EN 12952-3:2001

(Main)Water-tube boilers and auxilliary installations - Part 3: Design and calculation for pressure parts

Water-tube boilers and auxilliary installations - Part 3: Design and calculation for pressure parts

This Part of this European Standard specifies the requirements for the design and calculation of water-tube boilers

as defined in EN 12952-1.

Wasserrohrkessel und Anlagenkomponenten - Teil 3: Konstruktion und Berechnung für drucktragende Teile

Dieser Teil der Europäischen Norm legt Anforderungen für die Konstruktion und Berechnung von Wasserrohrkesseln nach der Definition in EN 12952-1 fest.

Chaudières à tubes d'eau et installations auxiliaires - Partie 3: Conception et calcul des parties sous pression

Cette partie de la Norme européenne spécifie les règles de conception et de calcul des chaudières à tubes d'eau telles que définies dans l'EN 12952-1.

Vodocevni kotli in pomožne napeljave - 3. del: Konstrukcija in izračun delov, ki so pod tlakom

General Information

- Status

- Withdrawn

- Publication Date

- 11-Dec-2001

- Withdrawal Date

- 20-Dec-2011

- Technical Committee

- CEN/TC 269 - Shell and water tube boilers

- Drafting Committee

- CEN/TC 269/WG 1 - Water-tube boilers

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 21-Dec-2011

- Completion Date

- 21-Dec-2011

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 28-Dec-2011

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

EN 12952-3:2001 is a standard published by the European Committee for Standardization (CEN). Its full title is "Water-tube boilers and auxilliary installations - Part 3: Design and calculation for pressure parts". This standard covers: This Part of this European Standard specifies the requirements for the design and calculation of water-tube boilers as defined in EN 12952-1.

This Part of this European Standard specifies the requirements for the design and calculation of water-tube boilers as defined in EN 12952-1.

EN 12952-3:2001 is classified under the following ICS (International Classification for Standards) categories: 27.040 - Gas and steam turbines. Steam engines. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12952-3:2001 has the following relationships with other standards: It is inter standard links to EN 12952-3:2011, EN 12952-14:2004, EN 12952-5:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12952-3:2001 is associated with the following European legislation: EU Directives/Regulations: 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12952-3:2001 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Wasserrohrkessel und Anlagenkomponenten - Teil 3: Konstruktion und Berechnung für drucktragende TeileChaudieres a tubes d'eau et installations auxiliaires - Partie 3: Conception et calcul des parties sous pressionWater-tube boilers and auxilliary installations - Part 3: Design and calculation for pressure parts27.060.30Grelniki vode in prenosniki toploteBoilers and heat exchangersICS:Ta slovenski standard je istoveten z:EN 12952-3:2001SIST EN 12952-3:2002en01-maj-2002SIST EN 12952-3:2002SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12952-3December 2001ICS 27.040English versionWater-tube boilers and auxilliary installations - Part 3: Designand calculation for pressure partsChaudières à tubes d'eau et installations auxiliaires - Partie3: Conception et calcul des parties sous pressionWasserrohrkessel und Anlagenkomponenten - Teil 3:Konstruktion und Berechnung für drucktragende TeileThis European Standard was approved by CEN on 25 July 2001.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2001 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12952-3:2001 ESIST EN 12952-3:2002

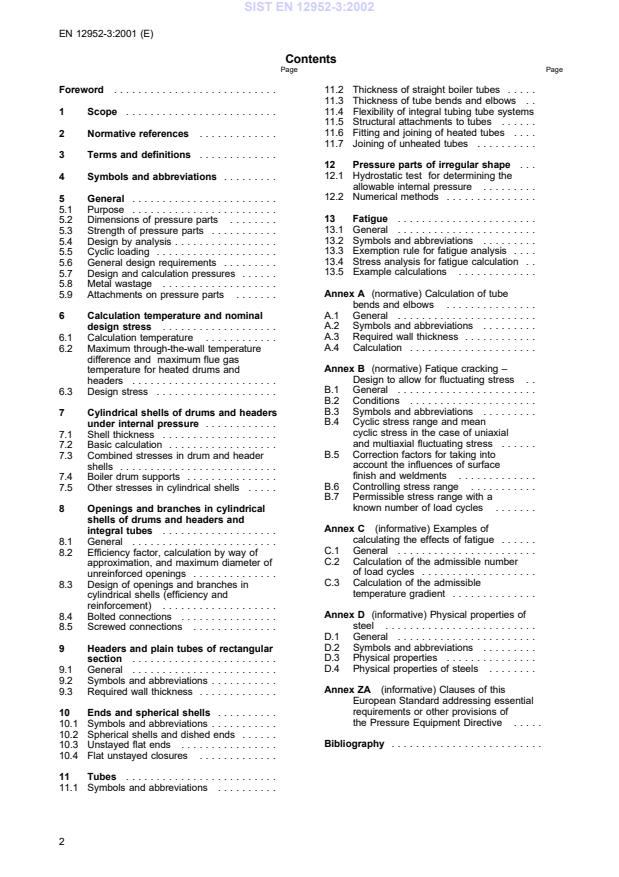

5.4Design by analysis.

5.5Cyclic loading .5.6General design requirements .5.7Design and calculation pressures .5.8Metal wastage .5.9Attachments on pressure parts .6Calculation temperature and nominal design stress .6.1Calculation temperature . 6.2Maximum through-the-wall temperaturedifference and maximum flue gastemperature for heated drums and headers .6.3Design stress .7Cylindrical shells of drums and headersunder internal pressure.7.1Shell thickness .7.2Basic calculation .7.3Combined stresses in drum and header shells .7.4Boiler drum supports.7.5Other stresses in cylindrical shells .8Openings and branches in cylindrical shells of drums and headers and integral tubes .8.1General .8.2Efficiency factor, calculation by way ofapproximation, and maximum diameter of unreinforced openings .8.3Design of openings and branches in cylindrical shells (efficiency and reinforcement) .8.4Bolted connections .8.5Screwed connections .9Headers and plain tubes of rectangular section .9.1General .9.2Symbols and abbreviations.9.3Required wall thickness.10Ends and spherical shells .10.1Symbols and abbreviations.10.2Spherical shells and dished ends .10.3Unstayed flat ends .10.4Flat unstayed closures .11Tubes .11.1Symbols and abbreviations .11.2Thickness of straight boiler tubes .11.3Thickness of tube bends and elbows .11.4Flexibility of integral tubing tube systems 11.5Structural attachments to tubes .11.6Fitting and joining of heated tubes .11.7Joining of unheated tubes .12Pressure parts of irregular shape .12.1Hydrostatic test for determining the allowable internal pressure .12.2Numerical methods .13Fatigue .13.1General .13.2Symbols and abbreviations .13.3Exemption rule for fatigue analysis .13.4Stress analysis for fatigue calculation .13.5Example calculations .Annex A (normative) Calculation of tube bends and elbows .A.1General .A.2Symbols and abbreviations .A.3Required wall thickness .A.4Calculation .Annex B

(normative) Fatique cracking – Design to allow for fluctuating stress .B.1General .B.2Conditions .B.3Symbols and abbreviations .B.4Cyclic stress range and meancyclic stress in the case of uniaxial and multiaxial fluctuating stress .B.5Correction factors for taking into account the influences of surface finish and weldments .B.6Controlling stress range .B.7Permissible stress range with a known number of load cycles .Annex C

(informative) Examples of calculating the effects of fatigue .C.1General .C.2Calculation of the admissible numberof load cycles .C.3Calculation of the admissible temperature gradient .Annex D (informative) Physical properties ofsteel .D.1General .D.2Symbols and abbreviations .D.3Physical properties .D.4Physical properties of steels .Annex ZA (informative) Clauses of this European Standard addressing essentialrequirements or other provisions of the Pressure Equipment Directive .Bibliography .2SIST EN 12952-3:2002

Part 4 is not applicable during the design, construction and installation stages.The annexes A and B of this European Standard are normative.The annexes C, D, and ZA of this European Standard are informative.3SIST EN 12952-3:2002

ScopeThis Part of this European Standard specifies the requirements for the design and calculation of water-tube boilersas defined in EN 12952-1.2

Normative referencesThis Part of the European Standard incorporates by dated or undated reference, provisions from other publications.These normative references are cited at the appropriate places in the text and the publications are listed hereafter.For dated references, subsequent amendments to, or revisions of any of these publications apply to this EuropeanStandard only when incorporated in it by amendment or revision. For undated references, the latest editions of thepublication referred to applies (including amendments).prEN 1092-1,

Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories, PN de-signated — Part 1: Steel flanges.EN 1591,

Flanges and their joints — Design rules for gasketed circular flange connections — Calculation method.prEN 1759-1,

Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories, classdesignated — Part 1: Steel flanges NPS ½ to 24.EN 10025,

Hot rolled products of non-alloy structural steels — Technical delivery conditions (includes amendmentA1 : 1993).prEN 10266,

Steel tubes, fittings and structural hollow sections — Definitions and symbols for use in productstandards.prEN 12953-3,

Shell boilers — Part 3: Design and calculation.EN 12952 series,

Water-tube boilers and auxilliary installations.prEN 13445 series,

Unfired pressure vessels.prEN 13480 series,

Metallic industrial piping.ISO 7-1,

Pipe threads where pressure-tight joints are made on the threads — Part 1: Dimensions, tolerances anddesignations.ISO 4287,

Geometrical Product Specification (GPS) — Surface texture: Profile method — Terms, definitions andsurface texture parameters.3

Terms and definitionsFor the purpose of this standard the terms and definitions given in EN 12952-1 apply.4SIST EN 12952-3:2002

Symbols and abbreviationsFor the purposes of this standard, the symbols given in Table 4-1 of EN 12952-1 shall apply. Throughout thisEuropean Standard, additional terminology and symbols have been included where necessary to meet therequirements of the specific text concerned.5

General5.1

PurposeWater-tube boiler pressure parts shall be designed in accordance with the requirements of EN 12952-3. Theresulting designs shall be reproduced in the form of approved drawings and specifications to ensure the properapplication of the design requirements during the manufacturing and inspection stages.5.2

Dimensions of pressure partsThe wall thickness and other dimensions of pressure parts sufficient to withstand the calculation pressure atcalculation temperature for the design lifetime shall be determined in accordance with EN 12952-3 using materialsin accordance with EN 12952-2.The design for loadings arising from the following situations shall also be determined in accordance with this part ofEN 12952:a)the bending of a drum or header as a beam under self weight and imposed loads;b)local support loads on drums;c)thermally induced forces and moments within or arising from systems of integral tubing;d)local loading of tubes by structural attachments;e)rapid and frequent changes of pressure and temperature.Methods for calculating stresses caused by external loads applied to nozzles and to attachments shall be inaccordance with prEN 13445.NOTE

The purpose of this part is to give specific design rules for common forms of loadings to which boiler parts are normallysubjected to and general rules on how other loadings are to be considered. It does not give specific design rules for loadings otherthan those described in a) to e).These design rules are adequate for boilers of established construction, installed and operated in accordance withthe manufacturer's instructions.Determination of the dimensions of pressure parts shall be given special consideration not included in this standard,when abnormal conditions are present, such as:f)abnormally high corrosive products of combustion;g)highly pressurized products of combustion;h)poor feedwater.Deviations from the requirements of this standard by the use of alternative design methods shall be permitted,provided it can be shown that the adoption of such methods does not impair the safety of the component. A recordof all deviations shall be recorded in the manufacturer`s dossier. See also clause 7 of EN 12952-1.5.3

Strength of pressure partsThe strengths of the pressure parts shall be such as to withstand the following loads:a)internal pressure5SIST EN 12952-3:2002

Design by analysisIt shall be permissible to design by analysis provided the safety and functional requirements of the components arenot impaired.The results of any stress calculations carried out for loadings not explicitly covered by equations in this clause shallbe determined by using the criteria given in prEN 13445.5.5

Cyclic loadingBoiler components are deemed to be exposed to cyclic loading if the boiler is designed for more than 500 cold startups. Where cylindrical or spherical pressure parts with openings are subject to cyclic loading, the followingcalculation shall be carried out:(5.5.-1)vt

550N/mm2 p0

am×dmns×ems 0,5

Ze2mswherep0 is the maximum operating pressure,dmis the mean diameter of the shell,emsis the minimum wall thickness;ns= 2 for cylindrical shells orns= 4 for spherical shells;am = 4 or if there is any doubt that this value is conservative, the exact value taken from Figure 13.4-5 orFigure 13.4-7 shall be used;Z= 2 K mm4/(N s) for ferritic steels orZ= 1 K mm4/(N s) for austenitic and martensitic steels orZ=

(5.5.-2)

0,5DthgcylspatbtE/(1 v)Where exact values Dth, bt, E, v may be taken from annex D, gcyl sp from Figure 13.4-6 or 13.4-9 and at from Figure13.4-8.If the result of this calculation is smaller than the required temperature transient at start up, or if it is negative, then13.4 shall apply.For designs subject to cyclic loading, careful attention shall be paid to the design configuration in order to avoidstress raising features and to ensure good stress distribution. Stamping of materials shall not be done in criticalareas.In considering operating conditions, the design shall make adequate allowance for corrosion and fatigue.The level of non-destructive testing adopted shall meet the acceptance criteria for main drum welds in EN 12952-6.6SIST EN 12952-3:2002

Other design requirements5.6.1 GeneralIn particular, cognizance shall be taken of the following requirements in EN 12952-5 and EN 12952-6:a)the design shall be such that manufacturing and welding in accordance with EN 12952-5 and inspection inaccordance with EN 12952-6 shall be possible; b)where partial penetration welds are to be used, the depth of the required weld preparation groove shall bespecified on the drawing;c)the welds attaching branches, nozzles, stubs and supports to drums and headers shall not involve any combina-tion of austenitic and ferritic steel;d)the requirements covering the attachment of nozzles and branches to drums and headers without strengthwelding shall be to 9.3 of EN 12952-5;e)the requirements covering tube connections to drums and headers without strength welding shall be to 9.4 ofEN 12952-5;f)limits of operation for cast iron valves and fittings;g)where random NDE of welds is permitted by EN 12952-6, it shall be demonstrated that the welding is adequatefor the imposed loading when a weld joint factor of 0,85 is applied;h)the special requirements applicable to coil boilers are given in annex D of EN 12952-5;i)the special requirements applicable to chemical recovery boilers are given in annex E of EN 12952-5.For major components operating in the creep range, facilities shall be provided for monitoring the creep in relationto operation.5.6.2 AccessThe boiler shall be designed to ensure adequate access is provided to facilitate the internal examination of thedrums and headers. The examination may be either manual or remote in accordance with the physical size of thecomponents. The requirements and limitations of access and inspection openings shall be in accordance with 9.2of EN 12952-5.5.6.3 Drainage and ventingThe boiler shall be provided with adequate means of drainage and venting in order to avoid water hammer andvacuum collapse, and to enable internal inspections to be carried out.5.7

Design, calculation and test pressures5.7.1

Design pressureFor the purpose of EN 12952-3 the design pressure pd shall be equal to/or greater than the maximum allowablepressure PS.For each compartment of the water-tube boiler, the design pressure shall be at least the highest set pressure of anysafety valve mounted on that compartment.NOTE

A compartment is any pressurized section of plant which can be isolated by shut-off valves.7SIST EN 12952-3:2002

Calculation pressureEach compartment might be divided into sections, each with its own calculation pressure pc and calculation tempe-rature tc. The design of each section shall be based on one of the following.a)For parts whose design stress has been derived from tensile strength Rm or minimum yield proof strength Rp 0,2 tc,the calculation pressure shall be the design pressure increased to the highest pressure possible when the plantis operating at the calculation temperature. Any difference between design pressure and calculation pressuremight be caused by hydrostatic pressure and by pressure drop caused by fluid flow. Differences in hydrostaticheight less than or equal to 0,05 MPa can be ignored;b)For parts whose design stress has been derived from the creep rupture stress, the calculation pressure shall bethe lowest set pressure of any safety valve at the superheater/reheater outlet, as appropriate, increased by thehighest pressure difference possible under continuous rating at the calculation temperature.A check shall be made of the thickness calculated by method b), using the calculation pressure of a) above with adesign stress derived from tensile strength Rm or minimum yield/proof strength Rp 0,2/tc at the calculation temperatureused in b), and the greater thickness used.If the minimum yield strength data at higher temperatures are not available, linear extrapolation may be allowed.5.7.3

Calculation pressure for pressure differencesFor parts with a design pressure not less than 1 N/mm2, which are simultaneously subject to both internal andexternal pressure, e.g. surface type attemperators in boiler drums, and where the design ensures that bothpressures always occur together, the calculation pressure shall be the maximum pressure difference, but not lessthan 1 N/mm2. The loading occurring during hydrostatic testing shall be taken into account.5.7.4 Hydrostatic test pressure5.7.4.1

GeneralIn order to demonstrate, the strength and integrity of individual components and of the completely assembled water-tube boiler, and to establish that no major error or defect has occurred, completely assembled water-tube boilersshall be hydrostatically tested to the test pressure specified in 5.7.4.3 and individual components shall be hydro-statically tested in accordance with 5.7.4.3 without any sign of weakness or defect.The hydrostatic tests shall be carried out on welded components or the completed water-tube boiler after all weldingand heat treatment has been completed, but may be carried out prior to the drilling of holes for expanded tubes inthe boiler drum.5.7.4.2 Hydrostatic tests on individual componentsBoiler drums shall be hydrostatically tested to the test pressure specified in 5.7.4.3 before assembly into the water-tube boiler, unless these devices are to be assembled into a water-tube boiler and the assembled water-tube boileris then to be tested in the manufacturer's workshop to the test pressure specified in 5.7.4.3.All components which are not reasonably accessible for inspection after assembly into the water-tube boiler shall beindividually hydrostatically tested to the test pressure specified in 5.7.4.3 before assembly into the water-tube boiler.Components other than those specified above shall not require to be individually tested before assembly in thewater-tube boiler.5.7.4.3 Test pressureA boiler assembly comprises of a number of components each having its own specific calculation pressure anddesign temperature. The test pressure pt for components as defined in 5.7.4.2 shall be determined directly in accord-ance with 5.7.4.4.8SIST EN 12952-3:2002

Calculation of hydrostatic test pressureThe hydrostatic test pressure for a component or completely assembled boiler, shall be determined as follows:pt = 1,43 × PS(5.7-1)or(5.7-2)pt 1,25×pc×

Rp0,220Kwhich ever is the greater, wherepcis the calculation pressure of the component under considerationptis the test pressure for the component under considerationThe ratio Rp0,2 20/K to be used shall be the highest of those permitted for the component under consideration, basedon the material properties and the specific calculation temperature and should not be less than 1, see also 6.3.5.8

Metal wastageNOTE

For the purpose of design in accordance with EN 12952-3 metal wastage includes oxidation, corrosion, erosion andabrasion.5.8.1

Internal wastageInternal wastage is normally small and shall not be considered for boilers operated with feedwater in accordancewith EN 12952-12. For components exposed to risk of greater than normal wastage (e.g. erosion by turbulence),appropriate countermeasures shall be provided.The magnetite layer shall be protected in accordance with 13.4.1.1.5.8.2

External wastageExternal wastage of pressure parts not exposed to flue gases is normally small, and the thickness determined by thisEN 12952-3 shall be adequate without further addition.Tubes exposed to flue gases shall experience wastage to a varying extent. If the boiler design data indicates thatwastage can be significant, the tubes shall be increased in thickness accordingly. Also other means of tubeprotection may occur. In this case the wall thickness allowance shall be specified by the manufacturer unless thepurchaser has specified a higher allowance.In the special case of chemical recovery boilers, it shall be permitted to provide for wastage by means of metallurgi-cally bonded, composite materials tubing with corrosion resistant layers.9SIST EN 12952-3:2002

RequirementsWhere an allowance for wastage is made, the amount shall be specified in the design documents stipulating whetherthis allowance is "internal or external". Strength calculations shall use the dimensions after the wastage allowancesare removed.However, for tubes designed using design strengths derived from creep rupture properties, integration over time ofthe effects of creep and wastage shall be permitted, so that failure can be predicted at a time not less than thedesign lifetime. In such cases the tube thickness towards the end of the design life might be less than required byequations (11.2-2 to -5).5.8.4

Stress corrosionWith boiler water quality controlled in accordance with EN 12952-12, stress corrosion would not be expected tooccur in ferritic tubing under normal boiler operating conditions. The risk of such corrosion in austenitic superheatermaterials can be satisfactorily reduced by ensuring no water droplets are carried over into the austenitic tubing.Carry over can be considered to have been adequately restricted if the steam has an enthalpy of 2 900 kJ/kg orgreater, or the enthalpy corresponds to a temperature of 425 °C or higher.Where it is predicted that exceptional conditions of chemical concentration may occur for prolonged periods ofoperation, the effects of stress corrosion and corrosion gouging shall be considered, and the materials selectedaccordingly.NOTE

It is not possible to compensate for stress corrosion by increasing the thickness of components.5.8.5

Mechanical requirementsWhere there is a likelihood of in-service relative movement or fretting between a pressure part and a non-pressurepart in contact with it, consideration shall be given to wastage of the components. If necessary wear pads shall bewelded to the pressure part, or other equivalent means shall be employed.5.9

Attachments on pressure parts5.9.1

Load carrying attachmentsLoad-carrying attachments shall be defined by the design engineer and indicated as such on the drawing.Load-carrying attachments are:a)attachments designed for primary loads which are completely definable and are usually for support purposes,or;b)attachments which are usually provided for alignment and/or restraint purposes where the loading is not easilydefined. Such attachments may be loaded by either primary or secondary loads.Stresses caused by load-carrying attachments shall be calculated in accordance with prEN 13445.5.9.2

Non-load-carrying attachmentsNon-load-carrying attachments are attachments which carry no significant primary or secondary loads duringmanufacture, erection, testing or any operating condition.10SIST EN 12952-3:2002

Calculation temperature and nominal design stress6.1

Calculation temperature6.1.1 GeneralFor the purpose of EN 12952 the maximum allowable temperature TS shall be that at the steam/hot water outlet.The reference temperature tor shall the mean fluid operation temperature of the component under consideration,which is to be expected during use.Where steam or water flows through components in parallel, tor for each component shall take account of variationsin heat transfer and fluid flow between the parallel parts.The calculation temperature tc of a component shall be calculated by taking account of variations in heat transfer andfluid flow in the boiler. If such calculations are not carried out then the calculation temperature tc shall be composedof the reference temperature tor and the temperature allowance in accordance with 6.1.2 to 6.1.10. The temperatureallowances in Table 6.1-1 shall be regarded as minimum values, except where calculations of tc are carried out, andis allowed by 6.1.5.Table 6.1-1 — Reference temperatures and temperature allowancesPhysicalstateReferencetemperatureTemperature allowancesUnheatedcomponentsaHeated componentsaHeatingmainly byradiationbHeatingmainly byconvectionProtectedagainstradiationWater orwater/steammixtureSaturationtemperature atallowable(working gauge)pressure ps 1 orat allowable(total gauge)pressure ps 20 °C50 °CFor headersc(30 + 3 es) °Cbut not lessthan 50 °C(15 + 2 es) °C but not morethan 50 °C20 °CSuperheatedsteamSuperheatedsteam,see also 6.1.315 °C,see also 6.1.550 °C35 °C20 °Ca

For definitions of types of heating see 6.1.7 to 6.1.10b

Platen type superheaters are treated like convection type superheaters.c

For definition of header see 6.1.66.1.2

Circulation boilersFor circulation boilers, the reference temperature and the temperature allowance shall be in accordance withTable 6.1-1.6.1.3

Once-through boilers, superheaters and reheatersThe calculation temperature tc shall be calculated taking into account of variations in heat transfer and fluid flow inthe boiler.For once-through boilers, superheaters and reheaters the reference temperature shall be the mean temperatureexpected during service, of the fluid flowing through the various boiler parts.6.1.4

Hot water generatorsFor the special case of hot water generators, where the temperature of the contained fluid is limited by thermostats1),the reference temperature of the components shall be the fluid temperature.

1) Temperature limiters manufactured and tested in accordance with EN 12952-11 are considered to be reliable11SIST EN 12952-3:2002

Temperature allowances for unheated componentsFor unheated components carrying superheated steam, the temperature allowance of 15 °C given in Table 6.1-1shall be reduced to 5 °C (measuring tolerance) if it shall be ensured that the temperature required by the designcannot be exceeded.This can be achieved by:a)temperature control upstream of the said components;b)the arrangement of cooling or mixing points (e.g. by headers through which the fluid flows in a longitudinaldirection) upstream of the said components;c)connection measures for heating surface arrangement or the like.6.1.6

HeadersTubular hollow parts with a nominal external diameter greater than 76,2 mm, into which there are three or morenon-axial tube entries, shall be considered as headers.6.1.7

Unheated componentsComponents shall be considered to be unheated ifa)they are behind refractory brickwork, and an intermeditate space of at least 100 mm is between the brickworkand the components;b)a gas-tight-welded waterwall is arranged between the components and the furnace or gas pass;c)the components are protected by a layer of refractory bricks or refractory lining and this layer is not primarilysubject to heat absorption due to radiative heat transfer2); in this case, the brickwork or refractory lining shall beattached to the suspended part by means of holding devices. In the case of headers, studding can be providedfor this purpose;d)the highest possible temperature of the flue gas is less than the reference temperature of the component.6.1.8

Components protected against radiationComponents shall be considered to be protected against radiation2) if they are screened by closely spaced tubes(maximum clear distance 3 mm) and no substantial flow of flue gases can occur between the screening tubes andthe components.6.1.9

Components heated by convectionComponents shall be considered to be primarily heated by convection ifa)they are not subject to radiation2);b)the components are protected by a layer of refractory brickwork or refractory lining against radiative heat trans-fer1). In this case, the bricks or refractory lining shall be attached to the suspended part by holding devices,which in the case of headers, can be studding;

2) see 6.1.1012SIST EN 12952-3:2002

P0P90pl2£0,1whereP0is the longitudinal pitch with Æ = 0;P90is the circumferential tube pitch on the external surface with Æ = 90;lis the distance between component and furnace envelope.6.1.10

Components heated by radiationUnscreened components shall be considered to be primarily heated by radiation, if they are subject to radiation byflue gases with a temperature > 950 °C.Figure 6.1-1 — Components protected by one row of tubes13SIST EN 12952-3:2002

Maximum through-the-wall temperature difference and maximum flue gas temperature forheated drums and headers6.2.1

Maximum through-the-wall temperature differenceThe through-the-wall temperature difference (defined as outside wall temperature minus inside wall surfacetemperature) of heated drums and headers, shall not exceed 30 K.NOTE

Components made from ferritic steel not exceeding 32 mm wall thickness and exposed to a heat flux less or equal to 40kW/m2 will meet this requirement.6.2.2

Headers exposed to flue gasesSurfaces of superheater and reheater headers shall not be exposed to flue gas temperatures in excess of 500 °C.6.2.3

Allowable deviationsIn cases where it is necessary to deviate from 6.2.1 and 6.2.2 it shall be verified that unsteady and steady thermalstresses do not lead to unacceptable stresses in the component wall.6.3

Design stress6.3.1

Design stress for componentsThe design stress f to be used for the design of components primarily subjected to static loading shall be the lowestvalue obtained from equation (6.3-1)(6.3-1)f

KSwhere the material strength value K and the safety factor S are given in Tables 6.3-1 or 6.3-2.6.3.2 Design stress for welded connections operating under creep conditionWhen the creep properties of the welded connection are known, the smallest of the design strengths of the weldedconnection and the two joined materials shall be used for loading at right angles to the weld seam.When the creep properties of the welded connection are not known, but those of the filler material are known, thedesign strength for this loading shall be reduced by 20 % from the smaller of the design strengths of the joinedmaterials. When the creep strength of the filler metal is not known, the joint strength shall be reduced by a further20 %.6.3.3 Design stress for austenitic steelsIn the case of austenitic steels, the following shall be used:–if its elongation after rupture exceeds 30 %,

of Re t;–or, alternatively, and if its elongation after rupture exceeds 35 %, 5/6 of Re t and

of Rm 20.6.3.4

Design stress for test pressureAt the test pressure p' the design stress shall be(6.3-2)f

K S where the material strength value K' and the safety factor S' are given in Table 6.3-3.15SIST EN 12952-3:2002

RequirementsThe shell thickness after deduction of allowances, ers = es

c1

c2 of drums and headers shall be the greatest ofthose required by the following:a)a minimum of 9,5 mm for headers 300 mm outside diameter and above, and a minimum of 6 mm for headersbelow 300 mm outside diameter;b)the requirements of 7.2 by applying 8.2 or 8.3.3 and 8.3.4;c)the requirements of 7.3 and 7.4 (if applicable).7.1.2 Required wall thickness including allowancesThe required wall thickness including allowances shall be derived fromes' = ecs + c1 + c2(7.1-1)7.2 Basic calculation7.2.1

Required wall thickness without allowancesThe required wall thickness without allowances ecs, in mm, of a cylindrical shell shall be determined by either of thefollowing equationsif dis is given(7.2-1)ecs

pcdis(2fs pc)vorif dos is given(7.2-2)ecs

pcdos(2fs pc)v 2pcwhere the following applies in addition to Table 4-1 of EN 12952-1:– v is the minimum efficiency for isolated or adjacent branches vb or vm, respectively, isolated or adjacentopenings in longitudinal, oblique or circumferential direction, determined in accordance with 8.2 by way ofapproximation or in accordance with 8.3.3 and 8.3.4.Cladding for the purpose of metal wastage resistance shall not be taken into account.The calculation of the required wall thickness of a main body reduced in strength by openings shall only be possibleby iteration since strength reduction depends on the wall thickness.The equivalent value of the stress in the shell shall be calculated using an inversion of equations (7.2-1) or (7.2-2).Thermal stress caused by through-the-wall-temperature-difference shall be taken into account in accordance with therequirements of clause 13.17SIST EN 12952-3:2002

ppcd2is4As

WAswhere As is the shell cross-sectional area at the section considered, see Figure 7.3-1. When openings in the shellare reinforced by thickening the walls of branches in accordance with 8.1 to 8.3, the areas of compensation in thebranch wall can be included in As.The following condition shall apply at any circumferential section through the shell:(7.3-2)fd

pc2£fs18SIST EN 12952-3:2002

Shell cross-sectional area2

Neutral axisFigure 7.3-1 — Net area of shell cross-section subject to longitudinal loads7.3.3 Longitudinal bending stressThe bending moment MR at any section shall be the algebraic sum of the resultant bending moments due to theeccentricity of the end pressure ME and due to self weight, weight of water and externally applied loads MW.MR = ME + MW(7.3-3)The resultant bending moment ME due to the eccentricity a of the end pressure shall be calculated from:(7.3-4)ME

pcd2ispa4wherea

is the eccentricity of the net cross section.The resultant bending moment MW due to externally applied loads shall be calculated by treating the shell as a beamcarrying the externally applied loads including its own weight and that of the contents under working conditions. MWshall be the bending moment at the section subjected to the greatest bending from this cause.The stress due to bending fM shall be calculated as follows:(7.3-5)fM

MRYIAwhereYis the distance from the neutral axis of the net cross section to the extreme mid point of the shell thicknessin mm;IAis the second moment of area.The values of MR, Y and IA shall depend on the direction of the neutral axis of bending. The direction shall be chosenso that the resulting stress fM is a maximum.Taking fd shown in 7.3.2 into consideration the following condition shall apply:(7.3-6)fd fM

pc2£fs19SIST EN 12952-3:2002

pcdis2ersLet the longitudinal stress on cross sectional area of circumferential section f2 be:f2 = vm2 (fd + fM)(7.3-8)where vm2 is the ligament efficiency on a circumferential section at the point where fd and fM act, see Figure 7.3-2.Key1 Longitudinal axis of shell2 Developed radial view on shell mid-thicknessFigure 7.3-2 — Tubes holes with diagonal ligaments – efficiency factors for ligament ABWhere the ligament under consideration is between holes of equal size the apparent ligament efficiency on thediagonal line shall be given by:(7.3-9)vm3 1

dobPFWhere holes are of unequal size, the coefficient for the diagonal line shall be given by:(7.3-10)vm3 1

(dob1 dob2)cosF2Pb020SIST EN 12952-3:2002

1vm3

f1 f22

(f1 f2)cos2F2The average transverse stress fB on the ligament shall be given by:(7.3-12)fB vm3

f1 f22

(f1 f2)cos2F2The average shear stress fC on the ligament shall be given by:(7.3-13)fC

(f1 f2)sin2F2vm3The stress f3 in N/mm2 on the ligament shall be given by:(7.3-14)f3

fA fB

(fA fB)2 4f2C(7.3-15)f3

pc2£fs7.4 Boiler drum supportsWhere large diameter but relatively thin drums are carrying heavy loads on saddles or slings, equation (7.4-1) shallbe used as a guide to assess whether precise calculations are needed to determine local stresses:(7.4-1)fc 0,78

Wlsers

rmsers£fswhereWis t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...