EN 15015:2007

(Main)Plastics piping systems - Systems for hot and cold water not intended for human consumption - Performance characteristics for pipes, fittings and their joints

Plastics piping systems - Systems for hot and cold water not intended for human consumption - Performance characteristics for pipes, fittings and their joints

This European Standard specifies performance requirements for plastics pipes, fittings and their joints intended for hot and cold water installations for the conveyance of water and for heating systems with the exception of drinking water distribution for human consumption, and gives associated test methods for verification and evaluation of conformity with this European Standard.

NOTE Compliance of pipes, fittings and their joints with this document does not confer a presumption of fitness of the product for the transport of water intended for human consumption within the meaning of the Directive 89/106/EEC. However, until the operation of the envisaged European Acceptance Scheme for construction products in contact with water intended for human consumption and the revision of this standard, products conforming to this standard could be used for the transport of water intended for human consumption if they conform to the relevant national, regional or local regulatory provisions or recommendations applicable in the place of use.

Kunststoff-Rohrleitungssysteme - Rohrleitungssysteme für Warm- und Kaltwasser nicht für den menschlichen Gebrauch - Eigenschaften für die Gebrauchstauglichkeit von Rohren, Formstücken und deren Verbindungen

Diese Europäische Norm legt Leistungsanforderungen an Kunststoffrohre, formstücke und deren Verbindungen fest, die für die Warm und Kaltwasserinstallation für den Transport von Wasser und für Heizungssysteme, ausgenommen die Verteilung von Wasser für den menschlichen Gebrauch, vorgesehen sind, und sie gibt damit verbundene Prüfverfahren zur Verifizierung und Bewertung der Konformität mit dieser Europäischen Norm an.

ANMERKUNG Die Übereinstimmung von Rohren, Formstücken und deren Verbindungen mit diesem Dokument stellt keine Annahme der Gebrauchstauglichkeit des Produktes für den Transport von Wasser für den menschlichen Gebrauch im Sinne der Richtlinie 89/106/EWG dar. Bis zum In Kraft Treten des geplanten Europäischen Anerkennungssystems für Bauprodukte im Kontakt mit Wasser für den menschlichen Gebrauch und der Überarbeitung dieser Norm könnten Produkte bei Übereinstimmung mit dieser Norm für den Transport von Wasser für den menschlichen Gebrauch verwendet werden, sofern sie die entsprechenden am Einsatzort geltenden nationalen, regionalen oder örtlichen gesetzlichen Bestimmungen oder Empfehlungen erfüllen.

Systèmes de canalisations en plastique - Systèmes pour eau chaude et froide non destinée à la consommation humaine - Caractéristiques de performance pour tubes, raccords et leurs assemblages

Le présent document spécifie les exigences de performance pour les tubes, raccords et leurs assemblages en plastique destinés aux installations pour le transport de l'eau chaude et froide et aux systèmes de chauffage, à l'exception de la distribution de l'eau potable destinée à la consommation humaine, et indique les méthodes associées pour la vérification et l'évaluation de la conformité au présent document.

NOTE Pour cette application, la " résistance à l'écrasement ", la " résistance à la flexion longitudinale ", la " charge maximale pour la déformation admissible ", la " résistance à la température élevée (pour réseaux de chauffage) ", la " résistance au choc ", la " soudabilité (pour réseaux de gaz) ", la " résistance à la pénétration (pour réseaux de gaz) ", le " comportement électrostatique (pour réseaux de fioul) ", la " perméabilité ", les " propriétés thermiques " et l'" isolation thermique (associée à l'économie d'énergie) " ne sont pas traitées.

Cevni sistemi iz polimernih materialov - Sistemi za vročo in hladno nepitno vodo - Lastnosti cevi, fitingov in njihovih spojev

General Information

- Status

- Withdrawn

- Publication Date

- 23-Oct-2007

- Withdrawal Date

- 20-Jan-2026

- Technical Committee

- CEN/TC 155 - Plastics piping systems and ducting systems

- Drafting Committee

- CEN/TC 155 - Plastics piping systems and ducting systems

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 01-Jul-2020

- Completion Date

- 28-Jan-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 19-Jan-2023

- Effective Date

- 18-Jan-2023

Frequently Asked Questions

EN 15015:2007 is a standard published by the European Committee for Standardization (CEN). Its full title is "Plastics piping systems - Systems for hot and cold water not intended for human consumption - Performance characteristics for pipes, fittings and their joints". This standard covers: This European Standard specifies performance requirements for plastics pipes, fittings and their joints intended for hot and cold water installations for the conveyance of water and for heating systems with the exception of drinking water distribution for human consumption, and gives associated test methods for verification and evaluation of conformity with this European Standard. NOTE Compliance of pipes, fittings and their joints with this document does not confer a presumption of fitness of the product for the transport of water intended for human consumption within the meaning of the Directive 89/106/EEC. However, until the operation of the envisaged European Acceptance Scheme for construction products in contact with water intended for human consumption and the revision of this standard, products conforming to this standard could be used for the transport of water intended for human consumption if they conform to the relevant national, regional or local regulatory provisions or recommendations applicable in the place of use.

This European Standard specifies performance requirements for plastics pipes, fittings and their joints intended for hot and cold water installations for the conveyance of water and for heating systems with the exception of drinking water distribution for human consumption, and gives associated test methods for verification and evaluation of conformity with this European Standard. NOTE Compliance of pipes, fittings and their joints with this document does not confer a presumption of fitness of the product for the transport of water intended for human consumption within the meaning of the Directive 89/106/EEC. However, until the operation of the envisaged European Acceptance Scheme for construction products in contact with water intended for human consumption and the revision of this standard, products conforming to this standard could be used for the transport of water intended for human consumption if they conform to the relevant national, regional or local regulatory provisions or recommendations applicable in the place of use.

EN 15015:2007 is classified under the following ICS (International Classification for Standards) categories: 23.040.01 - Pipeline components and pipelines in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15015:2007 has the following relationships with other standards: It is inter standard links to EN ISO 11372:2011, EN 13501-1:2018, EN ISO 1167-2:2006, EN 681-2:2000, EN ISO 3126:2005, EN ISO 1167-4:2007, EN 15012:2007, EN ISO 19893:2018, EN ISO 1167-3:2007, EN ISO 1167-1:2006, EN ISO 9080:2012, EN 681-1:1996, EN ISO 9001:2000, prEN 15015, FprEN 15015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15015:2007 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/131. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15015:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Kunststoff-Rohrleitungssysteme - Rohrleitungssysteme für Warm- und Kaltwasser nicht für den menschlichen Gebrauch - Eigenschaften für die Gebrauchstauglichkeit von Rohren, Formstücken und deren VerbindungenSystemes de canalisations en plastique - Systemes pour eau chaude et froide non destinée a la consommation humaine - Caractéristiques de performance pour tubes, raccords et leurs assemblagesPlastics piping systems - Systems for hot and cold water not intended for human consumption - Performance characteristics for pipes, fittings and their joints91.140.60Sistemi za oskrbo z vodoWater supply systems23.040.45Fitingi iz polimernih materialovPlastics fittings23.040.20Cevi iz polimernih materialovPlastics pipesICS:Ta slovenski standard je istoveten z:EN 15015:2007SIST EN 15015:2008en,fr01-januar-2008SIST EN 15015:2008SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 15015October 2007ICS 23.040.01 English VersionPlastics piping systems - Systems for hot and cold water notintended for human consumption - Performance characteristicsfor pipes, fittings and their jointsSystèmes de canalisations en plastique - Systèmes poureau chaude et froide non destinée à la consommationhumaine - Caractéristiques de performance pour tubes,raccords et leurs assemblagesKunststoff-Rohrleitungssysteme - Rohrleitungssysteme fürWarm- und Kaltwasser nicht für den menschlichenGebrauch - Eigenschaften für die Gebrauchstauglichkeitvon Rohren, Formstücken und deren VerbindungenThis European Standard was approved by CEN on 23 August 2007.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2007 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 15015:2007: ESIST EN 15015:2008

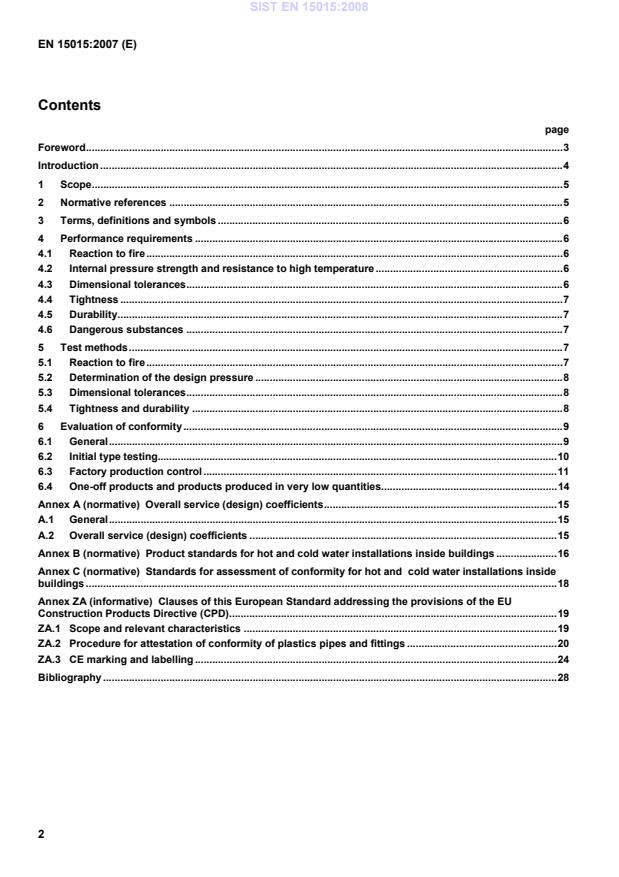

Overall service (design) coefficients.15 A.1 General.15 A.2 Overall service (design) coefficients.15 Annex B (normative)

Product standards for hot and cold water installations inside buildings.16 Annex C (normative)

Standards for assessment of conformity for hot and

cold water installations inside buildings.18 Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive (CPD).19 ZA.1 Scope and relevant characteristics.19 ZA.2 Procedure for attestation of conformity of plastics pipes and fittings.20 ZA.3 CE marking and labelling.24 Bibliography.28

Material independent

Specific solutions

For the harmonisation of plastics piping systems for hot and cold water (this European Standard) the following applies: For pipes and fittings

For valves Figure 1 SIST EN 15015:2008

Compliance of pipes, fittings and their joints with this document does not confer a presumption of fitness of the product for the transport of water intended for human consumption within the meaning of the Directive 89/106/EEC. However, until the operation of the envisaged European Acceptance Scheme for construction products in contact with water intended for human consumption and the revision of this standard, products conforming to this standard could be used for the transport of water intended for human consumption if they conform to the relevant national, regional or local regulatory provisions or recommendations applicable in the place of use. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 681-1,

Elastomeric seals — Materials requirements for pipe joint seals used in water and drainage applications — Part 1: Vulcanized rubber EN 681-2,

Elastomeric seals — Materials requirements for pipe joint seals used in water and drainage applications — Part 2: Thermoplastic elastomers EN 12293,

Plastics piping systems — Thermoplastics pipes and fittings for hot and cold water — Test method for the resistance of mounted assemblies to temperature cycling EN 13501-1,

Fire classification of construction products and

building elements — Part 1: Classification using test data from reaction to fire tests EN 15012:2007, Plastics piping systems — Soil and waste discharge systems within the building structure — Performance characteristics for pipes, fittings and their joints EN ISO 1167-1,

Thermoplastics pipes, fittings and assemblies for the conveyance of fluids — Determination of the resistance to internal pressure — Part 1: General method (ISO 1167-1:2006) EN ISO 1167-2,

Thermoplastics pipes, fittings and assemblies for the conveyance of fluids — Determination of the resistance to internal pressure — Part 2: Preparation of pipe test pieces (ISO 1167-2:2006) prEN ISO 1167-3,

Thermoplastics pipes, fittings and assemblies for the conveyance of fluids — Determination of the resistance to internal pressure — Part 3: Preparation of components (ISO/DIS 1167-3:2005) prEN ISO 1167-4,

Thermoplastics pipes, fittings and assemblies for the conveyance of fluids — Determination of the resistance to internal pressure — Part 4: Preparation of assemblies (ISO/DIS 1167-4:2006) EN ISO 3126,

Plastics piping systems — Plastics components — Determination of dimensions (ISO 3126:2005) EN ISO 9001:2000,

Quality management systems — Requirements (ISO 9001:2000) EN ISO 9080,

Plastics piping and ducting systems — Determination of the long-term hydrostatic strength of thermoplastics materials in pipe form by extrapolation (ISO 9080:2003) ISO 10508:2006,

Plastics piping systems for hot and cold water installations — Guidance for classification and design SIST EN 15015:2008

Plastics piping systems — Multilayer pipes — Determination of the long-term strength BS 7291-1:2006,

Thermoplastics pipes and associated fittings for hot and cold water for domestic purposes and heating installations in buildings — Part 1: General requirements 3 Terms, definitions and symbols For the purposes of this document, the following terms, definitions and symbols apply. 3.1 nominal outside diameter dn specified outside diameter, in millimetres, assigned to a nominal size 3.2 design pressure PD highest pressure related to the circumstances for which the system has been designed and is intended to be used 4 Performance requirements 4.1 Reaction to fire Where subject to regulatory requirements, the product shall be tested and classified in accordance with 5.1. 4.2 Internal pressure strength and resistance to high temperature 4.2.1 Determination of design pressure PD When determined in accordance with 5.2, the internal pressure strength of the pipe and fitting shall be expressed as a design pressure PD of preferably 4 bar, 6 bar, 8 bar or 10 bar for a given class of application according to ISO 10508:2006 or class S according to BS 7291-1:2006 and declared by the manufacturer. 4.2.2 Verification of pressure strength The verification of the internal pressure strength of pipes and fittings shall be done in accordance with 5.2.3. 4.3 Dimensional tolerances The manufacturer shall declare the dimensional tolerances for the jointing of the components, either by means of: a) reference to a specific European Standard listed in Clause 2 or in Annex B, or b) in the absence of a European Standard, reference to a specific European product specification published by a recognized European organization, or c) in the absence of a) and b), reference to an International Standard, or d) in the absence of a), b) and c), by stating the values of his own specification and associated jointing method. Dimensions shall be measured in accordance with 5.3 and shall be within the declared tolerances. SIST EN 15015:2008

The manufacturer of plastics pipes and fittings should give guidance on type of water treatment required and on aspects of applications such as oxygen permeation. 4.5.2 Long-term joint tightness The long-term joint tightness shall be tested in accordance with 5.4. No leakage shall occur during the test period. 4.5.3 Durability of elastomeric sealing joints Elastomeric sealing joints shall be deemed to be durable if the sealing element conforms to EN 681-1 or EN 681-2, as applicable. 4.6 Dangerous substances Attention is drawn to NOTE 1 and NOTE 2 in ZA.1. NOTE Mandate M/366 “Development of horizontal standardised assessment methods for harmonised approaches relating to dangerous substances under the Construction Products Directive (CPD)” as issued by the European Commission, will require specifications relating to dangerous substance once applicable to the covered products. 5 Test methods 5.1 Reaction to fire Classification shall be done in accordance with EN 13501-1. Mounting and fixing of pipes shall conform to Annex A of EN 15012:2007. NOTE In case where e.g. the given dimensions do not exist the choice of dimensions and the mounting and fixing should be agreed between the manufacturer and the notified body.

For advice see the basic material standards ISO 3213 [2] for PP, ISO 10146 [3] for PE-X, ISO 12230 [4] for PB,

ISO 24033 for PE-RT[5] and product standard EN ISO 15877-2 (see Annex B) for PVC-C. For material not covered by Annex A the manufacturer shall declare overall service coefficients with appropriate verification methods, e.g. by making reference to a European product specification [see 4.3 b)]. 5.2.2 Other pipe designs For multi-layer pipes the hydrostatic stress properties shall be determined according to ISO 17456. The result shall then be used as described in 5.2.1. The design pressure for designs where single dimensions are pressure rated at specific temperatures shall be calculated using the same procedure as in 5.2.1 but based on pressure instead of hydrostatic stress. 5.2.3 Internal pressure strength For checking the internal pressure strength testing shall be done in accordance with the appropriate parts of

EN ISO 1167 using hoop stresses relevant for the material, which were established when determining the design pressure PD in accordance with 5.2.1 or 5.2.2. 5.3 Dimensional tolerances The dimensions shall be measured in accordance with EN ISO 3126. 5.4 Tightness and durability The tightness of joints and the durability shall be tested in accordance with EN 12293 taking the design pressure PD and the declared classification of service conditions as in ISO 10508:2006, using parameters given in Table 1 or BS 7291-1:2006. SIST EN 15015:2008

Class 1 Class 2 Class 3 Class 4 Class 5 Highest test temperature, in °C 90 90 60 80 95 Lowest test temperature, in °C 20 20 20 20 20 Test pressure, in bar PD PD PD PD PD Number of cycles a 5 000 5 000 5 000 5 000 5 000 Number of test pieces One set of fittings in accordance with the configuration shown in EN 12293 Pre-stress force b b b b b a

Each cycle shall comprise of 1510+ min at the highest test temperature and 1510+ min at the lowest test temperature. b

The tensile stress to calculate the pre-stress force is calculated using the following equation:

σt = α × ∆T × E

where σt is the tensile stress, expressed in megapascals ( MPa); α is the coefficient of thermal expansion, expressed per Kelvin (1/K); ∆T is the temperature difference, expressed in Kelvins (K); E is the modulus of elasticity, expressed in megapascals (MPa).

6 Evaluation of conformity 6.1 General The conformity of pipes and fittings with the requirements of this standard and with the declared values (including classes) shall be demonstrated by: initial type testing; factory production control by the manufacturer, including product assessment. For the purposes of testing, pipes and fittings may be grouped into families, where it is considered that the results for one or more characteristics from any product within the family are representative for the same characteristics for all products within that family. NOTE 1 A product can be in more than one family for different characteristics. For type testing the following family groups applies. a) Pressure groups for pipes and fittings as given in Table 2. Table 2 — Pressure groups Pressure group Design pressure, PD bar 1 ≤ 6 2 > 6

b) Size groups for pipes and fittings as given in Table 3. SIST EN 15015:2008

Size group Range of nominal diameters, dn 1 dn ≤ 63 2 63 < dn ≤ 160

c) Fitting groups for fittings as given in Table 4. Table 4 — Fitting groups Fitting group Fittings 1 Elbows and tees 2 Reducers, couplers, end caps 3 All fittings except those included in group 1 and group 2.

6.2 Initial type testing 6.2.1 General Relevant type tests shall be carried out on new products and whenever there is a change in design, in material and/or in production method, other than routine in-process adjustment and extension of the product range (see Table 3). A change of supplier of a material or stabiliser does not lead to a change in performance if the chemical composition remains the same. Material modifications within certain limits are not considered as a change of material. Guidance for these limits can be found in the standards given in Annex C. For tests previously performed in accordance with the provisions of the standards listed in Annex B, or the recognized European specification, as applicable, (same product, same characteristic(s), same test method, same system of attestation etc.) the results may be taken into account. All characteristics given in Clause 4 shall be subject to calculation and/or initial type testing, except 4.5.3, where the characteristics of the components used have already been determined by the component manufacturer on the basis of conformity with other product standards. However this does not relieve the manufacturer of the piping system from the responsibility of ensuring that the system conforms to the requirements of this document. 6.2.2 Initial type test requirements The initial type testing of the characteristics according to Clause 4 shall be performed in accordance with the sampling procedure given under type tests (TT) of the applicable product specific standards for assessment of conformity as given in Annex C. If the standard does not contain one or the other of the characteristics, then testing as given in Table 5 shall apply. For products where no such standard exists Table 5 shall apply. SIST EN 15015:2008

(see 4.4) Once/material or formulation

See 4.4 a I

is initial type test in case of new system;

M is change of material;

D is change of fitting design;

E is extension of the product range with new pressure group, size group or fitting group;

+ denotes testing relevant for the characteristic-occurrence-combination. b Only obligatory if subject to regulatory requirements applicable in the place of use.

Test reports shall be kept by the manufacturer for at least 10 years after discontinuation of the product. 6.3 Factory production control 6.3.1 General The manufacturer shall establish, document and maintain an FPC system to ensure that the products placed on the market conform to the stated performance characteristics. The FPC system shall consist of procedures, regular inspections and tests and/or assessments and the use of the results to control raw and other incoming materials or components, equipment, the production process and the product. If the manufacturer has the component designed, manufactured, assembled, packed, processed and labelled by subcontracting, FPC of the original manufacturer may be taken into account. However, where subcontracting takes place, the manufacturer shall retain the overall control of the component and ensure that he receives all the information that is necessary to fulfil his responsibilities according to this European Standard. The manufacturer who subcontracts all of his activities may in no circumstances discharge himself of his responsibilities to a subcontractor. All the elements, requirements and provisions adopted by the manufacturer shall be documented in a systematic manner in the form of written policies and procedures. This production control system documentation shall ensure a common understanding of conformity evaluation and enable the achievement of the required component characteristics and the effective operation of the production control system to be checked. Factory production control therefore brings together operational techniques and all measures allowing maintenance and control of the conformity of the component with its technical specifications. Its implementation may be achieved by controls and tests on raw materials and constituents, processes, manufacturing equipment and finished components, including material properties in components, and by making use of the results thus obtained. SIST EN 15015:2008

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...