EN 1570-1:2011

(Main)Safety requirements for lifting tables - Part 1: Lifting tables serving up to two fixed landings

Safety requirements for lifting tables - Part 1: Lifting tables serving up to two fixed landings

1.1 This European Standard specifies the safety requirements for industrial lifting tables for raising and/or lowering goods and the operator(s):

- where the lifting table does not pass a fixed landing;

- serving not more than 2 fixed landings.

1.2 This European Standard deals with all significant hazards pertinent to lifting tables when they are used as intended by the operating instructions and under the conditions foreseen (including foreseeable misuse) with the operating instructions (see Clause 4). This European Standard specifies the appropriate technical measures to eliminate or reduce the risks arising from the significant hazards.

1.3 Both power operated and manually operated lifting tables are included whether stationary or mobile.

1.4 This European Standard does not apply to the following equipment:

- lifting tables, serving more than 2 fixed landings of a building, for lifting goods with a vertical travel speed not exceeding 0,15 m/s (EN 1570-2);

- lifting tables, serving more than 2 fixed landings of a building for lifting operators, with a vertical travel speed not exceeding 0,15 m/s (EN 1570-3);

- lifting tables carrying operators and installed in full enclosures (EN 1570-3);

- permanently and temporarily installed lifting tables, serving specific levels of a building for lifting operators, with a vertical travel speed exceeding 0,15 m/s (EN 81-1 and EN 81-2);

- lifting tables with flat or toothed belts lifting systems for the carrying of operators;

- lifting tables whose vertical travel speed exceeds 0,15 m/s (unless safe by position and non person carrying);

- power operated lifting platforms for persons with impaired mobility (EN 81-41);

- mobile lifting tables for airport ground support equipment (EN 1915-2 and EN 12312 1);

- lifting tables which are designed as part of a lift according to Directive (95/16/EC);

- lifting tables used on ships;

- lifting tables with flat or toothed belt drives intended to lift persons;

- mobile elevating work platforms (EN 280);

- static elevating work platforms;

- vehicle lifts for maintenance (EN 1493);

- mobile lifting tables used for fire fighting (EN 1777);

- mobile lifting tables used as fork lift trucks and order pickers;

- mobile lifting tables with a horizontal travelling speed of more than 1,6 m/s;

- rail dependent storage and retrieval equipment (EN 528);

- theatre stage lifts intended to move performers;

- scissor lift pallet trucks (EN ISO 3691-5);

- suspended lifting tables;

- lifting tables operated by pushing chains.

1.5 This standard does not establish the additional requirements for:

- electromagnetic compatibility;

- operation in severe conditions (e.g. extreme climates, freezer applications, strong magnetic fields);

- operation subject to special rules (e.g. potentially explosive atmospheres, mines);

- handling of loads, the nature of which could lead to dangerous situations (e.g. molten metal, acids, radiating materials, especially brittle loads);

- hazards occurring during construction, transportation and disposal;

- equipment installed on the load platform or replacing it;

- integration into systems or other machines, control from more than two control stations, etc.;

- cable-less controls;

- lifting tables where the hydraulic pressure is derived directly from gas pressure;

- the power supply to the lifting table by internal combustion engine.

Sicherheitsanforderungen an Hubtische - Teil 1: Hubtische, die bis zu zwei feste Haltestellen anfahren

Diese Europäische Norm beschreibt Sicherheitsanforderungen für Industriehubtische zum Heben

und/oder Senken von Gütern und Bedienpersonen:

⎯ wobei der Hubtisch keine feste Haltestelle durchfährt;

⎯ wobei nicht mehr als 2 feste Haltestellen angefahren werden.

1.2 Diese Europäische Norm behandelt alle von Hubtischen ausgehenden signifikanten Gefährdungen,

wenn diese bestimmungsgemäß nach der Bedienungsanleitung und unter den darin vorgesehenen

Bedingungen (einschließlich vorhersehbarer Fehlanwendung) benutzt werden (siehe Abschnitt 4). Diese

Europäische Norm beschreibt die geeigneten technischen Maßnahmen zur Vermeidung oder Verminderung

der Risiken, die sich aus den zutreffenden Gefährdungen ergeben.

1.3 Sowohl kraftbetriebene als auch handbetriebene Hubtische, die ortsfest oder ortsveränderlich sein

können, werden erfasst.

1.4 Diese Europäische Norm findet keine Anwendung auf folgende Geräte:

⎯ Hubtische zum Heben von Gütern, die mehr als 2 Haltestellen eines Gebäudes anfahren und deren

Hubgeschwindigkeit 0,15 m/s (EN 1570-2) nicht überschreitet;

⎯ Hubtische zum Heben von Bedienungspersonen, die mehr als 2 Haltestellen eines Gebäudes anfahren

und deren Hubgeschwindigkeit 0,15 m/s (EN 1570-3) nicht überschreitet;

⎯ Hubtische zum Tragen von Bedienungspersonen mit einer vollständig eingebauten Einhausung

(EN 1570-3);

⎯ Dauerhaft und vorübergehend eingebaute Hubtische, die festgelegte Ebenen eines Gebäudes zum

Transportieren von Bedienpersonen anfahren, mit einer vertikalen Hubgeschwindigkeit, die 0,15 m/s

(EN 81-1 und EN 81-2) überschreitet;

⎯ Hubtische mit Flach- oder Zahnriemenantrieb zum Heben von Bedienpersonen;

⎯ Hubtische, deren Hubgeschwindigkeit 0,15 m/s überschreitet (es sei denn der Hubtisch ist sicher durch

die Einbauposition und es werden keine Personen transportiert);

⎯ Kraftbetriebene Hubplattformen für Behinderte (EN 81-41);

⎯ Fahrbare Hubtische als Flughafenbodengeräte (EN 1915-2 und EN 12312-1);

⎯ Hubtische, die als Teil eines Aufzuges nach der Aufzugsrichtlinie (95/16/EG) ausgelegt werden;

⎯ Hubtische für die Verwendung auf Schiffen;

⎯ Fahrbare Hubarbeitsbühnen (EN 280);

⎯ Feststehende Hubarbeitsbühnen;

⎯ Fahrzeughebebühnen für die Instandhaltung (EN 1493);

⎯ Fahrbare Hubtische zur Feuerbekämpfung (EN 1777);

⎯ Fahrbare Hubtische, die als Gabelstapler und Kommissionierhubwagen verwendet werden;

⎯ Fahrbare Hubtische mit einer horizontalen Fahrgeschwindigkeit von mehr als 1,6 m/s;

Prescriptions de sécurité des tables élévatrices - Partie 1: Tables élévatrices desservant jusqu’à 2 niveaux définis

1.1 La présente Norme européenne spécifie les prescriptions de sécurité applicables aux tables élévatrices

industrielles utilisées pour monter et/ou descendre des marchandises et des opérateurs :

- lorsque la table élévatrice ne traverse pas un palier fixe ;

- lorsqu’elle dessert au maximum deux paliers fixes.

1.2 La présente Norme européenne traite de tous les phénomènes dangereux significatifs relatifs aux

tables élévatrices utilisées comme prévu dans les instructions d’utilisation et dans les conditions prévues (y

compris un mauvais usage prévisible) par les instructions d’utilisation (voir l’Article 4). La présente Norme

européenne spécifie les mesures techniques appropriées pour éliminer ou réduire les risques émanant des

phénomènes dangereux significatifs.

1.3 Elle vise à la fois les tables élévatrices motorisées et manuelles, qu’elles soient fixes ou mobiles.

1.4 La présente Norme européenne ne concerne pas les matériels suivants :

- les tables élévatrices desservant plus de deux paliers fixes d’un bâtiment, utilisées pour transporter des

marchandises, et dont la vitesse de déplacement vertical ne dépasse pas 0,15 m/s (EN 1570-2) ;

- les tables élévatrices desservant plus de deux paliers fixes d’un bâtiment, utilisées pour transporter des

opérateurs, et dont la vitesse de déplacement vertical ne dépasse pas 0,15 m/s (EN 1570-3) ;

- les tables élévatrices transportant des opérateurs et installées dans des enceintes closes (EN 1570-3) ;

- les tables élévatrices installées de manière permanente ou provisoire, desservant des niveaux

spécifiques d’un bâtiment pour transporter des opérateurs, et dont la vitesse de déplacement vertical est

supérieure à 0,15 m/s (EN 81-1 et EN 81-2) ;

- les tables élévatrices avec des systèmes de levage par courroie crantée ou plate utilisés pour transporter

des opérateurs ;

- les tables élévatrices dont la vitesse de déplacement vertical est supérieure à 0,15 m/s (sauf si elles sont

sûres de par leur position et ne transportent pas de personnes) ;

- les plates-formes élévatrices motorisées à l’usage des personnes à mobilité réduite (EN 81-41) ;

- les tables élévatrices mobiles destinées au matériel au sol pour aéronefs (EN 1915-2 et EN 12312-1) ;

- les tables élévatrices conçues pour faire partie d’un ascenseur en vertu de la Directive (95/16/CE) ;

- les tables élévatrices utilisées à bord de navires ;

- les plates-formes de travail élévatrices mobiles (EN 280) ;

- les plates-formes de travail élévatrices fixes ;

- les élévateurs de véhicules pour la maintenance (EN 1493) ;

- les tables élévatrices mobiles utilisées pour lutter contre les incendies (EN 1777) ;

- les tables élévatrices mobiles utilisées comme chariots élévateurs à fourche et préparateurs de

commandes ;

- les tables élévatrices mobiles dont la vitesse de déplacement horizontal est supérieure à 1,6 m/s ;

- les transtockeurs (EN 528) ;

- les ascenseurs de théâtre destinés à déplacer des personnes ;

- les transpalettes à ciseaux (EN ISO 3691-5) ;

- les tables élévatrices suspendues ;

- les tables élévatrices actionnées par des chaînes passeuses.

1.5 La présente norme ne fixe pas de prescriptions supplémentaires concernant :

- la compatibilité électromagnétique ;

- l’utilisation dans les conditions sévères (par exemple, climats extrêmes, applications dans les chambres

froides, champs magnétiques élevés) ;

- l’utilisation soumise à des règles spéciales (par exemple, atmosphères potentiellement explosives,

mines) ;

- la manutention de charges dont la nature pourrait engendrer des situations dangereuses (par exemple,

métal fondu, acides, matériaux rayonnants, charges particulièrement fragiles) ;

(...)

Varnostne zahteve za dvižne mize - 1. del: Dvižne mize za dvigovanje do dveh stalnih nivojev

Ta evropski standard določa varnostne zahteve za industrijske dvižne mize za dvigovanje in/ali spuščanje blaga in upravljavcev: pri čemer dvižna miza ne gre mimo stalnega nivoja in se uporablja za največ dva stalna nivoja. Ta evropski standard obravnava vse pomembne nevarnosti, ki se nanašajo na dvižne mize, kadar se uporabljajo kot predvideno in pod pogoji (vključno s predvidljivo napačno uporabo), ki so predvideni v navodilih za uporabo (glej točko 4). Ta evropski standard določa primerne tehnične ukrepe za odpravo ali zmanjšanje tveganj, ki se pojavijo zaradi pomembnih nevarnosti. Vključene so gnane in ročno vodene dvižne mize, nepremične in premične.

General Information

- Status

- Withdrawn

- Publication Date

- 25-Oct-2011

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 98 - Lifting platforms

- Drafting Committee

- CEN/TC 98/WG 2 - Lifting tables

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 01-Oct-2014

- Completion Date

- 11-Feb-2026

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 15-Aug-2009

- Effective Date

- 30-Jul-2014

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Frequently Asked Questions

EN 1570-1:2011 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety requirements for lifting tables - Part 1: Lifting tables serving up to two fixed landings". This standard covers: 1.1 This European Standard specifies the safety requirements for industrial lifting tables for raising and/or lowering goods and the operator(s): - where the lifting table does not pass a fixed landing; - serving not more than 2 fixed landings. 1.2 This European Standard deals with all significant hazards pertinent to lifting tables when they are used as intended by the operating instructions and under the conditions foreseen (including foreseeable misuse) with the operating instructions (see Clause 4). This European Standard specifies the appropriate technical measures to eliminate or reduce the risks arising from the significant hazards. 1.3 Both power operated and manually operated lifting tables are included whether stationary or mobile. 1.4 This European Standard does not apply to the following equipment: - lifting tables, serving more than 2 fixed landings of a building, for lifting goods with a vertical travel speed not exceeding 0,15 m/s (EN 1570-2); - lifting tables, serving more than 2 fixed landings of a building for lifting operators, with a vertical travel speed not exceeding 0,15 m/s (EN 1570-3); - lifting tables carrying operators and installed in full enclosures (EN 1570-3); - permanently and temporarily installed lifting tables, serving specific levels of a building for lifting operators, with a vertical travel speed exceeding 0,15 m/s (EN 81-1 and EN 81-2); - lifting tables with flat or toothed belts lifting systems for the carrying of operators; - lifting tables whose vertical travel speed exceeds 0,15 m/s (unless safe by position and non person carrying); - power operated lifting platforms for persons with impaired mobility (EN 81-41); - mobile lifting tables for airport ground support equipment (EN 1915-2 and EN 12312 1); - lifting tables which are designed as part of a lift according to Directive (95/16/EC); - lifting tables used on ships; - lifting tables with flat or toothed belt drives intended to lift persons; - mobile elevating work platforms (EN 280); - static elevating work platforms; - vehicle lifts for maintenance (EN 1493); - mobile lifting tables used for fire fighting (EN 1777); - mobile lifting tables used as fork lift trucks and order pickers; - mobile lifting tables with a horizontal travelling speed of more than 1,6 m/s; - rail dependent storage and retrieval equipment (EN 528); - theatre stage lifts intended to move performers; - scissor lift pallet trucks (EN ISO 3691-5); - suspended lifting tables; - lifting tables operated by pushing chains. 1.5 This standard does not establish the additional requirements for: - electromagnetic compatibility; - operation in severe conditions (e.g. extreme climates, freezer applications, strong magnetic fields); - operation subject to special rules (e.g. potentially explosive atmospheres, mines); - handling of loads, the nature of which could lead to dangerous situations (e.g. molten metal, acids, radiating materials, especially brittle loads); - hazards occurring during construction, transportation and disposal; - equipment installed on the load platform or replacing it; - integration into systems or other machines, control from more than two control stations, etc.; - cable-less controls; - lifting tables where the hydraulic pressure is derived directly from gas pressure; - the power supply to the lifting table by internal combustion engine.

1.1 This European Standard specifies the safety requirements for industrial lifting tables for raising and/or lowering goods and the operator(s): - where the lifting table does not pass a fixed landing; - serving not more than 2 fixed landings. 1.2 This European Standard deals with all significant hazards pertinent to lifting tables when they are used as intended by the operating instructions and under the conditions foreseen (including foreseeable misuse) with the operating instructions (see Clause 4). This European Standard specifies the appropriate technical measures to eliminate or reduce the risks arising from the significant hazards. 1.3 Both power operated and manually operated lifting tables are included whether stationary or mobile. 1.4 This European Standard does not apply to the following equipment: - lifting tables, serving more than 2 fixed landings of a building, for lifting goods with a vertical travel speed not exceeding 0,15 m/s (EN 1570-2); - lifting tables, serving more than 2 fixed landings of a building for lifting operators, with a vertical travel speed not exceeding 0,15 m/s (EN 1570-3); - lifting tables carrying operators and installed in full enclosures (EN 1570-3); - permanently and temporarily installed lifting tables, serving specific levels of a building for lifting operators, with a vertical travel speed exceeding 0,15 m/s (EN 81-1 and EN 81-2); - lifting tables with flat or toothed belts lifting systems for the carrying of operators; - lifting tables whose vertical travel speed exceeds 0,15 m/s (unless safe by position and non person carrying); - power operated lifting platforms for persons with impaired mobility (EN 81-41); - mobile lifting tables for airport ground support equipment (EN 1915-2 and EN 12312 1); - lifting tables which are designed as part of a lift according to Directive (95/16/EC); - lifting tables used on ships; - lifting tables with flat or toothed belt drives intended to lift persons; - mobile elevating work platforms (EN 280); - static elevating work platforms; - vehicle lifts for maintenance (EN 1493); - mobile lifting tables used for fire fighting (EN 1777); - mobile lifting tables used as fork lift trucks and order pickers; - mobile lifting tables with a horizontal travelling speed of more than 1,6 m/s; - rail dependent storage and retrieval equipment (EN 528); - theatre stage lifts intended to move performers; - scissor lift pallet trucks (EN ISO 3691-5); - suspended lifting tables; - lifting tables operated by pushing chains. 1.5 This standard does not establish the additional requirements for: - electromagnetic compatibility; - operation in severe conditions (e.g. extreme climates, freezer applications, strong magnetic fields); - operation subject to special rules (e.g. potentially explosive atmospheres, mines); - handling of loads, the nature of which could lead to dangerous situations (e.g. molten metal, acids, radiating materials, especially brittle loads); - hazards occurring during construction, transportation and disposal; - equipment installed on the load platform or replacing it; - integration into systems or other machines, control from more than two control stations, etc.; - cable-less controls; - lifting tables where the hydraulic pressure is derived directly from gas pressure; - the power supply to the lifting table by internal combustion engine.

EN 1570-1:2011 is classified under the following ICS (International Classification for Standards) categories: 53.020.99 - Other lifting equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1570-1:2011 has the following relationships with other standards: It is inter standard links to EN 1570:1998+A2:2009, EN 1570-1:2011+A1:2014, ISO 4308-2:1988, EN 60529:1991, EN IEC 60947-5-1:2025, EN 61310-2:2008, EN IEC 61496-1:2020, EN 61310-3:2008, CLC/TS 61496-2:2006, EN 60947-5-3:2013, EN 61310-1:2008, EN ISO 13849-1:2008, EN 14504:2016, EN ISO 10960:1996, EN ISO 5366-1:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1570-1:2011 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/008, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1570-1:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Varnostne zahteve za dvižne mize - 1. del: Dvižne mize za dvigovanje do dveh stalnih nivojevSicherheitsanforderungen an Hubtische - Teil 1: Hubtische, die bis zu zwei feste Haltestellen anfahrenPrescriptions de sécurité des tables élévatrices - Partie 1: Tables élévatrices desservant jusqu’à 2 niveaux définisSafety requirements for lifting tables - Part 1: Lifting tables serving up to two fixed landings53.020.99Druga dvigalna opremaOther lifting equipmentICS:Ta slovenski standard je istoveten z:EN 1570-1:2011SIST EN 1570-1:2012en,fr,de01-januar-2012SIST EN 1570-1:2012SLOVENSKI

STANDARDSIST EN 1570:1999+A2:20101DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1570-1

October 2011 ICS 53.020.99 Supersedes EN 1570:1998+A2:2009English Version

Safety requirements for lifting tables - Part 1: Lifting tables serving up to two fixed landings

Prescriptions de sécurité des tables élévatrices - Partie 1: Tables élévatrices desservant jusqu'à 2 niveaux définis

Sicherheitsanforderungen an Hubtische -Teil 1: Hubtische, die bis zu zwei feste Haltestellen anfahren This European Standard was approved by CEN on 17 September 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1570-1:2011: ESIST EN 1570-1:2012

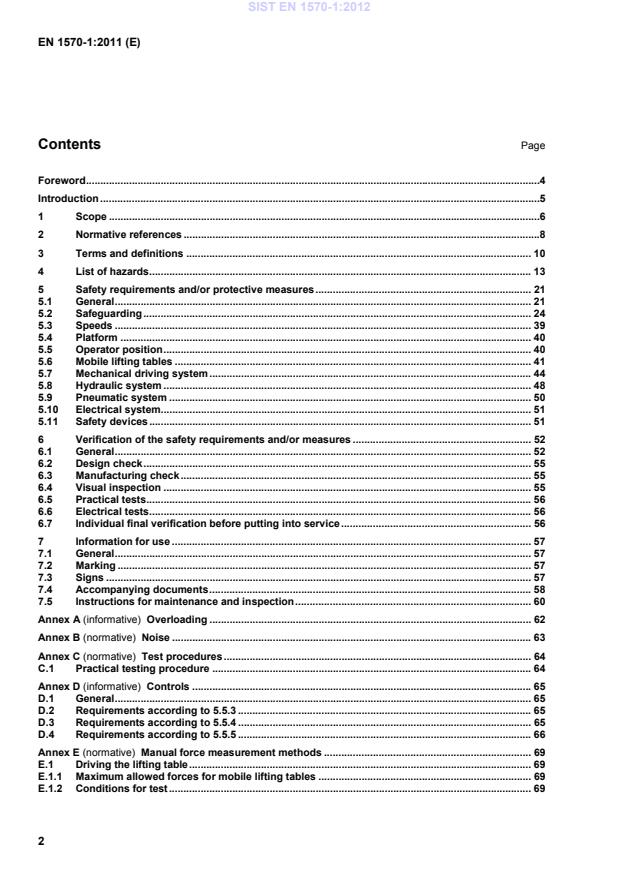

Overloading . 62Annex B (normative)

Noise . 63Annex C (normative)

Test procedures . 64C.1Practical testing procedure . 64Annex D (informative)

Controls . 65D.1General . 65D.2Requirements according to 5.5.3 . 65D.3Requirements according to 5.5.4 . 65D.4Requirements according to 5.5.5 . 66Annex E (normative)

Manual force measurement methods . 69E.1Driving the lifting table . 69E.1.1Maximum allowed forces for mobile lifting tables . 69E.1.2Conditions for test . 69SIST EN 1570-1:2012

Signs . 71Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC . 72Bibliography . 73 SIST EN 1570-1:2012

Part 1 of this standard deals with the protection at landings and safety requirements of lifting tables serving up to two fixed landings. Part 2 will deal with slow lifting tables serving more than 2 fixed landings for accessible only goods lifts and Part 3 will deal with slow lifting tables serving more than 2 fixed landings for operator carrying lifts. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom.

As lifting tables are used in a wide range of applications it is also essential to make individual risk assessments in accordance with EN ISO 12100 for the actual operating conditions. Products sold indirectly to end users should be made for all the risks, which are related to the use and conditions foreseen by the manufacturer, as described in the instruction manual. While producing this standard, it was assumed that: only trained operators using the equipment in accordance with manufacturers instructions operate the lifting tables and that the working area is adequately lit; lifting tables are operating on substantially firm, smooth, even and prepared surfaces. It is not necessary to consider centrifugal forces specifically as the current requirements consider all lateral forces; where there is a special requirement for a low noise level, e.g. hospital applications, theatre applications etc. this will be specified by the customer and appropriate measures taken by the manufacturer. When provisions of this type C standard are different from those which are stated in type A or B standards, the provisions of this type C standard take precedence over the provisions of the other standards, for machines that have been designed and built according to the provisions of this type C standard.

1.4

This European Standard does not apply to the following equipment: lifting tables, serving more than 2 fixed landings of a building, for lifting goods with a vertical travel speed not exceeding 0,15 m/s (EN 1570-2); lifting tables, serving more than 2 fixed landings of a building for lifting operators, with a vertical travel speed not exceeding 0,15 m/s (EN 1570-3); lifting tables carrying operators and installed in full enclosures (EN 1570-3); permanently and temporarily installed lifting tables, serving specific levels of a building for lifting operators, with a vertical travel speed exceeding 0,15 m/s (EN 81-1 and EN 81-2); lifting tables with flat or toothed belts lifting systems for the carrying of operators; lifting tables whose vertical travel speed exceeds 0,15 m/s (unless safe by position and non person carrying); power operated lifting platforms for persons with impaired mobility (EN 81-41); mobile lifting tables for airport ground support equipment (EN 1915-2 and EN 12312-1); lifting tables which are designed as part of a lift according to Directive (95/16/EC);

lifting tables used on ships; mobile elevating work platforms (EN 280); static elevating work platforms; vehicle lifts for maintenance (EN 1493); mobile lifting tables used for fire fighting (EN 1777); mobile lifting tables used as fork lift trucks and order pickers; mobile lifting tables with a horizontal travelling speed of more than 1,6 m/s; rail dependent storage and retrieval equipment (EN 528); SIST EN 1570-1:2012

EN 60204-1:2006, Safety of machinery — Electrical equipment of machines — Part 1: General requirements (IEC 60204-1:2005, modified) EN 60529, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989) EN 60947-5-1, Low-voltage switchgear and control gear — Part 5-1: Control circuit devices and switching elements — Electromechanical control circuit devices (IEC 60947-5-1:2003) EN 60947-5-3, Low-voltage switchgear and control gear — Part 5-3: Control circuit devices and switching elements — Requirements for proximity devices with defined behaviour under fault conditions (PDF) (IEC 60947-5-3:1999) EN 61310-1, Safety of machinery — Indication, marking and actuation — Part 1: Requirements for visual, acoustic and tactile signals (IEC 61310-1:2007) EN 61310-2, Safety of machinery — Indication, marking and actuation — Part 2: Requirements for marking (IEC 61310-2:2007) EN 61310-3, Safety of machinery — Indication, marking and actuation — Part 3: Requirements for the location and operation of actuators (IEC 61310-3:2007) EN 61496-1, Safety of machinery — Electro-sensitive protective equipment — Part 1: General requirements and tests (IEC 61496-1:2004, modified) CLC/TS 61496-2:2006, Safety of machinery — Electro-sensitive protective equipment — Part 2: Particular requirements for equipment using active opto-electronic protective devices (AOPDs) (IEC 61496-2:2006) EN ISO 4413, Hydraulic fluid power — General rules and safety requirements for systems and their components (ISO 4413:2010) EN ISO 4414, Pneumatic fluid power — General rules and safety requirements for systems and their components (ISO 4414:2010) EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk reduction (ISO 12100:2010) EN ISO 13849-1:2008, Safety of machinery — Safety related parts of control systems — Part 1: General principles for design (ISO 13849-1:2006) EN ISO 13850:2008, Safety of machinery — Emergency stop — Principles for design (ISO 13850:2006)

EN ISO 13857, Safety of machinery — Safety distances to prevent hazard zones being reached by upper and lower limbs (ISO 13857:2008) SIST EN 1570-1:2012

3.23 assisted hinged connecting plate hinged connecting plate that is counterbalanced by spring force or weights to reduce the manual effort of operating the plate 3.24 power actuated hinged connecting plate hinged connecting plate that requires no manual effort to operate

3.25 split hinged connecting plate hinged connecting plate that is divided into two or more sections SIST EN 1570-1:2012

Potential

consequences b 1 Mechanical hazards Acceleration, deceleration

(kinetic energy) Being run over Being thrown Crushing Cutting or severing Drawing-in or trapping Entanglement Friction or abrasion Impact Injection Shearing Slipping, tripping and falling Stabbing or puncture Suffocation 5.1.2.6, 5.1.2.7, 5.3.2,

Angular parts 5.2.1, 5.2.5, 5.2.10.1 Approach of a moving element to a fixed part 5.2.1, 5.2.2.2.3, 5.2.2.3.1, 5.2.2.5, 5.2.3/4/5, 5.2.10.3, 5.2.10.6,

Cutting parts 5.2.5 Elastic elements 5.9.7, 7.2.6 Falling objects 5.2.9, 5.2.10.11, 5.2.12, 5.4.2 Gravity (stored energy) 5.1.2.7 Height from the ground 5.2.9, 5.2.11/12,

High pressure 5.8.2/3, 5.8.4.1, 5.8.8, 5.9.3/4/5/6/7/9, 7.3.5, 7.5.7 Machinery mobility 5.3.2, 5.5.1, 5.6 Moving elements 5.2.2.2/3/4/5/6, 5.2.5/6/7, 5.6 Rotating elements 5.2.11, 5.2.12.2, 5.2.13.3/4, 5.3.3, 5.4.4 Rough, slippery surface 5.2.5, 5.4.1, 5.4.4 Sharp edges 5.2.5, 5.2.10.13, 5.7.5.4, D.4 d) Stability 5.1.3, 6.2 Vacuum Not applicable

Potential

consequences b 2 Electrical hazards Arc Burn Chemical effects Effects on medical implants Electrocution Falling, being thrown Fire Projection of molten particles Shock Not applicable Electromagnetic phenomena 5.10.2 Electrostatic phenomena 5.10.2 Live parts 5.10.2, 6.6, 7.3.6 Not enough distance to live parts under high voltage 5.10.2 Overload 5.7.2.2, 5.7.3.2, 5.7.4.2, 5.7.5.6, 5.7.6.5 Parts which have become live under fault conditions 5.10.1/2 Short-circuit 5.10.1/2 Thermal radiation 5.2.14 3 Thermal hazards Explosion Burn Dehydration Discomfort Frostbite Injuries by the radiation of heat sources Scald Not applicable Flame Not applicable Objects or materials with a high or low temperature 5.2.14, 5.9.12 Radiation from heat sources Not applicable 4 Noise hazards Cavitation phenomena Discomfort Loss of awareness Loss of balance Permanent hearing loss Stress Tinnitus Tiredness Any other (e.g. mechanical, electrical) as a consequence of an interference with speech communication or with acoustic signals Not applicable Exhausting system Not applicable Gas leaking at high speed Not applicable Manufacturing process (stamping, cutting, etc.) 7.4.2.3, Annex B Moving parts Scraping surfaces

7.4.2.3 Unbalanced rotating parts

Not applicable Whistling pneumatics

Not applicable Worn parts Not applicable SIST EN 1570-1:2012

Potential

consequences b 5 Vibration hazards Cavitation phenomena Discomfort Low-back morbidity Neurological disorder Osteo-articular disorder Trauma of the spine Vascular disorder Not applicable Misalignment of moving parts

Not applicable Mobile equipment Not applicable Scraping surfaces Not applicable Unbalanced rotating parts Not applicable Vibrating equipment Not applicable Worn parts Not applicable 6 Radiation hazards

Ionising radiation source Burn Damage to eyes and skin Effects on reproductive capability Genetic mutation Headache, insomnia, etc. Not applicable Low frequency electromagnetic radiation

Optical radiation (infrared, visible and ultraviolet), including laser Not applicable Radio frequency electro-magnetic radiation Not applicable 7

Material / substance hazards Aerosol Breathing difficulties, suffocation Cancer Corrosion Effects on reproductive capability Explosion Fire Infection Mutation Poisoning Sensitization Not applicable Biological and microbiological (viral or bacterial) agent Not applicable Combustible Not applicable Dust Not applicable Explosive Not applicable Fibre Not applicable Flammable

Fluid 7.5.4/6 Fume Not applicable Gas Not applicable Mist Not applicable Oxidizer Not applicable 8 Ergonomic hazards Access Discomfort Fatigue Musculoskeletal disorderStress 5.2.15 Design or location of indi-cators and visual displays units 5.8.4.2 Design, location or Annex D, 5.2.12.1, 5.2.12.4, SIST EN 1570-1:2012

Potential

consequences b identification of control devices Any other (e.g. mechanical, electrical) as a consequence of human error

5.5.1, 5.5.6, 5.7.7.1, 7.4.2.14 Effort 5.2.11 d), 5.6.4, 5.6.12, 5.8.11 Flicker, dazzling, shadow, stroboscopic effect Not applicable Local lighting Introduction Mental overload/underload

Posture Repetitive activity 5.6.4, 5.6.11, 5.8.11 Visibility 7.1, Table 3, 5.2.2.2.4, 5.2.2.5, 5.2.12.1, 5.5.1, 7.4.2.14 9 Hazards associated with environment in which the machine is used Dust and fog Burn Slight disease Slipping, falling Suffocation Any other as a consequence of the effect caused by the sources of the hazards on the machine or parts of the machine

Not applicable Electromagnetic disturbance

Lightning Not applicable Moisture Not applicable Pollution 5.8.5, 7.5.6 Snow Not applicable Temperature 5.9.12, E.1.2, 5.2.14 Water Not applicable Wind 5.1.2.3 Lack of oxygen Not applicable 10 Combination of hazards

e.g. repetitive activity + effort + high environmental temperature e.g. dehydration, loss of awareness, heat stroke

Not applicable Examples of hazards according to EN ISO 12100:2010, A.1: a One origin of hazards can have several potential consequences. b For each type or group of hazards, some potential consequences can be related with several origins of hazards.

Feeding, filling, loading of ancillary fluids (e.g. lubricant, grease, glue) 7.5.9 Fencing Not applicable Fixing, anchoring 7.4.2.6 Preparations for the installation (e.g. foundations, vibration isolators) E.1.2, 7.4.2.1 Running the machine without load Annex C Testing Trials with load or maximum load Annex C Setting Teaching/programming and/or process changeover Adjustment and setting of protective devices and other components Annex C Adjustment and setting or verification of functional parameters of the machine (e.g. speed, pressure, force, travelling limits) Clamping/fastening the work piece Annex C Feeding, filling, loading of raw material

Functional test, trials Annex C Mounting or changing tools, tool-setting Not applicable Programming verification Annex C Verification of the final product Clause 6 Operation Clamping/fastening the work piece 7.4.1 Control/inspection 5.5.4 Driving the machine 5.5.4

Feeding, filling, loading of raw material Not applicable Manual loading/unloading Annex C Minor adjustments and setting of functional parameters of the machine (e.g. speed, pressure, force, travel limits) Annex C Minor interventions during operation (e.g. removing waste material, eliminating jams, local cleaning) Not applicable Operating manual controls Annex D Restarting the machine after stopping / interruption 5.5.3 Supervision 7.4.1 Verification of the final product 6.7 Cleaning Maintenance Adjustments 7.4.1 Cleaning, disinfection 7.4.1 Dismantling/removal of parts, components, devices of the machine 7.5 Housekeeping 7.5 Isolation and energy dissipation

Lubrication 7.5.9 Replacement of tools Not applicable Replacement of worn parts 7.5 Resetting 7.5.8 Restoring fluid levels 7.5, 7.5.5, 5.8.9 Verification of parts, components, devices of the machine 7.5.8

Table 1c — Examples of hazardous events according to EN ISO 12100:2010, A.4 Origin related to Hazardous event Clause in this standard Shape and/or superficial finishing of accessible parts of the machine Contact with rough surfaces 5.2.5 Contact with sharp edges and corners, protruding parts 5.2.5 Moving parts of the machine Contact with moving parts 5.2.1, 5.2.2.2.3, 5.2.2.3.1, 5.2.2.5, 5.2. /4/5/6, 5.2.10.3, 5.2.10.6 Contact with rotating open ends

Kinetic energy and/or potential energy (gravity) of the machine, parts of the machine, tools and materials used, processed, handled Falling or ejection of objects 5.3, 5.4.2

Projection of high pressure fluids 5.8.1/2/3/4, 7.5.6 Uncontrolled movements 5.6.3, 5.8.10, 5.9.11 Electrical equipment Direct contact 5.10.1/2 Disruptive discharge

Electric arc Not applicable Fire Not applicable Indirect contact 5.10.1/2 Short-circuit 5.10.1/2 Control system Dropping or ejection of a moving part of the machine or of a work piece clamped by the machine Not applicable Failure to stop moving parts 5.5.5, 5.6.2, 5.6.8, 5.7.8.1/2/4, 5.8.8, 5.9.9, 5.11.2, 7.4.1 6 Machine action resulting from inhibition (defeating or failure) of protective devices

Uncontrolled movements (including speed change) 5.6.3, 5.8.10, 5.9.11 Unintended/unexpected start-up 5.2.11 Other hazardous events due to failure(s) or poor design of the control system 5.2.12.1, 5.2.12.4-g, 5.2.13.3-c, 5.2.13.4-c, 5.2.17, 5.3.2, 5.5.1 Materials and substances or with physical factors (temperature, noise, vibration, radiation and environment)

Contact with objects with high or low temperature 5.2.14, 5.9.12 Emission of a substance that can be hazardous 5.8.2/3, 7.5.6 Emission of a level of noise that can be hazardous Annex B Emission of a level of noise that can interfere with a speech communication or with acoustic signals Annex B Emission of a level of vibration that can be hazardous Not applicable Emission of radiation fields that can be hazardous Not applicable Harsh environmental conditions Not applicable (see scope) SIST EN 1570-1:2012

5.1 General

5.1.1 Introduction Machinery shall comply with the safety requirements and/or protective measures of this clause. In addition, the machine shall be designed according to the principles of EN ISO 12100 for relevant but not significant hazards, which are not dealt with by this standard. 5.1.2 Calculations Calculations for stress shall meet the following requirements: 5.1.2.1 The lifting table shall be designed in accordance with usual calculation codes and good engineering practice and all failure modes of the material shall be considered including fatigue failure. 5.1.2.2 The stresses in any part of the lifting table using the permissible stress method, under normal working conditions, shall not exceed the lower of the following unless stated otherwise: a) 0,66 times the yield stress of the material used or b) 0,5 times the ultimate tensile stress of the material used. 5.1.2.3 The stresses shall be calculated for the condition of the lifting table carrying its rated load and being used in accordance with the manufacturer's instructions. The loads shall include all actual static and dynamic forces both vertical and horizontal, all wind forces, and all forces applied to the platform during loading and unloading. 5.1.2.4 The minimum dynamic forces to be used for the calculations of 5.1.2.3 shall result from

the total vertical load (this includes the rated load and the self weight of the moving parts of the structure) increased by the dynamic factor for the category of lift shown in Table 2 and the horizontal load coefficient for the category of lift shown in Table 2 taken as acting horizontally at the platform level, in the direction causing the maximum stress in the part being considered. NOTE 1 If barriers prevent loading or unloading across a side, or other means prevent movement of the platform in a particular direction, the horizontal load coefficient in this direction need not be considered. SIST EN 1570-1:2012

2 1,1 2,5 % 8 Lifting tables with a clearly defined lifting load and where other forces can be excluded; height adjustment without systematic lateral forces. 3 1,2 5,0 % 32 Lifting tables suited for the use of manual work; e.g. adjustable height work station. 4 1,3 10 % 128 Lifting tables suited for crossing with, e.g. manually operated industrial trucks, electric pallet-stacking trucks with a maximum braking of 10 %.

Lifting tables with mounted gravity conveyors. 5 1,4 10 % 512 Lifting tables suited for a high number of cycles When a lifting table is crossed by vehicles, or is integrated in a handling device, the lateral forces have to be verified in individual cases. Higher horizontal load coefficients have to be established if required. a This minimum number of cycles shall be increased by the manufacturer according to the purpose of use of the lifting table. b When used (load cycle) according to lifting categories lifetime of lifting tables is generally 10 years when maintained in accordance with the manufacturers instructions.

NOTE 2 If barriers prevent loading or unloading across a side, or other means prevent movement of the platform in a particular direction, the horizontal load coefficient in this direction need not be considered. 5.1.2.5 If operators are to be carried on the platform, their load shall be taken as 80 kg, concentrated in an area of 0,2 m by 0,2 m for each operator, spaced apart at 0,5 m centre to centre and placed in the most unfavourable position on the platform for stress calculations. 5.1.2.6 It shall be possible for the forces produced when the safety device is operated, to be accepted without permanent deformation of the normal load bearing parts, when used in accordance with the manufacturer’s instructions. 5.1.2.7 Platform deflection 5.1.2.7.1 When the lifting table is not designed for a specific loading, it shall be designed to meet the following requirements: in one case lift half the rated load distributed over half the length or longest side of the platform; and in another case lift one third of the rated load distributed over half the width or shortest side of the platform. SIST EN 1570-1:2012

%/)2(1−+=y b) is the maximum tilting or deflection ( y ) of any side above 2,0m ( l ) long and is

%0,1=y

Dimensions in metres

Key y percentage tilting or deflection of a side l

l length of the side of a lifting table platform (in metres) a maximum tilting or deflection of any side up to 2,0 m b maximum tilting or deflection of any side above 2,0 m

Figure 1 — Deflection of platform 5.1.2.7.2 When the lifting table is designed for a known specific loading, there shall be a sign or instruction on the lifting table, clearly readable from the control position, indicating the safe intended load distribution. 5.1.3 Stability 5.1.3.1 Lifting tables shall be stable (i.e. will not overturn) in all conditions of the platform or table, whether stationary or moving. The calculated factor of safety shall not be less than 1,3. This shall be calculated by dividing the sum of all the stabilizing moments by the sum of all the overturning moments including the relevant horizontal load coefficient as defined in 5.1.2.4. The overturning moments are to include all dynamic forces and all externally imposed forces including those caused by transfer on and off the platform and those caused by operators. For this calculation the rated load shall be evenly distributed over an area half the length times half the width of the platform, in any overturning position. SIST EN 1570-1:2012

5.2.2.1 General As an alternative to minimum gaps defined in 5.2.1, the travel zone below the platform may be protected by the following measures which are summarised in Table 3. These are minimum measures and should not be considered as the only method of protection, alternative methods offering an equivalent or higher level of safety may be used. SIST EN 1570-1:2012

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...