EN 1279-5:2005+A1:2008

(Main)Glass in building - Insulating glass units - Part 5: Evaluation of conformity

Glass in building - Insulating glass units - Part 5: Evaluation of conformity

This European Standard specifies requirements, the evaluation of conformity and the factory production control of insulating glass units for use in buildings.

NOTE 1 For glass products with electrical wiring or connections for e.g. alarm or heating purposes, other directives, e.g. Low Voltage Directive, may apply.

The main intended uses of the insulating glass units are installations in windows, doors, curtain walling, roofs and partitions where there exists protection against direct ultraviolet radiation at the edges.

NOTE 2 In cases where there is no protection against direct ultra-violet radiation at the edges, such as structural sealant glazing systems, additional European technical specifications should be followed (e.g. !EN 15434", !EN 13022-1").

NOTE 3 Units for which the intended use is only ‘artistic’ and therefore no essential requirement is required, are not subject to CE marking and are not part of this European Standard.

Glas im Bauwesen - Mehrscheiben-Isolierglas - Teil 5: Konformitätsbewertung

Diese Europäische Norm legt Anforderungen an sowie die Konformitätsbewertung und die werkseigene Produktionskontrolle für Mehrscheiben Isolierglas zur Verwendung in Gebäuden fest.

ANMERKUNG 1 Für Glasprodukte mit elektrischer Verdrahtung oder elektrischen Anschlüssen, z. B. zu Alarm oder Heizzwecken, gelten möglicherweise weitere Richtlinien, z. B. die Niederspannungsrichtlinie.

Der vorgesehene Hauptverwendungszweck der Mehrscheiben Isoliergläser ist der Einbau in Fenster, Türen, Vorhangfassaden, Dächer und Trennwände, wobei die Ränder des Glases gegen direkte UV Strahlung geschützt sind.

ANMERKUNG 2 Falls die Ränder nicht gegen direkte UV Strahlung geschützt sind, wie z. B. bei geklebten Verglasungen ("Structural Sealant Glazing"-Systeme), sollten zusätzliche Europäische Technische Spezifikationen befolgt werden (z. B. EN 15434, EN 13022-1).

ANMERKUNG 3 Einheiten, die nur für "künstlerische" Zwecke vorgesehen sind und für die daher keine wesentlichen Anforderungen gelten, sind nicht Gegenstand der CE Kennzeichnung und werden von dieser Europäischen Norm nicht erfasst.

Verre dans la construction - Vitrage isolant - Partie 5: Evaluation de la conformité

La présente Norme européenne spécifie des exigences relatives à l'évaluation de la conformité et au contrôle de la production en usine des vitrages isolants utilisés dans la construction.

NOTE 1 Pour les produits verriers équipés d'un câblage ou de branchements électriques pour les besoins d'alarme ou de chauffage, par exemple, d’autres directives, comme par exemple la Directive «Basse(s) Tension(s)», peuvent s’appliquer.

Les usages prévus des vitrages isolants sont principalement les installations dans des fenêtres, portes, murs rideaux, toitures et cloisons offrant une protection des bords contre les rayonnements ultraviolets directs.

NOTE 2 En l’absence de protection contre les rayonnements ultraviolets directs sur les bords, comme par exemple pour les vitrages extérieurs collés, il convient de se conformer à d'autres spécifications techniques européennes (par exemple !EN 15434", !EN 13022-1").

NOTE 3 Les vitrages de nature purement «artistique», et pour lesquels aucune exigence essentielle n’est requise, ne sont pas soumis au marquage CE et ne sont pas couverts par la présente Norme européenne.

Steklo v gradbeništvu - Izolacijsko steklo - 5. del: Ovrednotenje skladnosti

General Information

- Status

- Withdrawn

- Publication Date

- 11-Nov-2008

- Withdrawal Date

- 04-May-2010

- Technical Committee

- CEN/TC 129 - Glass in building

- Drafting Committee

- CEN/TC 129/WG 4 - Insulating glass units

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 05-May-2010

- Completion Date

- 05-May-2010

Not Harmonized89/106/EEC - Construction productsOJ Ref: C 152, C 152, C 152, C 152, C 152, C 152, C 152, C OJ Date: 04-Jul-2009

Relations

- Effective Date

- 19-Jan-2023

- Merged From

EN 1279-5:2005 - Glass in building - Insulating glass units - Part 5: Evaluation of conformity - Effective Date

- 22-Dec-2008

- Amended By

EN 1279-5:2005/FprA2 - Glass in building - Insulating glass units - Part 5: Evaluation of conformity - Effective Date

- 01-Aug-2009

Frequently Asked Questions

EN 1279-5:2005+A1:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Glass in building - Insulating glass units - Part 5: Evaluation of conformity". This standard covers: This European Standard specifies requirements, the evaluation of conformity and the factory production control of insulating glass units for use in buildings. NOTE 1 For glass products with electrical wiring or connections for e.g. alarm or heating purposes, other directives, e.g. Low Voltage Directive, may apply. The main intended uses of the insulating glass units are installations in windows, doors, curtain walling, roofs and partitions where there exists protection against direct ultraviolet radiation at the edges. NOTE 2 In cases where there is no protection against direct ultra-violet radiation at the edges, such as structural sealant glazing systems, additional European technical specifications should be followed (e.g. !EN 15434", !EN 13022-1"). NOTE 3 Units for which the intended use is only ‘artistic’ and therefore no essential requirement is required, are not subject to CE marking and are not part of this European Standard.

This European Standard specifies requirements, the evaluation of conformity and the factory production control of insulating glass units for use in buildings. NOTE 1 For glass products with electrical wiring or connections for e.g. alarm or heating purposes, other directives, e.g. Low Voltage Directive, may apply. The main intended uses of the insulating glass units are installations in windows, doors, curtain walling, roofs and partitions where there exists protection against direct ultraviolet radiation at the edges. NOTE 2 In cases where there is no protection against direct ultra-violet radiation at the edges, such as structural sealant glazing systems, additional European technical specifications should be followed (e.g. !EN 15434", !EN 13022-1"). NOTE 3 Units for which the intended use is only ‘artistic’ and therefore no essential requirement is required, are not subject to CE marking and are not part of this European Standard.

EN 1279-5:2005+A1:2008 is classified under the following ICS (International Classification for Standards) categories: 81.040.20 - Glass in building. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1279-5:2005+A1:2008 has the following relationships with other standards: It is inter standard links to EN 1279-5:2005+A2:2010, EN 1279-5:2005, EN 1279-5:2005/FprA2. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1279-5:2005+A1:2008 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/135. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1279-5:2005+A1:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Steklo v gradbeništvu - Izolacijsko steklo - 5. del: Ovrednotenje skladnostiGlas im Bauwesen - Mehrscheiben-Isolierglas - Teil 5: KonformitätsbewertungVerre dans la construction - Vitrage isolant - Partie 5: Evaluation de la conformitéGlass in building - Insulating glass units - Part 5: Evaluation of conformity81.040.20Steklo v gradbeništvuGlass in buildingICS:Ta slovenski standard je istoveten z:EN 1279-5:2005+A1:2008SIST EN 1279-5:2005+A1:2009en,fr,de01-maj-2009SIST EN 1279-5:2005+A1:2009SLOVENSKI

STANDARDSIST EN 1279-5:20051DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1279-5:2005+A1

November 2008 ICS 81.040.20 Supersedes EN 1279-5:2005 English Version

Glass in building - Insulating glass units - Part 5: Evaluation of conformity

Verre dans la construction - Vitrage isolant - Partie 5: Evaluation de la conformité

Glas im Bauwesen - Mehrscheiben-Isolierglas - Teil 5: Konformitätsbewertung This European Standard was approved by CEN on 24 March 2005 and includes Amendment 1 approved by CEN on 2 October 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2008 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1279-5:2005+A1:2008: ESIST EN 1279-5:2005+A1:2009

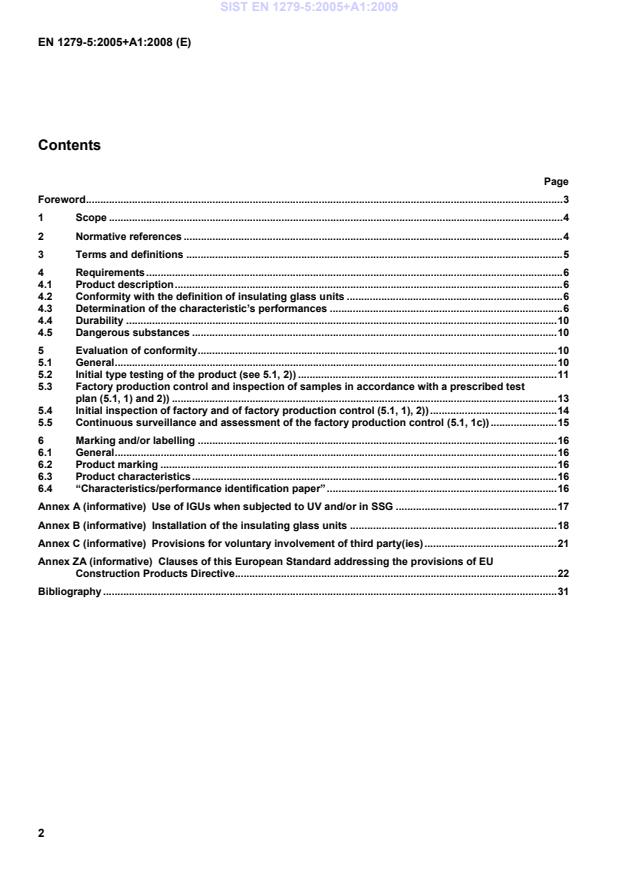

Use of IGUs when subjected to UV and/or in SSG.17 Annex B (informative)

Installation of the insulating glass units.18 Annex C (informative)

Provisions for voluntary involvement of third party(ies).21 Annex ZA (informative)

Clauses of this European Standard addressing the provisions of EU Construction Products Directive.22 Bibliography.31

Characteristic

Symbol

Unit - density - hardness - Young's modulus - Poisson's ratio - characteristic bending strength - specific heat capacity - coefficient of linear expansion - thermal conductivity - mean refractive index to visible radiation - emissivity - light transmittance - solar direct transmittance - total solar energy transmittance ρ HK 0,1/20 E µ fk c α λ n ε τv τe g kg/m³ GPa Pa Dimensionless Pa J/(kg·K) K-1 W/(m·K) Dimensionless Dimensionless Dimensionless Dimensionless Dimensionless

4.3.2 Determination of characteristics of insulating glass units 4.3.2.1 General If the insulating glass manufacturer wishes to claim that any performance characteristic is independent of the production equipment used then the factory production control system shall be in accordance with this European Standard including his specific process control conditions. 4.3.2.2 Safety in the case of fire - Resistance to fire Fire resistance shall be determined and classified in accordance with EN 13501-2. NOTE EN 357 may be used as a classification reference specific to fire resistant glazed elements. 4.3.2.3 Safety in the case of fire - Reaction to fire Reaction to fire shall be determined and classified in accordance with EN 13501-1. For classification, consideration shall be given to: a) the following product changes require new type testing on reaction to fire: reduction of the reaction to fire classification of the glass components in the insulating glass unit; reduction of the reaction to fire performance of the organic sealant in the edge seal; b) however when not tested, the insulating glass unit shall be classified either: by the reaction to fire classification of the glass component used in the insulating glass unit, or by the classification of an insulating glass units using the same organic sealant in the edge seal, SIST EN 1279-5:2005+A1:2009

!EN 13022-1" using a sealant in accordance with !EN 15434". See Annex A. 4.3.2.11 Direct airborne sound reduction The sound reduction indexes shall be determined in accordance with EN 12758. 4.3.2.12 Energy conservation and heat retention - Thermal properties The thermal transmittance value (U-value) shall be determined by calculation in accordance with EN 673 with: emissivity ε: the declared value of the glass manufacturer. If the information is not available, the emissivity shall be determined in accordance with EN 12898; nominal thickness of the glass panes; nominal thickness of any other material layer, if any; the nominal cavity width; assuming that the panes are parallel; the nominal gas concentration ci,o , or the final gas concentration ci,f (see EN 1279-3). NOTE In the case of gas filled units EN 1279-3 should be consulted in order that the U-value for publication includes all the relevant negative aspects. In those instances when the thermal transmittance value (U-value) cannot be calculated then it shall be determined by testing in accordance with EN 674 or EN 675. 4.3.2.13 Energy conservation and heat retention - Radiation properties: Light transmittance and reflectance The light transmittance and reflectance shall be determined in accordance with EN 410. SIST EN 1279-5:2005+A1:2009

1 The terms ‘manufacturer’ and ‘producer’ are understood as being synonyms (see CPD working document NB-CPD/02/019-issued 24 April 2002 – page1). SIST EN 1279-5:2005+A1:2009

Applicable to:

Seal performance: Validation method: (Demonstration by means of available test report or by testing)

Requirement:

All systems of IGU Moisture vapour penetration EN 1279-2 refer to EN 1279-2

Adhesion sealant-glass (*) EN 1279-4 refer to EN 1279-4 NOTE Tests can be carried out by different test laboratories. (*) The test report of the component manufacturer may be used to validate the ITT test. " SIST EN 1279-5:2005+A1:2009

Table 3 - Seal performance, supplementary validation methods and supplementary requirements for gas-filled insulating glass units and units with coated glass

Applicable to:

Seal performance: Validation method: (Demonstration by means of available test report or by testing)

Requirement: Gas-filled IGU: Type of gas Gas leakage rate EN 1279-3 refer to EN 1279-3 Gas filled units: gas concentration

Subject of factory production control in accordance with EN 1279-6 refer to EN 1279-6:2002, Annex A.3 Seal bonding to glass coating (*) Adhesion: - sealant/coating - interlayers of coating EN 1279-4:2002, Annex D refer to EN 1279-4 NOTE Tests can be performed by different test laboratories. (*) The test report of the component manufacturer may be used to validate the ITT test. " Substitution of materials and of components shall maintain the conformity of the system with the definition of insulating glass units. The relevant seal properties, components and the related derived requirements are summarized in EN 1279-1:2004, Tables B.1 and B.2, together with the validation methods. The component manufacturer test reports may be used to validate the substitution. During factory production control the short climate test value of the test report shall be confirmed by the outcome value of the periodic test of the factory production control. Only one substitution shall be made at any one time. When a relevant material changes the short climate test shall be repeated (EN 1279-6:2002, B.4.2). When meeting the requirements, the substituting materials and components shall be added to the system description. In case of system description (processed edge seal description) change, test report on prototype can be used. During factory production control the short climate test value of the test report shall be confirmed by the outcome value of the periodic test of the factory production control. If glass panes are used which are not covered by European specifications, it shall be demonstrated that those glasses have a chemical and mechanical stability over time comparable with: soda lime silicate glass according to EN 572-1; or borosilicate glass according to EN 1748-1-1; or glass ceramics according to EN 1748-2-1; or alkaline earth silicate glass according to EN 14178-1. 5.2.5 Initial type testing of performances of characteristics (5.1, 2)) All characteristics in 4.3.2 shall be subject to initial type tests in accordance with 5.2.1. 5.3 Factory production control and inspection of samples in accordance with a prescribed test plan (5.1, 1) and 2)) Factory production control means the permanent internal control of production exercised by the manufacturer. SIST EN 1279-5:2005+A1:2009

NOTE 1 There may be a need to involve a third party for the purpose of regulatory marking (see Annex ZA). SIST EN 1279-5:2005+A1:2009

B and C 2 Release of dangerous substances - Checking incoming materials Annex A 3 Bullet resistance Explosion resistance Burglar resistance Human impact resistance Resistance against sudden temperature changes and temperature differentials Wind, snow, permanent and imposed load resistance of the glass unit Wind, snow, permanent and imposed load resistance of the edge seal - Checking incoming materials - Checking production control - Labelling outgoing insulating glass units - Edge seal dimensions, gas filling rate, flatness and fogging - Periodic, low frequency tests and inspections Annexes A,

B and C 4 Sound reduction Light transmittance and reflection Solar energy characteristic Thermal conductivity - Checking incoming materials - Checking production control

- Labelling outgoing insulating glass units - Edge seal dimensions, gas filling rate, flatness and fogging - Periodic, low frequency tests and inspections Annexes A,

B and C

5.5 Continuous surveillance and assessment of the factory production control (5.1, 1c)) The continuous surveillance and assessment of the factory production control shall cover the parameters listed in Table 4 in conjunction with EN 1279-6:2002, Annex A. NOTE There may be a need to involve a third party for the purpose of regulatory marking (see Annex ZA). The frequency of production surveillance shall be twice per year for new production facilities or for facilities that do not already have an established factory production control system in accordance with this European Standard. When assessment of FPC fails to identify major non-conformances during four successive assessments, the frequency can be reduced to once a year. When a major non-conformance is recorded, the inspection shall be repeated within two month. The frequency of production surveillance shall return to, or remain at twice a year. When the repeated inspection also results in a non-conformance, then the production shall be subject within two months to a repeated initial inspection of the factory and of the factory production control together with a surveillance inspection. When this repeated initial inspection and surveillance inspection also results in a major non-conformance then the products are considered as no longer conforming to this European Standard. SIST EN 1279-5:2005+A1:2009

The manufacturer or his agent shall organise a system of references that allows for the following: the identification of exactly which characteristics have to be assessed (see 4.3.2); those characteristics that will be assessed; the values, classes, categories, etc. that have been determined for those characteristics. This system shall be documented as part of the evaluation of conformity. 6.4 “Characteristics/performance identification paper” The manufacturer shall prepare a “characteristics/performance identification paper” based on the information collected on the product characteristics (see 6.3). This document shall be part of the manufacturers technical file and is the basis for the accompanying information as required for regulator purposes. The "characteristics/performance identification paper" can be a catalogue in any media format (paper, disk, website, etc.), always identifiable by the reference that accompanies the marking with the product. The catalogue shall contain the values or classes of the characteristics for which a performance is declared. If no performance is declared, an indication of no performance determined (NPD) shall be made. NOTE 1 The conditions of use of NPD are given in Annex ZA. NOTE 2 The catalogue should not contain any information other than that relevant to the “characteristics/performance identification paper”. SIST EN 1279-5:2005+A1:2009

Use of IGUs when subjected to UV and/or in SSG A.1 General The scope of the EN 1279 series of standards does not cover the use of IGUs in these applications. However, IGUs are used in these applications and should be capable of offering the same durability and performance as an IGU used in a frame system. A.2 System description The manufacturer should be able to write a system description for this particular end use application. The description should contain, over and above that required by EN 1279-1, the following information that is specific to this intended end use: a) design considerations, e.g. resistance against wind, snow, permanent load, and other mechanical, (quasi-)static action; b) dimensioning of the seal system in accordance with !EN 13022-1"; c) specification of the ultra-violet resistant/structural sealant in accordance with !EN 15434"; d) specific factory production control requirements over and above those in EN 1279-6. A.3 Testing The durability of the insulating glass unit design should be determined by testing in accordance with EN 1279-2 and EN 1279-3. The performance of the ultra-violet resistant/structural sealant should be checked in accordance with EN 1279-4 and !EN 13022-1". A.4 Evaluation of conformity This should be in accordance with this European Standard taking account of the requirements for factory production control from EN 1279-6 and the system description. A.5 Marking Insulating glass units for this specific end use should be marked as follows: Name or trade mark of the manufacturer; EN 1279; Special end use – UV and/or structural [as appropriate]. A.6 Regulatory marking An example of a CE Marking label is shown as Figure ZA.2. SIST EN 1279-5:2005+A1:2009

Installation of the insulating glass units B.1 General In order to satisfy the relevant aspects of the performances related to health, safety and energy saving during an economically reasonable working life as it is aimed by the scope of this European Standard, it is recommended that the subclauses below relating to glazing and installation are followed. B.2 Appropriate supports Within this European Standard an appropriate support is understood as a support where: a) the sides of the insulating glass unit are covered by fixing beads or some other part of the support, and b) entrapment of stationary water, long term condensation and/or enhanced water vapour pressure against the seal of the insulating glass is prevented in order to avoid chemical and/or physical attack on the components of the insulating glass and to avoid excessive water vapour penetration into the insulating glass, and c) showing a sufficient stiffness to limit the edge deflection of the insulating glass unit under loads, such as wind and snow, to avoid reduction of service life, e.g. due to loss of adhesion. A means of obtaining a recommended minimum support stiffness is to consider when the support either over the height H or over the width B of the glazing together with an infill of low edge rigidity, e.g. a single glass, exhibits a deflection of H/200 or less, and B/200 or less, and a maximum of 12 mm for either when exposed to design loads, either as single load or as combined load. B.3 Installation and glazing conditions B.3.1 General Depending on materials and devices used for installation and glazing, and depending on the system of insulating glass unit, the installation conditions may vary. In the subclauses below, a number of gene

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...