EN 12111:2002

(Main)Tunnelling machines - Road headers, continuous miners and impact rippers - Safety requirements

Tunnelling machines - Road headers, continuous miners and impact rippers - Safety requirements

This European Standard specifies all significant hazards, hazardous situations and events relevant to road headers, continuous miners and impact rippers, when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). This standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards.This European Standard is applicable to road headers, continuous miners and impact rippers used in tunnelling and underground mining.

Certain associated matters are not included in the scope of this standard:

¾ the supply of electricity up to the machine;

¾ the provision of a cab or similar accommodation for an operator;

¾ ancillary tools and equipment used for, at or on the machine;

¾ equipment for use in flammable/explosive atmospheres;

¾ any method for monitoring gases in the atmosphere of the tunnel or other workplace;

¾ the method of calculation of the design of any part described or the verification of this;

¾ loading and transport equipment which is not an integral part of the machine;

¾ electromagnetic compatibility;

¾ pressure vessels.

NOTE Directive 94/9/EC concerning equipment and protective systems intended for use in potentially explosive atmos-pheres can be applicable to the type of machine or equipment covered by this European Standard. The present standard is not intended to provide means of complying with the essential health and safety requirements of Directive 94/9/EC.

Tunnelbaumaschinen - Teilschnittmaschinen, Continuous Miners und Schlagkopfmaschinen - Sicherheitstechnische Anforderungen

Diese Europäische Norm gilt für Teilschnittmaschinen, Continuous Miners und Schlagkopfmaschinen, die im Tunnel-, Stollen- und Bergbau eingesetzt werden.

Einige hiermit im Zusammenhang stehende Sachverhalte sind in den Anwendungsbereich dieser Norm nicht mit eingeschlossen:

¾ elektrische Energieversorgung bis zur Maschine;

¾ das Vorsehen einer Kabine oder vergleichbaren Einrichtung für den Maschinenbediener;

¾ Hilfswerkzeuge und -ausrüstungen, die für die Maschine, an oder auf der Maschine benutzt werden;

¾ Geräte zur Verwendung in explosionsfähiger Atmosphäre;

¾ Methoden zur Überwachung von Gasen in der Tunnelatmosphäre oder an anderen Einsatzorten;

¾ Berechnungsmethoden für die Konstruktion eines jeden beschriebenen Bauteils sowie deren Verifikation;

¾ Lade- und Transporteinrichtungen, die nicht integraler Bestandteil der Maschine sind;

¾ elektromagnetische Verträglichkeit;

¾ Druckbehälter.

ANMERKUNG 1 Die Richtlinie 94/9/EG bezüglich Ausrüstungen und Schutzsysteme, die für den Gebrauch in explosionsfähiger Atmosphäre vorgesehen sind, kann auf den Maschinentyp oder die Ausrüstungen dieser Europäischen Norm anzuwenden sein. Diese Norm liefert keine Anforderung zur Übereinstimmung mit den wesentlichen Gesundheits- und Sicherheitsanforderungen der Richtlinie 94/9/EG.

ANMERKUNG 2 prEN 1710 �Maschinen für den Bergbau unter Tage - Anforderungen für den Einsatz in grubengas-gefährdeten Bereichen von Bergwerken - Sicherheit" ist bei CEN/TC 305 in Vorbereitung.

1.2 Diese Norm behandelt alle signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungs-ereignisse, die auf Teilschnittmaschinen, Continuous Miners und Schlagkopfmaschinen zutreffen, wenn sie bestimmungsgemäß und entsprechend den vorhersehbaren Bedingungen des Herstellers verwendet werden (siehe Abschnitt 4). Diese Norm spezifiziert die geeigneten technischen Maßnahmen, um die Risiken, die von den schwerwiegenden Gefährdungen ausgehen, auszuschließen oder zu verringern.

1.3 Dieses Dokument gi

Machines pour la construction de tunnels - Machines à attaque ponctuelle, mineurs continus, brise-roches - Règles de sécurité

La présente Norme européenne traite tous les phénomènes dangereux, les situations et les événements dangereux relatifs aux machines à attaque ponctuelles, aux mineurs continus et aux brise-roches hydrauliques, lorsque ceux-ci sont utilisés dans les conditions prévues par le constructeur (voir l'article 4). La présente norme spécifie les mesures techniques appropriées pour éliminer ou réduire les risques engendrés par les phénomènes dangereux significatifs. La présente norme européenne s'applique aux machines à attaque ponctuelle, aux mineurs continus et aux brise-roches hydrauliques utilisés dans la construction de tunnels et les mines.

Certaines parties associées ne font pas partie du domaine d'application de cette norme :

¾ réseau d'alimentation électrique jusqu'à la machine ;

¾ fourniture d'une cabine ou autre disposition similaire pour un opérateur ;

¾ outils et équipements auxiliaires utilisés pour, dans ou sur la machine ;

¾ équipements pour une utilisation en atmosphère inflammable/explosive ;

¾ toute méthode pour le contrôle des gaz dans l'atmosphère du tunnel ou à d'autres lieux de travail ;

¾ la méthode de calcul de la conception de toute partie décrite ou de sa vérification ;

¾ équipements de chargement et de transport ne faisant pas partie intégrante de la machine ;

¾ compatibilité électromagnétique ;

¾ réservoirs à pression.

NOTE La directive 94/9/CE concernant les équipements et les systèmes de protection prévus pour être utilisés en atmosphère potentiellement explosive peut s'appliquer à ce type de machine ou équipement couverts par la présente Norme européenne. La présente norme ne fournit pas les moyens de satisfaire aux exigences de sécurité et de santé de la directive 94/9/CE.

Le présent document ne s'applique pas aux machines qui ont été construites avant la date de publication du présent document par le CEN.

Stroji za gradnjo predorov – Odkopne naprave – Varnostne zahteve

General Information

- Status

- Withdrawn

- Publication Date

- 03-Dec-2002

- Withdrawal Date

- 30-Jun-2009

- Technical Committee

- CEN/TC 151 - Construction equipment and building material machines - Safety

- Drafting Committee

- CEN/TC 151/WG 4 - Tunnelling machines - Safety

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 01-Jul-2009

- Completion Date

- 01-Jul-2009

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 06-May-2009

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Revised

EN 12111:2014 - Tunnelling machines - Road headers and continuous miners - Safety requirements - Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 12111:2002 is a standard published by the European Committee for Standardization (CEN). Its full title is "Tunnelling machines - Road headers, continuous miners and impact rippers - Safety requirements". This standard covers: This European Standard specifies all significant hazards, hazardous situations and events relevant to road headers, continuous miners and impact rippers, when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). This standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards.This European Standard is applicable to road headers, continuous miners and impact rippers used in tunnelling and underground mining. Certain associated matters are not included in the scope of this standard: ¾ the supply of electricity up to the machine; ¾ the provision of a cab or similar accommodation for an operator; ¾ ancillary tools and equipment used for, at or on the machine; ¾ equipment for use in flammable/explosive atmospheres; ¾ any method for monitoring gases in the atmosphere of the tunnel or other workplace; ¾ the method of calculation of the design of any part described or the verification of this; ¾ loading and transport equipment which is not an integral part of the machine; ¾ electromagnetic compatibility; ¾ pressure vessels. NOTE Directive 94/9/EC concerning equipment and protective systems intended for use in potentially explosive atmos-pheres can be applicable to the type of machine or equipment covered by this European Standard. The present standard is not intended to provide means of complying with the essential health and safety requirements of Directive 94/9/EC.

This European Standard specifies all significant hazards, hazardous situations and events relevant to road headers, continuous miners and impact rippers, when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). This standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards.This European Standard is applicable to road headers, continuous miners and impact rippers used in tunnelling and underground mining. Certain associated matters are not included in the scope of this standard: ¾ the supply of electricity up to the machine; ¾ the provision of a cab or similar accommodation for an operator; ¾ ancillary tools and equipment used for, at or on the machine; ¾ equipment for use in flammable/explosive atmospheres; ¾ any method for monitoring gases in the atmosphere of the tunnel or other workplace; ¾ the method of calculation of the design of any part described or the verification of this; ¾ loading and transport equipment which is not an integral part of the machine; ¾ electromagnetic compatibility; ¾ pressure vessels. NOTE Directive 94/9/EC concerning equipment and protective systems intended for use in potentially explosive atmos-pheres can be applicable to the type of machine or equipment covered by this European Standard. The present standard is not intended to provide means of complying with the essential health and safety requirements of Directive 94/9/EC.

EN 12111:2002 is classified under the following ICS (International Classification for Standards) categories: 91.220 - Construction equipment; 93.060 - Tunnel construction. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12111:2002 has the following relationships with other standards: It is inter standard links to EN 12111:2002+A1:2009, EN 12111:2002/prA1, EN 12111:2002/AC:2004, EN 12111:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12111:2002 is associated with the following European legislation: EU Directives/Regulations: 98/37/EC; Standardization Mandates: M/BC/CEN/91/1. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12111:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2003

Stroji za gradnjo predorov – Odkopne naprave – Varnostne zahteve

Tunnelling machines - Road headers, continuous miners and impact rippers - Safety

requirements

Tunnelbaumaschinen - Teilschnittmaschinen, Continuous Miners und

Schlagkopfmaschinen - Sicherheitstechnische Anforderungen

Machines pour la construction de tunnels - Machines a attaque ponctuelle, mineurs

continus, brise-roches - Regles de sécurité

Ta slovenski standard je istoveten z: EN 12111:2002

ICS:

91.220 Gradbena oprema Construction equipment

93.060 Gradnja predorov Tunnel construction

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN 12111

NORME EUROPÉENNE

EUROPÄISCHE NORM

December 2002

ICS 91.220; 93.060

English version

Tunnelling machines - Road headers, continuous miners and

impact rippers - Safety requirements

Machines pour la construction de tunnels - Machines à Tunnelbaumaschinen - Teilschnittmaschinen, continuous

attaque ponctuelle, mineurs continus, brise-roches - Règles miners und Schlagkopfmaschinen - Sicherheitstechnische

de sécurité Anforderungen

This European Standard was approved by CEN on 9 October 2002.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the official

versions.

CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,

Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2002 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12111:2002 E

worldwide for CEN national Members.

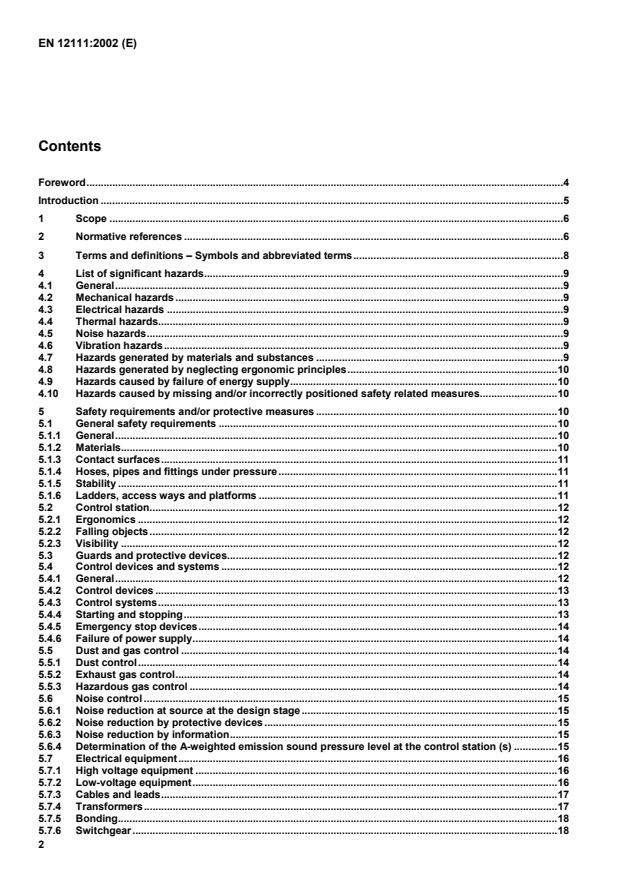

Contents

Foreword.4

Introduction .5

1 Scope .6

2 Normative references .6

3 Terms and definitions – Symbols and abbreviated terms.8

4 List of significant hazards.9

4.1 General.9

4.2 Mechanical hazards .9

4.3 Electrical hazards .9

4.4 Thermal hazards.9

4.5 Noise hazards.9

4.6 Vibration hazards.9

4.7 Hazards generated by materials and substances .9

4.8 Hazards generated by neglecting ergonomic principles.10

4.9 Hazards caused by failure of energy supply.10

4.10 Hazards caused by missing and/or incorrectly positioned safety related measures.10

5 Safety requirements and/or protective measures .10

5.1 General safety requirements .10

5.1.1 General.10

5.1.2 Materials.10

5.1.3 Contact surfaces.11

5.1.4 Hoses, pipes and fittings under pressure .11

5.1.5 Stability .11

5.1.6 Ladders, access ways and platforms .11

5.2 Control station.12

5.2.1 Ergonomics .12

5.2.2 Falling objects.12

5.2.3 Visibility .12

5.3 Guards and protective devices.12

5.4 Control devices and systems .12

5.4.1 General.12

5.4.2 Control devices .13

5.4.3 Control systems.13

5.4.4 Starting and stopping.13

5.4.5 Emergency stop devices.14

5.4.6 Failure of power supply.14

5.5 Dust and gas control .14

5.5.1 Dust control.14

5.5.2 Exhaust gas control.14

5.5.3 Hazardous gas control .14

5.6 Noise control .15

5.6.1 Noise reduction at source at the design stage.15

5.6.2 Noise reduction by protective devices .15

5.6.3 Noise reduction by information.15

5.6.4 Determination of the A-weighted emission sound pressure level at the control station (s) .15

5.7 Electrical equipment.16

5.7.1 High voltage equipment .16

5.7.2 Low-voltage equipment.16

5.7.3 Cables and leads.17

5.7.4 Transformers.17

5.7.5 Bonding.18

5.7.6 Switchgear.18

5.7.7 Batteries.18

5.8 Lighting.18

5.8.1 General.18

5.8.2 Emergency lighting.18

5.9 Hydraulic and pneumatic systems.18

5.10 Fire protection.19

5.10.1 General.19

5.10.2 Fire extinguishers.19

5.10.3 Location of fire extinguishers .19

5.11 Marking .19

5.11.1 Warning signs .19

5.11.2 Symbols .20

6 Verification of safety requirements and/or protective measures .20

7 Information for use .20

7.1 General.20

7.2 Accompanying documents.21

7.2.1 Content of general instructions handbook .21

7.2.2 Content of operator's handbook .21

7.2.3 Content of maintenance handbook.22

7.2.4 Spare parts list.22

7.3 Marking .22

7.3.1 General.22

Annex A (normative) Protective measures for electrical accessories and lighting.24

Annex B (normative) Verification of safety requirements and/or protective measures .25

Annex C (informative) Figures .27

Annex ZA (informative) Relationship of this document with EC Directives.30

Bibliography .31

Foreword

This document EN 12111:2002 has been prepared by Technical Committee CEN /TC 151, "Construction

equipment and building material machines - Safety" the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an identical text or

by endorsement, at the latest by June 2003, and conflicting national standards shall be withdrawn at the latest by

June 2003.

This document has been prepared under a mandate given to CEN by the European Commission and the European

Free Trade Association and supports essential requirements of EC Directive(s).

Annex A is normative and contains “Protective measures for electrical accessories and lighting”, Annex B is

normative and contains “Verification of safety requirements and/or protective measures” and Annex C is informative

and contains “Figures”.

For relationship with EC Directives, see informative Annex ZA, which is an integral part of this document.

This document includes a bibliography.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard : Austria, Belgium, Czech Republic, Denmark, Finland,

France, Germany, Greece, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain,

Sweden, Switzerland and the United Kingdom.

Introduction

This document is a type C-standard as stated in EN 1070.

The machinery concerned and the extent to which hazards, hazardous situations and events are covered are indi-

cated in the scope of this document.

Due to the wide range of geological and environmental conditions in which these types of machines are likely to be

employed, it is not possible always to give precise technical requirements in this standard.

The particular conditions of use and places of use of the machinery (e.g. ground and local safety conditions, haz-

ardous gas concentration (see 5.5.3)) are the subjects of negotiation between the manufacturers and the

user/purchaser.

NOTE “Manufacturer” should be understood within the European Union as intended in the Machinery Directive.

When provisions of this type C standard are different from those which are stated in type A or B standards, the pro-

visions of this type C standard take precedence over the provisions of the other standards, for machines that have

been designed and built according to the provisions of this type C standard.

1 Scope

1.1 Description of the machine

This European Standard specifies all significant hazards, hazardous situations and events relevant to road

headers, continuous miners and impact rippers, when they are used as intended and under the conditions foreseen

by the manufacturer (see clause 4). This standard specifies the appropriate technical measures to eliminate or

reduce risks arising from the significant hazards. This European Standard is applicable to road headers, continuous

miners and impact rippers used in tunnelling and underground mining.

Certain associated matters are not included in the scope of this standard:

the supply of electricity up to the machine;

the provision of a cab or similar accommodation for an operator;

ancillary tools and equipment used for, at or on the machine;

equipment for use in potentially explosive atmospheres;

any method for monitoring gases in the atmosphere of the tunnel or other workplace;

the method of calculation of the design of any part described or the verification of this;

loading and transport equipment which is not an integral part of the machine;

electromagnetic compatibility;

pressure vessels.

NOTE 1 Directive 94/9/EC concerning equipment and protective systems intended for use in potentially explosive atmos-

pheres can be applicable to the type of machine or equipment covered by this European Standard. The present standard is not

intended to provide means of complying with the essential health and safety requirements of Directive 94/9/EC.

NOTE 2 prEN 1710 “Equipment and components intended for use in potentially explosive atmospheres in mines” is currently

under preparation in CEN/TC 305.

1.2 This standard deals with all significant hazards, hazardous situations and events relevant to road headers,

continuous miners and impact rippers, when they are used as intended and under the conditions foreseen by the

manufacturer (see clause 4). This standard specifies the appropriate technical measures to eliminate or reduce

risks arising from the significant hazards.

1.3 This document is not applicable to machines which are manufactured before the date of publication of this

document by CEN.

2 Normative references

This European Standard incorporates by dated or undated reference, provisions from other publications. These

normative references are cited at the appropriate places in the text, and the publications are listed hereafter. For

dated references, subsequent amendments to or revisions of any of these publications apply to this European

Standard only when incorporated in it by amendment or revision. For undated references the latest edition of the

publication referred to applies (including amendments).

EN 3-1, Portable fire extinguishers — Part 1: Description, duration of operation, class A and B fire test.

EN 292-1, Safety of machinery — Basic concepts, general principles for design — Part 1: Basic terminology,

methodology.

EN 292-2:1991, Safety of machinery — Basic concepts, general principles for design — Part 2: Technical principles

and specifications.

EN 418:1992, Safety of machinery — Emergency stop equipment, functional aspects — Principles for design.

EN 474-1, Earth-moving machinery — Safety - Part 1: General requirements.

EN 563, Safety of machinery — Temperatures of touchable surfaces — Ergonomics data to establish temperature

limit values for hot surfaces.

EN 617, Continuous handling equipment and systems – Safety and EMC requirements for the equipment for the

storage of bulk materials in silos, bunkers, bins and hoppers.

EN 619, Continuous handling equipment and systems – Safety and EMC requirements for equipment for

mechanical handling of units loads.

EN 954-1:1996, Safety of machinery — Safety related parts of control systems — Part 1: General principles for de-

sign.

EN 982, Safety of machinery — Safety requirements for fluid power systems and their components — Hydraulics.

EN 983, Safety of machinery — Safety requirements for fluid power systems and their components — Pneumatics.

EN 1070:1998, Safety of machinery — Terminology.

EN 60204-1:1997, Safety of machinery — Electrical equipment of machines — Part 1: General requirements

(IEC 60204-1:1997).

EN 60204-11, Safety of machinery - Electrical equipment of machines - Part 11: Requirements for HV equipment

for voltages above 1000 V a.c. or 1500 V d.c. and not exceeding 36 kV (IEC 60204-11:2000).

EN 60439-1:1999, Low-voltage switchgear and controlgear assemblies — Part 1: Type-tested and partially type-

tested assemblies (IEC 60439-1:1999).

EN 60439-2, Low-voltage switchgear and controlgear assemblies — Part 2: Particular requirements for bushbar

trunking systems (bushways) (IEC 60439-2:2000).

EN 60439-3, Low-voltage switchgear and controlgear assemblies — Part 3: Particular requirements for low-voltage

switchgear and controlgear intended to be installed in places where unskilled persons have access for their use —

Distribution boards (IEC 60439-3:1991).

EN 60439-4, Low-voltage switchgear and controlgear assemblies — Part 4: Particular requirements for assemblies

for construction sites (ACS) (IEC 60439-4:1990).

EN 60529:1991, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989).

EN 60947-1, Low-voltage switchgear and controlgear — Part 1: General rules (IEC 60947-1:1999, modified).

EN 61310-1, Safety of machinery - Indication, marking and actuation — Part 1: Requirements for visual, auditory

and tactile signals (IEC 61310-1:1995).

EN ISO 2867:1998, Earth-moving machinery — Access systems (ISO 2867:1994).

EN ISO 3411, Earth-moving machinery — Human physical dimensions of operators and minimum operator space

envelope (ISO 3411:1995).

prEN ISO 3457:2000, Earth-moving machinery — Guards and shields — Definitions and specifications (ISO/DIS

3457:2000).

EN ISO 7096, Earth-moving machinery — Laboratory evaluation of operator seat vibration (ISO 7096:2000).

EN ISO 11202, Acoustics — Noise emitted by machinery and equipment — Measurement of emission sound

pressure levels at a workstation and at other specified positions — Survey method in situ (ISO 11202:1995).

EN ISO 11688-1, Acoustics — Recommended practice for the design of low-noise machinery and equipment —

Part 1: Planning (ISO/TR 11688-1:1995).

ISO 3795, Road vehicles, and tractors and machinery for agriculture and forestry — Determination of burning

behaviour of interior materials.

ISO 3864, Safety colours and safety signs.

ISO 4413, Hydraulic fluid power — General rules relating to systems.

ISO 4414, Pneumatic fluid power — General rules relating to systems.

ISO 6405-1, Earth-moving machinery — Symbols for operator controls and other displays — Part 1: Common

symbols.

ISO 8643, Earth-moving machinery — Hydraulic excavator and backhoe loader boom-lowering control device —

Requirements and tests.

ISO 10567, Earth-moving machinery — Hydraulic excavators — Lift capacity.

ISO 12508, Earth-moving machinery — Operator station and maintenance areas — Bluntness of edges.

3 Terms and definitions – Symbols and abbreviated terms

For the purposes of this European Standard, the terms and definitions given in EN 1070:1998 and the following

apply.

3.1

road header

self-propelled tunnel driving machine, normally mounted on crawler tracks, which is designed and intended to cut

and load soft to medium hard rock in sections by means of a rotating cutting tool mounted axially or transversely on

a boom. Spoil may be discharged at the rear of the machine. As an example see Figure C.1

3.2

continuous miner

self-propelled machine, normally mounted on crawler tracks, which is designed and intended to cut coal or soft

minerals by means of a transversely mounted rotating drum. Spoil may be discharged at the rear of the machine.

As an example see Figure C.2

3.3

impact ripper

self-propelled tunnel driving machine which is designed and intended to excavate the rock in sections by means of

a tool such as a percussive hammer. Such tools are excluded from this standard. The machine may be fitted with

loading and transport equipment. As an example see Figure C.3

3.4

control station

location on a machine from where the functions of the machine can be controlled by an operator. In the basic

design, the control station will not be covered by a canopy. Control may alternatively be from a remote station by

cable or radio

3.5

servicing point

any location on a machine where servicing and maintenance is carried out

4 List of significant hazards

4.1 General

This clause contains all the significant hazards, hazardous situations and events, as far as they are dealt with in

this standard, identified by risk assessment as significant for this type of machinery and which require action to

eliminate or reduce the risk.

4.2 Mechanical hazards

a) crushing or shearing, see: 5.3, 5.4.4.2;

b) cutting, see: 5.1.3.1;

c) drawing-in or trapping, see: 5.3;

d) high-pressure fluid injection, see: 5.1.4;

e) loss of stability, see: 5.1.5;

f) slip, trip and fall, see: 5.1.6, 5.8.1;

g) shape, see: 5.1.3.1;

4.3 Electrical hazards

a) direct or indirect electrical contact, see: 5.7;

b) approach of persons to live parts, especially in the range of high voltage,

see: 5.7.1;

c) external influences on electrical equipment, see: 5.4.1, 5.7, 5.8.1;

4.4 Thermal hazards

See: 5.1.3.2;

4.5 Noise hazards

See: 5.6;

Hazards that can occur are:

a) hearing damage (deafness);

b) accidents due to interference with speech communication and acoustical signals.

4.6 Vibration hazards

See clause: 5.2.1;

4.7 Hazards generated by materials and substances

a) inhalation of harmful gases including exhaust gases from diesel engines;

the composition of gases is not dealt with, see: 5.5.2, 5.5.3, 5.7.3, 5.7.4;

b) inhalation of dusts, see: 5.4.3, 5.5.1, 5.7.4;

c) fire and explosion, see: 5.5.3.1, 5.7.3, 5.10;

d) rock fall, see: 5.2.2;

4.8 Hazards generated by neglecting ergonomic principles

a) unhealthy postures or excessive efforts, see: 5.2.1;

b) inadequate local lighting, see: 5.8;

4.9 Hazards caused by failure of energy supply

a) failure of energy supply, see: 5.4.3, 5.4.6;

b) failure of control system, see: 5.4.3;

4.10 Hazards caused by missing and/or incorrectly positioned safety related measures

a) all kinds of guards, see: 5.3;

b) all kinds of safety-related devices, see: 5.3, 5.4;

c) starting and stopping devices, see: 5.4.2, 5.4.4, 5.4.6;

d) warning signs and tags, see clause: 5.11, 7.2, 7.3;

e) all kinds of information and warning devices, see: 5.4.4.2, 5.11, 7.2.1, 7.2.2;

f) energy supply disconnecting devices, see: 5.4.3, 5.4.4;

g) emergency devices, see clause: 5.4.5;

h) handling of machinery or parts there of, see: 7.2.3;

i) essential measures for safe maintenance and repair, see: 5.3, 5.4.3, 5.7.2, 7.2.3;

5 Safety requirements and/or protective measures

5.1 General safety requirements

5.1.1 General

Machinery shall comply with the safety requirements and/or protective measures of this clause.

In addition, the machines shall be designed according to the principles of EN 292 for hazards relevant but not sig-

nificant which are not dealt with by this document (e. g. sharp edges).

Design calculations shall be carried out in accordance with usual engineering practice and calculation codes shall

include the effect of elastic deformation. All failure modes of the materials shall be considered including fatigue and

wear.

5.1.2 Materials

Materials shall be chosen so that they do not cause any danger to the health or safety of exposed persons. The

materials shall be suitable for the foreseen ambient temperatures.

5.1.3 Contact surfaces

5.1.3.1 Sharp edges and corners

All parts on a machine within 1,8 m of any access way or the ground shall not present any sharp edges or acute

angles or corners. The radius of corners and the bluntness of edges shall comply with ISO 12508.

5.1.3.2 Hot surfaces

All parts on a machine within 1,8 m of any access way or the ground shall be designed and manufactured so that

no injury due to contact with hot surfaces is possible. See EN 563.

5.1.4 Hoses, pipes and fittings under pressure

Hoses, pipes and fittings shall be able to withstand the stresses anticipated. Hoses shall be marked with the rated

working pressure and when required by its fluid, pressure or location, a hose shall be secured by means of ade-

quate restraints. The requirements of EN 982 and EN 983 shall be complied with. Where there is a risk that rupture

of a hose would cause a hazard to the operator, the hoses in this area shall be provided with protective guards e.g.

by protective plates or rubber sheets etc. Hoses, such as those carrying hydraulic oil, air or grout shall be secured

by means of adequate restraints.

Any part or component of a machine placed between the pipes or hoses and the operator which may direct the

hazard from the operator can be considered a protective device.

Low pressure hydraulic control circuits are not included in these requirements.

5.1.5 Stability

Machines shall be constructed and equipped to ensure stability when used as intended.

For road headers and continuous miners, calculations shall be made particularly for transverse stability, and for

impact rippers for both longitudinal and transverse stability taken together.

For road headers and continuous miners, the stability against overturning ,S, with respect to the most unfavourable

axis - normally the longitudinal axis - shall be equal to or greater than 1,25, where S = M /M

s k

and M is the stabilising moment of the total permanent load with respect to that axis,

s

and M is overturning moment caused by cylinder forces and cutting forces, according to the rated power in-

k

stalled, with respect to that axis.

For impact rippers, the stability shall be calculated and verified as indicated by ISO 10567.

5.1.6 Ladders, access ways and platforms

Ladderways and stairways with a height exceeding 1200 mm shall be safeguarded by handrails on open sides.

Elevated access ways and working platforms shall be safeguarded by side protection to prevent operators from

falling off. They shall have a non-slip surface and be bounded with a toeboard. See clauses 6 and 7 of

EN ISO 2867:1998.

5.2 Control station

5.2.1 Ergonomics

When remote control is not used, the machine is to be equipped with a control station which shall be ergonomically

designed in order to minimise operator fatigue and stress. Consideration shall be given to the fact that operators

may wear personal protection equipment.

Where the design permits, the control station shall be dimensioned in accordance with EN ISO 3411. See EN 474-

1.

Machines with provision for a seated operator shall be fitted with an adjustable seat that retains the operator in a

stable position and allows the operator to control the machine under all expected operating conditions. The seat

shall be designed to minimise transmission of vibration to the operator. See EN ISO 7096.

5.2.2 Falling objects

The control station shall be protected where necessary by guarding against spoil rolling down the cutter arm, boom

or conveyor e.g. by deflector plates. When necessary due to its position, the control station shall be capable of be-

ing equipped with a rugged canopy and bars to protect the operator against falling rocks and other objects for

which fixings and/or anchorage shall be provided. The maximum dimensions of any opening in such a guard shall

not exceed 80 mm x 1 000 mm. The guarding elements shall be designed so that a force of 1 kN will create a de-

flection of not more than 2 mm.

The conveyor shall be designed and built in such a way that no spoil can fall onto the control station.

5.2.3 Visibility

The control station shall be positioned to allow the operator sufficient visibility of the cutting tool for safe operation.

For movement of machine, further aids such as mirrors may be provided.

5.3 Guards and protective devices

Wherever persons work or have access and there is a risk of injury by trapping, cutting or seizing due to rotating

parts, these parts shall be made safe by guards or other protective devices.

Driving drums, front rollers and idlers of conveyor belts shall be provided with protective devices to prevent injury

by trapping or seizing. See EN 617 and EN 619.

5.4 Control devices and systems

5.4.1 General

Control devices and systems shall be so designed and constructed that they match the high demands of an under-

ground environment and are reliable in service.

The component parts of control systems shall comply with the requirements of EN 954-1. They shall be able to

withstand rigorous handling, severe stresses, shocks and vibration.

Each safety-related part of a control system shall fulfil the requirements of one of the categories described in

clause 6 of EN 954-1:1996 in accordance with the following schedule as given in Table 1:

Table 1 — Categories

Nature of part Category to be fulfilled

Mechanical 1

Hydraulic 2

Electrical 2

Electronic 2

5.4.2 Control devices

For lifting, slewing and travel control, hold-to-run control devices shall be used. The control device for starting the

cutter head motor shall be safeguarded against unintentional operation, for example by double action-control, a two

handed-device or mechanical or electrical protection.

5.4.3 Control systems

Control systems shall be configured so that:

no dangerous condition can occur should the electric power input to the control system fail;

the sequence of operations necessary to avoid dangerous operating conditions (for example dust suppression

system - conveyor system - cutter head) can only be started or stopped in the prescribed sequence;

for maintenance and special operation of the machine, individual movements of the machine shall be possible

by means of a lockable operational mode selection switch;

machines fitted with dust suppression systems can only cut rock or mineral when the dust suppression system

is in operation, unless ground conditions are such that no dust is created.

5.4.4 Starting and stopping

5.4.4.1 Power supply switch

Machines shall be provided with switches for connecting and disconnecting the main power supply at the point of

input to the electrical equipment supplied by the manufacturer, excepting ancillary circuits. After normal stopping or

stopping due to an emergency stop device, restarting after resetting shall only be possible with the corresponding

control device. A control cable may be included in the power supply cable in order to isolate the machine from the

main transformer, which is situated in the tunnel behind the machine.

5.4.4.2 Warning devices

Machines shall be equipped with automatic warning devices activated when electric motors of hydraulic systems,

cutter booms and cutter heads are started. These warning devices may be audible. Warning devices shall be inter-

locked so that the drive motors automatically start following completion of the warning period (normally 5 s to 10 s)

when the warning devices cease to operate.

Reversing of the machine shall automatically actuate warning systems such as continuously flashing warning lights.

Warning devices, both audible and by bright flashing lamps, shall be ruggedly designed and fabricated. They shall

be so mounted, that they cannot be rendered inoperative and shall be placed prominently on the machine.

5.4.4.3 Stopping and braking

Machines shall be equipped with braking devices for the crawler tracks, conveyor, slewing drive, and movements of

all hydraulic cylinders including those for slewing and for lifting and lowering the boom. Movements driven by hy-

draulic motors, for example crawler tracks, shall be braked hydrostatically. Movement which is electrically operated,

for example crawler tracks, shall be braked by switching off the supply.

In the case of crawler tracks, braking as above shall be augmented by the activation of an automatically-acting me-

chanical brake which also acts as a parking brake capable of preventing the machine from moving when parked on

a slope. The maximum permissible slope on which the machine can be operated shall be defined in the instruction

manual.

Movements controlled by hydraulic cylinders, for example slewing and boom control, shall be stopped by hydraulic

control valves. Stop valves (pipe rupture valves) shall secure the mechanism should a hydraulic hose or pipe

break. When slewing motions are controlled by hydraulic motors, braking shall be augmented by a mechanical

brake.

5.4.5 Emergency stop devices

Emergency stop devices shall be located in particular at the control station and on both sides of the machine, at the

rear of the machine, and where appropriate at the front of the machine.

Emergency stop devices shall conform to EN 418 and in particular:

function as Category '0' as defined in 4.1.5 of EN 418:1992;

operate in separate safety circuits;

be easily and safely accessible from the control station and reachable from the floor at a height not greater

than 1,8 m.

5.4.6 Failure of power supply

Any interruption or return of power following an interruption, or any other change in the power supply to the ma-

chine shall not lead to a hazardous situation.

5.5 Dust and gas control

5.5.1 Dust control

Each machine shall be made so that it is possible to install an effective dust suppression system.

5.5.2 Exhaust gas control

Internal combustion engines used to drive the machines in tunnels shall be diesel engines. Exhaust gases shall not

be discharged upwards. Suitable in this respect are engines with two-stage combustion systems and/or exhaust

gas purification equipment, for example, a particulate filter and catalytic converter. The exhaust gas composition

shall comply with the relevant National Regulations for operation and testing by analysis.

5.5.3 Hazardous gas control

5.5.3.1 Safety requirements for use in formations with potential for containing flammable or explosive

gas

When the negotiation between manufacturers and user/purchaser foresees a future use in such formations, as in-

dicated in the Introduction, the machine shall be designed to be able to incorporate a system for continuously

monitoring the presence of flammable or explosive gas.

NOTE For the operation and use in future in formations in which potentially flammable or explosive gas occurs

the requirements of prEN 1710 should be considered.

5.5.3.2 Safety requirements for duty in other gas hazards

The design of the machine shall permit the installation of continuous monitoring equipment capable of detecting

oxygen deficiency and/or the presence of toxic gases possibly occurring in the expected formations including gases

which are radioactive such as radon. The monitoring equipment shall trigger an optical/acoustical alarm at the con-

trol station as soon as the preset critical threshold value is attained.

5.6 Noise control

5.6.1 Noise reduction at source at the design stage

Main noise sources are cutter head, conveyor and main drive which can be diesel driven or electrical driven. When

designing the machine, the available information and technical measures to control noise at source at the design

stage shall be taken into account, in particular see EN ISO 11688-1.

NOTE EN ISO 11688-2 gives useful information on noise generation mechanisms in machinery.

5.6.2 Noise reduction by protective devices

Noise can be reduced, for example, by the following means:

the use of machinery components with low noise emission;

reducing vibration;

encapsulation.

5.6.3 Noise reduction by information

Information on residual risk after technical measures to control noise emission have been implemented shall be

given by the manufacturer, see clause 7.

5.6.4 Determination of the A-weighted emission sound pressure level at the control station (s)

5.6.4.1 General

A-weighted sound pressure levels at the control station(s) shall be measured according to EN ISO 11202. Whether

or not a control station is within a cab, no environmental correction shall be made. These measurements shall be

carried out at the first assembly with no excavation process noise present.

NOTE The measurement method given in this clause is not a full noise test code for tunnelling machines. It is one step

towards it.

5.6.4.2 Operating conditions

Operating conditions that are typical of normal operation of the tunnelling machine and provide the highest noise

levels shall be chosen. The measurement of the tunnelling machine covers the machine in service without load and

without the crawler belt, that means no movement of the chassis. During the measurement the following

components shall be in service:

• electric driven motor with all hydraulic drive units; and

• excavation unit; and

• discharge conveyor if the machine is equipped with this; and

• conveyor belt if the machine is equipped with this; and

• loading unit and gear box if the machine is equipped with these.

5.6.4.3 Measurement position

The measurement point shall be at the control station. If the machine is equipped with a seat at the control station,

the measurement point is at a height of 0,80 m – 0,05 m above the seat. If the machine has no seat at the control

station the measurement point is at a height of 1,70 m – 0,05 m at the control station.

The measurement point for a machine with a cab shall be at the control station at a height of 0,80 m – 0,05 m

above the seat and closed cab.

Positions of the measurement points (control station(s)) and detailed information on the operating conditions during

the noise measurement shall be recorded and reported.

5.6.5 Verification of technical measures

Verification of technical measures to reduce noise emission shall be done from measurements made according to

5.6.4, see also annex B.

5.7 Electrical equipment

5.7.1 High voltage equipment

Equipment or parts of equipment operating at voltages higher than 1 kV a.c. or 1,5 kV d.c. shall comply with the

requirements of EN 60204-11.

5.7.2 Low-voltage equipment

5.7.2.1 General

The provisions of EN 60204-1 apply to electrical equipment or parts of equipment which operate with nominal

supply voltages not exceeding 1 kV a.c. or 1,5 kV d.c. between lines and nominal frequencies not exceeding

200 Hz, together with additional requirements as follows.

5.7.2.2 Protective measures

Due to the adverse conditions during tunnel construction, additional protective measures against electrical shock

should be considered, such as:

use of Residual Current Devices (RCDs) with a maximum rated tripping current not exceed

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...