EN 10208-2:2009

(Main)Steel pipes for pipelines for combustible fluids - Technical delivery conditions - Part 2: Pipes of requirement class B

Steel pipes for pipelines for combustible fluids - Technical delivery conditions - Part 2: Pipes of requirement class B

This European Standard specifies the technical delivery conditions for seamless and welded steel pipes for the on land transport of combustible fluids primarily in gas supply systems but excluding pipeline applications in the petroleum and natural gas exploration and production industries. It includes more stringent quality and testing requirements than those in EN 10208-1.

NOTE 1 Steel pipes for pipeline transportation systems within the petroleum and natural gas exploration and production industries are covered by ISO 3183 [1]. This standard specifies products with the same (and additional) strength levels and partly similar (but not identical) requirements as EN 10208-1 and EN 10208-2 and is with two additional annexes specifying deviating or additional requirements also published as API Spec 5L [4].

NOTE 2 This European Standard does not apply to cast steel pipe.

Stahlrohre für Rohrleitungen für brennbare Medien - Technische Lieferbedingungen - Teil 2: Rohre der Anforderungsklasse B

Diese Europäische Norm legt die technischen Lie¬ferbedingungen für nahtlose und geschweißte Stahlrohre für den Transport brennbarer Medien an Land, vorzugsweise für Gasversorgungssysteme, fest, schließt aber Anwendungen in der Erdöl und Erdgasindustrie aus. Sie enthält Qualitäts und Prüfanforderungen, die über die in EN 10208 1 fest¬gelegten hinausgehen.

ANMERKUNG 1 Rohre für Rohrleitungstransportsysteme zur Anwendung in der Erdöl und Erdgasindustrie sind in ISO 3183 festgelegt. Dies Norm spezifiziert Erzeugnisse mit demselben (und einem erhöhten) Anforderungsniveau und teilweise ähnlichen (aber nicht identischen) Anforderungen wie EN 10208 1 und EN 10208 2. Sie wurde mit zwei zusätzlichen Anhängen, in denen abweichende oder Zusatzanforderung festgelegt sind, auch als API Spec 5L [4] veröffentlicht.

ANMERKUNG 2 Diese Europäische Norm gilt nicht für Stahlguss¬rohre.

Tubes en acier pour conduites de fluides combustibles - Conditions techniques de livraison - Partie 2: Tubes de la classe de prescription B

La présente Norme européenne donne les conditions techniques de livraison de tubes en acier soudés et

sans soudure pour le transport terrestre de fluides combustibles principalement dans les systèmes

d'adduction de gaz mais elle exclut les applications mettant en oeuvre des canalisations dans les industries

d'exploration et de production de pétrole et de gaz naturel. Elle inclut des prescriptions de qualité et d'essai

plus strictes que celles de l'EN 10208-1.

NOTE 1 Les tubes en acier pour les systèmes de transport par canalisation dans les industries d'exploration et de

production de pétrole et de gaz naturel sont couverts par l'ISO 3183 [1]. La présente norme spécifie des produits avec les

mêmes niveaux de résistance (et des niveaux supplémentaires) que ceux des EN 10208-1 et EN 10208-2 et des

prescriptions partiellement similaires (mais pas identiques) à celles de ces normes. Elle comporte deux annexes

supplémentaires spécifiant des prescriptions déviantes ou additionnelles également publiées comme API Spec 5L [4].

NOTE 2 La présente Norme européenne n'est pas applicable aux tubes en acier moulé.

Jeklene cevi za cevovode za prenos plinastih in tekočih goriv - Tehnični dobavni pogoji - 2. del: Cevi razreda zahtevnosti B

General Information

- Status

- Withdrawn

- Publication Date

- 17-Mar-2009

- Withdrawal Date

- 31-Oct-2012

- Technical Committee

- ECISS/TC 110 - Steel tubes, and iron and steel fittings

- Drafting Committee

- ECISS/TC 29/SC 2 - Line pipe

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 01-Nov-2012

- Completion Date

- 01-Nov-2012

Relations

- Effective Date

- 23-Mar-2009

- Effective Date

- 23-Mar-2009

- Effective Date

- 14-Nov-2012

Frequently Asked Questions

EN 10208-2:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Steel pipes for pipelines for combustible fluids - Technical delivery conditions - Part 2: Pipes of requirement class B". This standard covers: This European Standard specifies the technical delivery conditions for seamless and welded steel pipes for the on land transport of combustible fluids primarily in gas supply systems but excluding pipeline applications in the petroleum and natural gas exploration and production industries. It includes more stringent quality and testing requirements than those in EN 10208-1. NOTE 1 Steel pipes for pipeline transportation systems within the petroleum and natural gas exploration and production industries are covered by ISO 3183 [1]. This standard specifies products with the same (and additional) strength levels and partly similar (but not identical) requirements as EN 10208-1 and EN 10208-2 and is with two additional annexes specifying deviating or additional requirements also published as API Spec 5L [4]. NOTE 2 This European Standard does not apply to cast steel pipe.

This European Standard specifies the technical delivery conditions for seamless and welded steel pipes for the on land transport of combustible fluids primarily in gas supply systems but excluding pipeline applications in the petroleum and natural gas exploration and production industries. It includes more stringent quality and testing requirements than those in EN 10208-1. NOTE 1 Steel pipes for pipeline transportation systems within the petroleum and natural gas exploration and production industries are covered by ISO 3183 [1]. This standard specifies products with the same (and additional) strength levels and partly similar (but not identical) requirements as EN 10208-1 and EN 10208-2 and is with two additional annexes specifying deviating or additional requirements also published as API Spec 5L [4]. NOTE 2 This European Standard does not apply to cast steel pipe.

EN 10208-2:2009 is classified under the following ICS (International Classification for Standards) categories: 23.040.10 - Iron and steel pipes. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 10208-2:2009 has the following relationships with other standards: It is inter standard links to EN 10208-2:1996/AC:1996, EN 10208-2:1996, EN ISO 3183:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 10208-2:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stahlrohre für Rohrleitungen für brennbare Medien - Technische Lieferbedingungen - Teil 2: Rohre der Anforderungsklasse BTubes en acier pour conduites de fluides combustibles - Conditions techniques de livraison - Partie 2 : Tubes de la classe de préscription BSteel pipes for pipelines for combustible fluids - Technical delivery condi-tions - Part 2: Pipes of requirement class B77.140.75Jeklene cevi in cevni profili za posebne nameneSteel pipes and tubes for specific use75.200Petroleum products and natural gas handling equipmentICS:Ta slovenski standard je istoveten z:EN 10208-2:2009SIST EN 10208-2:2009en,de01-junij-2009SIST EN 10208-2:2009SLOVENSKI

STANDARDSIST EN 10208-2:1998/AC:1998SIST EN 10208-2:19981DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 10208-2March 2009ICS 23.040.10Supersedes EN 10208-2:1996

English VersionSteel pipes for pipelines for combustible fluids - Technicaldelivery conditions - Part 2: Pipes of requirement class BTubes en acier pour conduites de fluides combustibles -Conditions techniques de livraison - Partie 2: Tubes de laclasse de préscription BStahlrohre für Rohrleitungen für brennbare Medien -Technische Lieferbedingungen - Teil 2: Rohre derAnforderungsklasse BThis European Standard was approved by CEN on 25 January 2009.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre:

Avenue Marnix 17,

B-1000 Brussels© 2009 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 10208-2:2009: ESIST EN 10208-2:2009

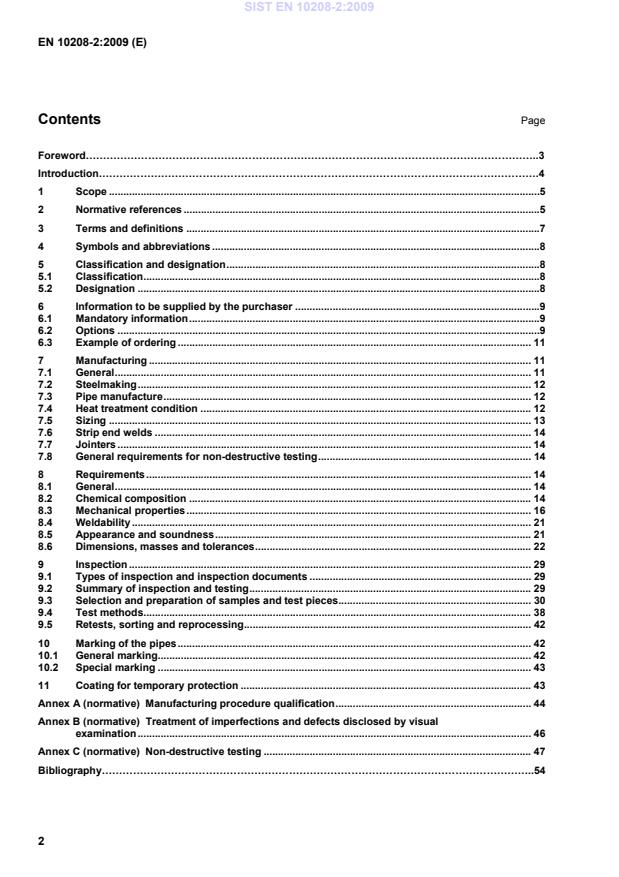

Page Foreword………………………………………………………………………………………………………………….3 Introduction……………………………………………………………………………………………………………….4 1 Scope .5 2 Normative references .5 3 Terms and definitions .7 4 Symbols and abbreviations .8 5 Classification and designation .8 5.1 Classification .8 5.2 Designation .8 6 Information to be supplied by the purchaser .9 6.1 Mandatory information .9 6.2 Options .9 6.3 Example of ordering . 11 7 Manufacturing . 11 7.1 General . 11 7.2 Steelmaking . 12 7.3 Pipe manufacture . 12 7.4 Heat treatment condition . 12 7.5 Sizing . 13 7.6 Strip end welds . 14 7.7 Jointers . 14 7.8 General requirements for non-destructive testing . 14 8 Requirements . 14 8.1 General . 14 8.2 Chemical composition . 14 8.3 Mechanical properties . 16 8.4 Weldability . 21 8.5 Appearance and soundness . 21 8.6 Dimensions, masses and tolerances . 22 9 Inspection . 29 9.1 Types of inspection and inspection documents . 29 9.2 Summary of inspection and testing . 29 9.3 Selection and preparation of samples and test pieces. 30 9.4 Test methods . 38 9.5 Retests, sorting and reprocessing . 42 10 Marking of the pipes . 42 10.1 General marking. 42 10.2 Special marking . 43 11 Coating for temporary protection . 43 Annex A (normative)

Manufacturing procedure qualification . 44 Annex B (normative)

Treatment of imperfections and defects disclosed by visual

examination . 46 Annex C (normative)

Non-destructive testing . 47 Bibliography…………………………………………………………………………………………………………….54

Foreword This document (EN 10208-2:2009) has been prepared by Technical Committee ECISS/TC 29 “Steel tubes and fittings for steels tubes”, the secretariat of which is held by UNI. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by September 2009, and conflicting national standards shall be with-drawn at the latest by September 2009. Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights. This document supersedes EN 10208-2:1996 This European Standard consists of the following parts, under the general title Steel pipes for pipelines for combustible fluids — Technical delivery conditions: Part 1: Pipes of requirement class A Part 2: Pipes of requirement class B According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Repub-lic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom. SIST EN 10208-2:2009

Introduction It was the intention, when preparing this document, to avoid specifying the quality of line pipe to be used for a particular application. However, it was recognized that there are several quality levels commonly used, and it was decided to reflect these in the standard by the differentiation between two quality levels. Firstly, the need was recognized to provide a basic quality level. This is designated requirement class A and considered in EN 10208-1. Secondly, many purchasers impose requirements additional to the basic standard, for instance concerning toughness and non-destructive inspection. This approach is common, for example, for transmission pipelines. Such enhanced requirements are addressed in requirement class B and considered in EN 10208-2. For offshore applications and other applications outside the scope of EN 10208-1 and EN 10208-2, other standards may be applicable, e.g. ISO 3183 [1]. The Charpy impact energy requirements in this document have been derived from established data, in accor-dance with EPRG recommendations [2], and are intended to prevent the occurrence of long running shear fracture in pipelines transporting clean, dry natural gas. It is the responsibility of the designer to decide whether these energy requirements suffice for the intended application. For example, rich gas or two-phase fluids may require additional testing to be carried out. For pipes of requirement class B, a weld efficiency factor of 1,0 can be used in design calculations, due to the conditions specified for the manufacture of the pipes and for the testing of the tubes. The selection of the requirement class depends on many factors: the properties of the fluid to be conveyed, the service conditions, design code and any statutory requirements should all be taken into consideration. Therefore this document gives no detailed guidelines. It is the ultimate responsibility of the user to select the appropriate requirement class for the intended application. NOTE This document combines a wide range of product types, dimensions and technical restrictions in accordance with the functional requirements for gas supply systems referred to in EN 1594 [3]. SIST EN 10208-2:2009

Location and preparation of samples and test pieces for mechanical testing (ISO 377:1997) EN ISO 2566-1, Steel — Conversion of elongation values — Part 1: Carbon and low alloy steels

(ISO 2566-1:1984) EN ISO 6506-1, Metallic materials — Brinell hardness test — Part 1: Test method (ISO 6506-1:2005) EN ISO 6508-1, Metallic materials — Rockwell hardness test — Part 1: Test method (scales A, B, C, D, E, F, G, H, K, N, T) (ISO 6508-1:2005) EN ISO 8492, Metallic materials — Tube — Flattening test (ISO 8492:1998) EN ISO 14284, Steel and iron — Sampling and preparation of samples for the determination of the chemical composition (ISO 14284:1996) ISO 19232-1, Non-destructive testing — Image quality of radiographs — Part 1: Image quality indicators (wire type) — Determination of image quality value CEN/TR 10261, Iron and steel — Review of available methods of chemical analysis SIST EN 10208-2:2009

normalizing forming

[deviating from EN 10052:1993] forming process in which the final deformation is carried out in a certain temperature range leading to a mate-rial condition equivalent to that obtained after normalizing so that the specified values of the mechanical pro-perties are retained even after normalizing

NOTE The abbreviated form of this delivery condition is N. 3.2 thermomechanical forming

[as in EN 10052:1992, but supplemented]

forming process in which the final deformation is carried out in a certain temperature range leading to a mate-rial condition with certain properties which cannot be achieved or repeated by heat treatment alone NOTE 1 Subsequent heating above 580 °C may lower the strength values. NOTE 2 The abbreviated form of this delivery condition is M (included, where applicable, in the steel name). NOTE 3 Thermomechanical forming leading to the delivery condition M may include processes of increased cooling rates without or with tempering including self-tempering but excluding definitively direct quenching and quenching and tempering. NOTE 4 As a consequence of lower carbon content and carbon equivalent values, material in the delivery condition M has improved weldability properties. 3.3 quenching and tempering heat treatment comprising of quench hardening followed by tempering, where quench hardening implies aus-tenitization followed by cooling, under conditions such that austenite transforms more or less completely into martensite and possibly into bainite NOTE 1 By tempering to specific temperatures (< Ac1) one or more times or holding at these temperatures, followed by cooling at an appropriate rate, the properties are brought to the required level. NOTE 2 The abbreviated form of this delivery condition is Q (in this document, included in the steel name).

3.4 cold forming (in this context) the process by which a flat product is formed into a pipe without heating of the plate or strip 3.5

cold finishing

cold working operation (normally cold drawing) with a permanent strain greater than the maximum strain of 1,5 % which differentiates it from sizing operations specified in 7.5 3.6 pipe body for seamless pipe, the entire pipe; for welded pipes, the entire pipe excluding weld(s) and heat affected zone (HAZ)

3.7 imperfection irregularity in the wall or on the pipe surfaces detectable by methods described in this document SIST EN 10208-2:2009

3.9 jointer two lengths of pipe coupled or welded together by the manufacturer 3.10 by agreement/agreed [as in EN 10266] agreement between manufacturer and purchaser at the time of enquiry and order 4 Symbols and abbreviations For symbols and abbreviations, see EN 10266:2003. NOTE 1 EN 10266 includes definitions of types of pipe and their abbreviations. NOTE 2 Symbols from EN 10266:2003 most frequently used in this document are: D

specified outside diameter; Dmin

(specified) minimum outside diameter; T

specified wall thickness; Tmin

(specified) minimum wall thickness.

5 Classification and designation

5.1 Classification The steel grades specified in this document are non-alloy quality or non-alloy or alloy special steels. Their classification in accordance with EN 10020 is indicated in Table 1. 5.2 Designation The specified steel grades are designated with steel names in accordance with EN 10027-1. The correspond-ing steel numbers have been allocated in accordance with EN 10027-2.

6 Information to be supplied by the purchaser 6.1 Mandatory information The purchaser shall state in his enquiry and order the following minimum information: a) quantity ordered (e.g. total tonnage or total length of pipe); b) type of pipe (see Table 2, column 1); c) product form (i.e. pipe); d) pipe outside diameter and wall thickness in millimetres (see 8.6.1.2); e) random length group or, if a fixed length is required, the length in millimetres (see 8.6.3.3 and Table 11); f) number of this European Standard (EN 10208-2); g) steel name or number (see Table 1); h) which impact energy requirements, Table 6 or Table 7, shall apply; i) type of inspection document required (see 9.1.1). 6.2 Options A number of options are specified in this document and these are listed below. If the purchaser does not indi-cate a wish to implement any of these options at the time of enquiry and order, the pipe shall be supplied in accordance with the basic specification (see 6.1). SIST EN 10208-2:2009

columns 2 and 3); 6) party to issue the inspection document 3.2 (see 9.1.1). b) Unless otherwise agreed – left to the discretion of the manufacturer 1) method of verification of dimensional and geometrical requirements (see 9.4.10.4); 2) timing of NDT of seamless and HFW pipe (see C.2.2); 3) radiographic inspection for the detection of longitudinal imperfections (see C.5.4 a); c) Optional agreement – options which may be agreed 1) approval of the quality system and/or verification of the manufacturing procedure (see 7.1 and Annex A); 2) steelmaking process (see 7.2.1); 3) manufacture of SAWL pipe with two seams (see 7.3); 4) acceptance of strip end welds in SAWH/COWH pipe (see 7.6.1); 5) Mo content (see Table 3, footnote g); 6) lower CEV (see Table 3, footnote d); 7) DWT test (see Tables 6 and 7, footnote d); 8) weldability data or weld tests (see 8.4.2); 9) application of the diameter tolerance to the inside diameter (see Table 9, footnote c); 10) application of the diameter tolerance to the outside diameter (see Table 9, footnote d); 11) special bevel configuration (see 8.6.4.2); 12) offset of strip end welds (see Table 13, footnote a); 13) impact test for the heat affected zone (see 9.2.2); 14) test piece direction (see Table 18, footnote b); 15) use of circular test pieces (see 9.3.2.2, second paragraph); 16) use of flattened and heat treated test coupons (see 9.3.2.2, last paragraph); SIST EN 10208-2:2009

with DWT test, inspection certificate EN 10204:3.2 7 Manufacturing 7.1 General The pipe manufacturer and the stockist, where products are supplied through a stockist, shall operate a qual-ity system. An approval of the quality system may be agreed. In special cases, the verification of the manufacturing procedure either by available data or in accordance with Annex A may also be agreed. SIST EN 10208-2:2009

Steelmaking 7.2.1 The steels shall be made using the basic oxygen process or the electric furnace process. Other equivalent steelmaking processes may be used by agreement. 7.2.2 The steels shall be fully killed and be made according to fine grain practice. 7.3

Pipe manufacture Acceptable types of pipe are listed together with acceptable manufacturing routes in Table 2. The type of pipe and the type of heat treatment as given in the steel name shall be specified by the purchaser.

SAWH pipes shall be manufactured using strip with a width not less than 0,8 or more than 3,0 times the pipe outside diameter. SAWL pipe may be manufactured with two seams by agreement.

7.4 Heat treatment condition The pipes shall be delivered in one of the forming and heat treatment conditions given in Table 2. SIST EN 10208-2:2009

Heat treatment condition Symbol for the heat treatment Seamless (S) Ingot or billet Hot rolling Normalized or normalizing formed N

Quenched and tempered Q

Hot rolling and cold finishing Normalized N

Quenched and tempered Q High frequency welded (HFW) Normalizing rolled strip Cold forming Normalized weld area N Thermomechanically rolled strip Heat treated weld area M

Hot rolled or norma-lizing rolled strip Normalized (entire pipe) N Cold forming and hot stretch reducing un-der controlled tem-perature resulting in a normalized condition – N Submerged arc-welded (SAW) – longitudinal

seam (SAWL) – helical seam

(SAWH), Combination welded (COW) – longitudinal

seam COWL) – helical seam'

(COWH) Normalized or nor-malizing rolled plate or strip Cold forming – N Thermomechanicallyrolled plate or strip M As rolled plate or strip Normalizing forming – N Normalized or nor-malizing rolled plate or strip a See 3.4 and 3.5.

7.5 Sizing The pipes may be sized to their final dimensions by expanding or reducing. This shall not produce excessive permanent strain. Where no further heat treatment or only a heat treatment of the weld area is carried out, the sizing ratio sr

achieved by this cold working shall not exceed 0,015. It shall be calculated according to the for-mula: sr = DDDba−

(1) where Da is the outside diameter after sizing; SIST EN 10208-2:2009

7.6.2 For welded pipe with a longitudinal seam, strip end welds are not permitted in the pipe. 7.7 Jointers The delivery of jointers is not permitted.

7.8 General requirements for non-destructive testing All NDT activities shall be carried out by qualified and competent level 1, 2 and/or 3 personnel authorized to operate by the employer. The qualification shall be in accordance with EN 10256 or, at least, an equivalent to it. It is recommended that the level 3 personnel be certified in accordance to EN 473 or, at least an equivalent to it. The operating authorization issued by the employer shall be in accordance with a written procedure.

NDT operations shall be authorized by a level 3 NDT individual approved by the employer. NOTE The definition of level 1, 2 and 3 can be found in appropriate standards, e.g. EN 473 and EN 10256. 8 Requirements 8.1 General The requirements specified in this document apply on condition that the relevant specifications for test piece selection, test piece preparation and test methods given in 9.3 and 9.4 are complied with. NOTE Table 17 gives a survey on the tables and clauses containing requirements and specifications for testing. 8.2 Chemical composition 8.2.1 Cast analysis The cast analysis reported by the steel producer shall apply and comply with the requirements of Table 3. SIST EN 10208-2:2009

Si Mn c P S V Nb Ti Others CEV d

max. Steels for seamless and welded pipes L245NB 1.0457 0,16 0,40 1,10 0,025 0,020 – – – e

0,42 L290NB 1.0484 0,17 0,40 1,20 0,025 0,020 0,05 0,05 0,04 e 0,42 L360NB 1.0582 0,20 0,45 1,60 0,025 0,020 0,10 0,05 0,04 e, f

0,45 L415NB 1.8972 0,21 0,45 1,60 0,025 0,020 0,15 0,05 0,04 e, f, g

as agreed Steels for seamless pipes L360QB 1.8948 0,16 0,45 1,40 0,025 0,020 0,05 0,05 0,04 e 0,42 L415QB 1.8947 0,16 0,45 1,60 0,025 0,020 0,08 0,05 0,04 e, f, g

0,43 L450QB 1.8952 0,16 0,45 1,60 0,025 0,020 0,09 0,05 0,06 e, f, g

0,45 L485QB 1.8955 0,16 0,45 1,70 0,025 0,020 0,10 0,05 0,06 e, f, g

0,45 L555QB 1.8957 0,16 0,45 1,80 0,025 0,020 0,10 0,06 0,06 f, h

as agreed Steels for welded pipes L245MB 1.0418 0,16 0,45 1,50 0,025 0,020 0,04 0,04 – e 0,40 L290MB 1.0429 0,16 0,45 1,50 0,025 0,020 0,04 0,04 – e 0,40 L360MB 1.0578 0,16 0,45 1,60 0,025 0,020 0,05 0,05 0,04 e 0,41 L415MB 1.8973 0,16 0,45 1,60 0,025 0,020 0,08 0,05 0,06 e, f, g

0,42 L450MB 1.8975 0,16 0,45 1,60 0,025 0,020 0,10 0,05 0,06 e, f, g

0,43 L485MB 1.8977 0,16 0,45 1,70 0,025 0,020 0,10 0,06 0,06 e, f, g

0,43 L555MB 1.8978 0,16 0,45 1,80 0,025 0,020 0,10 0,06 0,06 e, f, g

as agreed a Elements not mentioned in this table shall not be added intentionally without purchaser's approval except for elements which may be

added for deoxidation and finishing of the heat (see footnote e). b Chemical composition for larger wall thicknesses up to 40 mm is to be agreed. c For each reduction of 0,01 % below the max. carbon content an increase of 0,05 % manganese above the specified maximum value is

permitted with a max. increase of 0,2 %. d 15CuNi5VMoCr6MnCCEV++++++=; the CEV is only specified for the product analysis.

For grades with values higher than 0,43 a max. CEV of 0,43 may be agreed. e 0,015 ≤ Altot < 0,060; N ≤ 0,012; NAl≥ 12; Cu ≤ 0,25; Ni ≤ 0,30; Cr ≤ 0,30; Mo ≤ 0,10. f The sum of V, Nb, Ti shall not exceed 0,15 %. g For these steel grades, a molybdenum content up to 0,35 % may be agreed. h Al, N, Al/N and Cu see footnote e; Ni ≤ 0,60; Cr ≤ 0,50; Mo ≤ 0,35.

8.2.2 Product analysis The product analysis shall not deviate from the limiting values for the cast analysis as specified in Table 3 by more than the values given in Table 4. SIST EN 10208-2:2009

< 0,060 ± 0,005 N ≤ 0,012 + 0,002

8.3 Mechanical properties The pipe shall, as applicable (see Table 17, column 2), comply with the requirements given in Table 5 and Tables 6 or 7. The purchaser shall state, at the time of enquiry and order, which impact energy requirements, depending on the safety factor to be used, shall apply.

NOTE 1 In case of hot forming and/or subsequent field heat treatment of pipes delivered in the quenched and tem-pered or thermomechanically rolled condition, an adverse change of mechanical properties can occur (see for example 3.2). Where appropriate, the purchaser should contact the manufacturer for more detailed information. NOTE 2 The impact requirements in Tables 6 and 7 have been determined using among other parameters a safety factor. The safety factors 1,4 and 1,6 have been chosen as typical examples in the range of commonly used safety fac-tors. SIST EN 10208-2:2009

(SAW and COW pipe) Entire pipe Yield strength Rt0,5

MPa Tensile strength Rm

MPa min.

Rt0,5/Rm c

max. Elongation d A

% min. Diameter of the mandrel for bend test e

(see 9.4.5) Hydrostatic test

(see 9.4.8) Steel name

Steel number L245NB 1.0457 245 to 440 415 0,80 22 3 T Each length of pipe shall withstand the test without showing leakage or visible de-formation L245MB 1.0418 0,85 L290NB 1.0484 290 to 440 415 0,85 21 3 T L290MB 1.0429 0,85 L360NB 1.0582 360 to 510 460 0,85 20 4 T L360QB 1.8948 0,88 L360MB 1.0578 0,85 L415NB 1.8972 415 to 565 520 0,85 18 5 T L415QB 1.8947 0,88 L415MB 1.8973 0,85 L450QB 1.8952 450 to 570 535 0,90 18 6 T L450MB 1.8975 0,87 L485QB 1.8955 485 to 605 570 0,90 18 6 T L485MB 1.8977 0,90 L555QB 1.8957 555 to 675 625 0,90 18 6 T L555MB 1.8978 0,90 a Mechanical properties of pipes with greater wall thicknesses up to 40 mm are to be agreed. b The same Rm values apply for the weld seam of HFW, SAW and COW pipe. c The values for the yield strength ratio apply to the product "pipe". They cannot be required for the starting material. d These values apply to transverse specimens taken from the pipe body. When longitudinal specimens are tested (see Table 18), the

values of elongation shall be 2 units higher. e T = specified wall thickness of the pipe. SIST EN 10208-2:2009

DWT test d

Minimum shear fracture area in % Pipe body (pipe outside diameter D in mm)

Weld seam Pipe body

(D in mm) Steel name Steel number ≤ 510 > 510 ≤ 610 > 610 ≤ 720 > 720 ≤ 820 > 820 ≤ 920 > 920 ≤ 1 020 > 1 020 ≤ 1 120 > 1 120 ≤ 1 220 > 1 220 ≤ 1 430 D ≤ 1 430 transverse to the seam 500 < D ≤ 1 430 transverse to the pipe axis (longitudinal to the pipe axis in angular brackets)c

L245NB 1.0457 40 (30) [60 (45)] 40 (30) 40 (30) 40 (30) not applicable L245MB 1.0418 L290NB 1.0484 42 (32) L290MB 1.0429 L360NB 1.0582 L360QB 1.8948 L360MB 1.0578 L415NB 1.8972 85 e

L415QB 1.8947 L415MB 1.8973 L450QB 1.8952 40 (30) 42 (32) 43 (32) 47 (35) L450MB 1.8975 L485QB 1.8955 40 (30) [60 (45)] 41 (31) [62 (47)] 45 (34) [68 (51)] 48 (36) 51 (38) 53 (40) 56 (42) 58 (44) 63 (47) L485MB 1.8977 L555QB 1.8957 48 (36) [72 (54)] 55 (41) [83 (62)] 61 (46) [92 (69)] 66 (50) 72 (54) 77 (58) 82 (62) 87 (65) 96 (72) L555MB 1.8978 a See Note 2 in 8.3. b The values apply for standard test pieces. For sub-size test pieces, see 9.4.3.2. The specified values without brackets are the transverse minimum average values for three tests; the speci-fied transverse minimum individual values (75 % of the average values) are indicated in round brackets. The impact requirements do not apply for the heat affected zone (HAZ).

For outside diameters D > 1 430 mm and/or wall thickness T > 25 mm values shall be agreed.

The test pieces shall be taken transverse to the pipe axis as long as minimum sub-size test pieces with a width w ≥ 5 mm are still obtainable without flattening. d To be carried out by agreement of for pipes with an outside diameter D > 500 mm, a wall thickness T > 8 mm and a specified yield strength > 360 MPa. e Average value of two tests. SIST EN 10208-2:2009

DWT test d

Minimum shear fracture area in % Pipe body (pipe outside diameter D in mm)

Weld seam Pipe body

(D in mm) Steel name Steel number ≤ 510 > 510 ≤ 610 > 610 ≤ 720 > 720 ≤ 820 > 820 ≤ 920 > 920 ≤ 1 020 > 1 020 ≤ 1 120 > 1 120 ≤ 1 220 > 1 220 ≤ 1 430 D ≤ 1 430 transverse to the seam 500 < D ≤

1 430 transverse to the pipe axis (longitudinal to the pipe axis in angular brackets) c

L245NB 1.0457 40 (30) [60 (45)] 40 (30) 40 (30) 40 (30) not applicable L245MB 1.0418 L290NB 1.0484 42 (32) L290MB 1.0429 L360NB 1.0582 L360QB 1.8948 L360MB 1.0578 L415NB 1.8972 40 (30) 41 (31) 44 (33) 46 (35) 48 (36) 51 (38) 85 e

L415QB 1.8947 L415MB 1.8973 L450QB 1.8952 40 (30) [60 (45)] 41 (31) [62 (47)] 43 (32) 46 (35) 48 (36) 51 (38) 53 (40) 57 (43) L450MB 1.8975 L485QB 1.8955 46 (35) [69 (52)] 50 (38) [75 (56)] 55 (41) [83 (62)] 58 (44) 62 (47) 65 (49) 68 (51) 71 (53) 77 (58) L485MB 1.8977 L555QB 1.8957 61 (46) [92 (69)] 68 (51) [102 (77)] 76 (57) [114 (86)] 83 (62) 90 (68) 96 (72) 102 (77) 108 (81) 120 (90) L555MB 1.8978 SIST EN 10208-2:2009

For outside diameters D > 1 430 mm and/or wall thickness T > 25 mm values shall be agreed.

c The test pieces shall be taken transverse to the pipe axis as long as minimum sub-size test pieces with a width w ≥ 5 mm are still obtainable without flattening. d To be carried out by agreement of for pipes with an outside diameter D > 500 mm, a wall thickness T > 8 mm and a specified yield strength > 360 MPa. e Average value of two tests. SIST EN 10208-2:2009

However, account should be taken of the fact that the behaviour of the steel during and after welding is de-pendent not only on the steel, but also on the welding consumables used and on the conditions of preparing for and carrying out the welding.

8.4.2 If so agreed, the manufacturer shall supply for the type of steel concerned weldability data or perform weld tests. In the case of weld tests, the details for carrying out the tests and the acceptance criteria are also to be agreed. 8.5 Appearance and soundness 8.5.1 The pipes shall be free from defects in the finished condition. 8.5.2 The internal and external surface finish of the pipes shall be typical of the manufacturing process and the heat treatment employed. The surface condition shall be such that any surface imperfections requiring dress-ing can be identified. 8.5.3 Surface imperfections disclosed by visual inspection shall be investigated, classified and treated as follows: a) imperfections with a depth equal to or less than 12,5 % of the specified wall thickness, and which do not encroach on the specified minimum wall thickness, shall be classified as acceptable imperfections and treated in accordance with B.1; b) imperfections with a depth greater than 12,5 % of the specified wall thickness, but which do not encroach on the specified minimum wall thickness, shall be classified as defects and shall either be dressed-out by grinding in accordance with B.2 or treated in accordance with B.3 as appropriate; c) imperfections which encroach the specified minimum wall thickness shall be classified as defects and treated in accordance with B.3. 8.5.4 Geometric deviations for the normal cylindrical contour of the pipe which occur as a result of the pipe forming process or manufacturing operations (e.g. dents, flat spots, peaks) shall not exceed the following val-ues: a) 3 mm (flat spots, peaks and cold formed dents with sharp bottom gouges); b) 6 mm (other dents). These limits refer to the gap between the extreme point of the deviation and the prolongation of the normal contour of the pipe.

For the measurement of flat spots and peaks see 9.4.10.3. For dents, the length in any direction shall not ex-ceed one half of the pipe outside diameter. 8.5.5 For undercuts disclosed by visual inspection of SAW and COW pipes, the acceptance criteria given in C.5.5.2 d) to C.5.5.2 f) apply. 8.5.6 Surface imperfections may be removed, but only by grinding or machining. The tube thickness in the dressed area shall not be less than the specified minimum wall thickness. All dressed areas shall blend smoothly into the contour of the tube. SIST EN 10208-2:2009

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...