EN 14080:2005

(Main)Timber structures - Glued laminated timber - Requirements

Timber structures - Glued laminated timber - Requirements

This European Standard specifies the requirements for glued laminated timber for use in load bearing structures.

It also specifies the requirements for large finger joints in the glued laminated timber.

This European Standard specifies the requirements for glued laminated timber produced from untreated timber or from timber treated against biological attack.

Holzbauwerke - Brettschichtholz - Anforderungen

Dieses Dokument legt Anforderungen an Brettschichtholz für tragende Zwecke fest.

Des Weiteren werden die Anforderungen an Universal-Keilzinkenverbindungen in Brettschichtholz festgelegt.

Dieses Dokument legt Anforderungen an Brettschichtholz aus unbehandeltem Holz oder aus Holz, das gegen

biologischen Befall behandelt wurde, fest.

Structures en bois - Bois lamellé collé - Exigences

La présente norme européenne prescrit les exigences relatives au bois lamellé collé utilisé dans les structures portantes.

Elle prescrit également les exigences relatives aux aboutages à entures de grandes dimensions dans le bois lamellé collé.

La présente norme prescrit les exigences relatives au bois lamellé collé produit à partir de bois non traité ou de bois traité contre les attaques biologiques.

Lesene konstrukcije – Lepljeni lamelirani les – Zahteve

General Information

- Status

- Withdrawn

- Publication Date

- 14-Jun-2005

- Withdrawal Date

- 25-Jun-2013

- Technical Committee

- CEN/TC 124 - Timber structures

- Drafting Committee

- CEN/TC 124/WG 3 - Glued laminated timber

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 26-Jun-2013

- Completion Date

- 26-Jun-2013

- Directive

- 89/106/EEC - Construction products

Relations

- Replaced By

EN 14080:2013 - Timber structures - Glued laminated timber and glued solid timber - Requirements - Effective Date

- 03-Jul-2013

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Gozdarski inštitut Slovenije

Slovenian Forestry Institute. Forest management certification support, timber testing.

Sponsored listings

Frequently Asked Questions

EN 14080:2005 is a standard published by the European Committee for Standardization (CEN). Its full title is "Timber structures - Glued laminated timber - Requirements". This standard covers: This European Standard specifies the requirements for glued laminated timber for use in load bearing structures. It also specifies the requirements for large finger joints in the glued laminated timber. This European Standard specifies the requirements for glued laminated timber produced from untreated timber or from timber treated against biological attack.

This European Standard specifies the requirements for glued laminated timber for use in load bearing structures. It also specifies the requirements for large finger joints in the glued laminated timber. This European Standard specifies the requirements for glued laminated timber produced from untreated timber or from timber treated against biological attack.

EN 14080:2005 is classified under the following ICS (International Classification for Standards) categories: 79.060.99 - Other wood-based panels. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14080:2005 has the following relationships with other standards: It is inter standard links to EN 14080:2013, EN 717-1:2004, EN 302-1:2023, EN 385:2001, EN 387:2001, EN 302-2:2023, EN 384:2016+A2:2022, EN 302-6:2004, EN 1194:1999, EN 302-3:2023, EN 302-7:2023, EN 13501-1:2018, EN 302-5:2023, EN 408:2010+A1:2012, EN 14358:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14080:2005 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/112. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14080:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Timber structures - Glued laminated timber - RequirementsLesene konstrukcije – Lepljeni lamelirani les – ZahteveStructures en bois - Bois lamellé collé - ExigencesHolzbauwerke - Brettschichtholz - AnforderungenTa slovenski standard je istoveten z:EN 14080:2005SIST EN 14080:2005en91.080.2079.060.99ICS:SLOVENSKI

STANDARDSIST EN 14080:200501-december-2005

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14080June 2005ICS 79.060.99English versionTimber structures - Glued laminated timber - RequirementsStructures en bois - Bois lamellé collé - ExigencesHolzbauwerke - Brettschichtholz - AnforderungenThis European Standard was approved by CEN on 25 April 2005.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2005 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14080:2005: E

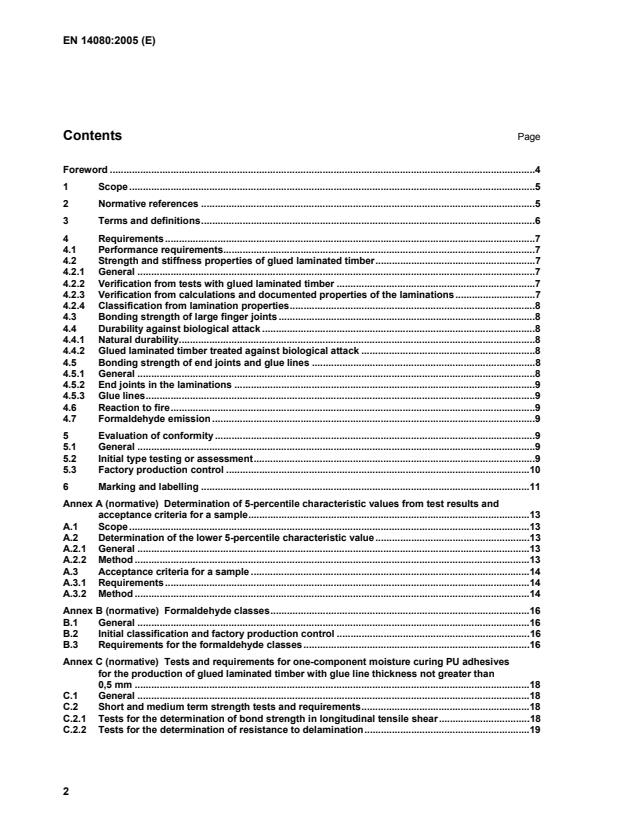

Determination of 5-percentile characteristic values from test results and acceptance criteria for a sample.13 A.1 Scope.13 A.2 Determination of the lower 5-percentile characteristic value.13 A.2.1 General.13 A.2.2 Method.13 A.3 Acceptance criteria for a sample.14 A.3.1 Requirements.14 A.3.2 Method.14 Annex B (normative)

Formaldehyde classes.16 B.1 General.16 B.2 Initial classification and factory production control.16 B.3 Requirements for the formaldehyde classes.16 Annex C (normative)

Tests and requirements for one-component moisture curing PU adhesives for the production of glued laminated timber with glue line thickness not greater than 0,5 mm.18 C.1 General.18 C.2 Short and medium term strength tests and requirements.18 C.2.1 Tests for the determination of bond strength in longitudinal tensile shear.18 C.2.2 Tests for the determination of resistance to delamination.19

Determination of properties of use of the adhesive.28 D.1 Determination of the conventional assembly time.28 D.2 Determination of the conventional pressing time.28 D.3 Determination of the initial dynamic viscosity.28 D.4 Tests on influence of open and closed assembly times on shear strength.28 Annex E (normative)

Reaction to fire: Euroclass without the need for further testing.30 Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive.31 Z.1 Scope and relevant characteristics.31 Z.2 Procedure for the attestation of conformity.32 Z.2.1 System of attestation of conformity.32 E.1 bending strength;.33 E.2 compressive strength;.33 E.3 tensile strength;.33 E.4 shear strength;.33 E.5 bonding strength of the laminate end joints, glue lines and large finger joints;.33 E.6 durability of the wood;.33 E.7 formaldehyde class.33 Z.2.2 Specific tasks of the notified body.33 Z.2.3 Certificate and Declaration of Conformity.34 Z.3 CE Marking.35

5-percentile values and acceptance criteria for a sample prEN 15228, Structural timber – Structural timber preservative treated against biological attack 3 Terms and definitions For the purposes of this European Standard, the terms and definitions given in EN 385:2001, EN 386:2001 and EN 387:2001 together with the following apply. 3.1 characteristic density population lower 5-percentile value with mass and volume corresponding to equilibrium moisture content at a temperature of 20 °C and a relative humidity of 65 % 3.2 characteristic strength population lower 5-percentile value obtained from the results of tests with a duration of 300 s using test pieces at an equilibrium moisture content resulting from a temperature of 20 °C and a relative humidity of 65 % 3.3 characteristic bending strength of glued laminated timber strength related to a depth of 600 mm 3.4 characteristic tensile strength of glued laminated timber strength parallel to the grain related to a width of 600 mm 3.5 characteristic compression strength of glued laminated timber strength parallel to the grain 3.6 characteristic shear strength of glued laminated timber strength related to a specimen with a uniformly stressed volume of 0,000 5 m3 3.7 characteristic modulus of elasticity of glued laminated timber population mean value obtained under the same climate conditions as defined in 3.1

EN 1194:1999, Annex B gives the glulam strength class for a given strength class of the timber. 4.3 Bonding strength of large finger joints The bonding strength of large finger joints shall be evaluated as the bending strength of the joints. For large finger joints with a specific geometry in the glued laminated member made from a specific species the characteristic bending strength of the joints in straight beams shall be derived from tests in accordance with EN 408. The sample size n shall be not less than 20 selected from at least four batches. The specimens and the testing of large finger joints shall be in accordance with Clause 8 of EN 387:2001. The characteristic bending strength shall be calculated from Annex A of this document. For the initial type testing of large finger joints produced with a finger geometry and a wood species for which the characteristic bending strength has been determined previously, the number of finger joint samples shall be at least five and they shall be taken from joints in glued laminated timber of the highest strength to be produced. 4.4 Durability against biological attack 4.4.1 Natural durability The natural durability of the wood, from which the glued laminated timber is manufactured, against biological attacks shall be assessed in accordance with EN 350-1 and EN 350-2. 4.4.2 Glued laminated timber treated against biological attack Provisions related to preservative treated timber against biological attack are given in prEN 15228. 4.5 Bonding strength of end joints and glue lines 4.5.1 General The adhesive shall be capable of producing strong and durable joints so that the integrity of the bond is maintained throughout the intended lifetime of the structure for the defined service class. Acceptable strength and durability can be achieved by the use of: polycondensation adhesive of the phenolic or aminoplastic type as defined in EN 301; polyurethane adhesive tested and assessed in accordance with the requirements given in Annex C of this document. Adhesives of type I according to EN 301 may be employed for structural members to be used in all Service Classes. Adhesives of type II according to EN 301 may only be used for Service Class 1 and 2 provided the temperature of the member in the structure will always be below 50 °C.

EN 387:2001 can be used. These schemes will need to be supplemented to take into consideration any special production methods, conditions, materials or functional requirements. The factory production control defined in these two standards shall be documented and implemented. Any deviations shall be noted and recorded. Procedures to be followed when control values and criteria are not met shall be established. The manufacturer shall document from calibration tests his capability to select specimens and to conduct the tests prescribed by EN 386 and/or EN 387. The sample size is given in Table 1.

6 Marking and labelling Products complying with this document shall be clearly marked on the product or on a durable label with the following information: a) number of this document; b) identity of the manufacturer, logo or name; c) characteristic values. This may be done by reference to a documented strength profile or a strength class defined in EN 1194; d) adhesive type, e.g. I or II according to EN 301; e) production week and year.

Determination of 5-percentile characteristic values from test results and acceptance criteria for a sample A.1 Scope This annex gives a method for calculating the 5-percentile characteristic value from test results for a population, and a method to estimate whether the 5-percentile value for a sample drawn from the production is below a declared value. NOTE This annex has been elaborated because no other European Standard covers the scope. As soon as EN 14358 covering the above scope has been implemented, this standard will be used instead of Annex A. A.2 Determination of the lower 5-percentile characteristic value A.2.1 General The 5-percentile value shall be estimated as the lower endpoint in the one-sided 84,1 % confidence interval assuming a log-normal distribution. The coefficient of variation shall not be taken as less than 0,10. A.2.2 Method Draw a sample of n test pieces from the population, and test the pieces in accordance with the appropriate standard for the property called x. Determine the mean value m{x} and the coefficient of variation v{x}. Estimate the characteristic value xk as: xk

=

k1 m{x}

(A.1) where k1

=

exp{ -(2,645+1/√n) v{x} + 0,15}

(A.2) The value of v{x} shall not be taken as less than 0,10. Values of k1 are given in Table A.1. NOTE

The value determined by Equations (A.1) and (A.2) is the highest value the producer may declare as the characteristic value. If the product is subject to a quality control procedure involving testing and evaluation as described in Equation A.3 it may be advisable to declare a lower value to avoid an unreasonable rejection rate.

A.3 Acceptance criteria for a sample A.3.1 Requirements The probability of accepting a sample with a 5-percentile value less than 95 % of the declared characteristic value fk should be less than 15,9 % assuming a log-normal distribution. It is assumed that the value of the coefficient of variation is known, e.g. from a running production control. The coefficient of variation shall not be taken as less than 0,10. A.3.2 Method Draw a sample of n test pieces from the batch, and test them in accordance with the appropriate standard for the property called x. Calculate the mean value m{x} and the coefficient of variation v {x}. The sample shall be accepted if: m{x} ≥ k2 xk

(A.3) where k2

=

exp{ (2,645+1/√n) v{x} - 0,1875}

(A.4)

Formaldehyde classes B.1 General For the production of glued laminated timber an adhesive containing formaldehyde is used in some cases. NOTE 1 Glued laminated timber products are known to release little or no formaldehyde. Internal control is only carried out if there are changes in the production with regard to the glue system. However, it remains the responsibility of the manufacturer to ensure compliance with the declared formaldehyde content class. Where such formaldehyde containing adhesives are used, the subsequent release of formaldehyde shall be assessed by testing according to EN 717-1 or be classified as E2 without testing. The evaluation of emission shall be carried out for each combination of adhesive and wood species. The testing in a chamber shall be carried out with a loading factor of 0,3 m2/m3. A test chamber with a volume of 1 m3 should be used. For such a chamber the following size of a glued laminated member should be used:

width x depth x length = 90 mm x 200 mm x 517 mm. (B.1) The lamination thickness shall be 40 mm. All dimensions shall have a tolerance of ± 2 mm. The ends of the specimen shall be sealed. According to the results, the product shall be classified into one of two classes: E1 or E2 (see B.3). NOTE 2 In conventional structures under typical conditions of use, glued laminated timber conforming to formaldehyde emission Class E1 is unlikely to result in an indoor air concentration exceeding 0,1 ppm HCHO. NOTE 3 It is envisaged that the adhesive manufacturer will provide the documentation to the manufacturer of glued laminated timber. B.2 Initial classification and factory production control Once initial classification has been obtained by testing, factory production control of the production may be carried out by checking that only adhesives for which an initial classification has been carried out are used. This shall be done by inspecting the received adhesives. B.3 Requirements for the formaldehyde classes The maximum values of the steady state emission values for glued laminated timber complying with formaldehyde emission Classes E1 or E2 are given in Table B.1.

Tests and requirements for one-component moisture curing PU adhesives for the production of glued laminated timber with glue line thickness not greater than 0,5 mm C.1 General This annex specifies the tests and requirements for one-component moisture curing PU adhesives for the production of glued laminated timber members made from softwoods with glue line thickness not greater than 0,5 mm. The PU adhesive can be used for finger joints in the laminations and for the production of glued laminated members by bonding the laminations. PU adhesives can be classified as a type I or a type II adhesive as defined in EN 301 when fulfilling the requirements given in this annex. NOTE This annex has been elaborated because no other European Standard covers the scope. As soon as a European Standard covering the above scope has been implemented, this standard will be used instead of Annex C. C.2 Short and medium term strength tests and requirements C.2.1 Tests for the determination of bond strength in longitudinal tensile shear Tests to determine the bond strength in longitudinal tensile shear shall be performed in accordance with EN 302-1, except that the thickness of the thick glue lines shall be changed from 1,0 mm to 0,5 mm. The tensile shear strength values of glue line thickness 0,1 mm (thin glue line) shall conform to the requirements specified in EN 301. For the glue line thickness of 0,5 mm, the requirements given in Table C.1 apply. Table C.1 – Requirements for minimum mean tensile shear strength in N/mm2 for treatments A1-A5 defined in EN 301 Adhesive type Treatment I II A1 A2 A3 A4 A5 9 5 7,2 5 7,2 9 5 7,2 - -

For adhesives of Type II, testing and assessment according to temperature condition B3 may be omitted. For adhesives of Type I, testing and assessment according to temperature condition B2 may be omitted. C.3 Long-term sustained load test at cyclic climate conditions with specimens loaded perpendicular to the glue line C.3.1 General description The tests shall be performed with specimens according to EN 302-3. As a change to EN 302-3, the specimens are made from beech wood with glue line thickness of 0,1 mm and 0,5 mm. The beech wood boards from which the specimens are cut shall be free from knots, straight grained and shall have a density larger than 650 kg/m3 at 20 °C/65 % rh. The timber prior to specimen manufacture shall be conditioned in a climate chamber at storage conditions of (20 ± 2) °C and (65 ± 5) % rh; the moisture content shall be within the limits of (12 ± 1) %. The manufacture of the specimens shall conform to the specifications given in C.3.2. C.3.2 Manufacture of specimens In total, 5 sticks with a cross-section of 50 x 60 mm2 and a length of about 700 mm, enabling the cutting of 8 test specimens and 2 reserve specimens from each stick of the specimen type described in EN 302-3, shall be manufactured for each glue line thickness. The ten specimens for each test are therefore made up of two specimens (see Figure C.1) from each stick. Figure C.1 gives a view of the stick and of the cutting scheme for its subdivision into 10 specimens for the determination of the tensile strength perpendicular to the glue line. The manufacture and build-up of the sticks shall follow the scheme shown in Figure C.2a and C.2b. The annual ring orientation of both components

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...