket, wedge;

— solvent welding: socket;

— electrofusion welding: socket, saddle.

This Technical Specification applies to the welding of the following products and semi-finished products

made of thermoplastic materials:

— sheet;

— pipe;

— fittings;

— lining membrane.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

EN ISO 6947, Welding and allied processes - Welding positions (ISO 6947)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

welding procedure

specified course of action to be followed in making a weld, including the welding process(es), reference to

materials, welding consumables, preparation, preheating (if necessary), method and control of welding

and necessary equipment to be used

3.2

welding process

technique characterized by the method of softening to obtain permanent assembly

3.3

welding procedure specification

WPS

document that has been qualified and provides the required variables of the welding procedure to ensure

repeatability during production welding

3.4

work instruction

simplified welding procedure specification (WPS), suitable for direct application

3.5

welding procedure qualification record

WPQR

record comprising all necessary data needed for qualification of a welding procedure specification

3.6

welding consumable

materials consumed in the making of a weld, including filler material

3.7

essential variable

welding condition that influences the quality of the welded joint and requires qualification

3.8

non essential variable

welding condition addressed in the WPS, but not requiring qualification

3.9

parent material

parts to be joined by welding

3.10

welding organization

organization responsible for the welding production

4 Technical content of welding procedure specification (WPS)

4.1 General

A Welding Procedure Specification (WPS) shall provide all the necessary information required to make a

weld.

The minimum information required in a WPS is given in 4.2 to 4.5.

Welding procedure specifications cover a certain range for each essential / non-essential variable.

A work instruction can be prepared for each specific job as part of detailed production planning.

Examples of the WPS format are shown in Annexes A, B, C, D, E, F, G, H, I.

The procedure for measuring each variable should be according to agreed specifications.

4.2 Related to the welding organization

— Identification of the welding organization;

— WPS number;

— Welding Procedure Qualification Record (WPQR) number, if applicable;

— signature of the person responsible for approval, appointed by the welding organization.

4.3 Related to the parent material(s)

4.3.1 Parent material(s) type

— Designation of the material(s) and reference standard(s), if any.

An alternative identification shall be used if a reference standard does not exist.

4.3.2 Parent material(s) dimensions

— Thicknesses (Standard Dimension Ratio (SDR) for pipes and spigot fittings);

— nominal diameters (for pipes and fittings).

4.4 Common to all welding procedures

4.4.1 Joint preparation

— Cutting and surface preparation method (e.g. machining or scraping);

— initial cleaning (chemical or mechanical);

— jigging, fixtures, clamping.

4.4.2 Welding process

4.4.3 Joint design

— Joint and weld type;

— a sketch of the joint design/configuration and dimensions or reference to standards which provide

such information.

4.4.4 Welding position

— Welding positions (in accordance with EN ISO 6947, where applicable).

4.4.5 Ambient temperature

4.5 Specific to a welding process

4.5.1 Hot gas round nozzle and high speed nozzle welding

— Initial joint geometry;

— weld rod/wire [

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...