CEN/TS 45545-2:2009

(Main)Railway applications - Fire protection on railway vehicles - Part 2: Requirements for fire behaviour of materials and components

Railway applications - Fire protection on railway vehicles - Part 2: Requirements for fire behaviour of materials and components

This part specifies the reaction to fire performance requirements for materials and products used on railway vehicles as defined in CEN/TS 45545-1.

The operation and design categories defined in CEN/TS 45545-1 are used to establish hazard levels that are used as the basis of a classification system.

For each hazard level, this part specifies the test methods, test conditions and reaction to fire performance requirements.

It is not within the scope of this Technical Specification to describe measures that ensure the preservation of the vehicles in the event of a fire.

Bahnanwendungen - Brandschutz in Schienenfahrzeugen - Teil 2: Anforderungen an das Brandverhalten von Materialien und Komponenten

Dieser Teil der EN 45545 legt die Brandschutzanforderungen an Werkstoffe und Komponenten für Schienfahrzeuge nach prEN 45545-1 fest.

Applications ferroviaires - Protection contre les incendies dans les véhicules ferroviaires - Partie 2 : Exigences du comportement au feu des matériaux et des composants

Cette Partie spécifie les exigences de performance au feu pour les matériaux et produits utilisés à bord de véhicules ferroviaires telles que définis dans la CEN/TS 45545-1.

Les catégories d’exploitation et de conception définies dans la CEN/TS 45545-1 sont utilisées pour établir les niveaux de risque qui sont utilisés comme la base du système de classification.

Pour chaque niveau de risque, cette partie spécifie la méthode d’essai, les conditions d’essai, et les exigences de réaction au feu.

La description des mesures qui garantissent la préservation des véhicules en cas de feu, n’est pas dans le domaine d’application de la présente Spécification Technique.

Železniške naprave – Požarna zaščita na železniških vozilih – 2. del: Zahteve za obnašanje materialov in sestavnih delov v požaru

General Information

- Status

- Withdrawn

- Publication Date

- 27-Jan-2009

- Withdrawal Date

- 05-Mar-2013

- Technical Committee

- CEN/CLC/WG FPR - Fire protection for railway applications

- Drafting Committee

- CEN/CLC/WG FPR - Fire protection for railway applications

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 06-Mar-2013

- Completion Date

- 06-Mar-2013

Relations

- Effective Date

- 12-Dec-2009

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN ISO 1182:2020 - Reaction to fire tests for products - Non-combustibility test (ISO 1182:2020) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

CEN/TS 45545-2:2009 is a draft published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Fire protection on railway vehicles - Part 2: Requirements for fire behaviour of materials and components". This standard covers: This part specifies the reaction to fire performance requirements for materials and products used on railway vehicles as defined in CEN/TS 45545-1. The operation and design categories defined in CEN/TS 45545-1 are used to establish hazard levels that are used as the basis of a classification system. For each hazard level, this part specifies the test methods, test conditions and reaction to fire performance requirements. It is not within the scope of this Technical Specification to describe measures that ensure the preservation of the vehicles in the event of a fire.

This part specifies the reaction to fire performance requirements for materials and products used on railway vehicles as defined in CEN/TS 45545-1. The operation and design categories defined in CEN/TS 45545-1 are used to establish hazard levels that are used as the basis of a classification system. For each hazard level, this part specifies the test methods, test conditions and reaction to fire performance requirements. It is not within the scope of this Technical Specification to describe measures that ensure the preservation of the vehicles in the event of a fire.

CEN/TS 45545-2:2009 is classified under the following ICS (International Classification for Standards) categories: 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

CEN/TS 45545-2:2009 has the following relationships with other standards: It is inter standard links to EN 45545-2:2013, EN 61034-1:2005, EN 60332-1-2:2004, EN IEC 60332-3-24:2018, EN 50305:2002, EN 60584-1:2013, EN 61034-2:2005, EN ISO 1182:2020, EN ISO 12952-2:1998, EN 13501-1:2018, EN ISO 12952-2:2010, EN ISO 4589-2:2017, EN 14770:2012, EN ISO 9239-1:2025, EN 4651:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

CEN/TS 45545-2:2009 is associated with the following European legislation: EU Directives/Regulations: 2008/57/EC, 93/38/EEC, 96/48/EC; Standardization Mandates: M/024, M/275. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

CEN/TS 45545-2:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI OSIST prEN 45545-2:2005

PREDSTANDARD

januar 2005

Železniške naprave – Požarna zaščita na železniških vozilih – 2. del: Zahteve

za obnašanje materialov in sestavnih delov v požaru

(istoveten prEN 45545-2:2004)

Railway applications - Fire protection on railway vehicles - Part 2: Requirements for

fire behaviour of materials and components

ICS 13.220.20; 45.060.01 Referenčna številka

© Standard je založil in izdal Slovenski inštitut za standardizacijo. Razmnoževanje ali kopiranje celote ali delov tega dokumenta ni dovoljeno

DRAFT

EUROPEAN STANDARD

prEN 45545-2

NORME EUROPÉENNE

EUROPÄISCHE NORM

September 2004

ICS

English version

Railway applications - Fire protection on railway vehicles - Part

2: Requirements for fire behaviour of materials and components

Applications ferroviaires - Protection contre les incendies Bahnanwendungen - Brandschutz in Schienenfahrzeugen -

dans les véhicules ferroviaires - Partie 2 : Exigences du Teil 2: Anforderungen an das Brandverhalten

comportement au feu des matériaux et des composants

This draft European Standard is submitted to CEN and CENELEC members for enquiry. It has been drawn up by the Technical Committee

CEN/CLC/WG FPR.

If this draft becomes a European Standard, CEN and CENELEC members are bound to comply with the CEN/CENELEC Internal

Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN and CENELEC in three official versions (English, French, German). A version in

any other language made by translation under the responsibility of a CEN or CENELEC member into its own language and notified to the

CEN Management Centre has the same status as the official versions.

CEN and CENELEC members are the national standards bodies and national electrotechnical committees, respectively, of Austria,

Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia,

Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and United

Kingdom.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without notice and

shall not be referred to as a European Standard.

CEN Management Centre: CENELEC Central Secretariat:

rue de Stassart, 36 B-1050 Brussels rue de Stassart, 35 B-1050 Brussels

© 2004 CEN/CENELEC All rights of exploitation in any form and by any means reserved Ref. No. prEN 45545-2:2004 E

worldwide for CEN national Members and for CENELEC

Members.

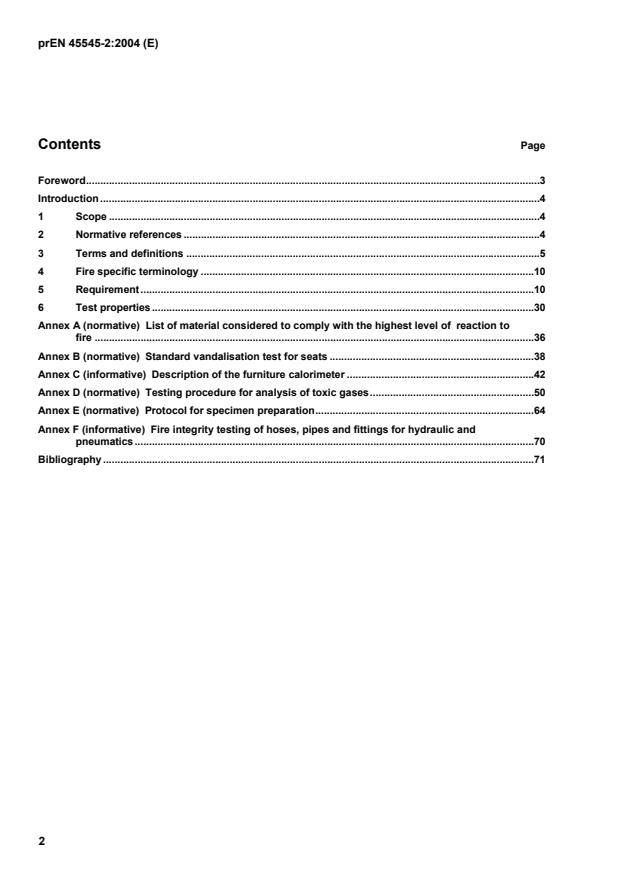

prEN 45545-2:2004 (E)

Contents Page

Foreword.3

Introduction .4

1 Scope .4

2 Normative references .4

3 Terms and definitions .5

4 Fire specific terminology .10

5 Requirement.10

6 Test properties.30

Annex A (normative) List of material considered to comply with the highest level of reaction to

fire .36

Annex B (normative) Standard vandalisation test for seats .38

Annex C (informative) Description of the furniture calorimeter .42

Annex D (normative) Testing procedure for analysis of toxic gases.50

Annex E (normative) Protocol for specimen preparation.64

Annex F (informative) Fire integrity testing of hoses, pipes and fittings for hydraulic and

pneumatics .70

Bibliography .71

prEN 45545-2:2004 (E)

Foreword

This document (prEN 45545-2:2004) has been prepared by Technical Committee CEN/TC 256 “Railway

applications”, the Secretariat of which is held by DIN, in cooperation with CENELEC/TC 9X “Electrical and

electronic applications for railways".

This document is currently submitted to the parallel CEN/CENELEC Enquiry.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive(s).

Council Directive 96/48/EC of 23 July 1996 on the Interoperability of the trans-European high-speed rail

1)

system

CEN/TC 256/WG 1 and CENELEC/TC 9X / WG 3 started in 1991 with the elaboration of this European

Standard. The co-ordination with other fire safety standardisation within CEN and CENELEC was carried out

by CEN/BT/WG 50, Fire safety technology.

This series of European Standards EN 45545 “Railway applications — Fire protection on railway vehicles”

consists of the following parts:

Part 1: General

Part 2: Requirements for fire behaviour of materials and components

Part 3: Fire resistance requirements for fire barriers and partitions

Part 4: Fire safety requirements for railway rolling stock design

Part 5: Fire safety requirements for electrical equipment including that of trolley buses, track guided

buses and magnetic levitation vehicles

Part 6: Fire control and management systems

Part 7: Fire safety requirements for flammable liquid and flammable gas installations

1)

Official Journal of the European Communities No L 235/6 of 17.09.96

prEN 45545-2:2004 (E)

Introduction

This European Standard is based on existing fire safety regulations for railway vehicles from the International

Union of Railways (UIC) and different European countries.

In using the operation and design categories defined in prEN 45545-1, the requirements laid down in this part

take into account the current operating conditions for European public rail transport.

1 Scope

This part of EN 45545 specifies the reaction to fire performance requirements for materials and products used

on railway vehicles as defined in prEN 45545-1.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

EN 13501-1, Fire classification of construction products and building elements — Part 1: Classification using

test data from reaction to fire tests.

prEN 45545-1, Railway applications — Fire protection of railway vehicles — Part 1: General.

prEN 45545-3:1998, Railway applications — Fire protection of railway vehicles — Part 3: Fire resistance

requirements for fire barriers and partitions.

prEN 45545-5:2003, Railway applications — Fire protection of railway vehicles — Part 5: Fire safety

requirements for electrical equipment including that of trolley buses, track guided buses and magnetic

levitation vehicles.

prEN 45545-6, Railway applications — Fire protection of railway vehicles — Part 6: Fire control and

management systems.

EN 50266-1, Common test methods for cables under fire conditions — Test for vertical flame spread of

vertically-mounted bunched wires or cables — Part 1: Apparatus.

EN 50266-2-4, Common test methods for cables under fire conditions — Test for vertical flame spread of

vertically-mounted bunched wires or cables — Part 2-4: Procedures; Category C.

EN 50268-1, Common test methods for cable under fire conditions — Measurement of smoke density of

cables burning under defined conditions — Part 1: Apparatus.

EN 50268-2, Common test methods for cables under fire conditions — Measurement of smoke density of

cables burning under defined conditions — Part 2: Procedure.

EN 60529, Degrees of protection provided by enclosures (IP code) (IEC 60529:1989).

EN ISO 4589-2, Plastics — Determination of burning behaviour by oxygen index — Part 2: Ambient-

temperature test (ISO 4589-2:1996).

prEN 45545-2:2004 (E)

EN ISO 5659-2, Plastics — Smoke generation — Part 2: Determination of optical density by a single-chamber

test (ISO 5659-2:1994, including Technical Corrigendum 1:1997

EN ISO 9239-1, Reaction to fire tests for floorings — Part 1: Determination of the burning behaviour using a

radiant heat source (ISO 9239-1:2002

EN ISO 11925-2, Reaction to fire tests — Ignitability of building products subjected to direct impingement of

flame — Part 2: Single-flame source test (ISO 11925-2:2002).

EN ISO 12952-3, Textiles — Burning behaviour of bedding items — Part 3: General test methods for the

ignitability by a small open flame (ISO 12952-3:1998).

EN ISO 12952-4, Textiles — Burning behaviour of bedding items — Part 4: Specific test methods for the

ignitability by a small open flame (ISO 12952-4:1998).

EN ISO 13943, Fire safety — Vocabulary (ISO 13943:1999).

ISO 3261, Fire tests; Vocabulary Bilingual edition.

ISO 5660-1, Reaction-to-fire tests — Heat release, smoke production and mass loss rate — Part 1: Heat

release rate (cone calorimeter method).

ISO 5658-2, Reaction to fire tests — Spread of flame — Part 2: Lateral spread on building products in vertical

configuration.

ISO 8421-1, Fire protection; Vocabulary; Part 1: General terms and phenomena of fire Bilingual edition.

ISO 9705, Fire tests; full-scale room test for surface products.

ISO 15540, Ships and marine technology — Fire resistance of hose assemblies — Test methods.

ISO/TR 9705-2, Reaction-to-fire tests — Full-scale room tests for surface products — Part 2: Technical

background and guidance

ISO/DIS 19702, Analysis of fire gases using Fourier infra-red technique (FTIR).

IEC/TS 60695-1-40, Fire hazard testing — Part 1-40 : Guidance for assessing the fire hazard for

electrotechnical materials — Insulating liquids.

NF F 00-201, Railway material in general — Antivandalism protection — Test method of laceration resistance,

with a blade, of vandal-proof covering.

NF X 70-100-1:2001 Fire tests — Analysis of gaseos effluents — Part 1: Methods for analysing gases

stemming from thermal degradation.

3 Terms and definitions

3.1 Definition of parameters

3.1.1

Average Rate of Heat Emission (ARHE) and its Maximum (MARHE)

the Average Rate of Heat Emission at time t, ARHE(t), is defined as the cumulative heat emission in the

period t=0 to t=t divided by t. The maximum value of the ARHE curve in the period t=0 to t=t is defined as

end

the Maximum Average Rate of Heat Emission (MARHE). MARHE can be applied to data in the form of kW vs

-2

time or kWm vs time

ARHE can be generated as follows :

prEN 45545-2:2004 (E)

Given that the rate of heat emission data comprises pairs of data points where the first data point is (t ,p )

1 1

where t is the time and p is the rate of heat emission then ARHE(t ), (using a trapezoidal area assumption), is

n

given by :

n

(p + p )

n n-1

(t − t )×

∑

n n-1

2

ARHE(t ) =

n

t − t

n 1

(Generally t =0 and p =0, or at least t can be rescaled to meet this condition and the expression can be further

1 1

simplified).

This formula is derived from expressions for the heat for each time element and the summation of these

elements as follows:

The heat for each time element, (h ), is calculated (the first heat element is derived from data points 1 and 2

n

and is assigned to data point 2; its designation is therefore h )

(p + p )

n n-1

h = (t − t ) ×

n n n −1

Summing these elements from n=2 to n=n and dividing by the interval from t to t generates ARHE(t ).

1 n n

n

h

∑ n

ARHE(t ) =

n

t − t

n 1

3.1.2

Specific optical density – D (n)

s

this term is defined in EN ISO 5659-2. D is the specific optical density,

s

(n indicates “at time n min into the test”)

The physical meaning of D is the optical density developed across opposite faces of a 1m cube when the

s

smoke from 1m of material is dispersed within the 1m cube. D is dimensionless.

s

3.1.3

VOF4 (Valeur obscurcissement fumée in 4 min)

VOF4 is the area under the Ds vs. time curve during the test period t=0 to t=4, using a trapezoidal area

assumption and a finite element (t) of 1 min

n=3

t(D (n) + D (n +1))

s s

VOF4 =

∑

n=0

With D (0)=0 and t=1 this simplifies to:

s

VOF4 = D (1) + D (2) + D (3) + D (4)/2

s s s s

VOF4 has dimensions of min.

3.1.4

Toxic measurement

Toxic fume requirements are defined in term of the Conventional Index of Toxicity (CIT). CIT has a specific

meaning for specific materials/items but in all cases CIT comprises two terms:

CIT = [Precursor Term] x [Summation Term]

prEN 45545-2:2004 (E)

CIT is always dimensionless and the Summation Term is generally produced from ratios of the emission level

to the reference level of the gas components. For the scope of this European Standard the following 8 gas

)

components shall be analysed : CO ; CO; HF; HCL; HBr; HCN; S O ;NO .

2 2

It may be assumed that the units of the Precursor Term are such as to generate a dimensionless CIT.

CIT – General (CIT)

The CIT is defined as follows:

i=8

c

i

CIT = 0.0805 ×

∑

Ci

i=1

th -3

c = concentration of the I gas in the chamber (mgm ).

i

th -3

C = reference concentration 2 of the I gas (mgm ).

i

CIT – Non-Listed Items (CIT )

NLI

For non listed items there are two options for the determination.

Option 1 utilises the EN ISO 5659-2 chamber, option 2 utilises the NF X70-100-1 tube furnace

Option 1

The CIT measured with the smoke box is defined as follows:

NLI

i=8

362 c

i

CIT = ×

NLI ∑

W C

i=1

i

th -3

c = concentration of the I gas in the chamber (mgm ).

i

th -3

C = reference concentration 2 of the I gas (mgm ).

i

W = mass of 1m of the material at 3mm thickness (g)

Option 2

The CIT measured with the tube furnace according to NF X70-100-1 with 8 gases is defined as follows :

NLI

i=8

c

i

CIT = 3×

NLI ∑

C

i=1

i

th -1

c = measured emission of the I gas for (mgg ).

i

th -3

C = reference concentration of the I gas (mgm ).

i

CIT – Cable (CIT )

C

For a single combustible component within a cable, i.e. material (j) the contribution to CIT shall be calculated

C

as follows. The calculation shall be carried out for each combustible component and the individual

contributions summed to give the final CIT .

C

)

NO includes both NO and NO quoted as NO

2 2 2

prEN 45545-2:2004 (E)

For material 1:

i=8

0.75 × w(j) c (j)

i

CIT (j) = ×

C ∑

d C

i=1

i

th -1

ci (j) = measured emission of the I gas for combustible material 1 (mgg ).

th -3

C = reference concentration of the I gas (mgm ).

i

W(j) = mass of combustible material (j) per metre of cable (g)

d = cable diameter (mm)

The calculation shall be carried out for each combustible component (materials j = 1 to N) the invidual

contributions summed to give the final CIT

C

j=N

CIT = CIT (j)

C ∑ C

j=1

The reference concentrations C of the gas components in Table 1 shall be used.

i

Table 1 — Reference concentration of the gas components

Gas Reference

components concentration

-3

mgm

CO 72000

CO 1380

HF 25

HCl 75

HBr 99

HCN 55

NO 38

SO 262

NO includes both NO and NO quoted as NO

2 2 2

-3

Both NO and NO shall be measured. The mgm of NO shall be multiplied by 46/30 to produce the equivalent

-3

mgm of NO . The total NO is given by the sum of the two values.

2 2

3.2 Explanation of expressions

Expressions used in this European Standard are explained on Table 2.

For fire terms and definitions used in this European Standard, see EN ISO 13943.

The numbers indicated in column “references” refer to clauses within this European Standard.

prEN 45545-2:2004 (E)

Table 2 — Table of expressions

Expressions Explanation References

Armrest An element which may function as a support for a seated person’s 5.3.4

arm but which may also be part of a seat which defines the width

of a seat place. For testing purposes an armrest shall be

considered to be formed from four surfaces including their

substrates. Not all surfaces will be present for all types of armrest.

Coating Product applied as liquid or powder to a substrate which will cure or

dry into a continuous surface to the substrate.

Composite A combination of materials which are recognised in building

construction as discrete entities, for example, coated, faced or

laminated materials.

Exterior of the body shell If the path taken by the fire effluent to reach a passenger or staff

area uses only space outside of the physical envelope of the

vehicle, then the item or surface is exterior else the item or surface

is interior.

A gangway area between fire resisting vehicle ends is defined as

an exterior area

Homogeneous product a product, consisting of a single material, having uniform density

and composition throughout the product

Listed item Product included in the Table 3 4.2.2

Non listed item Any item which is not listed in Table 3 4.2.3

Material Single basic substance or uniformly dispersed mixture e.g. metal,

stone, timber, concrete, mineral wool with uniformly dispersed

binder, polymers.

Non-homogeneous A product that does not satisfy the requirements of a homogeneous

product product.

Product The material, composite or assembly about which information is

required.

Limited Surfaces For a listed item which is permitted to be a limited surface to be

classified as a limited surface:

The area shall be less than 0,25 m

and : On a ceiling:

- the maximum dimension in any direction on the surface shall be

less than 1m

and

- the separation from another limited surface shall be greater than

the maximum extent of the surface (measured horizontally in any

direction on the surface)

Or : On a wall:

- the maximum dimension in a vertical direction shall be less

than 1 m

and

- the separation from another limited surface shall be greater than

the maximum extent of the surface (measured vertically)

The total area of all limited surfaces on walls and ceilings

(including windows and transverse partitions) within each

passenger or staff compartment and each passenger or staff area,

shall be less than 15 % of the total surface area of these walls and

ceilings.

prEN 45545-2:2004 (E)

Table 2 (continued)

Expressions Explanation References

Specimen A specimen is a representative sample of the thing which is tested.

Substrate A material or materials which are used immediately beneath the

product.

Cable containment Cable containment placed in assemblies or equipment rooms.

(linear products), limited (considered to be a Non Listed item)

4 Fire specific terminology

For the purposes of this European Standard, the following terms and definitions given in EN ISO 13943,

ISO 3261 and ISO 8421-1 apply.

5 Requirement

5.1 Essential

The design of rolling stock and the materials used shall be aimed at limiting fire development should an

ignition event occur.

According to different operation conditions, sizes of passenger areas and probable ignition sources, it shall be

possible for passengers and staff to leave any area impacted by the products of fire unaided and to reach a

place safety.

If it can be shown in agreement with the responsible certification body that any of the requirements specified

are not technically achievable with functionally suitable materials, then it is acceptable to use "best available"

products until and unless a suitable compliant material is developed.

5.2 Items requiring testing

5.2.1 General

There are two kinds of items defined:

The "listed items" (requirements on 5.2.2)

The "non-listed items" . (requirements on 5.2.3)

Both kinds of items shall be tested for their reaction to fire performance.

The principles on 5.2.3 apply to non listed items

The following principles applies to both kinds of items :

The materials listed in Annex A are considered to comply with the highest level of reaction to fire

performance within this part by definition.

Items placed in technical cabinets, which are fitted with an automatic fire detection and fire extinguishing

system, as defined in prEN 45545-6, may fulfil only the HL1 requirements, irrespectively of the hazard

level of the vehicle / train.

The failure rate of the Automatic detection and extinguishing system to detect and respond to fire shall

-6

not be less or equal than 10 .

prEN 45545-2:2004 (E)

Machine compartments of vehicles, and any installations and equipment in this machine compartment,

which are separated by at least a A1-15 fire barrier according to prEN 45545-3 from the cab or passenger

areas, shall be treated as exterior applications.

Mechanical or electric items, which are contained in an sealed, fire resisting enclosure may fulfil reduced

requirements due to oxygen consumption or restriction according to the following rules:

No requirements with a defined sealing quality of IP 54 according to EN 60529.

and

if the enclosure is made by a A2-5 fire barrier and the enclosed volume is ≤ 1 m

or

if the enclosure is made by a A2-10 fire barrier and the enclosed volume is ≤ 2 m

or if the enclosure is made by a A1-30 fire barrier

NOTE Fire barriers A1 and A2 according to prEN 45545-3, but with 5, 10 or 30 min of fire resistance.

For new build products the paints interior and exterior shall be tested in end use condition.

To reduce testing effort, qualifying one colour is sufficient.

Other colours of this paint system are qualified, without further testing

5.2.2 Requirement of listed items

The set of material requirements are listed in 5.3 and the short name of the set of material requirements is

visible on the column "Requirement" on each listed item.

The column "Remarks" shows relationships to special requirements e.g. sample preparation , fire resistance.

Table 3 — Requirements of listed items

Item No Name Description Require- Remark

ment

IN Interiors

IN1 Interior components – horizontal Interior components (structure and R1

downward facing surface; coverings) such as ceiling panelling as also

horizontal upwards facing; flaps, boxes, hoods, louvers, and the body

surfaces within cavities, shell in this area.

walls – vertical surfaces

Interior components (structure and

covering) such as side walls, front walls /

end-walls, partitions, room dividers, as also

flaps, boxes, hoods, louvers, in this area,

interior doors, interior lining of the front-

/end-wall doors and external doors, luggage

area, windows (plastics, glazing with foils)

also body shell in this area; kitchen interiors

surfaces (except those of kitchen

equipment)

IN2 Limited Surface All listed items, which meet the R2

requirements according to Table 2 column

“limited surface “

Exception :

A limited surface with an area less

than 0,1 m may optionally be tested

against R25 alternatively

prEN 45545-2:2004 (E)

Table 3 (continued)

Item No Name Description Require- Remark

ment

IN Interiors

IN3 Interior lighting Lighting diffuser, light covering, covering for R1

lamps (lamps itself and signal lamps are not

within the scope)

IN4 Luggage rack Overhead luggage racks, vertical luggage R1

racks, luggage lockers

IN5 Driver’s desk Panelling and surfaces of the driver’s desk. R1

IN6A Interior surfaces of gangways Interior side of gangway membrane(below), R1

interior lining of the gangway, (except

flooring of the gangway) if there is no fire

Type A

barrier at both bulk-head sides of the

gangway

IN6B Interior surfaces of gangways Interior side of gangway membrane(below), R6

interior lining of the gangway,(except

flooring of the gangway), if there is a fire

Type B

barrier at both bulk-head sides of the

gangway

IN 7 Window frame Window frame R1

IN 8 Curtains and sunblind in Curtains and sunblind except where R3

passenger and enclosed within a double glassed window

staff areas, staff compartments

IN10 A Tables, folding tables top, Upward surface of the tables or toilet wash R2

including toilet wash basins basins and surrounds .

IN10 B Tables, folding tables downward Bottom surface of a table, the exposed R1

facing surface vertical sides of drop down tables or any

surface of a folding table that may become a

bottom surface

IN 11 Container interior Water container, air container. R2

IN12 A Sound and thermal insulation R1

material in wall and ceiling

areas.

IN12 B Sound and thermal insulation R2

material in floor areas.

IN13 A Interior surface of air ducts Which are connected to the interior of the R1

vehicle.

IN14 B Exterior surface of air ducts Which are interior installed to the vehicle R1

IN15 Air filter materials Air filter materials for equipment ventilation R4

heating and air conditioning

prEN 45545-2:2004 (E)

Table 3 (continued)

Item No Name Description Require- Remark

ment

IN Interiors

IN16 Devices for passenger info Devices for passenger info R1

This item can be a IN 2 requirements

IN17 Floor composite Includes the floor substrate and floor R9

covering in end use condition

EX Exterior located

EX 1 External body shell, walls Vertical parts of external structure of body R6

shell, cab housing and door leafs

(including paint/coating systems, films)

EX 2 External body shell, roof External roof structure of the car body R7

(including paint/coating systems, films)

EX 3 External body shell, underframe External surfaces of underframe structure of R6

the body shell (floor) including paint and

coating systems (thermal, design and

acoustic coating) and protective floor

panelling

EX 4 Exterior ducts Exterior surface and interior surface of ducts R6

which are not connected to the interior of

the vehicle

EX 5 External design features External design features (e.g. streamlining R6

parts, ventilation grills, flaps, skirts,

coverings for HVAC systems, enclosures,

etc.)

EX 6A Container exterior Water container, air container placed in the R6

underframe.

EX 6B Container exterior Water container, air container placed on the R7

roof.

EX 7 Outer membrane of R6

intercommunication gangways

EX 8 Bogie parts , structural Bogie frames; spring leaf guide R6

EX 9 Air bags for pneumatic Air bags for pneumatic suspension R8

suspension

EX 11 Parts of the drive Wheel sets , brake disc R8

EX12 Tyres R6

prEN 45545-2:2004 (E)

Table 3 (continued)

Item No Name Description Require- Remark

ment

F Furniture

F1 Complete passenger seat Complete passenger seat including arm R17 Extent of

and head rests, separate pillows, tip up vandalisatio

seats and driver seat accessible to the n

passenger see Annex

B

F2A Driver’s seat Driver’s seat upholstery R18

F2B Driver’s seat Driver’s seat Back and Base shell R19 Fire

integrity

5.2.1

F3 Mattresses Mattresses R21

F4 Upholstery for seats and head Upholstery for seats and head rest R21

rest

F5 Bed clothes for couchettes and Bed clothes for couchettes and beds R20

beds (blanket, duvets, pillows, (blanket, duvets, pillows)

sleeping bags and sheets)

F6A Armrest – Upwards Facing Armrest – Surface on which the arm rests R22

Surface

F6B Armrest – Vertical Surface Armrest – Inside surface (or outside surface R23 Fire

on transverse seating) which is against the integrity

body of the seat occupant 5.2.1

F6C Armrest – Downwards Facing Armrest – Underside surface of the arm rest R23 Fire

Surface integrity

5.2.1

F7A Back shell; base shell of Back shell; base shell of passenger seats R19 Fire

passenger seats integrity

5.2.1

F7B Underside surface of couchettes Underside surface of couchettes and beds R1 Fire

and beds integrity

5.2.1

E Electrotechnical Equipment

E1A Cables for interior R14

E1B Cables for exterior R15

E2A Cable containment Cable containment surface related (cable R1

(linear product) for interior duct, cable conduit)

E2B Cable containment Cable containment surface related (cable R6

(linear product) for exterior duct, cable conduit)

prEN 45545-2:2004 (E)

Table 3 (continued)

Item No Name Description Require- Remark

ment

E3 Enclosures Enclosure for electrical equipment R1

E4A Arc resistant insulation materials Arc resistant insulation material ; R10

Type A Arc barrier type A

see definition prEN 45545- 5, 3.1.1

E4B Arc resistant insulation materials Arc resistant insulation material; R11

Type B Arc barrier type B

see definition prEN 45545-5, 3.1.2

E4C Arc splash barrier materials Arc splash barrier R6

see definition prEN 45545-5, 3.2

E5 Flammable insulation liquid Flammable insulation liquid R13

E6 Supply line system devices Surge arrester; Isolators; switches; R26

exterior Main circuit breakers.

E7A Supply line system and high Isolators; current and voltage transformers, R25

power devices. Main circuit breakers;

supposed as interior Contactors

E7B Supply line system and high Isolators; current and voltage transformers, R26

power devices. Main circuit breakers;

supposed as exterior Contactors

E8A Choke and coils Chokes for supply line filtering, coils for air R25

supposed as interior cooled transformers, including spacers and

air guiding plates

E8B Choke and coils Chokes for supply line filtering, coils for air R26

supposed as exterior cooled transformers, including spacers and

air guiding plates and traction motor

winding insulation

E9 Brake resistors Brake resistor air cooled R12

M Mechanical Equipment

M2 Flexible metal/rubber units Flexible metal/rubber units including R8

elements in bogies

5.2.3 Requirement of “Non listed” items

5.2.3.1 Principle of non listed item

All items not listed in column “listed items” in Table 3 are intended having the requirement according to the

“non listed items”.

There are several possibilities to comply for non listed items:

The principles on 5.2.1.

prEN 45545-2:2004 (E)

The exposed area presented by the non listed item shall be less than 0,25 m , if non compliant to this

area restriction higher requirements are requested.

Table 4 — Requirements of non listed items according to the exposed area and location in the vehicle

Exposed Area Location Requirement

> 0,25 m² interior R 1

> 0,25 m² exterior R 6

≤ 0,25 m² interior R 25

exterior R 26

≤ 0,25 m²

The set of requirements R1, R6, R25, R26 are according to Table 6.

Is the exposed area of a non listed item less than 0,25 m and the non listed items have no compliance

according to 5.2.1, then the non listed item is compliant if:

they stay within the mass and area limits according to 5.2.3.2;

the stay with the allowable mass scheme according to 5.2.3.3.

The Figure 1 shows the process flow for compliance for non listed items.

prEN 45545-2:2004 (E)

Figure 1 — Process flow for compliance principles for non listed items

5.2.3.2 Non compliance to LOI requirements, mass and area limits

5.2.3.2.1 Interior located non listed items

An interior non listed item which fails to meet the LOI requirement shall be compliant if, after application of the

Flammability Grouping Rules, it meets either the mass or area requirement (or both).

prEN 45545-2:2004 (E)

Mass requirement:

The mass shall be < 100 g.

Area requirement:

The total exposed surface area of the grouped non listed items shall be less than < 0,1 m and for downward

facing or vertical surfaces, the exposed area per metre shall be < 0,05 m measured in any direction on a

downward facing surface and vertically on a vertical surface.

5.2.3.2.2 Exterior located non listed items

An exterior non listed item which fails to meet the LOI requirement shall be compliant if, after application of the

Flammability Grouping Rules it meets either the mass or area requirement (or both).

Mass requirement:

The mass shall be < 400 g.

Area requirement

The total exposed surface area of the grouped non listed items shall be less than < 0,2 m and for downward

facing or vertical surfaces the exposed area per metre shall be < 0,1 m measured in any direction on a

downward facing surface and vertically on a vertical surface.

5.2.3.2.3 Interior flammability grouping rules

Only non listed items which have shown failure to LOI requirement shall be considered for grouping.

The following grouping rules apply to interior non listed items which have failed the LOI requirement.

Grouping shall be carried across the boundary between surfaces of different orientation.

For non listed items fixed on, forming, or part of a downward facing surface e.g. orientated like ceiling, the

grouping consideration shall be extended to a maximum distance of 4 m, where 4 m is the total distance

on both vertical and downward facing surfaces.

For non listed items fixed on, forming, or part of a vertical surface e.g. orientated like wall, the grouping

consideration shall be extended to a maximum distance of 4 m, where 4 m is the total distance on both

vertical and downward facing surfaces.

For non listed items fixed on, forming, or part of a upward facing surface e.g. orientated like floor, the

grouping consideration shall be extended to a maximum distance of 1 m.

NOTE The maximum distance rules are useful when applied to LOI non-compliant continuous non listed items,

commonly in the form of strips.

To avoid being grouped with the first non listed item, (for the purposes of continuing the grouping analysis),

the second non listed item shall lie outside of the exclusion zones around the first non listed item.

There are two exclusion zones; Standard and Special.

Interior standard exclusion zone (Figures 2.1 and 3.1 )

The Standard exclusion zone is applicable to all items.

Horizontal planes are drawn at the highest and lowest point of the first non listed item. The first non listed item

is projected onto the lower plane. A perimeter is drawn around the projection of the first non listed item so that

the perimeter is not less than 20 mm from the projection. The perimeter is then projected onto the upper plane

and then a further 200 mm vertically upwards from the higher plane. The exclusion zone comprises the full

projected volume; i.e the volume between the planes plus the 200 mm upward projection.

prEN 45545-2:2004 (E)

Interior special exclusion zone (Figures 2.2 and 3.2 )

The special exclusion zone takes in account of fire plumes underneath a surface.

The special exclusion zone shall be applied where any part of the second non listed item is within 20 mm of a

downward facing surface and the vertical projection of the first non listed item intersects this surface. The

exclusion zone is 200 mm linear distance from the first non listed item. (The distance between first non listed

item and the downward facing surface is variable)

Dimensions in millimetres Dimensions in millimetres

Key Key

8 = not grouped 8 = not grouped

9 = grouped 9 = grouped

1 = first non listed item 1 = first non listed item

z = second non listed item [NOT TO SCALE]

= Projection of first non listed item

z = second non listed item [NOT TO SCALE]

Figure 2.1 —— Standard exlusion zone Figure 2.2 —— Special exclusion zone

—— ——

(The second (lower plane) is not shown.)

If a second non listed item is grouped under either or both of the above rules it may be ungrouped by barriers

placed within the exclusion zone. To qualify as a barrier the barrier material used shall meet one of the

following requirements:

A A2-10 fire barrier: i.e. a A2 barrier according to prEN 45545-3, but tested for 10 min only.

Testing shall be done on a sheet of at least 500 mm x 500 mm size.

prEN 45545-2:2004 (E)

B Meet the fire penetration requirement as the shell of a passenger seat according to 5.2.1.

The fire barrier shall be placed such, that :

For the Standard Exclusion Zone;

It fully occludes the vertical projection of the 20 mm spaced perimeter of the first non listed item

For the Special Exclusion Zone;

It fully occludes the lateral projection of the vertical projection of the 20 mm spaced perimeter of the first

non listed item and is not less than 20 mm depth.

Dimensions in millimetres Dimensions in millimetres

Key Key

8 = not grouped 8 = not grouped

9 = grouped 9 = grouped

1 = first non listed item 1 = first non listed item

z = second non listed item [NOT TO SCALE]

= Projection of first mass

z = second non listed item [NOT TO SCALE]

Figure 3.1 — Standard Exlusion Zone Figure 3.2 — Special Exclusion Zone

(The second (lower plane) is not shown.)

5.2.3.2.4 Exterior flammability grouping rules

For exterior non listed items either the interior scheme of flammability grouping rules shall be applied or the

exterior scheme of flammability grouping rules shall be applied.

prEN 45545-2:2004 (E)

For the exterior scheme the numerical value of the interior scheme shall be changed as follows :

All occurrences of 20 mm become 40 mm.

All occurrences of 200 mm become 400 mm.

5.2.3.3 Failure to meet smoke and/or toxic fume emission requirements

A group of N individual piece of material of these non listed items, which have individually failed to meet the

smoke and/or toxic fume requirements shall be compliant if, after application of the smoke and toxic fume

grouping rules, the requirements below are met.

i=N

m (i)

Smoke requirement: <1

∑

w (i)

i=1 smoke

and

i=N

m (i)

toxic fumes requirement : <1

∑

w (i)

i=1

toxic

where m(i) is the mass (g) of each individual material (i) non listed item within the group and

Required D (max)× 450

s

w (i) = (g)

smoke

Actual D (max)(i)

s

Required CIT × 450

w(i) = (g)

toxic

Actual CIT (i)

The "Required Ds(max)" – or " Required CIT"-values are those Ds(max) or CIT- requirements quoted

R 25(interior application) or R26 (exterior application) on Table 6.

The "Actual Ds(max) (i) " – or "Actual CIT (i) " values are those measured for one individual material (i).

5.2.3.3.1 Smoke and toxic fume grouping rules

The masses of all failed non listed items (m) shall be the maximum masses that can be bounded

by a 0,2 m x 0,2 m x 0,2 m cubical volume; the volume being applied to the as-installed condition.

5.2.4 Refurbishment and maintenance requirements

The following verification rules apply for exchange of non listed items and components during refurbishment

(see prEN 45545-1 clause 10). The train operator shall ensure that components introduced during regular

maintenance are able to comply with the relevant material requirements as described below.

prEN 45545-2:2004 (E)

5.2.4.1 General

After refurbishment it shall be demonstrated, that any new surface generated by any over-coating or over-

laminating process is not of a worse classification than original surface.

At the time of refurbishment process of a railway vehicle, it could be difficult to obtain the original substrate.

Therefore it is recommended to identify the equivalent substrates that can represent the performance of the

original substrate.

On trains built and approved according to this European Standard any new components introduced during

refurbishment shall be verified to the requirements on clause 4 (listed and non listed items).

For trains built and already approved to previous standards and regulations, e.g. National standards or

UIC-leaflets, the following applies:

Minor adjustments during maintenance as a consequence of product- and market development on

components may be performed to the already approved set of standards and regulations for the relevant

train at the time of its approval.

Refurbishment projects shall take into account the guidelines of this European Standard, and the new

components introduced shall be documented against the relevant acceptance criteria in 5.2.

5.2.4.2 Requirements for refurbishment of passenger seats

Parameters which may influence fire behaviour are :

composition nature;

shape;

mass , thickness, density;

supplier.

For minor changes in these parameters on cushions of passenger seats the Table 5 specifies test requirements

in relevant cases with reference to the Table 6.

Refurbished passenger seats having more than one of the listed parameters changed according to Table 5

shall be tested against the full set of requirement according to Table 3 item No F1.

prEN 45545-2:2004 (E)

Table 5 — Test requirement for refurbishment of the passenger seats

Parts Parameters Requirements

changed

R17 R21

Cover Colour only

- -

(the material shall

be the same)

Supplier only

- X

Interlayer Supplier only

- X

(fire barrier)

Glue Composition nature,

- X

Supplier

Foam Certified thickness

- -

less than ± 15 %

Certified thickness

X -

more than ± 15 %

5.3 Set of material requirements

In the following Table 6 the parameters used to define requirements and their characteristics, are listed.

A reported result equal to the requirement is compliant.

The column "Test method ref." Refers to the corresponding number in Table 7, where the test methods are

described more detailed with short explanation of the test-method, parameter, unit and requirement definition

including whether the numerical value in the tables of requirements represents a maximum or minimum for

compliance.

Where no requirement is specified in the Tables of requirements the symbol “-“ is inserted.

Table 6 — Set of material requirements

Short name of Test Method : Conditions HL1 HL2 HL3 HL4

requirement set method Parameter

ref.

R1 T02 ISO 5658-2 23,9 23,9 30,9 37,8

-2

CHF (kWm )

-2

T03.01 ISO 5660-1 : 50kWm - 90 90 60

MARHE

-2

T10.01 EN ISO 5659-2 : 50kWm 600 300 300 150

D (4)

s

-2

T10.02 EN ISO 5659-2 : 50kWm 1200 600 600 300

VOF4

-2

T11.01 EN ISO 5659-2 : 50kWm 1,2 0,9 0,9 0,75

CIT at 8 min

prEN 45545-2:2004 (E)

Table 6 (continued)

Short name of Test Method : Conditions HL1 HL2 HL3 HL4

requirement set method Parameter

ref.

R2 T02 ISO 5658-2 13,2 13,2 18,2 23,9

-2

CHF (kWm )

-2

T03.01 ISO 5660-1 : 50kWm - - - 90

MARHE

-2

T10.01 EN ISO 5659-2 : 50kWm 600 300 300 150

D (4)

s

-2

T10.02

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...