EN 14582:2007

(Main)Characterization of waste - Halogen and sulfur content - Oxygen combustion in closed systems and determination methods

Characterization of waste - Halogen and sulfur content - Oxygen combustion in closed systems and determination methods

This standard specifies a combustion method for the determination of halogen and sulphur contents in materials by combustion in a closed system containing oxygen (calorimetric bomb), and the subsequent analysis of the combustion product using different analytical techniques.

This method is applicable to solid, pasty and liquid samples containing more than 0,025 g/kg of halogen and/or 0,025 g/kg of sulphur content. The limit of detection depends on the element, the matrix and the determination technique used.

Insoluble halides and sulphate present in the original sample or produced during the combustion step are not completely determined by these methods.

Charakterisierung von Abfällen - Halogen- und Schwefelgehalt - Sauerstoffverbrennung in geschlossenen Systemen und Bestimmungsmethoden

Diese Norm legt ein Verbrennungsverfahren fest für die Bestimmung des Halogen- und Schwefelgehalts in Materialien durch Verbrennung in einem geschlossenen, Sauerstoff enthaltenden System (kalorimetrische Bombe) und die anschließende Analyse des Verbrennungsprodukts nach unterschiedlichen analytischen Verfahren.

Dieses Verfahren gilt für feste, pastöse und flüssige Proben mit mehr als 0,025 g/kg Halogengehalt und/oder 0,025 g/kg Schwefelgehalt. Die Nachweisgrenze hängt vom Element, von der Matrix und vom Bestimmungs¬verfahren ab.

In der ursprünglichen Probe vorhandene oder beim Verbrennungsschritt erzeugte unlösliche Halogenide und Sulfate werden mit diesen Verfahren nicht vollständig bestimmt.

Caractérisation des déchets - Teneur en halogènes et en soufre - Combustion sous oxygène en systèmes fermés et méthodes de dosage

La présente document spécifie une méthode permettant de déterminer la teneur en halogènes et en soufre des matériaux, par combustion dans un système fermé contenant de l’oxygène (bombe calorimétrique). Elle spécifie également l’analyse des produits de combustion à l’aide de différentes techniques analytiques.

Cette méthode est applicable aux échantillons solides, pâteux et liquides contenant une teneur en halogènes et/ou en soufre supérieure à 0,025 g/kg. La limite de détection dépend de l’élément, de la matrice et de la technique de dosage employée.

Les halogénures et le sulfate insolubles présents dans l’échantillon d’origine ou produits au cours de la phase de combustion ne sont pas complètement dosés par ces méthodes.

Karakterizacija odpadkov - Vsebnost halogena in žvepla - Sežig s kisikom v zaprtem sistemu in metode za določevanje

General Information

- Status

- Withdrawn

- Publication Date

- 13-Mar-2007

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 444 - Environmental characterization

- Drafting Committee

- CEN/TC 444/WG 3 - Inorganic analysis

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 03-Aug-2016

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 10-Aug-2016

- Refers

EN 15002:2015 - Characterization of waste - Preparation of test portions from the laboratory sample - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 14582:2007 is a standard published by the European Committee for Standardization (CEN). Its full title is "Characterization of waste - Halogen and sulfur content - Oxygen combustion in closed systems and determination methods". This standard covers: This standard specifies a combustion method for the determination of halogen and sulphur contents in materials by combustion in a closed system containing oxygen (calorimetric bomb), and the subsequent analysis of the combustion product using different analytical techniques. This method is applicable to solid, pasty and liquid samples containing more than 0,025 g/kg of halogen and/or 0,025 g/kg of sulphur content. The limit of detection depends on the element, the matrix and the determination technique used. Insoluble halides and sulphate present in the original sample or produced during the combustion step are not completely determined by these methods.

This standard specifies a combustion method for the determination of halogen and sulphur contents in materials by combustion in a closed system containing oxygen (calorimetric bomb), and the subsequent analysis of the combustion product using different analytical techniques. This method is applicable to solid, pasty and liquid samples containing more than 0,025 g/kg of halogen and/or 0,025 g/kg of sulphur content. The limit of detection depends on the element, the matrix and the determination technique used. Insoluble halides and sulphate present in the original sample or produced during the combustion step are not completely determined by these methods.

EN 14582:2007 is classified under the following ICS (International Classification for Standards) categories: 13.030.40 - Installations and equipment for waste disposal and treatment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14582:2007 has the following relationships with other standards: It is inter standard links to EN 14582:2016, EN 15002:2015, EN ISO 11465:2025, EN ISO 3696:1995. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14582:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Characterization of waste - Halogen and sulfur content - Oxygen combustion in closed systems and determination methodsCaractérisation des déchets - Teneur en halogenes et en soufre - Combustion sous oxygene en systemes fermés et méthodes de dosageCharakterisierung von Abfällen - Halogen- und Schwefelgehalt - Sauerstoffverbrennung in geschlossenen Systemen und Bestimmungsmethoden13.030.40Naprave in oprema za odstranjevanje in obdelavo odpadkovInstallations and equipment for waste disposal and treatmentICS:SIST EN 14582:2007en,fr,deTa slovenski standard je istoveten z:EN 14582:200701-julij-2008SIST EN 14582:2007SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14582March 2007ICS 13.030.40 English VersionCharacterization of waste - Halogen and sulfur content - Oxygencombustion in closed systems and determination methodsCaractérisation des déchets - Teneur en halogènes et ensoufre - Combustion sous oxygène en système fermé etméthodes de dosageCharakterisierung von Abfällen - Halogen- undSchwefelgehalt - Sauerstoffverbrennung in geschlossenenSystemen und BestimmungsmethodenThis European Standard was approved by CEN on 13 January 2007.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2007 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14582:2007: E

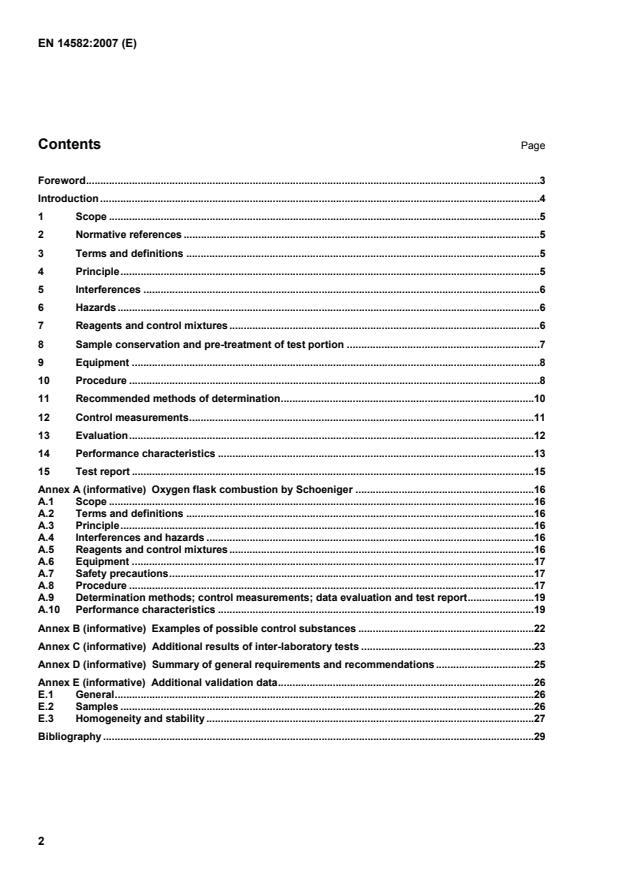

Oxygen flask combustion by Schoeniger.16 A.1 Scope.16 A.2 Terms and definitions.16 A.3 Principle.16 A.4 Interferences and hazards.16 A.5 Reagents and control mixtures.16 A.6 Equipment.17 A.7 Safety precautions.17 A.8 Procedure.17 A.9 Determination methods; control measurements; data evaluation and test report.19 A.10 Performance characteristics.19 Annex B (informative)

Examples of possible control substances.22 Annex C (informative)

Additional results of inter-laboratory tests.23 Annex D (informative)

Summary of general requirements and recommendations.25 Annex E (informative)

Additional validation data.26 E.1 General.26 E.2 Samples.26 E.3 Homogeneity and stability.27 Bibliography.29

Insoluble halides and sulphate present in the original sample or produced during the combustion step are not completely determined by these methods. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 14346, Characterization of waste — Calculation of dry matter by determination of dry residue or water content EN 15002, Characterization of waste — Preparation of test portions from the laboratory sample EN ISO 3696, Water for analytical laboratory use — Specification and test methods (ISO 3696:1987) 3 Terms and definitions For the purposes of this document, the following terms and definitions apply. 3.1 sulphur content sum of sulphur contained as organic and inorganic compounds that can be converted to sulphate by combustion and then absorbed or dissolved in an aqueous solution 3.2 halogen content sum of halogens contained as organic and inorganic compounds that can be converted to halides (fluoride, chloride, bromide, iodide) by combustion and then absorbed or dissolved in an aqueous solution NOTE Be aware that the above definitions are valid for this empirical EN only and do not comply with scientific definitions of sulphur and halogen content. 4 Principle The sample is oxidized by combustion in a closed system (a bomb containing oxygen under pressure). Halogenated and sulphur containing compounds are converted to fluoride, chloride, bromide, iodide and sulphate, which are absorbed and/or dissolved in an absorption solution. Several methods may be used for the determination of halides and sulphate concentrations in the absorption solution. In general this method is applicable for concentrations over 0,025 g/kg depending on the element, matrix and the determination technique. It may be used for aqueous samples or samples that burn with difficulty, which involves the use of a combustion enhancer.

NOTE Combined combustion of iodine and sulphur may interact to improve the reduction of iodine to iodide and the oxidation of sulphur to sulphate. If the actual samples only contain one of the elements a combined control mixture may give false assurance of the method capacity. An example of a mixture of control substances for the determination of fluorine, chlorine, and sulphur is: Mix 0,50 g 4-fluoro-benzoic acid; 2,0 g 4-chloro-benzoic acid; 2,0 g sulfanilic acid and 55,5 g cellulose. An example of a mixture of control substances for the determination of bromine and iodine is: Mix 0,25 g 4-bromo-benzoic acid; 0,25 g 4-iodo-benzoic acid and 59,5 g cellulose. Homogenize the mixtures, e. g. in a pebble mill. This first mixture of fluorine, chlorine, and sulphur contains 1,130 g/kg fluorine; 7,547 g/kg chlorine and 6,170 g/kg sulphur. The second mixture of iodine and bromine contains 1,656 g/kg bromine and 2,132 g/kg iodine. 8 Sample conservation and pre-treatment of test portion Biological active laboratory samples should be stored at 4 °C and the analyses of halogen and sulphur should be carried out within seven days after sampling. If this is not possible, the samples should be further preserved by e. g. freezing, if possible, to minimize biodegradation and loss of volatile halogenated and sulphur compounds. The test sample is prepared according to EN 15002. For solid materials the particle size should be less than 200 µm.

During preparation of the test sample the use of halogenated polymers, e. g. PVC gloves, should be avoided. Drying the laboratory sample may be carried out for homogenisation purposes if the sample, according to the accuracy of the method, contains only negligible amounts of halogen and sulphur compounds volatile at the temperature intended for the drying process. Dry matter is determined according to EN 14346 on a separate sub sample (the result will be used for calculation).

NOTE Heterogeneous moist or paste like samples may be mixed with aluminium oxide (7.1.8) until granular material is obtained and then reduced to a granular powder, preferably with a particle size less than 200 µm. In this case, the ratio of aluminium oxide to sample should be incorporated into the calculation of the halogen and sulphur content and combustion enhancer should be added if necessary.

Materials used for the bomb assembly, such as the head gasket and wire insulation, shall be heat and chemical action resistant and shall not undergo any reaction that will affect the results. Bombs with pitted surfaces should never be used because of their tendency to retain halides and sulphate. After repeated use of the bomb, a film may build up on the inner surface. This dullness should be removed by periodically polishing the bomb according to the manufacturer’s instructions. NOTE The internal surface of some calorimetric bombs may have a ceramic coating or platinum buckets, which have better resistance to corrosion. 9.2 Sample cup, platinum or stainless steel or quartz. 9.3 Firing wire, platinum or stainless steel. 9.4 Ignition circuit, capable of supplying a sufficient current to ignite the sample without melting the wire. 9.5 Absorption flask (e. g. a 200 ml test tube equipped with a glass frit dip-tube for bubbling the combustion gases). 9.6 Usual laboratory equipment, as homogenization devices (e. g. mixers, stirrers, grinders, mills), analytical balance (accurate at least to 0,1 mg), etc. 9.7 Safety precautions The bomb shall not contain any organic residue (vapours of organic solvents, grease, etc.). Respect shall be given to the manufacturer's instructions, especially to the oxygen pressure oxygen inside the bomb and the maximum allowable calorific value of the test portion. NOTE Combustion of 1 g of hydrocarbons such as lubricating oil produces about 40 kJ (the calorific powers of benzoic acid and isooctane are about 26 MJ/kg and 48 MJ/kg). 10 Procedure 10.1 General Before each series of determinations, a blank and quality check have to be carried out on a control mixture (7.2), according to clause 12. Alternately running samples high and low in halogen or sulphur content should be avoided whenever possible as it is difficult to rinse the last traces of ions from the internal surfaces of the apparatus and a tendency for residual elements to carry over from sample to sample has been observed. When a sample high in halogen or sulphur content has preceded a sample low in concentration, the test on the second sample should be repeated and one or both of the low values thus obtained should be considered suspect if they do not fall within the limits of repeatability of this method. It is good practice to insert a blank between each sample, unless the series of samples being analysed has similar expected concentrations. When the composition or homogeneity of the sample is unknown, it is better to carry out the analysis in duplicate or triplicate and report the mean result from all determinations.

NOTE 1 The ascorbic acid and large amount of nitrate may interfere with early eluting halogens (fluoride, chloride and bromide) if detected by ion chromatography. NOTE 2 It is important that iodine is in a defined oxidation step after combustion as ascorbic acid is used to reduce all iodine compounds to iodide. 10.3 Preparation of the bomb The bomb is prepared according to the manufacturer’s instructions and the free ends of the firing wire (9.3) attached to the electric terminals of the ignition circuit (9.4). If using an absorption solution inside the bomb, add 10 ml of this absorption solution (7.1.4 with or without 7.1.3 or 7.1.5), wetting the sides of the bomb (9.1). NOTE

The sample cup should not be in contact with the absorption solution. Depending on the bomb design, it may be necessary to add less than 10 ml of the absorption solution or trap the combustion gases in an external absorption flask (see 9.5.). 10.4 Combustion 0,05 g to 1 g of sample, depending on its calorific value, the amount of element present and on the end-determination method, is weighed (to the nearest 0,1 mg) into the sample cup (9.2). Samples that burn with difficulty (e. g. mineral samples or samples with high water content), may require the addition of a combustion enhancer (7.1.7). Liquid samples may be weighed in a capsule (7.1.9). To avoid swirling up of the sample when filling the bomb with oxygen, powdery samples may be covered with inert material (e. g. aluminium oxide (7.1.8)) or soaked with combustion enhancer (7.1.7), depending of their calorific value. Depending on the type of the bomb, the total sample mass plus enhancer should not exceed 1 g to 1,5 g to avoid dangerous high pressure and possible rupturing the bomb. NOTE 1 The combined energy from sample and enhancer is not important to recover halogens and sulphur from the sample compounds. Hence it may be necessary to optimize the enhancer/sample amount ratio. Place the sample cup in position and arrange the firing wire (9.3) so that it will be just in contact with the sample but not touching the sample cup (9.2). NOTE 2 Some operators use nylon thread or cotton wick and loop it around the wire so that its ends immerse directly in the liquid sample or are in contact with the solid sample. Assemble the bomb and tighten the cover securely. Admit oxygen (7.1.6) carefully (to avoid blowing the sample from the cup) to a pressure below the safety pressure specified by the manufacturer.

If pink vapours are seen, discard the determination and repeat using precautions to trap all the iodine (e. g. smaller test portion, addition of ascorbic acid). Rinse the interior of the bomb, terminals, inner surface of the bomb cover and the sample cup thoroughly with solution from the absorption flask or 20 ml of absorption solution (see 10.2). NOTE 3 Some calorimetric bombs are connected to a demineralized water supply, which enables automatic rinsing of the bomb interior before opening. In this case the rinsing water is pushed by weak overpressure out of the bomb and combined with the absorption solution. Transfer the solution into a volumetric flask. Dilute to the mark with water (7.1.2) or absorption solution (7.1.5). The choice of the final volume depends on the concentration of the halides and sulphate, as well as on the final method used for analysis. 10.6 Cleaning procedure If necessary, remove any residual fuse wire from the terminals and the cup. Using hot water, rinse the interior of the bomb, sample cup, terminals, and the inner surface of the bomb cover. Thoroughly rinse the bomb, cover and cup with demineralized water (7.1.2). 11 Recommended methods of determination ISO/CEN Standards for analysing water and waste water are applicable to analysing the absorption solutions obtained. Since the analysis of such absorption solutions is not in the scope of these standards, it is necessary to check their applicability. The methods referenced in the Bibliography are international standards and can be used. Other methods may be used (e. g. photometry, nephelometry or turbidimetry for sulphur and chlorine, atomic emission spectrometry for chlorine and iodine, capillary electrophoresis for all the elements) but shall be validated compared with the recommended standardised methods.

F Cl Br I S Ion Chromatography X X X X X Atomic emission spectrometry/ICP-MS

(X)ICP-MS X X Potentiometry (Ion selective electrode) X

Potentiometry (AgNO3 titration)

X X X

Gravimetry with BaCl2

X 12 Control measurements A blank test shall be carried out under the same conditions as the samples: absorption solution, combu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...