EN 1422:1997+A1:2009

(Main)Sterilizers for medical purposes - Ethylene oxide sterilizers - Requirements and test methods

Sterilizers for medical purposes - Ethylene oxide sterilizers - Requirements and test methods

1.1 This European standard specifies the minimum performance requirements and test methods of two types of sterilizers employing ethylene oxide gas as the sterilant, either as a pure gas or in admixture with other gases (whether supplied ready mixed or mixed at the point of use) in a temporarily sealed chamber.

These sterilizers are intended to be used for medical, dental, pharmaceutical, veterinary and industrial or related purposes. The two types of sterilizers have been designated Type A and Type B respectively using the following criteria:

- Type A sterilizers are capable of being programmed by the user;

- Type B sterilizers are of limited size and provided with one or more pre-set operating cycles which cannot be varied by the user.

The clauses of this standard apply to both types of sterilizer unless it is specifically indicated within the clause that it applies only to one of the types in particular.

1.2 This standard includes minimum performance and construction requirements for sterilizers working above or below atmospheric pressure:

- To ensure that the process is capable of being used to sterilize medical products;

- For the equipment and controls necessary to permit validation and monitoring of the sterilization process.

1.3 This standard does not specify those tests which are necessary to determine the probability of a processed product being sterile, nor the routine quality control tests required prior to release of sterile product. These topics are addressed in EN 550.

1.4 This standard does not specify the procedures and equipment which can be used to improve the efficacy and/or efficiency of the process before or after the sterilization cycle.

1.5 Considerations of operator safety are addressed in EN 61010-1: A2 and IEC 1010-2-042.

1.6 This standard is applicable when:

a) Specified in a contract for supply of an ethylene oxide sterilizer;

or,

b) A sterilizer manufacturer declares compliance when intending to supply an ethylene oxide st

Sterilisatoren für die medizinische Zwecke - Ethylenoxid-Sterilisatoren - Anforderungen und Prüfverfahren

1.1 Diese Europäische Norm legt Mindestleistungsanforderungen und Prüfverfahren an zwei Typen von

Sterilisatoren fest, die Ethylenoxid, entweder als reines Gas oder als Gas im Gemisch mit anderen Gasen, als

Sterilisiermittel verwenden (dabei kann das Gemisch in fertigem Zustand geliefert oder erst am Einsatzort

hergestellt werden).

Diese Sterilisatoren dienen zum Einsatz in der Allgemeinen-, Zahn- oder Tiermedizin, in der Pharmazie, der

Industrie oder zu anderen verwandten Zwecken. Die beiden Typen werden als Typ A bzw. Typ B bezeichnet

und unterscheiden sich wie folgt:

- Sterilisatoren des Typs A sind vom Anwender programmierbar;

- Sterilisatoren des Typs B sind in der Größe begrenzt und besitzen einen oder mehrere fest eingestellte

Arbeitszyklen, die durch den Anwender nicht verändert werden können.

Die Abschnitte dieser Norm gelten für beide Typen der Sterilisatoren, es sei denn, es ist im Abschnitt speziell

angegeben, dass dieser Abschnitt nur für einen Typ gilt.

1.2 Diese Norm enthält Mindestanforderungen an die Leistungsfähigkeit und den Aufbau von Sterilisatoren,

die mit Über- oder Unterdruck betrieben werden:

- damit sichergestellt ist, dass sich der Prozess zur Sterilisation von Medizinprodukten eignet;

- für die Einrichtung und Steuerung, die erforderlich sind, um den Sterilisationsprozess validieren zu

können.

1.3 Diese Norm legt keine Prüfungen fest, die erforderlich sind, um die Wahrscheinlichkeit festzustellen,

dass ein behandeltes Produkt steril ist und legt keine routinemäßigen Qualitätsprüfungen fest, die erforderlich

sind, um sterile Produkte frei zu geben. Diese Themen werden in EN 556 behandelt.

1.4 Diese Norm legt nicht die Verfahren und die Einrichtungen fest, die zur Verbesserung der Wirksamkeit

und/oder Leistungsfähigkeit des Prozesses vor oder nach dem Sterilisationszyklus verwendet werden können.

1.5 Angaben über Bedienersicherheit werden in EN 61010-1 + A2 und IEC 1010-2-042 behandelt.

Stérilisateurs à usage médical - Stérilisateurs à l'oxyde d'éthylène - Exigences et méthodes d'essai

1.1 La présente norme européenne spécifie les exigences minimales de fonctionnement et les méthodes d’essai

applicables à deux types de stérilisateurs employant de l'oxyde d'éthylène comme agent stérilisant, soit sous forme

de gaz pur, soit mélangé à d'autres gaz (que l'agent stérilisant soit déjà mélangé lorsqu'il est livré ou qu'il soit mélangé

sur place avant utilisation) dans une chambre hermétiquement close de façon temporaire.

Ces stérilisateurs sont destinés à être utilisés à des fins médicales, dentaires, pharmaceutiques, vétérinaires et

industrielles ou à des fins connexes. Les deux types de stérilisateurs — type A et type B — ont été respectivement

définis en fonction des critères suivants :

- les stérilisateurs de type A peuvent être programmés par l'utilisateur ;

- les stérilisateurs de type B sont de dimensions réduites et comportent un ou plusieurs cycles de fonctionnement

préprogrammés qui ne peuvent pas être modifiés par l'utilisateur.

Les articles de la présente norme s'appliquent à ces deux types de stérilisateurs, à moins qu'il ne soit précisé qu'ils

ne concernent que l'un d'entre eux.

1.2 La présente norme définit les exigences minimales de performance et de construction applicables aux

stérilisateurs fonctionnant au-dessus ou en-dessous de la pression atmosphérique :

- afin d'assurer que le procédé peut être utilisé pour stériliser des dispositifs médicaux ;

- pour l'équipement et les commandes nécessaires à la validation et à la surveillance du procédé de stérilisation.

1.3 La présente norme ne spécifie pas les essais qui doivent être effectués pour déterminer la probabilité selon

laquelle un objet traité est stérile, ni les essais de contrôle qualité de routine nécessaires avant de libérer un objet

stérile. Ces questions sont traitées dans l'EN 550.

Sterilizatorji za uporabo v medicini - Sterilizatorji z etilenoksidom - Zahteve in preskusne metode

General Information

- Status

- Withdrawn

- Publication Date

- 12-May-2009

- Withdrawal Date

- 20-May-2014

- Technical Committee

- CEN/TC 102 - Sterilizers for medical purposes

- Drafting Committee

- CEN/TC 102/WG 6 - Gas sterilizers

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 21-May-2014

- Completion Date

- 21-May-2014

Not Harmonized93/42/EEC - Medical devicesOJ Ref: C 293, C 293, C 293, C 293, C 293, C 293, C 293, C OJ Date: 02-Dec-2009

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 23-Mar-2009

- Effective Date

- 23-Mar-2009

- Effective Date

- 21-Nov-2009

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN IEC 60751:2022 - Industrial platinum resistance thermometers and platinum temperature sensors - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Sponsored listings

Frequently Asked Questions

EN 1422:1997+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Sterilizers for medical purposes - Ethylene oxide sterilizers - Requirements and test methods". This standard covers: 1.1 This European standard specifies the minimum performance requirements and test methods of two types of sterilizers employing ethylene oxide gas as the sterilant, either as a pure gas or in admixture with other gases (whether supplied ready mixed or mixed at the point of use) in a temporarily sealed chamber. These sterilizers are intended to be used for medical, dental, pharmaceutical, veterinary and industrial or related purposes. The two types of sterilizers have been designated Type A and Type B respectively using the following criteria: - Type A sterilizers are capable of being programmed by the user; - Type B sterilizers are of limited size and provided with one or more pre-set operating cycles which cannot be varied by the user. The clauses of this standard apply to both types of sterilizer unless it is specifically indicated within the clause that it applies only to one of the types in particular. 1.2 This standard includes minimum performance and construction requirements for sterilizers working above or below atmospheric pressure: - To ensure that the process is capable of being used to sterilize medical products; - For the equipment and controls necessary to permit validation and monitoring of the sterilization process. 1.3 This standard does not specify those tests which are necessary to determine the probability of a processed product being sterile, nor the routine quality control tests required prior to release of sterile product. These topics are addressed in EN 550. 1.4 This standard does not specify the procedures and equipment which can be used to improve the efficacy and/or efficiency of the process before or after the sterilization cycle. 1.5 Considerations of operator safety are addressed in EN 61010-1: A2 and IEC 1010-2-042. 1.6 This standard is applicable when: a) Specified in a contract for supply of an ethylene oxide sterilizer; or, b) A sterilizer manufacturer declares compliance when intending to supply an ethylene oxide st

1.1 This European standard specifies the minimum performance requirements and test methods of two types of sterilizers employing ethylene oxide gas as the sterilant, either as a pure gas or in admixture with other gases (whether supplied ready mixed or mixed at the point of use) in a temporarily sealed chamber. These sterilizers are intended to be used for medical, dental, pharmaceutical, veterinary and industrial or related purposes. The two types of sterilizers have been designated Type A and Type B respectively using the following criteria: - Type A sterilizers are capable of being programmed by the user; - Type B sterilizers are of limited size and provided with one or more pre-set operating cycles which cannot be varied by the user. The clauses of this standard apply to both types of sterilizer unless it is specifically indicated within the clause that it applies only to one of the types in particular. 1.2 This standard includes minimum performance and construction requirements for sterilizers working above or below atmospheric pressure: - To ensure that the process is capable of being used to sterilize medical products; - For the equipment and controls necessary to permit validation and monitoring of the sterilization process. 1.3 This standard does not specify those tests which are necessary to determine the probability of a processed product being sterile, nor the routine quality control tests required prior to release of sterile product. These topics are addressed in EN 550. 1.4 This standard does not specify the procedures and equipment which can be used to improve the efficacy and/or efficiency of the process before or after the sterilization cycle. 1.5 Considerations of operator safety are addressed in EN 61010-1: A2 and IEC 1010-2-042. 1.6 This standard is applicable when: a) Specified in a contract for supply of an ethylene oxide sterilizer; or, b) A sterilizer manufacturer declares compliance when intending to supply an ethylene oxide st

EN 1422:1997+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 11.080.10 - Sterilizing equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1422:1997+A1:2009 has the following relationships with other standards: It is inter standard links to EN 1422:1997, EN 1422:1997/prA1, EN 1422:1997/AC:2002, EN 1422:2014, EN 60584-1:2013, EN 60651:1994, ISO 6780:2003, EN IEC 61000-6-1:2019, EN IEC 60751:2022, EN IEC 61000-6-2:2019, EN 61010-1:1993/A2:1995, EN 61010-1:2001, EN IEC 61000-6-3:2021, EN 60804:1994, EN ISO 11138-1:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1422:1997+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2007/47/EC, 93/42/EEC; Standardization Mandates: M/023. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1422:1997+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sterilizatorji za uporabo v medicini - Sterilizatorji z etilenoksidom - Zahteve in preskusne metodeSterilisatoren für die medizinische Zwecke - Ethylenoxid-Sterilisatoren - Anforderungen und PrüfverfahrenStérilisateurs à usage médical - Stérilisateurs à l'oxyde d'éthylène - Exigences et méthodes d'essaiSterilizers for medical purposes - Ethylene oxide sterilizers - Requirements and test methods11.080.10Sterilizacijska opremaSterilizing equipmentICS:Ta slovenski standard je istoveten z:EN 1422:1997+A1:2009SIST EN 1422:2000+A1:2009en,fr,de01-oktober-2009SIST EN 1422:2000+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1422:1997+A1

May 2009 ICS 11.080.10 Supersedes EN 1422:1997English Version

Sterilizers for medical purposes - Ethylene oxide sterilizers - Requirements and test methods

Stérilisateurs à usage médical - Stérilisateurs à l'oxyde d'éthylène - Exigences et méthodes d'essai

Sterilisatoren für medizinische Zwecke - Ethylenoxid-Sterilisatoren - Anforderungen und Prüfverfahren This European Standard was approved by CEN on 30 August 1997 and includes Corrigendum 1 issued by CEN on 24 July 2002 and Amendment 1 approved by CEN on 12 April 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1422:1997+A1:2009: ESIST EN 1422:2000+A1:2009

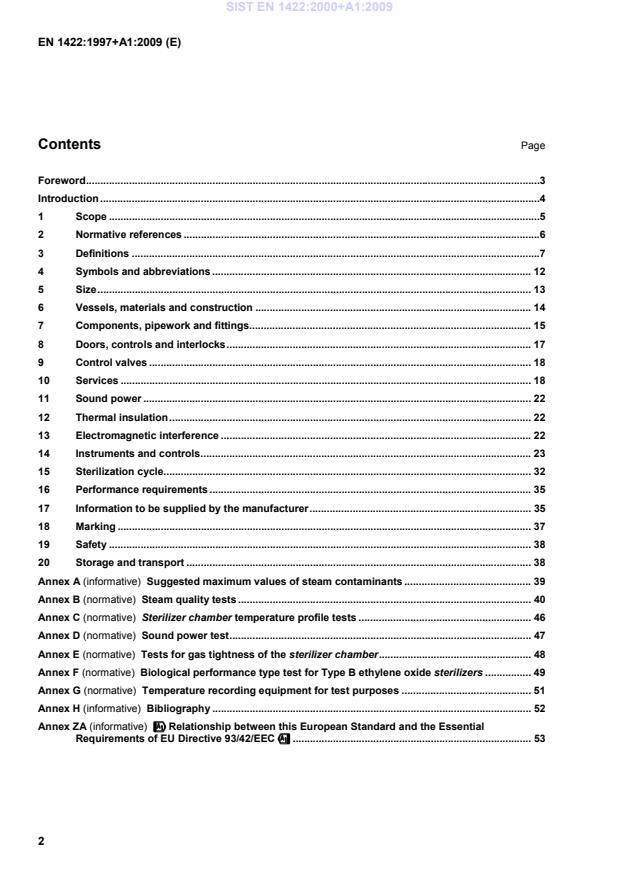

Suggested maximum values of steam contaminants . 39Annex B (normative)

Steam quality tests . 40Annex C (normative)

Sterilizer chamber temperature profile tests . 46Annex D (normative)

Sound power test . 47Annex E (normative)

Tests for gas tightness of the sterilizer chamber . 48Annex F (normative)

Biological performance type test for Type B ethylene oxide sterilizers . 49Annex G (normative)

Temperature recording equipment for test purposes . 51Annex H (informative)

Bibliography . 52Annex ZA (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 93/42/EEC"""" . 53 SIST EN 1422:2000+A1:2009

1 Scope 1.1 This European standard specifies the minimum performance requirements and test methods of two types of sterilizers employing ethylene oxide gas as the sterilant, either as a pure gas or in admixture with other gases (whether supplied ready mixed or mixed at the point of use) in a temporarily sealed chamber. These sterilizers are intended to be used for medical, dental, pharmaceutical, veterinary and industrial or related purposes. The two types of sterilizers have been designated Type A and Type B respectively using the following criteria: Type A sterilizers are capable of being programmed by the user; Type B sterilizers are of limited size and provided with one or more pre-set operating cycles which cannot be varied by the user. The clauses of this standard apply to both types of sterilizer unless it is specifically indicated within the clause that it applies only to one of the types in particular. 1.2 This standard includes minimum performance and construction requirements for sterilizers working above or below atmospheric pressure: To ensure that the process is capable of being used to sterilize medical products; For the equipment and controls necessary to permit validation and monitoring of the sterilization process. SIST EN 1422:2000+A1:2009

with the process specification [EN 550] (See also 3.58 validation) SIST EN 1422:2000+A1:2009

ethylene oxide N

nitrogen CO2

carbon dioxide RH

relative humidity s

second

min

minute h

hour SIST EN 1422:2000+A1:2009

micrometre mm

millimetre m

metre l

litre N

newton g

gram kg

kilogram Pa

pascal kPa

kilopascal NOTE All pressures given in kPa are absolute pressures. W

watt kW

kilowatt kJ

kilojoule ûC

degrees Celsius K

kelvin bar

bar mbar millibar EN

European standard IEC

International Electrotechnical Commission ISO

International Organization for Standardization v/v

volume in volume dilution m/m

mass in mass dilution dB

decibel lx

lux 5 Size 5.1 The size of the usable sterilizer chamber space shall be designed by reference to the principle dimensions, measured in metres (to three significant figures). In addition, for sterilizers up to 8000 l, the number of sterilization modules that can be accommodated in the usable sterilizer chamber space shall be stated (in integral numbers). For sterilizers of usable sterilizer chamber space greater than 8000 l, the number of pallets of plan dimensions (1200 mm x 1000 mm) and SIST EN 1422:2000+A1:2009

9 Control valves 9.1 Maintenance of the valves connected to the chamber shall not require the removal of any connecting pipes. 9.2 At least one strainer shall be fitted on each service supply line upstream of the first valve on the sterilizer for that service. The particulate retention efficiency of the strainer shall be compatible with the values stated by the valve manufacturer. 10 Services 10.1 Water 10.1.1 Provision shall be made to ensure that water which can contain EO cannot contaminate the public supply. NOTE 1 The water supply to vacuum pumps should incorporate an air break. NOTE 2 In addition, attention is drawn to the need to consider local requirements for the maximum quantities of EO that can be discharged in effluent water. 10.1.2 If water is required for use in the sterilizer, the sterilizer shall be designed to operate with water which is of potable quality and supplied at a temperature not exceeding 15 ûC. NOTE 1 The temperature of water should be as low as possible because of the effect of temperature on the performance of vacuum systems. Higher water temperatures can modify the specified vacuum levels. NOTE 2 The sterilizer should be designed to operate with water of a hardness value between 0,7 mmol/l and 2,0 mmol/l. Hardness values outside these limits can cause scaling and corrosion problems. NOTE 3 The water supply should be fitted with a backflow protection device. 10.1.3 The sterilizer shall be designed to operate with the water for the generation of steam used to humidify the chamber which is free from contaminants which can impair the sterilization process, or harm the sterilizer or sterilization load. NOTE Suggested maximum values of some contaminants are given in Annex A. 10.1.4 Direct injection of nebulized water shall not be used for humidification. 10.2 Steam 10.2.1 If the sterilizer utilizes steam supplied above atmospheric pressure for humidification, it shall be designed to operate with steam having a dryness value of not less than 0,9 and the degrees of superheat in free steam at atmospheric pressure not exceeding 5 K. The quality of the steam shall be determined in accordance with Annex B. SIST EN 1422:2000+A1:2009

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...