EN 10329:2006

(Main)Steel tubes and fittings for onshore and offshore pipelines - External field joint coatings

Steel tubes and fittings for onshore and offshore pipelines - External field joint coatings

This European Standard specifies the application and related testing of the corrosion protection coatings applied to steel surfaces left bare after the tubes and fittings (components) are joined by welding.

It defines the different types of coatings for buried and immersed pipelines defined in Table 1.

This European Standard applies to seamless or welded steel tubes used in the construction of pipelines for the conveyance of fluids.

Components coated with this type of coating may be further protected by means of cathodic protection.

Stahlrohre und -formstücke für erd- und wasserverlegte Rohrleitungen - Umhüllungen für Schweißverbindungen

Diese Europäische Norm legt die Anforderungen und die damit verbundenen Prüfungen an Korrosionsschutznachumhüllungen fest, die auf freigelassene Stahloberflächen von durch Schweißen miteinander verbundenen Rohren und Formteilen (Komponenten) aufgebracht werden.

Sie klassifiziert in Tabelle 1 die verschiedenen Nachumhüllungstypen für in Böden und Wässern verlegte Rohrleitungen.

Dieses Dokument gilt für nahtlose und längsnahtgeschweißte Stahlrohre zum Bau von Rohrleitungen für den Transport von Flüssigkeiten.

Komponenten, die mit diesen Typen von Nachumhüllungen beschichtet sind, können außerdem kathodisch geschützt werden.

Tubes et raccords en acier pour canalisations enterrées et immergées - Revêtements externes des assemblages réalisés sur site

La présente Norme européenne spécifié l'application et les essais correspondants des revêtements de protection contre la corrosion, appliqués aux surfaces en acier laissées nues après que les tubes et les raccords (éléments) aient été assemblés par soudage.

Elle définit les différents types de revêtements pour les canalisations enterrées et immergées, indiqués dans le Tableau 1.

La présente Norme européenne s'applique aux tubes en acier sans soudure ou soudés, utilisés dans la construction des conduites pour le transport de fluides.

Des éléments revêtus avec ce type de revêtement peuvent être protégés de manière complémentaire, au moyen d'une protection cathodique.

Jeklene cevi in fitingi za obalne in priobalne cevovode – Zunanje prevleke spojev

General Information

- Status

- Withdrawn

- Publication Date

- 17-Jan-2006

- Withdrawal Date

- 20-Jan-2026

- Technical Committee

- ECISS/TC 110 - Steel tubes, and iron and steel fittings

- Drafting Committee

- ECISS/TC 29/SC 4/WG 7 - External field joint coatings

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 16-Mar-2016

- Completion Date

- 21-Jan-2026

Relations

- Effective Date

- 23-Mar-2016

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Frequently Asked Questions

EN 10329:2006 is a standard published by the European Committee for Standardization (CEN). Its full title is "Steel tubes and fittings for onshore and offshore pipelines - External field joint coatings". This standard covers: This European Standard specifies the application and related testing of the corrosion protection coatings applied to steel surfaces left bare after the tubes and fittings (components) are joined by welding. It defines the different types of coatings for buried and immersed pipelines defined in Table 1. This European Standard applies to seamless or welded steel tubes used in the construction of pipelines for the conveyance of fluids. Components coated with this type of coating may be further protected by means of cathodic protection.

This European Standard specifies the application and related testing of the corrosion protection coatings applied to steel surfaces left bare after the tubes and fittings (components) are joined by welding. It defines the different types of coatings for buried and immersed pipelines defined in Table 1. This European Standard applies to seamless or welded steel tubes used in the construction of pipelines for the conveyance of fluids. Components coated with this type of coating may be further protected by means of cathodic protection.

EN 10329:2006 is classified under the following ICS (International Classification for Standards) categories: 23.040.01 - Pipeline components and pipelines in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 10329:2006 has the following relationships with other standards: It is inter standard links to EN ISO 21809-3:2016, EN ISO 2811-1:2023, EN ISO 8501-1:2007, EN ISO 868:2003, EN 1395-7:2007, EN ISO 1183-1:2025, EN ISO 527-3:2018, EN ISO 1133-1:2022, EN ISO 2815:2003, EN ISO 2808:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 10329:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Jeklene cevi in fitingi za obalne in priobalne cevovode – Zunanje prevleke spojevStahlrohre und -formstücke für erd- und wasserverlegte Rohrleitungen - Umhüllungen für SchweißverbindungenTubes et raccords en acier pour canalisations enterrées et immergées - Revetements externes des assemblages réalisés sur siteSteel tubes and fittings for onshore and offshore pipelines - External field joint coatings77.140.75Jeklene cevi in cevni profili za posebne nameneSteel pipes and tubes for specific use25.220.99Druge obdelave in prevlekeOther treatments and coatingsICS:Ta slovenski standard je istoveten z:EN 10329:2006SIST EN 10329:2006en01-april-2006SIST EN 10329:2006SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 10329January 2006ICS 23.040.01 English VersionSteel tubes and fittings for onshore and offshore pipelines -External field joint coatingsTubes et raccords en acier pour canalisations enterrées etimmergées - Revêtements externes des assemblagesréalisés sur siteStahlrohre und -formstücke für erd- und wasserverlegteRohrleitungen - Umhüllungen für SchweißverbindungenThis European Standard was approved by CEN on 9 December 2005.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2006 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 10329:2006: ESIST EN 10329:2006

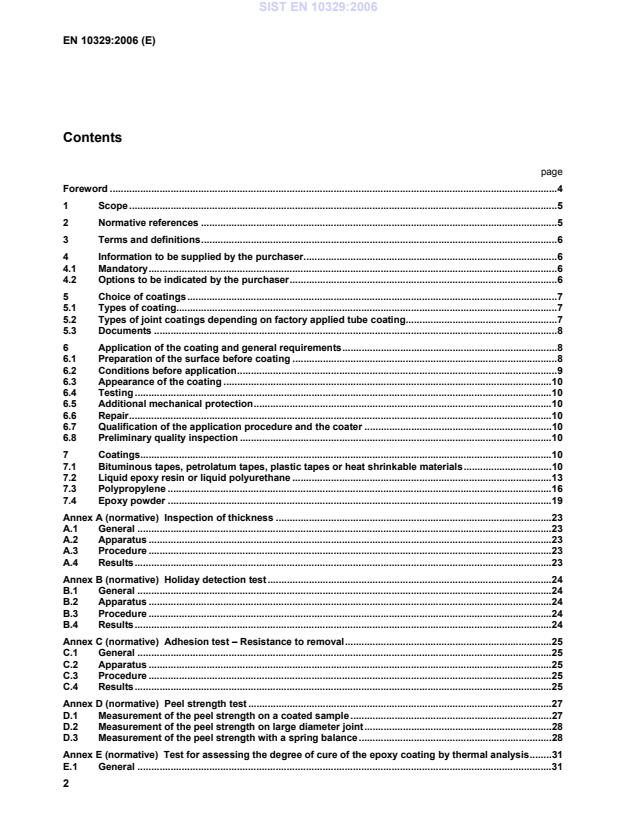

Inspection of thickness.23 A.1 General.23 A.2 Apparatus.23 A.3 Procedure.23 A.4 Results.23 Annex B (normative)

Holiday detection test.24 B.1 General.24 B.2 Apparatus.24 B.3 Procedure.24 B.4 Results.24 Annex C (normative)

Adhesion test – Resistance to removal.25 C.1 General.25 C.2 Apparatus.25 C.3 Procedure.25 C.4 Results.25 Annex D (normative)

Peel strength test.27 D.1 Measurement of the peel strength on a coated sample.27 D.2 Measurement of the peel strength on large diameter joint.28 D.3 Measurement of the peel strength with a spring balance.28 Annex E (normative)

Test for assessing the degree of cure of the epoxy coating by thermal analysis.31 E.1 General.31 SIST EN 10329:2006

Cathodic disbondment test.32 F.1 General.32 F.2 Apparatus.32 F.3 Sampling.33 F.4 Procedure.33 F.5 Investigation procedure.34 F.6 Results.34 Annex G (normative)

Impact test.38 G.1 General.38 G.2 Apparatus.38 G.3 Procedure.38 G.4 Results.39 Annex H (normative)

Indentation test.40 H.1 General.40 H.2 Apparatus.40 H.3 Procedure.40 H.4 Results.40 Annex I (informative)

Qualification of the application procedure and the coater.41 I.1 General.41 I.2 Qualification of the procedure and the coater.41 I.3 Frequency of inspections.41 I.4 Retest.41 Bibliography.45

NOTE It is intended for polyamide and polyethylene materials to be included in Table 1 in the next 5-year revision, when more experience with these coatings will be available. 5.2 Types of joint coatings depending on factory applied tube coating The combinations of the joint coating materials with different factory applied coatings are given for information in Table 2. In each case, the products used shall be compatible and suitable for the service temperature of the pipeline. The tests to be carried out on the joint coating are described in the following subclauses. The nature and the characteristics of the factory applied coating shall be known to the coater. SIST EN 10329:2006

Polyethylene coating X X X X X X

Polypropylene coating X X X X X X X

Bitumen X

X X X

Epoxy powder X X X X X X

X EN 10288 Extruded polyethylene (2-layer) X X X X X X

Fusion bonded powder polyethylene X X X X X X

EN 10289 Liquid epoxy and epoxy-modified coatings X X X X X X

EN 10290 Liquid polyurethane and polyurethane-modified coatings X X X X X X

5.3 Documents 5.3.1 Information for the coater Specific information on the coating materials will be given in the manufacturer’s product data sheets. An indication of the minimum amount of information required for a product data sheet is indicated in the chapter on the different coating materials. 5.3.2 Test certificate for the coating In case inspection operations are carried out as agreed by the purchaser and the coater at the time of enquiry and order, the inspection documents shall be according to EN 10204. 6 Application of the coating and general requirements 6.1 Preparation of the surface before coating 6.1.1 General Surface preparation shall be carried out in accordance with the recommendations of the manufacturer. SIST EN 10329:2006

If requested, qualification testing to demonstrate the characteristics of the coating shall be carried out. This test shall use the coating materials, the procedure, equipment and personnel that will be used on site and will take into account specific application conditions found on site; recommendations for the procedure are given in Annex I. 6.8 Preliminary quality inspection The coater shall ensure that: the products comply with the specification; the storage instructions are followed. 7 Coatings 7.1 Bituminous tapes, petrolatum tapes, plastic tapes or heat shrinkable materials 7.1.1 General All coatings made by tapes or heat shrinkable materials shall meet the requirements of EN 12068. SIST EN 10329:2006

EN 12068). 7.1.5 Application of the coating 7.1.5.1 General Application of the coating shall be carried out in accordance with the recommendations of the manufacturer (see manufacturer’s information, as required in EN 12068). 7.1.5.2 Application of the primer Where applicable application of the primer shall be carried out in accordance with the recommendations of the manufacturer (see manufacturer’s information, as required in EN 12068). For petrolatum tapes normally there is no primer necessary. 7.1.5.3 Application of the tape or the heat shrinkable material Application of the material shall be carried out in accordance with the recommendations of the manufacturer (see manufacturer’s information, as required in EN 12068). SIST EN 10329:2006

≥ 50 mm ≥ 25 mm

7.1.6 Characteristics of the coating applied 7.1.6.1 General The tests below shall be carried out. 7.1.6.2 Thickness The nominal thickness is the sum of the thickness of the individual layers before application. Unless agreed otherwise with the purchaser, the minimum thickness of the coating on the body of the joint shall be not less than 90 % of the nominal value given in EN 12068. Unless agreed otherwise with the purchaser, the minimum thickness on the top of the weld bead shall be not less that 0.6 mm. NOTE The thickness on the weld bead is normally less than on the body because some of the polymeric adhesive will flow from the bead to the body, both during and after application. This is necessary to prevent voids in the coating and is not detrimental to the corrosion protection. The thickness should be measured using the method given in Annex A. 7.1.6.3 Holiday detection The whole surface of the coated joint shall be checked for holidays or other discontinuities at a voltage of

5 kV per mm of coating thickness +5 kV, with a maximum of 15 kV, in accordance with the method given in

Annex B. No holidays or other discontinuities are allowed. 7.1.6.4 Peel strength The minimal waiting period between application of the coating and the peel force test is given in Table 4. The test shall be carried out in accordance with the method defined in Annex D. The peel strength on the joint shall meet the requirements given in EN 12068. SIST EN 10329:2006

The waiting period may be reduced by agreement with the manufacturer.

7.2 Liquid epoxy resin or liquid polyurethane 7.2.1 General The liquid epoxy resin (EP) and the liquid polyurethane (PUR) shall meet the qualification requirements defined in EN 10289 and EN 10290 except infrared scan and cut back at the end. 7.2.2 Definition of the coating The coating on the joints consists of the application of one or more coats of the liquid epoxy resin or liquid polyurethane, which may be modified. These materials may be applied with or without a primer coat. The thickness classes and maximum operating temperatures of epoxy and polyurethane coatings are given in EN 10289 and EN 10290. However, all classes of both coating types are suitable for use at temperatures down to - 20 °C. The different combinations of coating thickness and maximum operating temperature are given in Table 5. Table 5 — Coating thickness and maximum operating temperatures

class A class B class C Thickness 400 µm 800 µm 1 500 µm EP Maximum operating temperature 40 °C 40 °C 60 °C 40 °C 60 °C 80 °C Thickness 1 000 µm 1 500 µm - PUR Maximum operating temperature 40 °C 40 °C 60 °C 80 °C -

Other temperatures may be agreed between the interested parties, but full testing of the coating shall be carried out at the required temperature. 7.2.3 Information for the coater The technical data sheet drawn up by the product manufacturer shall contain as a minimum the information detailed in Table 6. SIST EN 10329:2006

+ Name of manufacturer

+ Commercial name of the product

+ Type of product

+ Storage conditions

+ Density of component A and B a + Density of mixture

+ Dose ratio in weight and volume

+ Application methods and conditions (ambient conditions)

+ Minimum and maximum temperature of the steel during application

+ Maximum operating temperature

+ Type of solvent

+ Solids by weight a + Solids by volume a + Time between coats

+ Shore D hardness EN ISO 868 + Maximum thickness per coat

+ Curing time and temperature

+ Colour

+ a Method given by the manufacturer.

7.2.4.2 On factory applied coating At least 50 mm of he factory applied coating adjacent to the joint shall also be prepared by mechanical or abrasive blast cleaning. 7.2.5 Application of the coating 7.2.5.1 General The method of application shall be in accordance with the recommendations of the manufacturer. SIST EN 10329:2006

8 kV per mm of the nominal coating thickness, with a maximum of 20 kV, in accordance with the method given in Annex B. No holidays or other discontinuities are allowed. 7.2.6.4 Adhesion The adhesion of the coating to the steel substrate shall be measured using the method given in Annex C. The acceptance criteria are given in Table 7. Table 7 — Adhesion Material Acceptance criteria EP rating 2 PUR rating 3

+ + + + Name of manufacturer

+ + + + Commercial name of the product

+ + + + Shelf life

+ +

Storage conditions

+ + + + Colour

+ + + + Density EN ISO 1183-1 +

+ + Density EN ISO 2811-1

+

Sieve analysis

+

+

Viscosity

+

Melt index EN ISO 1133

+ + Application methods and conditions (ambient conditions)

+ + + + Minimum and maximum temperature of the steel during application

+ + + + Maximum operating temperature

+ + + + Elongation at break EN ISO 527-3

+ + Infrared analysis

+ +

Gel time

+

Time between coats

+ + +

Vicat softening point at 9,8 N EN ISO 306 A50

+ + ∆Tg Annex E +

7.3.4.2 On factory applied coating At least 50 mm of he factory applied coating adjacent to the joint must also be prepared by mechanical or abrasive blast cleaning. 7.3.5 Application of the coating 7.3.5.1 General The method of application shall be in accordance with the recommendations of the manufacturer. 7.3.5.2 Heating of the area to be coated Immediately after surface preparation the area to be coated is heated to the required temperature by induction. The holding time and the temperature shall not: cause oxidation on the steel surface or the coating that would be detrimental to the quality of the coating of the joint; damage the factory applied coating. 7.3.5.3 Application of the primer coat The primer coat shall be applied by manual or automatic spray. SIST EN 10329:2006

10 kV per mm of the nominal coating thickness, with a maximum of 25 kV, in accordance with the method given in Annex B. No holidays or other discontinuities are allowed. 7.3.6.4 Peel strength If the thickness of the field joint coating is greater than 3 mm, the thickness may be reduced before testing. The peel strength of the polypropylene coating shall be measured at a temperature of (90 ± 2) °C according to the method given in Annex D; the minimum required value shall be 4 N/mm. 7.3.6.5 Degree of cure The degree of cure of the primer in powder is determined by differential thermal analysis of a sample of primer taken from the joint. The test is carried out in accordance with the method defined in Annex E. The acceptance criterion is the value of ∆Tg given by the manufacturer. 7.3.6.6 Cathodic disbondment The test is carried out in accordance with the method defined in Annex F. The average disbondment shall not be more than 7 mm after a period of: SIST EN 10329:2006

+ Name of manufacturer

+ Commercial name of the product

+ Type of product

+ Packaging

+ Storage conditions

+ Colour

+ Density EN ISO 1183-1 + Sieve analysis

+ Application methods and conditions (ambient conditions)

+ Minimum and maximum temperature of the steel during application

+ Maximum operating temperature

+ Gel time

Time between coats

+ Bucholz hardness of the cured film EN ISO 2815 + ∆Tg Annex E + Impact resistance Annex G + Maximum moisture content

+

7.4.4.2 On factory applied coating At least 50 mm of the factory applied coating adjacent to the joint shall also be prepared by mechanical or abrasive blast cleaning. 7.4.5 Application of the coating 7.4.5.1 General The method of appli

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...