EN 15011:2011+A1:2014

(Main)Cranes - Bridge and gantry cranes

Cranes - Bridge and gantry cranes

This European Standard applies to bridge and gantry cranes able to travel by wheels on rails, runways or roadway surfaces, and to gantry cranes without wheels mounted in a stationary position.

This European Standard specifies requirements for all significant hazards, hazardous situations and events relevant to bridge and gantry cranes when used as intended and under conditions foreseen by the manufacturer (see Clause 4).

This European Standard does not include requirements for the lifting of persons.

The specific hazards due to potentially explosive atmospheres, ionising radiation and operation in electromagnetic fields beyond the range of EN 61000-6-2 are not covered by this European Standard.

This European Standard is applicable to bridge and gantry cranes manufactured after the date of its publication as an EN.

Krane - Brücken- und Portalkrane

Appareils de levage à charge suspendue - Ponts roulants et portiques

!La présente Norme européenne s'applique aux portiques et ponts roulants pouvant se déplacer par l'intermédiaire de roues (galets) sur des rails, chemins de roulement ou routes et aux ponts roulants sans roues (galets) montés en position fixe."

La présente Norme européenne traite de l'ensemble des phénomènes dangereux significatifs, des situations et des événements dangereux liés aux ponts roulants et aux portiques lorsque ceux-ci sont utilisés conformément à l'usage prévu et dans les conditions prévues par le fabricant (voir Article 4).

La présente Norme européenne ne contient pas de prescriptions relatives au levage de personnes.

Les phénomènes dangereux spécifiques dus à des atmosphères potentiellement explosives, un rayonnement ionisant et un fonctionnement dans des champs électromagnétiques allant au-delà de la plage de l'EN 61000-6-2 ne sont pas couverts par la présente Norme européenne.

La présente Norme est applicable aux ponts roulants et aux portiques qui sont fabriqués après sa date de publication comme Norme Européenne (EN).

Žerjavi - Mostni in portalni (kozičasti) žerjavi (vključno z dopolnilom A1)

General Information

- Status

- Withdrawn

- Publication Date

- 18-Feb-2014

- Withdrawal Date

- 20-Jan-2026

- Technical Committee

- CEN/TC 147 - Cranes - Safety

- Drafting Committee

- CEN/TC 147/WG 14 - Bridge and gantry cranes

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 09-Dec-2020

- Completion Date

- 21-Jan-2026

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 30-Oct-2013

- Effective Date

- 15-Feb-2017

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Frequently Asked Questions

EN 15011:2011+A1:2014 is a standard published by the European Committee for Standardization (CEN). Its full title is "Cranes - Bridge and gantry cranes". This standard covers: This European Standard applies to bridge and gantry cranes able to travel by wheels on rails, runways or roadway surfaces, and to gantry cranes without wheels mounted in a stationary position. This European Standard specifies requirements for all significant hazards, hazardous situations and events relevant to bridge and gantry cranes when used as intended and under conditions foreseen by the manufacturer (see Clause 4). This European Standard does not include requirements for the lifting of persons. The specific hazards due to potentially explosive atmospheres, ionising radiation and operation in electromagnetic fields beyond the range of EN 61000-6-2 are not covered by this European Standard. This European Standard is applicable to bridge and gantry cranes manufactured after the date of its publication as an EN.

This European Standard applies to bridge and gantry cranes able to travel by wheels on rails, runways or roadway surfaces, and to gantry cranes without wheels mounted in a stationary position. This European Standard specifies requirements for all significant hazards, hazardous situations and events relevant to bridge and gantry cranes when used as intended and under conditions foreseen by the manufacturer (see Clause 4). This European Standard does not include requirements for the lifting of persons. The specific hazards due to potentially explosive atmospheres, ionising radiation and operation in electromagnetic fields beyond the range of EN 61000-6-2 are not covered by this European Standard. This European Standard is applicable to bridge and gantry cranes manufactured after the date of its publication as an EN.

EN 15011:2011+A1:2014 is classified under the following ICS (International Classification for Standards) categories: 53.020.20 - Cranes. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15011:2011+A1:2014 has the following relationships with other standards: It is inter standard links to EN 15011:2011/FprA1, EN 15011:2011, EN 15011:2020, EN ISO 11202:2010, EN ISO 11688-1:2009, EN ISO 4871:2009, EN ISO 11201:2010, EN 894-2:1997+A1:2008, EN 13586:2020, EN 795:2012, EN 13001-3-1:2025, EN ISO 3744:2010, EN 12644-1:2001+A1:2008, EN 894-1:1997+A1:2008, EN 13135:2013+A1:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15011:2011+A1:2014 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15011:2011+A1:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Krane - Brücken- und PortalkraneAppareils de levage à charge suspendue - Ponts roulants et portiquesCranes - Bridge and gantry cranes53.020.20DvigalaCranesICS:Ta slovenski standard je istoveten z:EN 15011:2011+A1:2014SIST EN 15011:2011+A1:2014en,fr,de01-marec-2014SIST EN 15011:2011+A1:2014SLOVENSKI

STANDARDSIST EN 15011:20111DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15011:2011+A1

February 2014 ICS 53.020.20 Supersedes EN 15011:2011English Version

Cranes - Bridge and gantry cranes

Appareils de levage à charge suspendue - Ponts roulants et portiques

Krane - Brücken- und Portalkrane This European Standard was approved by CEN on 18 December 2010 and includes Amendment 1 approved by CEN on 19 November 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2014 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15011:2011+A1:2014 ESIST EN 15011:2011+A1:2014

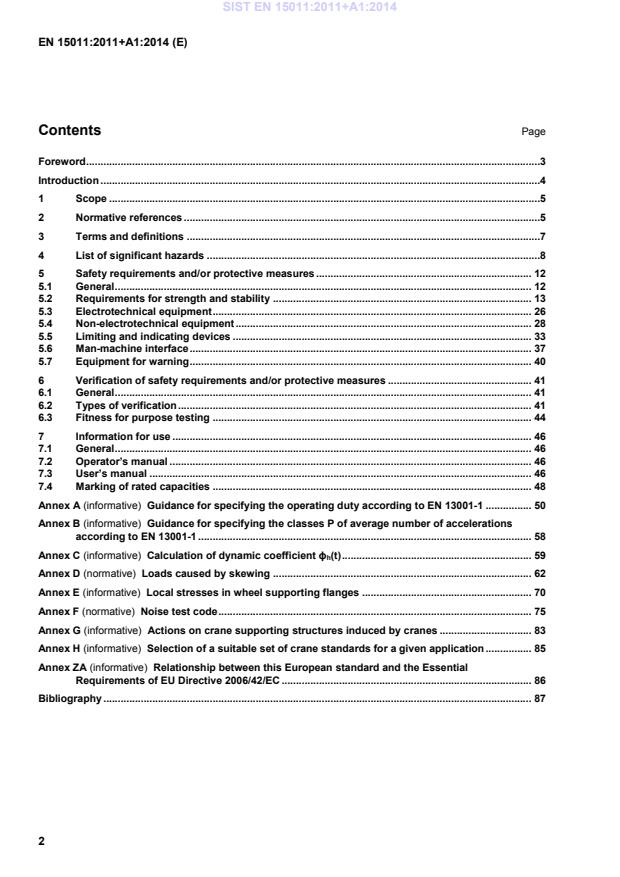

Guidance for specifying the operating duty according to EN 13001-1 . 50 Annex B (informative)

Guidance for specifying the classes P of average number of accelerations according to EN 13001-1 . 58 Annex C (informative)

Calculation of dynamic coefficient ¥h(t) . 59 Annex D (normative)

Loads caused by skewing . 62 Annex E (informative)

Local stresses in wheel supporting flanges . 70 Annex F (normative)

Noise test code . 75 Annex G (informative)

Actions on crane supporting structures induced by cranes . 83 Annex H (informative)

Selection of a suitable set of crane standards for a given application . 85 Annex ZA (informative)

Relationship between this European standard and the Essential Requirements of EU Directive 2006/42/EC . 86 Bibliography . 87

(IEC 60825-1:2007) EN 60947-5-5, Low-voltage switchgear and controlgear — Part 5-5: Control circuit devices and switching elements — Electrical emergency stop device with mechanical latching function (IEC 60947-5-5:1997) EN ISO 3744:2010, Acoustics — Determination of sound power levels and sound energy levels of noise sources using sound pressure — Engineering methods for an essentially free field over a reflecting plane (ISO 3744:2010) EN ISO 4871, Acoustics — Declaration and verification of noise emission values of machinery and equipment (ISO 4871:1996) EN ISO 11201, Acoustics — Noise emitted by machinery and equipment — Determination of emission sound pressure levels at a work station and at other specified positions in an essentially free field over a reflecting plane with negligible environmental corrections (ISO 11201:2010) EN ISO 11202:2010, Acoustics — Noise emitted by machinery and equipment — Determination of emission sound pressure levels at a work station and at other specified positions applying approximate environmental corrections (ISO 11202:2010) EN ISO 11203:2009, Acoustics — Noise emitted by machinery and equipment — Determination of emission sound pressure levels at a work station and at other specified positions from the sound power level (ISO 11203:1995) EN ISO 11204:2010, Acoustics — Noise emitted by machinery and equipment — Determination of emission sound pressure levels at a work station and at other specified positions applying accurate environmental corrections (ISO 11204:2010) EN ISO 11688-1, Acoustics — Recommended practice for the design of low-noise machinery and equipment — Part 1: Planning (ISO/TR 11688-1:1995) !EN ISO 12100, Safety of machinery — General principles for design — Risk assessment and risk reduction (ISO 12100)" SIST EN 15011:2011+A1:2014

1.1 Generated by machine parts or work pieces, e.g. by:

1.1.2 relative location 5.6.2 1.1.3 mass and stability 5.2 1.1.4 mass and velocity 5.2, 5.3.6, 5.4.4, 5.6.1 1.1.5 inadequacy of mechanical strength 5.2 1.2 Accumulation of energy inside the machinery, e.g. by:

1.2.2 fluids under pressure 5.4.1 1.3 Elementary forms of mechanical hazards

1.3.1 Crushing 5.1, 5.6.2, 7.2 1.3.2 Shearing 5.6.2.4 1.3.3 Cutting or severing

1.3.5 Drawing-in or trapping hazard - moving transmission parts 5.6.2.5, 5.6.2.6 1.3.6 Impact 5.5.3.1, 7.2 1.3.9 High pressure fluid injection or ejection hazard 7.3.3

2 Electrical hazards due to: 5.3 2.1 Contact of persons with live parts (direct contact) 5.3.2, 5.3.3 SIST EN 15011:2011+A1:2014

3 Thermal hazards, resulting in:

3.1 burns and scalds, by possible contact of persons with objects or materials with an extreme temperature, by flames, by radiation, etc. 5.4.8.1, 7.3.3 3.2 Hot or cold working environment 5.6.1

4 Hazards generated by noise, resulting in:

4.1 Hearing losses 5.6.4 4.2 Interference with speech communication, signals 5.6.4, 7.3.1

5 Hazards generated by vibration

5.2 Whole body vibration, particularly when combined with poor postures 5.2.2.6, 5.6.1

6 Radiation

6.0 External radiation See Introduction 6.5 Lasers 5.4.8.2

7 Processed materials and substances, used materials, fuels

7.1 Hazards from contact with harmful fluids, gases, mists, fumes and dusts 5.4.8.4 See Introduction 7.2 Fire or explosion hazard 5.4.8.3 See Introduction

8 Neglected ergonomic principles in machine design, e.g. hazards from:

8.1 Unhealthy postures or excessive efforts 5.6.1 8.2 Inadequate consideration of hand-arm or foot-leg anatomy 5.6.1 8.3 Neglected use of personal protection equipment 7.3.3 8.4 Inadequate local lighting 5.6.3 8.6 Human errors, human behaviour 5.5.2 SIST EN 15011:2011+A1:2014

10 Unexpected start-up, unexpected overrun/over speed (or any similar malfunction) from:

10.1 Failure/disorder of control systems 5.3.4 10.3 External influences on electrical equipment 5.3.5.3, 5.4.2 10.4 Other external influences (gravity, wind, etc.) 5.3.5.3, 5.3.6, 5.4.2, 5.5.2.2, 5.5.4 b) and c) 10.5 Errors in the software 5.3.4, 5.3.5.3, 5.4.2 10.6 Errors made by the operator (due to mismatch of machinery with human characteristics and abilities, see No. 8.6) 5.3.5.3, 5.4.2

11 Impossibility of stopping the machine in the best possible conditions 5.4.4.1, 5.4.5.1, 5.5.2.2 13 Failure of the power supply 5.3, 5.4.2 14 Failure of the control circuit 5.3, 5.6.1, 5.4.2 16 Break-up during operation 5.2, 5.4.3.6.1, 7.3.3 16.1 Thermal effect on the crane 5.3 17 Falling or ejected object or fluid 5.4.1, 7.3.3 18 Loss of stability / overturning of machinery 5.2.3 19 Slip, trip and falling of persons (related to machinery) 5.6.2 20 Relating to the travelling function

20.2 Movement without an operator at the driving position 5.3.5.3, 5.3.6, 5.6.1 20.4 Excessive speed of pedestrian controlled machinery 5.6.1 20.5 Excessive oscillations when moving 5.4.4.3, 5.5.4 e), 7.2 20.6 Insufficient ability of machinery to be slowed down, stopped and immobilized 5.4.3.6.1, 5.4.4, 5.5.2.2, 7.2 20.7 From derailment due to travelling 5.4.4.5

21 Linked to the work position (including driving station) on the machine

21.1 Fall of persons during access to (or at/from) the work position 5.6.2 21.2 Exhaust gases / lack of oxygen at the work position 5.4.8.4.1 SIST EN 15011:2011+A1:2014

- contact with the wheels - fall of objects, penetration by object - contact of persons with machine parts or tools (pedestrian control) 5.6.2.5, 5.6.1 21.5 Insufficient visibility from the working position 5.6.1 21.6 Inadequate lighting 5.6.3 21.7 Inadequate seating 5.6.1 21.8 Noise at the driving position 5.6.4 21.9 Vibration at the driving position 5.6.1 21.10 Insufficient means of evacuation/emergency exit 5.6.2, 5.4.8.3 22 Due to the control system 5.6.1 22.1 Inadequate location of controls /control devices 5.6.1 22.2 Inadequate design of the actuation mode and/or action mode of controls 5.6.1 23 From handling the machine (lack of stability) 5.4.4.3 25 From/to third persons

25.1 Unauthorized start-up/use

25.2 Drift of a part away from its stopping position 5.4.5.2 25.3 Lack or inadequacy of visual or acoustic warning means 5.7 26 Insufficient instructions for the driver / operator

26.1 Movement into prohibited area 5.5.3.1, 7.2 26.2 Tipping - Swinging 7.2 26.3 Collision: machines-machine 5.5.3.1, 5.5.3.3, 5.5.4 e), 7.2 26.4 Collision: machines-persons 5.5.3.1, 5.5.4 e), 7.2 26.5 Ground conditions 7.3.1 26.6 Supporting conditions 7.3.1 27 Mechanical hazards and events

27.1 from load falls, collision, machine tipping caused by:

27.1.1 lack of stability 5.2.3, 5.4.8.5 27.1.2 Uncontrolled loading - overloading – overturning moment exceeded 5.2.1.5, 5.2.1.6, 5.4.3.1 to 5.4.3.4, 5.4.8.5, 5.5.1, 5.5.2.1, 5.5.4 a) 27.1.3 Uncontrolled amplitude of movements 5.5.3.3, 7.2 27.1.4 Unexpected/unintended movement of loads 5.3.4, 5.4.1, 5.4.2, 5.4.3.1, 5.6, 7.2 27.1.5 Inadequate holding devices / accessories 5.4.1, 7.2 SIST EN 15011:2011+A1:2014

28 Electrical hazard

28.1 from lightning 7.3.3 29 Hazards generated by neglecting ergonomic principles

29.1 insufficient visibility from the driving position 5.6.1, 5.6.3 5 Safety requirements and/or protective measures 5.1 General Bridge and gantry cranes shall comply with the safety requirements and/or protective measures of Clause 5. In addition, these cranes shall be designed according to the principles of !EN ISO 12100"for relevant but not significant hazards, which are not dealt with by this European Standard. Bridge and gantry cranes shall be in accordance with the following standards as amended by this European Standard: — EN 13001-1, Cranes — General design — Part 1: General principles and requirements; — EN 13001-2, Cranes — General design — Part 2: Load !actions"; — !EN 13001-3-1", Cranes — General Design — Part 3-1: Limit States and proof competence of steel structures; — CEN/TS 13001-3-2, Cranes — General design — Part 3-2: Limit states and proof of competence of wire ropes in reeving systems; — !EN 13135, Cranes — Safety — Design — Requirements for equipment;" — EN 13155, Cranes — Safety — Non-fixed load lifting attachments; — EN 13157, Cranes — Safety — Hand powered cranes; — EN 13557, Cranes — Controls and control stations; SIST EN 15011:2011+A1:2014

!EN 13001-2". Where cranes work in atmospheres contaminated by process debris, such material accumulations deposited upon the upper surfaces of the crane shall be taken into account in the dead load computation. 5.2.1.3 Determination of dynamic factors 5.2.1.3.1 Hoisting and gravity effects acting on the mass of the crane The masses of the crane shall be multiplied with factor φ1 = 1 + δ when calculating the stresses in load combinations in accordance with EN 13001-2. !For masses with unfavourable gravitational load effect=the=factors=shall=be=taken=as=/==0,10=and=¥1 = 1,10, and=for=masses=with=favourable=gravitational=load=effect=as=/== -0,05 and ¥1 = 0,95, unless other values are obtained by measurements or calculations." SIST EN 15011:2011+A1:2014

¥2t = max{¥h(t); t < 3 s}. (A similar simulation can be used for a crane with a chain hoist.); — use one of the simplified Equation (1). a) for a crane with a rope hoist: b) for a crane with a chain hoist:

,max21/22.810,451500htrravRlZϕ×=+×+× ,max21/22.810,45150htuccavflZϕ×=+×+× (1) where vh,max is the maximum steady hoisting speed in metres per second; Rr is the rope grade according to EN 12385-4; fuc is the ultimate strength of the chain steel in newtons per square millimetre; SIST EN 15011:2011+A1:2014

¥2t ≤ 1,07 + 0,24vh,max HC1 1,07 + 0,24vh,max < ¥2t ≤ 1,12 + 0,41vh,max HC2 1,12 + 0,41vh,max < ¥2t ≤ 1,17 + 0,58vh,max HC3 1,17 + 0,58vh,max < ¥2t

HC4 5.2.1.3.2.4 Selection of the hoisting speed The hoisting speed representing the normal use in load combinations A and B, and an exceptional occurrence in load combination C, shall be selected according to the hoist drive class, HD, provided by the system and in !EN 13001-2". 5.2.1.3.2.5 Determination of ¥2 and hoisting class by testing The dynamic factor ¥2 can also be determined by measurement from an equivalent crane. The values measured with different hoisting speeds shall be directly used in calculations, without reference to a hoisting class. NOTE The dynamic increment of deflections found by measurement or dynamic simulation may include the dynamic effects from the mass of the crane including the trolley, see 5.2.1.3.1. The portion represented by the factor δ = 0,1 could be removed from the evaluation of the final ¥2 to avoid it being considered twice in ¥1 and also in ¥2. 5.2.1.3.3 Load caused by travelling on uneven surfaces The dynamic actions on the crane by travelling, with or without hoist load, on roadway or on rail tracks shall be considered by the specific factor φ4. For continuous rail tracks or welded rail tracks with finished ground joints without notches (steps or gaps) the specific factor φ4 = 1. For roadways or rail tracks with notches (steps or gaps) the specific factor φ4 shall be calculated according to !EN 13001-2". For rubber tyred cranes the flexibility of the tyre shall be taken into account. 5.2.1.3.4 Loads caused by acceleration of drives cor=crane=drive=motions,=the=change=in=load=effect,=ûp,=caused=by=acceleration=or=deceleration=is=presented=by=the following equation: SIST EN 15011:2011+A1:2014

!EN 13001-2" as follows: S = S(i) + ¥p „ ¥5 „ a „ m (3) where S(i) is the initial load effect caused by F(i); ¥5 is the amplification factor; ¥p is the factor for effect of sequential positioning movements; a is the acceleration or deceleration value; m is the mass for which a applies. The factor ¥5 shall be taken from Tables 3 and 4 unless more accurate factors are available from elastic model calculations or measurements. The factor ¥p shall be taken from Table 5. Where the force S is limited by friction or by the nature of the drive mechanism, this frictional force shall be used instead of calculated force S. SIST EN 15011:2011+A1:2014

Typical backlash for gearbox Considerable backlash, e.g. open gears Stepless speed control 1,2 1,5 Multi step speed control 1,6 2,0 Two step speed control 1,8 2,2 Single step speed control 2,0 2,4 " Table 4 — Factor ¥5 for hoist mechanism ! Drive type Factor ¥5 lifting Factor ¥5 lowering Stepless speed control 1,05 1,10 Multi step speed control 1,15 1,20 Two step speed control 1,20 1,35 Single step speed control 1,20 1,30 " NOTE 2 Factors in Tables 3 and 4 take account for switching on/off the speed and speed change. Table 5 — Factor ¥P Class of load positioning in accordance with EN 13001-1 ¥P P0 and P1 1,0 P2 1,15 P3 1,3 NOTE 3 Positioning movements may increase the total load effects, when made in non-optimal manner. This is taken into account by factor ¥P dependent upon the class P. Guidance for determining the class P is given in Annex B. 5.2.1.4 Loads caused by skewing 5.2.1.4.1 General Skewing forces for top running cranes and trolleys shall be calculated in accordance with 5.2.1.4.2 to 5.2.1.4.4 and Annex D, which provide simplified methods for calculating the forces generated when considering both RIGID and FLEXIBLE crane structures. Skewing forces for underhung cranes shall be calculated in accordance with 5.2.1.4.5. SIST EN 15011:2011+A1:2014

Figure 1 — Parameters of skew angle The total skew angle to be considered in design is

gwtαααα=++ where . is the skew angle to be considered in design; .g is the skew component sg/wb; .w is the component due to wear - rail and wheel flange/guide roller; .t is the component due to alignment tolerances of rail/wheel. The values for skew angles shall be determined according to Table 6. SIST EN 15011:2011+A1:2014

Crane travelling; Recommended minimum track clearances sgmin = 10 mm sgmin = 5 mm

Trolley traversing; Recommended minimum track clearances sgmin = 4 mm sgmin = 2 mm tα Tolerances (wheel alignment and straightness of the rail) 0,001tα= rad wα Wear of wheel flanges/rollers and rails 0,10/whbbWα=⋅ 0,03/whbbWα=⋅ " The skew angle shall be 0,015radα≤ in order to achieve good travel behaviour of the crane or the trolley. NOTE For larger track clearances the skew angle is reduced to 75 % because bridge and gantry cranes and their trolleys use the full track clearance only rarely. Usually only the forward guide means is in contact with the rail. 5.2.1.4.3 Friction slip relationship The following simplified empirical relationship shall be used to calculate the friction coefficient for longitudinal and lateral slip: ()25001feσµµ−=− (4) where f is the slip coefficient; !0 is the friction factor:

0 = 0,3 for cleaned rails;

0 = 0,2 for non-cleaned rails in usual environment;" e is the base of natural logarithms, 2,718; σ is the slip factor. NOTE The slip factor is the ratio of the slip distance – transverse and/or longitudinal – to the corresponding travel distance. For the transverse slip the slip factor is equal to the instantaneous total skewing angle (α or α+∆α). See D.3.2. !deleted text" SIST EN 15011:2011+A1:2014

Bridge crane, trolley. Even, horizontal, almost stiff. Guide means on one or both end carriages." Method RIGID

B

Crane with articulation, respectively crane with flexible support (≤= articulation about an axis parallel with crane track). Guide means on both end carriages. Each end carriage shall be calculated separately with the method RIGID. Concerning the skewing forces the crane divides into two almost independent, individually guided carriages.

C

Crane without articulation. Guide means on both end carriages. Method RIGID. D

Crane without articulation. Guide means on only one end carriage. The method depends on the flexibility of the structure. The decision is made by the result of the method RIGID. Procedure: a) Calculate the skewing forces with the method RIGID; SIST EN 15011:2011+A1:2014

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...