EN 1570:1998+A2:2009

(Main)Safety requirements for lifting tables

Safety requirements for lifting tables

1.1 This document specifies the safety requirements for lifting tables for raising and/or lowering goods and/or persons associated with the movement of goods carried by the lifting table (i.e. not for passenger use), for a vertical travel of up to 3,0 m.

1.2 This European Standard deals with all significant hazards pertinent to lifting tables when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). This European Standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards.

1.3 Both power operated and manually operated lifting tables are included whether stationary or mobile.

1.4 This document does not apply to the following equipment:

- permanently installed lifting tables, serving specific levels of a building and fitted with a car;

- permanently installed lifting tables, serving specific levels of a building, not fitted with a car but with a vertical travel of more than 2,0 m;

- power operated lifting platforms for persons with impaired mobility;

- lifting tables for airport ground equipment;

- lifting tables for marine use;

- mobile elevating work platforms;

- vehicle lifts for maintenance;

- mobile lifting tables used for fire fighting;

- mobile lifting tables used as fork lift trucks, pallet trucks and order pickers;

- mobile lifting tables with a travelling speed of more than 1,6 m/s;

- rail dependent storage and retrieval equipment;

- theatre stage lifts.

1.5 This standard does not consider the Power Supply to the lifting table by Internal Combustion Engine.

This standard does not establish the additional requirements for:

- Operation in severe conditions (e.g. extreme climates, freezer applications, strong magnetic fields);

- Operation subject to special rules (e.g. potentially explosive atmospheres, mines);

- Handling of loads, the nature of which could lead to dangerous situations (e.g. molten metal, acids, radiating materials, esp

Sicherheitsanforderungen an Hubtische

1.1 !Dieses Dokument beschreibt Sicherheitsanforderungen für Hubtische zum Heben und/oder Senken von Gütern und/oder Personen in Zusammenhang mit der Bewegung der vom Hubtisch gehobenen Güter (d. h. nicht für die Benutzung von Personen allein) bis zu einem vertikalen Hub von 3,0 m."

1.2 Diese Europäische Norm behandelt von Hubtischen ausgehende signifikante Gefährdungen, wenn diese bestimmungsgemäß unter den vom Hersteller vorgesehenen Bedingungen (siehe Abschnitt 4) benutzt werden. Diese Europäische Norm beschreibt die geeigneten technischen Maßnahmen zur Vermeidung oder Verminderung der Risiken, die sich aus den zutreffenden Gefährdungen ergeben.

1.3 Sowohl kraftbetriebene als auch handbetriebene Hubtische, die ortsfest oder ortsveränderlich sein können, werden erfasst.

1.4 !Dieses Dokument findet keine Anwendung auf folgende Geräte:

- dauerhaft eingebaute Hubtische, die eine Kabine besitzen und festgelegte Ebenen eines Gebäudes anfahren;

- dauerhaft eingebaute Hubtische mit einem vertikalen Hub über 2,0 m, die keine Kabine besitzen und festgelegte Ebenen eines Gebäudes anfahren;

- kraftbetriebene Hubplattformen für Behinderte;

- Hubtische als Bodengeräte der Luftfahrt;

- Hubtische für die Verwendung auf Schiffen;

- fahrbare Hubarbeitsbühnen;

- Fahrzeug-Hebebühnen für die Instandhaltung;

- fahrbare Hubtische zur Feuerbekämpfung;

- fahrbare Hubtische, die als Gabelstapler, Gabelhubwagen und Kommissionierhubwagen verwendet werden;

- fahrbare Hubwagen mit mehr als 1,6 m/s Fahrgeschwindigkeit;

- Regalbediengeräte;

- Versenk- und Hebevorrichtungen von Theaterbühnen."

1.5 Diese Norm berücksichtigt keinen verbrennungsmotorischen Antrieb des Hubtisches.

Diese Norm legt keine zusätzlichen Anforderungen fest für:

- Betrieb unter erschwerten Bedingungen (z. B. extremes Klima, Anwendungen im Gefrierbereich, starke Magnetfelder);

- Betrieb, der besonderen Regelungen unterliegt (z. B. explosive Atmosphäre, Bergwerk);

- (....)

Prescriptions de sécurité des tables élévatrices

1.1 !Le présent document définit les prescriptions de sécurité relatives aux tables élévatrices destinées à lever

et/ou à descendre des charges et/ou des personnes associées au déplacement des charges transportées par la table

élévatrice (c'est-à-dire pas pour le déplacement de passagers), avec une course verticale ne dépassant pas 3,0 m."

1.2 La présente norme européenne traite de tous les phénomènes dangereux significatifs relatifs aux tables

élévatrices utilisées selon les conditions prévues par le fabricant (voir article 4). La présente norme européenne

spécifie les mesures techniques appropriées pour réduire et éliminer les risques émanant des phénomènes

dangereux significatifs.

1.3 Elle vise à la fois les tables élévatrices motorisées et manuelles, qu'elles soient fixes ou mobiles.

1.4 !La présente Norme européenne ne concerne pas les matériels suivants :

- tables élévatrices installées de façon permanente, desservant des niveaux spécifiques d'une construction, et

équipées d'une nacelle ;

- tables élévatrices installées de façon permanente, desservant des niveaux spécifiques d'une construction, non

équipées d'une nacelle mais avec une course verticale de plus de 2,0 m ;

- tables élévatrices motorisées pour les personnes à mobilité réduire ;

- tables élévatrices pour l'équipement au sol des aéroports ;

- tables élévatrices à usage maritime ;

- plates-formes de travail élévatrices mobiles ;

- élévateurs de véhicules pour la maintenance ;

- tables élévatrices mobiles utilisées pour lutter contre les incendies ;

- tables élévatrices mobiles utilisées comme chariots élévateurs à fourche, chariots à palettes et préparateurs de

commande ;

- tables élévatrices mobiles dont la vitesse de translation est supérieure à 1,6 m/s ;

- transtockeur ;

- ascenseurs/élévateurs de théâtre."

Varnostne zahteve za dvižne mize

Ta dokument določa varnostne zahteve za dvižne mize za dvigovanje in/ali spuščanje blaga in/ali oseb, povezanih s premikom blaga, ki ga dvižna miza prenaša (tj. ne za potnike), za navpični hod do 3,0 m. Ta evropski standard obravnava vse velike nevarnosti, ki se nanašajo na dvižne mize, kadar se namensko uporabljajo, in pod pogoji, ki jih je predvidel proizvajalec (glej Klavzulo 4). Ta evropski standard določa primerne tehnične ukrepe za odpravo ali zmanjšanje tveganj, ki se pojavijo zaradi znatnih nevarnosti. Gnane in ročno vodene mize so vključene, tako nepremične kot premične. Ta dokument ne velja za naslednjo opremo: stalno nameščene dvižne mize, ki služijo določenim nivojem zgradbe in so opremljene za avtomobile; stalno nameščene dvižne mize, ki služijo določenim nivojem zgradbe in niso opremljene za avtomobile, ampak z navpičnim hodom večjim od 2,0 m; gnano vodene dvižne ploščadi za osebe, ki imajo težave z gibanjem; dvižne mize za opremo na letališču; dvižne mize za uporabo v pomorstvu; EN 1570:1998+A2:2009 (E) 6 premične dvižne delovne ploščadi; dvigovanje vozil za vzdrževanje; premične dvižne mize uporabljene pri gašenju požarov; premične dvižne mize uporabljene kot viličarji, vozički za premeščanje palet in ostali pobiralniki; premične dvižne mize s potovalno hitrostjo višjo od 1,6 m/s; oprema za shranjevanje ali razkladanje, ki je odvisna od tirov; dvigala gledaliških odrov. Ta standard ne obravnava napajalne enote dvižne mize z motorjem z notranjim zgorevanjem. Ta standard ne določa dodatnih zahtev za: delovanje v skrajnih pogojih (npr. ekstremna podnebja, uporaba v zamrzovalnikih, močnih elektromagnetnih poljih); delovanje ob upoštevanju posebnih pravil (npr. potencialno eksplozivne atmosfere, rudniki); ravnanje z bremeni, katerih lastnosti bi lahko privedle do nevarnih situacij (npr. staljena kovina, kisline, sevalni materiali, posebno krhka bremena); nevarnosti, ki se lahko pripetijo med postavitvijo, transportom ali odstranjevanjem; nameščanje opreme na nakladalni ploščadi ali njena zamenjava; povezovanje v sisteme drugih strojev, upravljanje iz več kot ene kontrolne postaje itd.; brezžične kontrole; dvižne mize, kjer hidravlični pritisk izvira neposredno iz plinskega tlaka.

General Information

- Status

- Withdrawn

- Publication Date

- 14-Jul-2009

- Withdrawal Date

- 25-Oct-2011

- Technical Committee

- CEN/TC 98 - Lifting platforms

- Drafting Committee

- CEN/TC 98/WG 2 - Lifting tables

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 26-Oct-2011

- Completion Date

- 26-Oct-2011

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 309, C 309, C 309, C 309, C 309, C 309, C 309, C OJ Date: 18-Dec-2009

Not Harmonized98/37/EC - Machinery

Relations

- Effective Date

- 19-Sep-2009

- Effective Date

- 30-May-2009

- Effective Date

- 15-Aug-2009

Frequently Asked Questions

EN 1570:1998+A2:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety requirements for lifting tables". This standard covers: 1.1 This document specifies the safety requirements for lifting tables for raising and/or lowering goods and/or persons associated with the movement of goods carried by the lifting table (i.e. not for passenger use), for a vertical travel of up to 3,0 m. 1.2 This European Standard deals with all significant hazards pertinent to lifting tables when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). This European Standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards. 1.3 Both power operated and manually operated lifting tables are included whether stationary or mobile. 1.4 This document does not apply to the following equipment: - permanently installed lifting tables, serving specific levels of a building and fitted with a car; - permanently installed lifting tables, serving specific levels of a building, not fitted with a car but with a vertical travel of more than 2,0 m; - power operated lifting platforms for persons with impaired mobility; - lifting tables for airport ground equipment; - lifting tables for marine use; - mobile elevating work platforms; - vehicle lifts for maintenance; - mobile lifting tables used for fire fighting; - mobile lifting tables used as fork lift trucks, pallet trucks and order pickers; - mobile lifting tables with a travelling speed of more than 1,6 m/s; - rail dependent storage and retrieval equipment; - theatre stage lifts. 1.5 This standard does not consider the Power Supply to the lifting table by Internal Combustion Engine. This standard does not establish the additional requirements for: - Operation in severe conditions (e.g. extreme climates, freezer applications, strong magnetic fields); - Operation subject to special rules (e.g. potentially explosive atmospheres, mines); - Handling of loads, the nature of which could lead to dangerous situations (e.g. molten metal, acids, radiating materials, esp

1.1 This document specifies the safety requirements for lifting tables for raising and/or lowering goods and/or persons associated with the movement of goods carried by the lifting table (i.e. not for passenger use), for a vertical travel of up to 3,0 m. 1.2 This European Standard deals with all significant hazards pertinent to lifting tables when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). This European Standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards. 1.3 Both power operated and manually operated lifting tables are included whether stationary or mobile. 1.4 This document does not apply to the following equipment: - permanently installed lifting tables, serving specific levels of a building and fitted with a car; - permanently installed lifting tables, serving specific levels of a building, not fitted with a car but with a vertical travel of more than 2,0 m; - power operated lifting platforms for persons with impaired mobility; - lifting tables for airport ground equipment; - lifting tables for marine use; - mobile elevating work platforms; - vehicle lifts for maintenance; - mobile lifting tables used for fire fighting; - mobile lifting tables used as fork lift trucks, pallet trucks and order pickers; - mobile lifting tables with a travelling speed of more than 1,6 m/s; - rail dependent storage and retrieval equipment; - theatre stage lifts. 1.5 This standard does not consider the Power Supply to the lifting table by Internal Combustion Engine. This standard does not establish the additional requirements for: - Operation in severe conditions (e.g. extreme climates, freezer applications, strong magnetic fields); - Operation subject to special rules (e.g. potentially explosive atmospheres, mines); - Handling of loads, the nature of which could lead to dangerous situations (e.g. molten metal, acids, radiating materials, esp

EN 1570:1998+A2:2009 is classified under the following ICS (International Classification for Standards) categories: 53.020.99 - Other lifting equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1570:1998+A2:2009 has the following relationships with other standards: It is inter standard links to EN 1570:1998/A1:2004, EN 1570:1998, EN 1570-1:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1570:1998+A2:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1570:1998+A2:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Varnostne zahteve za dvižne mizeSicherheitsanforderungen an HubtischePrescriptions de sécurité des tables élévatricesSafety requirements for lifting tables53.020.99Druga dvigalna opremaOther lifting equipmentICS:Ta slovenski standard je istoveten z:EN 1570:1998+A2:2009SIST EN 1570:1999+A2:2010en,fr,de01-februar-2010SIST EN 1570:1999+A2:2010SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1570:1998+A2

July 2009 ICS 53.020.99 Supersedes EN 1570:1998English Version

Safety requirements for lifting tables

Prescriptions de sécurité des tables élévatrices

Sicherheitsanforderungen an Hubtische This European Standard was approved by CEN on 7 May 1998 and includes Amendment 1 approved by CEN on 7 June 2004 and Amendment 2 approved by CEN on 19 June 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1570:1998+A2:2009: ESIST EN 1570:1999+A2:2010

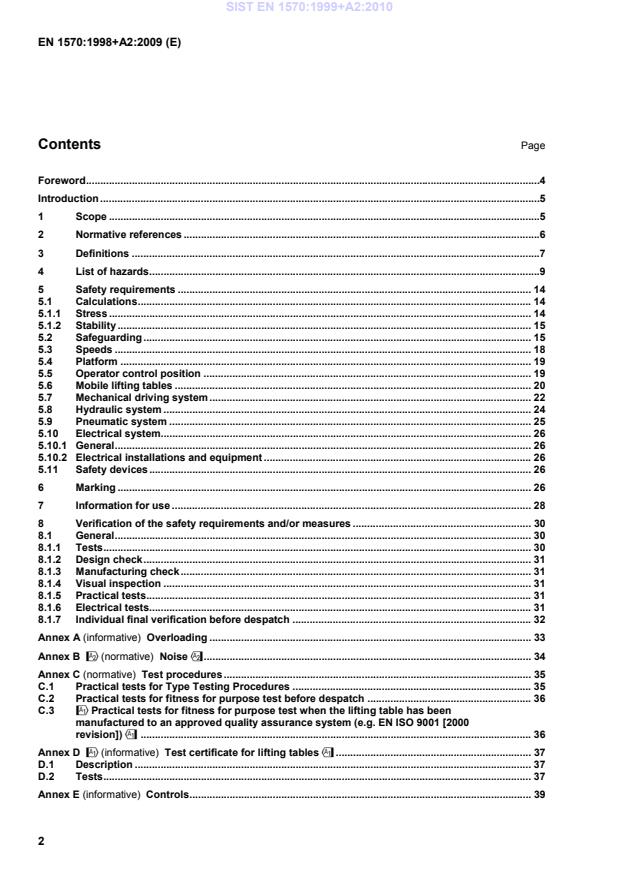

Overloading . 33Annex B #(normative)

Noise$ . 34Annex C (normative)

Test procedures . 35C.1 Practical tests for Type Testing Procedures . 35C.2 Practical tests for fitness for purpose test before despatch . 36C.3 !Practical tests for fitness for purpose test when the lifting table has been manufactured to an approved quality assurance system (e.g. EN ISO 9001 [2000 revision])" . 36Annex D !(informative)

Test certificate for lifting tables" . 37D.1 Description . 37D.2 Tests . 37Annex E (informative)

Controls . 39SIST EN 1570:1999+A2:2010

Manual force measurement methods . 42F.1 Maximum allowed forces for mobile lifting tables . 42F.2 Conditions for test . 42F.3 Measurement of starting force and rolling force . 42F.4 Starting force . 42F.5 Rolling force . 42F.6 Average forces . 42F.7 !Hand or foot forces . 43Annex ZA (informative)

#Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC$ . 44Annex ZB (informative)

#Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC$ . 45

# $. This European Standard has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association, and supports essential requirements of EU Directive(s). #For relationship with EU Directive(s), see informative Annexes ZA and ZB, which are integral parts of this document.$ Normative annexes C and D give Test procedure. #deleted text$ According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

Machine parts or work pieces, e.g.:

a) shape; 5.2.1, 5.2.8 b) relative location 5.2.8 c) mass and stability (potential energy of elements whichmay move under the effect of gravity); 5.1.1.7 d) mass and velocity (kinetic energy of elements in controlled and uncontrolled motion; 5.1.1.6 e) inadequacy of mechanical strength. 5.1 accumulation of energy inside the machinery, e.g.:

f) elastic elements (springs); 5.8.10, 5.9.6 g) liquids and gases under pressure; 5.8, 5.9 h) the effect of vacuum Not applicable 1.1 Crushing hazard 5.2.1/2/3/4/6 1.2 Shearing hazard 5.2.1/2/3/4/6 1.3 Cutting or severing hazard 5.2.8 1.4 Entanglement hazard 5.2.9 1.5 Drawing-in or trapping hazard 5.2.10 1.6 Impact hazard 5.2.11 1.7 Stabbing or puncture hazard Not applicable 1.8 Friction or abrasion hazard Not significant 1.9 High pressure fluid injection or ejection hazard 5.8.3

2.1 Contact of persons with live parts (direct contact) 5.10.1 2.2 Contact of persons with parts which have become live under faulty conditions (indirect contact) 5.10.1/2 2.3 Approach to live parts under high voltage 5.10.1/2 2.4 Electrostatic phenomena Not applicable 2.5 Thermal radiation or other phenomena such as the projection of molten particles and chemical effects from short circuits, overloads, etc. Not applicable 3 Thermal hazards, resulting in:

3.1 Burns, scalds and other injuries by a possible contact of persons with objects or materials with an extreme high or low temperature, by flames or explosions and also by the radiation of heat sources 5.2.16 3.2 Damage to health by hot or cold working environment Not applicable 4 Hazards generated by noise, resulting in #Annex B$ 4.1 Hearing loss (deafness), other physiological disorders (e.g. loss of balance, loss of awareness) Not applicable 4.2 Interference with speech communication, acoustic signals, etc. Not applicable 5 Hazards generated by vibration

5.1 Use of hand-held machines resulting in a variety of neurological and vascular disorders Not applicable 5.2 Whole body vibration, particularly when combined with poor postures Not applicable 6 Hazards generated by radiation

6.1 Low frequency, radio frequency radiation, micro waves Not applicable 6.2 Infrared, visible and ultraviolet light Not applicable 6.3 X and gamma rays Not applicable 6.4 Alpha, beta rays, electron or ion beams, neutrons Not applicable 6.5 Lasers Not applicable 7 Hazards generated by materials and substances (and their constituent element) processed or used by the machinery 5.8.2/3, 7.2.3 7.1 Hazards from contact with or inhalation of harmful fluids, gases, mists, fumes, and dusts 5.8.2/3, 7.2.3 7.2 Fire or explosion hazard Not significant 7.3 Biological or microbiological (viral or bacterial) hazards Not applicable 8 Hazards generated by neglecting ergonomic principles in machinery design as, e.g. hazards from: 5.6.4, 5.6.11,

5.8.11 8.1 Unhealthy postures or excessive effort 5.6.4, 5.6.11, 5.8.11 8.2 Inadequate consideration of hand-arm or foot-leg anatomy 5.2.1/2 8.3 Neglected use of personal protection of equipment

Not applicable 8.4 Inadequate local lighting Introduction SIST EN 1570:1999+A2:2010

10.1 Failure/disorder of the control system 5.10.1 10.2 Restoration of energy supply after an interruption 5.10.1 10.3 External influences on electrical equipment 5.10.1 10.4 Other external influences (gravity, wind, etc.)

5.5.3/4/5 10.5 Errors in the software Not dealt with 10.6 Errors made by the operator (due to mismatch of machinery with human characteristics and abilities, see 8.6) 5.5.3/4/5/6 11 Impossibility of stopping the machine in the best possible conditions 5.5.7 12 Variations in the rotational speed of tools Not applicable 13 Failure of the power supply 5.10.1 14 Failure of the control circuit 5.10.1 15 Errors of fitting 7.3 16 Break up during operation 5.1.1, 5.7.5, 5.8.7, 5.9.7, 7.1, 7.2 17 Falling or ejected objects or fluids 5.8.1/2/3/4, 5.9.1/2/3/4, 5.2.13/14, 7.1 18 Loss of stability / overturning of machinery 5.1.2 19 Slip, trip and fall of persons (related to machinery) 5.2.13/14, 5.4.1, 5.2.17 Additional Hazards, hazardous situations and hazardous events due to mobility 20 Relating to the travelling function

20.1 Movement when starting the engine 5.6.3 20.2 Movement without a driver at the driving position

5.6.2 20.3 Movement without all parts in safe position 5.2.19, 5.3.2 20.4 Excessive speed of pedestrian controlled machinery 5.3.2 20.5 Excessive oscillations when moving 5.3.3 20.6 Insufficient ability of machinery to be slowed down, stopped and immobilised 5.6.2, 5.6.5, 5.6.8 SIST EN 1570:1999+A2:2010

21.1 Fall of persons during access to (or at/from) the work position Not dealt with 21.2 Exhaust gases/lack of oxygen at the work position Not dealt with 21.3 Fire (flammability of the cab, lack of extinguishing means) Not dealt with 21.4 Mechanical hazards at the work position:

i) Contact with the wheels; 5.6.5 j) Rollover; 5.1.2.1 k) Fall of objects, penetration by objects; 5.2.13/14 l) Break-up of parts rotating at high speed; Not dealt with m) Contact of persons with machine parts or tools (pedestrian controlled machines). 5.2.11 21.5 Insufficient visibility from the work positions 5.5.1 21.6 Inadequate lighting Introduction 21.7 Inadequate seating Not applicable 21.8 Noise at work position Annex B Not dealt with 21.9 Vibration at the work position Not applicable 21.10 Insufficient means for evacuation/emergency exit Not applicable 22 Due to control system

22.1 Inadequate location of manual controls

5.5.1 22.2 Inadequate design of manual controls and their mode of operation 5.5.3/4/5, 5.6.2 23 From handling the machine (lack of stability) 7.1 24 Due to the power source and to the transmission of power

24.1 Hazards from the engine and the batteries Not applicable 24.2 Hazards from transmission of power between machines Not applicable 24.3 Hazards from coupling and towing 5.6.7 25 From/to third persons

25.1 Unauthorised start-up/use 5.5.3 25.2 Drift of a part away from its stopping position

5.5.2, 5.6.1/2/3 25.3 Lack or inadequacy of visual or acoustic warning means 5.2.11 26 Insufficient instructions for the driver/operator 7.1, Introduction Additional hazards, hazardous situations and hazardous events due to lifting 27 Mechanical hazards and hazardous events

27.1 from load falls, collisions, machine tipping caused by:

27.1.1 lack of stability 5.1.2.1

28.1 from lightning Not applicable 29 Hazards generated by neglecting ergonomic principles

29.1 insufficient visibility from the driving position 5.2.15, 5.5.1 Additional hazards, hazardous situations and hazardous events due to underground work 30 Mechanical hazards and hazardous events due to:

30.1 lack of stability of powered roof supports Not applicable 30.2 failing accelerator or brake control of machinery running on rails Not applicable 30.3 failing or lack of deadman’s control of machinery running on rails Not applicable 31 Restricted movement of persons Not applicable 32 Fire and explosion Not applicable 33 Emission of dust, gases etc. Not applicable Additional hazards, hazardous situations and hazardous events due to the lifting or moving of persons 34 Mechanical hazards and hazardous events due to:

34.1 inadequate mechanical strength – inadequate working coefficients 5.1 34.2 failing of loading control 5.1.2 34.3 failing of controls in person carrier (function, priority) 5.5.2 34.4 overspeed of person carrier 5.3, 5.7.5, 5.8.7, 5.9.7 35 Falling of person from person carrier 5.2.12/13/14 36 Falling or overturning of person carrier 5.1.2 37 Human error, human behaviour 6.0 " SIST EN 1570:1999+A2:2010

5 Safety requirements 5.1 Calculations 5.1.1 Stress 5.1.1.1 The lifting table shall be designed in accordance with usual calculation codes and good engineering practice and all failure modes of the material shall be considered including fatigue failure. 5.1.1.2 The stresses in any part of the lifting table, using the permissible stress method, under normal working conditions, shall not exceed the following: a) 0,66 times the yield stress of the material used; b) 0,50 times the ultimate tensile stress of the material used. 5.1.1.3 The stresses shall be calculated for the condition of the lifting table carrying its rated load and being used in accordance with the manufacturer's instructions. The loads shall include all actual static and dynamic forces both vertical and horizontal, all wind forces, and all forces applied to the platform during loading and unloading. 5.1.1.4 The minimum dynamic forces to be used for the calculations of 5.1.1.3 shall result from: a) the total vertical load (this includes the rated load and the selfweight of the moving parts of the structure) increased by 40 % and; b) 10 % of the rated load taken as acting horizontally at platform level, in the direction causing the maximum stress in the part being considered. If side barriers prevent movement of the load in a particular direction this direction need not be considered. 5.1.1.5 If persons are to be carried on the platform, their load shall be taken as 80 kg, concentrated in an area of 0,2 m by 0,2 m for each person, spaced apart at 0,5 m centre to centre and placed in the most unfavourable position on the platform for stress calculations. 5.1.1.6 It shall be possible for the forces produced when the safety device is operated, to be accepted without permanent deformation of the normal load bearing parts, when used in accordance with the manufacturer’s instructions. 5.1.1.7

Every lifting table shall also be designed to at least: 1) in one case lift half the rated load distributed over half the length of the platform; 2) and in another case lift one third of the rated load distributed over half the width of the platform. In neither case shall hazardous tilting or deflection take place when used as intended by the manufacturer. SIST EN 1570:1999+A2:2010

25 mm; for toes

50 mm; for hands

100 mm; for arms and closed hands

120 mm; for feet

120 mm; for the body

500 mm. 5.2.2 As an alternative to these minimum gaps other safety measures shall be taken to avoid the operator or any other persons being endangered e.g. Screen; Barriers; Deflectors; Non-mechanically actuated trip device complying with prEN 50100; Mechanically actuated trip device complying with category 1 of #EN 954-1:1996$; SIST EN 1570:1999+A2:2010

Figure 1 — Gaps between lifting table arms and base 5.2.3 !In scissor type lifts the minimum safety gaps between the scissor legs and the outer scissor leg and the base frame shall be as shown in Figure 1." 5.2.4 When lowering a minimum of free space for the feet shall be provided in accordance with figure 2 to prevent crushing and shearing of feet. Dimensions in millimetres

Figure 2 — Minimum foot clearances when lowering 5.2.5 Where the machine is totally enclosed by the manufacturer with an imperforate rigid guard or is “safe by position” the minimum gaps given in 5.2.1 are not necessary. If the machine is only partly enclosed by an imperforate rigid guard, then these gaps or an acceptable alternative (in accordance with clause 5.2.2), shall be provided in the parts of the machine not enclosed. If a perforate rigid guard is used then this shall comply with the requirements of standards EN 294 and EN 811. 5.2.6 If a mechanically actuated trip device is fitted to the outer edges of the platform then it is necessary to maintain only the minimum gaps for fingers inside the area safeguarded by the device. The outer surface of the device shall be not more than 8 mm from the outer edge of the platform as shown in figure 3. SIST EN 1570:1999+A2:2010

Figure 3 — Arrangement of mechanically actuated trip device 5.2.7 Safety devices shall operate so that the moving part causing the hazard comes to a stop before injury is caused. They shall not create another hazard. Where a mechanically actuated trip device (e.g. hanging or pivoted trip bar) is fitted to the underside of the platform, the trip device when actuated shall stop all movement of the platform downwards and hold it stopped until the Down control has been released, the obstruction removed, the device reset (either manually or automatically) and the down control re-operated. It shall always be possible to raise the platform in order to clear the obstruction. 5.2.8 All moving parts and parts which pass each other or fixed structures, and which persons may contact, shall have no sharp edges, no sharp angles and no rough surfaces. 5.2.9 All moving parts that could entangle a person or their clothing shall be avoided by design or where this is not possible they shall be guarded. 5.2.10 All nip points (belts, chains, ropes passing over pulleys flexible couplings, elements of telescopic guides, etc) shall be safeguarded to prevent drawing-in or injury to any persons. Care shall be taken that the guard itself does not form a hazard. 5.2.11 !Self-propelled lifting tables that are manually controlled shall be fitted with an audible warning device controlled from the operating position. If the automatically controlled lifting table is intended to be used in an area from which persons are not excluded, persons shall be automatically protected from impact of the lifting table (e.g. by pressure sensitive buffers or photo-electric devices) and an acoustic and/or visual warning device (e.g. flashing lamp) shall operate whenever movement takes place." 5.2.12 Lifting tables which have a fixed control point on the platform, shall have at least one standing place with an area of 0,5 m by 0,6 m, with a secure handhold for the operator. If outward opening gates are fitted they shall be automatically interlocked (e.g. electrically, pneumatically) with the control system of the vertical travel of the platform (interlocks shall be in accordance with EN 1088). 5.2.13 All lifting tables that have a vertical travel of more than 2,0 m shall be fitted with means to prevent persons or goods falling from the platform. 5.2.14 For persons these means shall, as a minimum, consist of guard-rails at least 1,1 m high, toeguards at 0,15 m high and intermediate guard-rails not further than 0,5 m from either the guard-rail or toeguards. If gates or opening parts of the barrier are fitted, they shall be interlocked with the control system so that the platform can be moved only when the barrier is closed. Furthermore outward opening parts shall be interlocked in such a way that these parts can only be opened when the platform is in a clearly defined access position. SIST EN 1570:1999+A2:2010

1,6 m/s, when travelling with the platform fully lowered, but shall also be capable of having their speed reduced to 1,1 m/s, by the operator. The horizontal travelling speed of “ride-on” self-propelled lifting tables shall not exceed 1,6 m/s, when travelling with the platform fully lowered. When the platform is not fully lowered the travelling speed shall be automatically limited to not more than

0,6 m/s, except where the platform is “safe by position”. SIST EN 1570:1999+A2:2010

Where the platform surface, or part of it (e.g. a turntable), can rotate, and it can be walked on at bottom level, an arrangement shall be present which prevents unintentional rotation when lowered. 5.5 Operator control position 5.5.1 The operator’s position shall give the operator a clear view of the hazardous parts of the platform and its load at all times throughout its vertical movement (see 5.2.15). If the operator’s position is not determined by the manufacturer, see clause 7. In the case of self-propelled lifting tables the operator shall have a clear view of the horizontal travel of the lifting table.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...