EN 408:2010

(Main)Timber structures - Structural timber and glued laminated timber - Determination of some physical and mechanical properties

Timber structures - Structural timber and glued laminated timber - Determination of some physical and mechanical properties

This European Standard specifies test methods for determining the following properties of structural timber and glued laminated timber: modulus of elasticity in bending; shear modulus; bending strength; modulus of elasticity in tension parallel to the grain; tension strength parallel to the grain; modulus of elasticity in compression parallel to the grain; compression strength parallel to the grain; modulus of elasticity in tension perpendicular to the grain; tension strength perpendicular to the grain; modulus of elasticity in compression perpendicular to the grain; compression strength perpendicular to the grain and shear strength.

In addition, the determination of dimensions, moisture content, and density of test pieces are specified.

The methods apply to rectangular and circular shapes (of substantially constant cross section) of solid unjointed timber or finger-jointed timber and glued laminated timber unless stated otherwise.

Holzbauwerke - Bauholz für tragende Zwecke und Brettschichtholz - Bestimmung einiger physikalischer und mechanischer Eigenschaften

Diese Europäische Norm legt Prüfverfahren zur Bestimmung der folgenden Eigenschaften von Bauholz für tragende Zwecke und Brettschichtholz fest: Biege-Elastizitätsmodul, Schubmodul, Biegefestigkeit, Zug-Elasti-zitätsmodul in Faserrichtung, Zugfestigkeit in Faserrichtung, Druck-Elastizitätsmodul in Faserrichtung, Druck-festigkeit in Faserrichtung, Zug-Elastizitätsmodul rechtwinklig zur Faserrichtung, Zugfestigkeit rechtwinklig zur Faserrichtung, Druck-Elastizitätsmodul rechtwinklig zur Faserrichtung, Druckfestigkeit rechtwinklig zur Faser-richtung sowie die Scherfestigkeit. Zusätzlich wird die Bestimmung der Maße, der Holzfeuchte und der Rohdichte festgelegt. Sofern nicht anders angegeben, gelten die Verfahren für rechteckige und kreisförmige Formen (mit im Wesentlichen konstantem Querschnitt) aus ungestoßenem oder keilgezinktem Bauholz und Brettschichtholz.

Structures en bois - Bois de structure et bois lamellé-collé - Détermination de certaines propriétés physiques et mécaniques

La présente Norme européenne définit des méthodes d'essai pour déterminer les propriétés suivantes du bois

de structure et du bois lamellé-collé : le module d'élasticité en flexion, le module de cisaillement, la résistance

à la flexion, le module d'élasticité en traction axiale, la résistance à la traction axiale, le module d'élasticité en

compression axiale, la résistance à la compression axiale, le module d'élasticité en traction transversale, la

résistance à la traction transversale, le module d'élasticité en compression transversale, la résistance à la

compression transversale et la résistance au cisaillement.

La détermination des dimensions, de la teneur en humidité et de la masse volumique des éprouvettes d'essai

est également définie.

Sauf indication contraire, les méthodes s'appliquent aux bois massifs non aboutés ou aboutés par entures

multiples et aux bois lamellés-collés, de formes rectangulaire et circulaire (de section relativement constante).

Lesene konstrukcije - Konstrukcijski les in lepljeni lamelirani les - Ugotavljanje nekaterih fizikalnih in mehanskih lastnosti

Ta evropski standard določa preskusne metode za ugotavljanje naslednjih lastnosti strukturnega lesa in lameliranega lepljenega lesa: modul elastičnosti upogibanja; strižni modul; moč upogibanja; modul elastičnosti pri napetosti, vzporedni z vlakni; modul elastičnosti pri moči stiskanja, vzporedni z vlakni; modul elastičnosti pri napetosti navpično na vlakna; moč stiskanja navpično na vlakna; modul elastičnosti pri stiskanju navpično na vlakna; moč stiskanja navpično na vlakna in moč striženja. Poleg tega je opredeljeno določevanje dimenzij, vlage in gostote preskušancev. Metode veljajo za pravokotne in okrogle oblike (konstantnega prereza) trdnega nespajanega lesa ali lesa, spajanega z zobatimi spoji, ter lameliranega lepljenega lesa, razen če je navedeno drugače.

General Information

- Status

- Withdrawn

- Publication Date

- 10-Aug-2010

- Withdrawal Date

- 24-Jul-2012

- Technical Committee

- CEN/TC 124 - Timber structures

- Drafting Committee

- CEN/TC 124/WG 2 - Solid timber

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 25-Jul-2012

- Completion Date

- 25-Jul-2012

Relations

- Effective Date

- 14-Aug-2010

- Effective Date

- 18-Jan-2023

- Effective Date

- 02-Oct-2010

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 408:2010 is a standard published by the European Committee for Standardization (CEN). Its full title is "Timber structures - Structural timber and glued laminated timber - Determination of some physical and mechanical properties". This standard covers: This European Standard specifies test methods for determining the following properties of structural timber and glued laminated timber: modulus of elasticity in bending; shear modulus; bending strength; modulus of elasticity in tension parallel to the grain; tension strength parallel to the grain; modulus of elasticity in compression parallel to the grain; compression strength parallel to the grain; modulus of elasticity in tension perpendicular to the grain; tension strength perpendicular to the grain; modulus of elasticity in compression perpendicular to the grain; compression strength perpendicular to the grain and shear strength. In addition, the determination of dimensions, moisture content, and density of test pieces are specified. The methods apply to rectangular and circular shapes (of substantially constant cross section) of solid unjointed timber or finger-jointed timber and glued laminated timber unless stated otherwise.

This European Standard specifies test methods for determining the following properties of structural timber and glued laminated timber: modulus of elasticity in bending; shear modulus; bending strength; modulus of elasticity in tension parallel to the grain; tension strength parallel to the grain; modulus of elasticity in compression parallel to the grain; compression strength parallel to the grain; modulus of elasticity in tension perpendicular to the grain; tension strength perpendicular to the grain; modulus of elasticity in compression perpendicular to the grain; compression strength perpendicular to the grain and shear strength. In addition, the determination of dimensions, moisture content, and density of test pieces are specified. The methods apply to rectangular and circular shapes (of substantially constant cross section) of solid unjointed timber or finger-jointed timber and glued laminated timber unless stated otherwise.

EN 408:2010 is classified under the following ICS (International Classification for Standards) categories: 79.040 - Wood, sawlogs and sawn timber; 79.060.99 - Other wood-based panels; 91.080.20 - Timber structures. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 408:2010 has the following relationships with other standards: It is inter standard links to EN 408:2003, EN 408:2010+A1:2012, EN 408:2010/FprA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 408:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

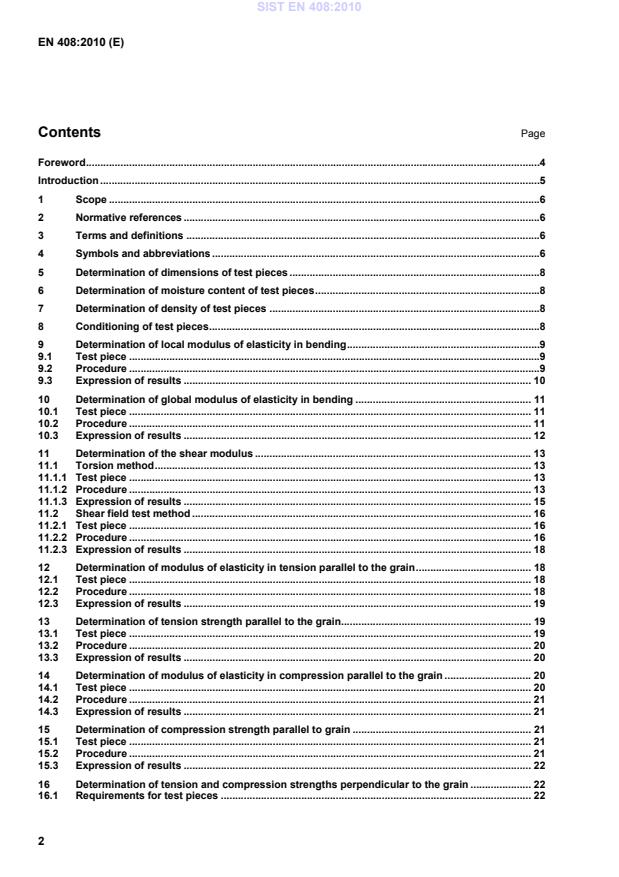

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Lesene konstrukcije - Konstrukcijski les in lepljeni lamelirani les - Ugotavljanje nekaterih fizikalnih in mehanskih lastnostiHolzbauwerke - Bauholz für tragende Zwecke und Brettschichtholz - Bestimmung einiger physikalischer und mechanischer EigenschaftenStructures en bois - Bois de structure et bois lamellé-collé - Détermination de certaines propriétés physiques et mécaniquesTimber Structures - Structural timber and glued laminated timber - Determination of some physical and mechanical properties91.080.20Lesene konstrukcijeTimber structures79.040Les, hlodovina in žagan lesWood, sawlogs and sawn timberICS:Ta slovenski standard je istoveten z:EN 408:2010SIST EN 408:2010en,fr,de01-november-2010SIST EN 408:2010SLOVENSKI

STANDARDSIST EN 408:20041DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 408

August 2010 ICS 79.040; 79.060.99; 91.080.20 Supersedes EN 408:2003English Version

Timber structures - Structural timber and glued laminated timber - Determination of some physical and mechanical properties

Structures en bois - Bois de structure et bois lamellé-collé -Détermination de certaines propriétés physiques et mécaniques

Holzbauwerke - Bauholz für tragende Zwecke und Brettschichtholz - Bestimmung einiger physikalischer und mechanischer Eigenschaften This European Standard was approved by CEN on 9 July 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 408:2010: ESIST EN 408:2010

(informative)

Example of compression perpendicular to grain test arrangement . 33Annex B

(informative)

Example of tension perpendicular to grain test arrangement with rigid fixings . 35Bibliography . 36 SIST EN 408:2010

Introduction This 2010 revision replaces the test for the determination of the shear strength parallel to grain. The revised edition of 2003 added a global bending modulus of elasticity, whilst renaming the existing test as the local modulus of elasticity. It also includes the methods for determination of shear strength and mechanical properties perpendicular to the grain, previously given in EN 1193, which has now been withdrawn. The values obtained in any determination of the properties of timber depend upon the test methods used. It is therefore desirable that these methods be standardized so that results from different test centres can be correlated. Moreover, with the adoption of limit state design and with the development of both visual and machine stress grading, attention will be increasingly centred on the determination and monitoring of the strength properties and variability of timber in structural sizes. Again, this can be more effectively undertaken if the basic data are defined and obtained under the same conditions.

This European Standard, which is based originally on ISO 8375, specifies laboratory methods for the determination of some physical and mechanical properties of timber in structural sizes. The methods are not intended for the grading of timber or for quality control.

For the determination of shear modulus, alternative methods have been specified. The choice of which to use will depend upon the objective of the investigation and, to some extent, on the equipment available. Following testing to this standard it is intended that the determination of characteristic values will normally be obtained according to procedures specified in other European Standards.

Attention is drawn to the advantages that may be gained, often with little extra effort, in extending the usefulness of test results by recording additional information on the growth characteristics of the pieces that are tested, particularly at the fracture sections. Generally, such additional information should include grade-determining features such as knots, slope of grain, rate of growth, wane, etc., on which visual grading rules are based, and strength indicating parameters such as localized modulus of elasticity, on which some machine stress grading is based. SIST EN 408:2010

Part 1: Determination by oven dry method 3 Terms and definitions Not applicable. 4 Symbols and abbreviations A

cross-sectional area, in square millimetres; a

distance between a loading position and the nearest support in a bending test, in millimetres; b width of cross section in a bending test, or the smaller dimension of the cross section, in millimetres; Ec,0

modulus of elasticity in compression parallel to the grain, in newtons per square millimetre; Ec,90 modulus of elasticity in compression perpendicular to the grain, in newtons per square millimetre; Em,g

global modulus of elasticity in bending, in newtons per square millimetre; Em,l

local modulus of elasticity in bending, in newtons per square millimetre; Et,0

modulus of elasticity in tension parallel to the grain, in newtons per square millimetre; Et,90 modulus of elasticity in tension perpendicular to the grain, in newtons per square millimetre; F

load, in newtons; Fc,90 compressive load perpendicular to the grain, in newtons; Fc,90,max maximum compressive load perpendicular to the grain, in newtons; Fc,90,max,est estimated maximum compressive load perpendicular to the grain, in newtons; Fmax

maximum load, in newtons; SIST EN 408:2010

estimated maximum load, in newtons; Ft,90 tensile load perpendicular to the grain, in newtons; Ft,90,max maximum tensile load perpendicular to the grain, in newtons; G shear modulus, in newtons per square millimetre; S first moment of area, in millimetres to the third power; fc,0

compressive strength parallel to the grain, in newtons per square millimetre; fc,90 compressive strength perpendicular to the grain, in newtons per square millimetre; fm

bending strength, in newtons per square millimetre; ft,0

tensile strength parallel to the grain, in newtons per square millimetre; ft,90 tensile strength perpendicular to the grain, in newtons per square millimetre; fv shear strength parallel to the grain, in newtons per square millimetre; fv,k characteristic shear strength parallel to the grain, in newtons per square millimetre; G

shear modulus, in newtons per square millimetre; Gtor,t

shear modulus in torsion, in newtons per square millimetre; Gtor,s shear modulus in shear field, in newtons per square millimetre;

h

depth of cross section in a bending test, or the larger dimension of the cross section, or the test piece height in perpendicular to grain and shear tests, in millimetres; h0 gauge length, in millimetres; I

second moment of area, in millimetres to the fourth power; K, k

coefficients; kG

coefficient for shear modulus; ktor torque stiffness, in newton metres per radian; ks shear stiffness; l

span in bending, or length of test piece between the testing machine grips in compression and tension, in millimetres; 1l

gauge length for the determination of modulus of elasticity or shear modulus, in millimetres; 2l distance between the supports and gauge length in torsion, in millimetres; t plate thickness, in millimetres; Tr torque, in newton millimetres; Vs shear force, in newtons; SIST EN 408:2010

section modulus, in millimetres to the third power; w

deformation or displacement, in millimetres; ϕ rotation, in radians; χ, η shape factors. Suffixes 1, 2

refer to loads or deformations or pieces at particular points of a test and are referred to as necessary in the text. 5 Determination of dimensions of test pieces The dimensions of the test piece shall be measured to an accuracy of 1 %. All measurements shall be made when the test pieces are conditioned as specified in Clause 8. If the width or thickness varies within a test piece, these dimensions should be recorded as the average of three separate measurements taken at different positions on the length of each piece. The measurements shall not be taken closer than 150 mm to the ends. Specimens for perpendicular to grain tests shall be planed. 6 Determination of moisture content of test pieces The moisture content of the test piece shall be determined in accordance with EN 13183-1 on a section taken from the test piece. For structural timber the section shall be of full cross section, free from knots and resin pockets. For perpendicular to grain test specimens the moisture content shall be determined from the whole specimen. In strength tests for bending and tension parallel to grain and compression parallel to grain, the section shall be cut as close as possible to the fracture. 7 Determination of density of test pieces The density of the whole cross section of the test piece shall be determined on a section taken from the test piece. For structural timber the section shall be of full cross section, free from knots and resin pockets. In strength tests, the section shall be cut as close as possible to the fracture. For perpendicular to grain test specimens the density of the test pieces shall be determined prior to test after conditioning from the measurements of mass and volume of the whole test piece. 8 Conditioning of test pieces All tests shall be carried out on pieces, which are conditioned at the standard environment of (20 ± 2) °C and (65 ± 5) % relative humidity. A test piece is conditioned when it attains constant mass. Constant mass is considered to be attained when the results of two successive weightings, carried out at an interval of 6 h, do not differ by more than 0,1 % of the mass of the test piece. Where the timber to be tested is not readily conditioned to the above standard environment (e.g. for hardwoods with high densities) that fact shall be reported. For small specimens, unless otherwise protected, test pieces shall not be removed from the conditioning environment more than 1 h before testing. SIST EN 408:2010

Figure 1 — Test arrangement for measuring local modulus of elasticity in bending SIST EN 408:2010

Use that section of the graph between 0,1 Fmax,est and 0,4 Fmax,est for a regression analysis. Find the longest portion of this section that gives a correlation coefficient of 0,99 or better. Provided that this portion covers at least the range 0,2 Fmax,est to 0,3 Fmax,est calculate the local modulus of elasticity from the following expression: ()()121221,16wwIFFalElm−−= (1) where F2 − F1

is an increment of load in newtons on the regression line with a correlation coefficient of 0,99 or better; and w2 − w1

is the increment of deformation in millimetres corresponding to F2 − F1 (see Figure 2). The local modulus of elasticity, Em,l shall be calculated to an accuracy of 1 %. If a portion of the graph cannot be found with a correlation coefficient of 0,99 or better covering the range 0,2 Fmax,est to 0,3 Fmax,est, check the test equipment and take measures to eradicate any errors caused by distorted specimens. If 0,99 is still not achieved, discard the specimen. The modulus of elasticity shall be calculated to an accuracy of 1 %. SIST EN 408:2010

Key F load w deformation Figure 2 — Load-deformation graph within the range of elastic deformation 10 Determination of global modulus of elasticity in bending 10.1 Test piece The test piece shall have a minimum length of 19 times the depth of the section. Where this is not possible, the span of the beam shall be reported. 10.2 Procedure The test piece shall be symmetrically loaded in bending at two points over a span of 18 times the depth as shown in Figure 3. If the test piece and equipment do not permit these conditions to be achieved exactly, the distance between the load points and the supports may be changed by an amount not greater than 1,5 times the piece depth, and the span and test piece length may be changed by an amount not greater than three times the piece depth, while maintaining the symmetry of the test. The test piece shall be simply supported. Small steel plates of length not greater than one-half of the depth of the test piece may be inserted between the piece and the loading heads or supports to minimize local indentation. Lateral restraint shall be provided as necessary to prevent lateral (torsional) buckling. This restraint shall permit the piece to deflect without significant frictional resistance. SIST EN 408:2010

The maximum load applied shall not exceed 0,4 Fmax,est or cause damage to the piece unless this test is carried out in conjunction with Clause 19. The estimated maximum load, Fmax,est of the material under test shall be obtained either from tests on at least ten pieces of the appropriate species, size and grade or from appropriate existing test data.

Figure 3 — Test arrangement for measuring global modulus of elasticity in bending The loading equipment used shall be capable of measuring the load to an accuracy of 1 % of the load applied to the test piece or, for loads less than 10 % of the applied maximum load, with an accuracy of 0,1 % of the maximum applied load.

The deformation w shall be measured at the centre of the span and from the centre of the tension or compression edge. When w is measured at the neutral axis it shall be the mean of measurements made on both sides of the test piece.

Deformations shall be determined with an accuracy of 1 % or, for deformations less than 2 mm, with an accuracy of 0,02 mm. If the test configuration differs from the above in any way then these differences are recorded and adjustment factors are determined. NOTE

The deformation w includes any local indentations that might occur at the supports and loading points and deformation of the supports themselves. Alternative determination methods based on the dynamic modulus of elasticity are allowed provided the correlation between the measured dynamic modulus of elasticity and the global modulus of elasticity is well established and documented. 10.3 Expression of results Use that section of the graph between 0,1 Fmax,est and 0,4 Fmax,est for a regression analysis. SIST EN 408:2010

is an increment of load in newtons on the regression line with a correlation coefficient of 0,99 or better; and w2 − w1

is the increment of deformation corresponding to F2 − F1, in millimetres (see Figure 2). If unknown, G can be taken as infinite. NOT

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...