EN 1857:2003+A1:2008

(Main + Amendment)Chimneys - Components - Concrete flue liners

Chimneys - Components - Concrete flue liners

This European Standard specifies the material, dimensional and performance requirements, including methods of test, for factory-made concrete flue liners and fittings for the construction of multi-wall chimneys. This standard also relates to storey-height and reinforced flue liners.

NOTE 1: Classes in this standard, unless otherwise specified, e.g. resistance to fire, are not derived from conditions referred to in article 3.2 of Directive 89/106/EC, and should only be considered as technical classes in the sense of Commission Guidance Paper E 'Levels and classes in the Construction Products Directive'.

NOTE 2 : Any reference to the term flue liners implies both flue liners and their fittings, except where otherwise indicated.

The amendment introduces resistance to freeze/thaw as essential characteristic.

Abgasanlagen - Bauteile - Betoninnenrohre

Diese Europäische Norm legt Werkstoffe, Maße, Leistungsanforderungen sowie die Prüfverfahren für

werkmäßig hergestellte Betoninnenrohre und -formstücke fest.

Diese Norm gilt ebenfalls für geschosshohe und bewehrte Innenrohre.

ANMERKUNG 1 Wenn nicht anders festgelegt, ist die Klassenbildung z. B. für Temperatur, Druck in dieser Norm, nicht

von den Bedingungen nach Richtlinie 89/106/EWG, Artikel 3.2 abgeleitet und sollte nur als technische Klasse im Sinne

des Leitpapiers E „Grenzwerte und Klassen in der Bauproduktenrichtlinie“ verstanden werden.

ANMERKUNG 2 Der Begriff „Innenrohr“ bedeutet in dieser Norm immer „Innenrohr und seine Verbindungsstücke“,

außer er ist ausdrücklich anders bezeichnet.

Conduits de fumée - Composants - Conduits intérieurs en béton

La présente Norme européenne spécifie les prescriptions relatives aux matériaux, les dimensions et les performances, ainsi que les méthodes d'essai, pour les conduits de fumée intérieurs et les accessoires préfabriqués en béton destinés à la réalisation de conduits de fumée multiparois.

La présente norme couvre également les conduits intérieurs hauteur d'étage et les conduits intérieurs armés.

NOTE 1 Les classes de cette norme, ainsi que les valeurs spécifiées telles que par exemple températures, pressions, ne constituent pas l’application des conditions mentionnées à l’Article 3.2 de la Directive 89/106/EC et devraient seulement être considérées comme des classes techniques au sens du guide E de la commission «Niveau et classes dans la Directive produits de Construction».

NOTE 2 Toute référence au terme conduit implique l’ensemble des conduits et leurs accessoires, sauf si indication différente.

Dimniki - Sestavni deli - Betonske tuljave

General Information

- Status

- Withdrawn

- Publication Date

- 26-Feb-2008

- Withdrawal Date

- 13-Apr-2010

- Technical Committee

- CEN/TC 166 - Chimneys

- Drafting Committee

- CEN/TC 166 - Chimneys

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 14-Apr-2010

- Completion Date

- 14-Apr-2010

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 18-Jan-2023

- Effective Date

- 18-Jan-2023

- Effective Date

- 21-Nov-2009

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 1857:2003+A1:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Chimneys - Components - Concrete flue liners". This standard covers: This European Standard specifies the material, dimensional and performance requirements, including methods of test, for factory-made concrete flue liners and fittings for the construction of multi-wall chimneys. This standard also relates to storey-height and reinforced flue liners. NOTE 1: Classes in this standard, unless otherwise specified, e.g. resistance to fire, are not derived from conditions referred to in article 3.2 of Directive 89/106/EC, and should only be considered as technical classes in the sense of Commission Guidance Paper E 'Levels and classes in the Construction Products Directive'. NOTE 2 : Any reference to the term flue liners implies both flue liners and their fittings, except where otherwise indicated. The amendment introduces resistance to freeze/thaw as essential characteristic.

This European Standard specifies the material, dimensional and performance requirements, including methods of test, for factory-made concrete flue liners and fittings for the construction of multi-wall chimneys. This standard also relates to storey-height and reinforced flue liners. NOTE 1: Classes in this standard, unless otherwise specified, e.g. resistance to fire, are not derived from conditions referred to in article 3.2 of Directive 89/106/EC, and should only be considered as technical classes in the sense of Commission Guidance Paper E 'Levels and classes in the Construction Products Directive'. NOTE 2 : Any reference to the term flue liners implies both flue liners and their fittings, except where otherwise indicated. The amendment introduces resistance to freeze/thaw as essential characteristic.

EN 1857:2003+A1:2008 is classified under the following ICS (International Classification for Standards) categories: 91.060.40 - Chimneys, shafts, ducts; 91.100.30 - Concrete and concrete products. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1857:2003+A1:2008 has the following relationships with other standards: It is inter standard links to EN 1857:2003, EN 1857:2003/AC:2007, EN 1857:2003/AC:2005, EN 1857:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1857:2003+A1:2008 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/105. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1857:2003+A1:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Chimneys - Components - Concrete flue linersDimniki - Sestavni deli - Betonske tuljaveConduits de fumée - Composants - Conduits intérieurs en bétonAbgasanlagen - Bauteile - BetoninnenrohreTa slovenski standard je istoveten z:EN 1857:2003+A1:2008SIST EN 1857:2003+A1:2008en,fr,de91.100.3091.060.40ICS:SLOVENSKI

STANDARDSIST EN 1857:2003+A1:200801-april-2008

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1857:2003+A1

February 2008 ICS 91.060.40; 91.100.30 Supersedes EN 1857:2003 English Version

Chimneys - Components - Concrete flue liners

Conduits de fumée - Composants - Conduits intérieurs en béton

Abgasanlagen - Bauteile - Betoninnenrohre This European Standard was approved by CEN on 2 December 2002 and includes Amendment 1 approved by CEN on 2 December 2007 and the Corrigendum issued by CEN on 25 April 2007.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2008 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1857:2003+A1:2008: E

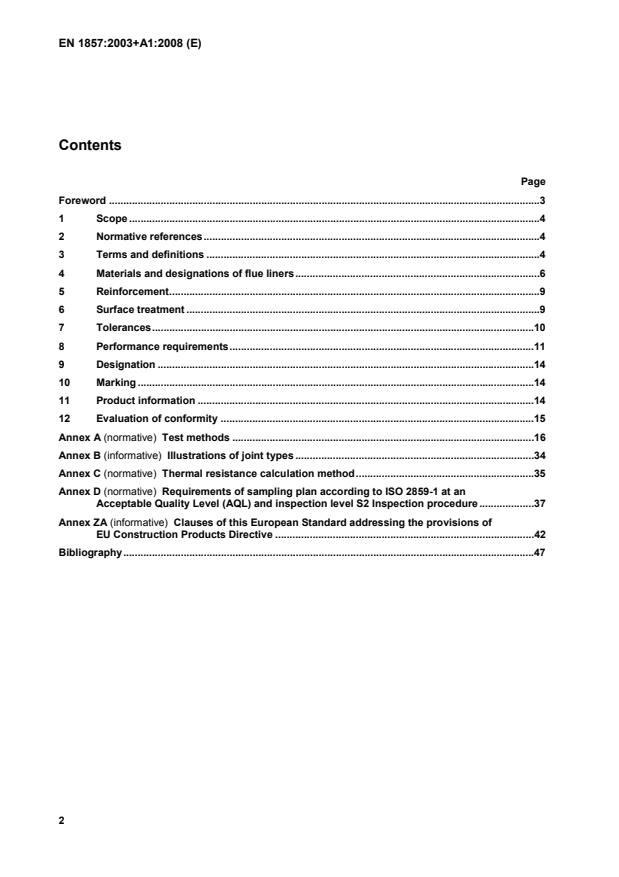

2 Contents Page Foreword.3 1 Scope.4 2 Normative references.4 3 Terms and definitions.4 4 Materials and designations of flue liners.6 5 Reinforcement.9 6 Surface treatment.9 7 Tolerances.10 8 Performance requirements.11 9 Designation.14 10 Marking.14 11 Product information.14 12 Evaluation of conformity.15 Annex A (normative)

Test methods.16 Annex B (informative)

Illustrations of joint types.34 Annex C (normative)

Thermal resistance calculation method.35 Annex D (normative)

Requirements of sampling plan according to ISO 2859-1 at an Acceptable Quality Level (AQL) and inspection level S2 Inspection procedure.37 Annex ZA (informative)

Clauses of this European Standard addressing the provisions of EU Construction Products Directive.42 Bibliography.47

Foreword This document (EN 1857:2003+A1:2008) has been prepared by Technical Committee CEN /TC 166, "Chimneys" the secretariat of which is held by UNI. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by August 2008 and conflicting national standards shall be withdrawn at the latest by August 2008. This document has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association and supports essential requirements of EU Directives. For the relationship with the EU Directives, see informative Annex ZA, which is an integral part of this document. This document includes Amendment 1 approved by CEN on 2007-12-02 and the corrigendum issued in 2007. The start and finish of text introduced or altered by amendment is indicated in the text by tags ! ". The modifications of the related CEN Corrigenda have been implemented at the appropriate places in the text and are indicated by the tags ˜™ This document supersedes EN 1857:2003. This standard is one of a series of standards dealing with the specification, design, testing and execution of chimneys with concrete liners, both single and multi wall.

The co-ordinated package of standards is further divided by material of construction and this European Standard is one of a series of specifications and execution documents dealing with design and execution of concrete chimney products and systems.

The standards in this series for concrete chimney products are :

EN 1857, Chimneys - Components - Concrete flue liners EN 1858, Chimneys - Components - Concrete flue blocks EN 12446, Chimneys - Components - Concrete outer wall elements In this European Standard the Annexes A, C and D are normative and Annexes B and ZA are informative. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

1 Scope This European Standard specifies the material, dimensional and performance requirements, including methods of test, for factory-made concrete flue liners and fittings for the construction of multi-wall chimneys. This standard also applies to storey-height and reinforced flue liners. NOTE 1 Classes in this standard, unless otherwise specified, e.g. temperature pressure, are not derived from conditions referred to in article 3.2 of Directive 89/106/EC, and should only be considered as technical classes in the sense of Commission Guidance Paper E ‘Levels and classes in the Construction Products Directive’. NOTE 2 Any reference to the term flue liners implies both flue liners and their fittings, except where otherwise indicated. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1443:2003, Chimneys — General requirements

EN 1859:2000, Chimneys— Metal chimneys — Test methods EN 10088-2, !Stainless steels - Part 2: Technical delivery conditions for sheet/plate and strip of corrosion resisting steels for general purposes" EN 10218-2, Steel wire and wire products - General — Part 2: Wire dimensions and tolerances EN 13384-1 Chimneys – Thermal and fluid dynamic calculation methods – Part 1: Chimneys serving one appliance !EN 14297:2004, Chimneys - Freeze-thaw resistance test method for chimney products" EN ISO 7500-1, !Metallic materials - Verification of static uniaxial testing machines - Part 1: Tension/compression testing machines - Verification and calibration of the force-measuring system (ISO 7500-1:2004)" ISO 2859-1, Sampling procedures for inspection by attributes — Part 1: Sampling schemes indexed by acceptable quality limit (AQL) for lot-by-lot inspection !deleted text".

3 Terms and definitions For the purposes of this European Standard the terms and definitions given in EN 1443:2003 and the following apply. 3.1

flue liner bend flue liner that changes the direction of the flue

manufacturer’s declared internal transverse dimensions

internal dimensions of the flue liner measured perpendicular to the longitudinal axis 3.3

manufacturer’s declared length internal length of the flue liner.

NOTE Examples of measurement are shown in Figure 1.

LL

a) with rebate

b) with plain end L Internal length Figure 1 — Manufacturers declared length 3.4

manufacturer’s declared structural height

maximum height of construction of the flue liners as declared by the manufacturer 3.5

reinforced flue liner

flue liner having reinforcement to assist handling

NOTE The reinforcement is not for structural stability 3.6

storey-height liner

flue liner having manufacturer’s declared length relating to the floor to floor height of a building 3.7

concrete

material formed by mixing cement, aggregate and water and with or without the incorporation of admixtures or additions, which develops its properties by hydration of the cement

[EN 206-1:2000]

6 3.8

precast concrete

concrete cast and cured in a place other than the final location of use 3.9

resistance to fire of flue liners

ability of the flue liners and fittings to be resistant to soot fires 4 Materials and designations of flue liners 4.1 Materials Flue liners shall be precast concrete. Materials used shall be identified for factory production control purposes. NOTE 1 Additions may include glass or steel fibres. NOTE 2 Attention is drawn to Commission decision 96/603/EC, as amended, in which non-combustible masonry units containing not more than a mass or volume fraction of 1 % (whichever is the more onerous) of homogeneously distributed organic materials are classified as reaction to fire class A1 without testing. 4.2 Designations and classes 4.2.1 General Flue liners shall be designated according to clause 9. Designation classes for flue liners for temperature, pressure, resistance to soot fire, condensate resistance and corrosion resistance shall be according to ˜4.2.2 to 4.2.6™. Abbreviated designations for common types of flue liners, according to temperature, pressure, soot fire resistance, and condensate resistance (wet or dry conditions) are given in Table 1. Where a flue liner is manufactured for an application not covered by the abbreviated designations A to L the manufacturer shall declare the characteristics and appropriate designation in full as in clause 9.

Table 1 — Abbreviated designations for common types of concrete flue liners

Temperature Pressure Sootfire Condensate resistance Type

resistance

A1 T600 Negative N1

Yes G Dry A2 T600 Negative N2 Yes G

Dry B1 T450 Negative N1 Yes G Dry B2 T450 Negative N2 Yes G Dry B3 T450 Negative N1 No O Dry C1 T400 Negative N1 Yes G Dry C2

T400 Negative N2 Yes G Dry C3 T400 Negative N1 No O Dry D1 T300 Negative N1 No O Dry D2 T300 Negative N1 No O Wet and Dry D3 T300 Positive P1 No O Wet and Dry E1 T250 Negative N1 No O Dry E2 T250 Negative N1 No O Wet and Dry E3 T250 Positive P1 No O Wet and Dry F1 T200 Negative N1 No O Dry F2 T200 Negative N1 No O Wet and Dry G1 T160 Negative N1 No O Wet and Dry G2 T160 Positive P1 No O Wet and Dry H1 T140 Negative N1 No O Wet and Dry H2 T140 Positive P1 No O Wet and Dry J1 T120 Negative N1 No O Wet and Dry J2 T120 Positive P1 No O Wet and Dry K1 T100 Negative N1 No O Wet and Dry K2 T100 Positive P1 No O Wet and Dry L1 T80 Negative N1 No O Wet and Dry L2 T80 Positive P1 No O Wet and Dry

NOTE A designated class of flue liner is suitable for use in a chimney with nominal working temperature up to a maximum of that designated. The designation for pressure, soot fire resistance, condensate resistance and corrosion resistance apply throughout the temperature range.

8 4.2.2 Temperature class.

For temperature class see Table 2. Table 2 — Temperature class Temperature class Nominal working temperature

oC T600 ≤600T450 ≤ 450 T400 ≤ 400 T300 ≤ 300 T250 ≤ 250 T200 ≤ 200 T160 ≤ 160 T140 ≤ 140 T120 ≤ 120 T100 ≤ 100 T080 ≤ 80

4.2.3 Pressure class

For pressure classes see Table 3. The pressure class is assigned a gas tightness level, expressed as a maximum leakage rate at a specified test pressure. for flue liners suitable for negative pressure chimneys : N1 and N2; for flue liners suitable for positive pressure chimneys : P1 and P2.; for flue liners suitable for high positive pressure chimneys : H1 and H2. Table 3 — Pressure classes and gas tightness

Pressure class Test pressure Gas tightness – Maximum leakage rate

Pa L/s/m2 N1 40 2,0 N2 20 3,0 P1 200 0,006 P2 200 0,120 H1 5000 0,006 H2 5000 0,120

Condensate resistance classes: W for flue liners for chimneys intended to operate under wet conditions; D for flue liners for chimneys intended to operate under dry conditions. 4.2.6 Corrosion resistance class

Corrosion resistance classes for flue liners for chimneys which convey products of combustion from gas or light oils and natural wood or heavy oils and solid mineral fuels, are given in Table 4. Table 4 — Corrosion resistance classes Corrosion from products of combustion according to fuel used Gas Light oils with sulphur content up to 0,2% and natural wood Heavy oils with sulphur content over 0,2% and solid mineral fuels and peat Corrosion resistance class of flue liners 1 2 3

5 Reinforcement 5.1 In a reinforced liner the reinforcement shall have a diameter of not more than 8 mm and a minimum concrete cover of 20 mm on all sides.

5.2 In reinforced liners having a bulk density of less than 2 000 kg/m3, when measured according to A.10, any reinforcement shall be protected against corrosion by:

a) use of stainless steel conforming to EN 10088-2; b) by completely covering any mild steel reinforcement conforming to EN 10218-2 with a coating. NOTE Typically ordinary Portland cement mixed with water to form a slurry or epoxy resin.) 6 Surface treatment Any surface treatment of the flue liner, e.g. coatings, shall be factory applied before the product is tested.

10 7 Tolerances 7.1 Size Tolerances on manufacturer’s declared dimensions, including taper, shall be:

a) Declared internal transverse dimensions

below 300 mm : ± 3 mm 300 mm and above : ± 3 % but not more than 10 mm. See A.1.1. b) Declared length

below 300 mm : ± 5 mm 300 mm to 700 mm

: ± 7 mm

above 700 mm : ± 3 % but not more than 10 mm. See A.1.2. c) Declared wall thickness

below 10 mm : + 2 mm

- 1 mm

10 mm to 40 mm

: + 5 mm

- 1,5 mm above 40 mm

: + 12 %

- 5 %

7.2 Straightness 7.2.1 When tested as described in A.2 the limit deviation from straightness of a straight concrete flue liner of manufacturer’s declared length less than or equal to 1 000 mm shall not be greater than 1% of the declared length. 7.2.2 When tested as described in A.2 for flue liners having a manufacturer’s declared length greater than 1 000 mm the limit deviation shall not be greater than 0,5 % of the manufacturer’s declared length.

7.3 Squareness of ends When tested in accordance with either procedure described in A.3 the flue liner shall not touch the upright

for the first procedure and the dimension ‘G’ shall not be greater than 5 mm for the second procedure.

The thermal testing shall be carried out on one size of flue liner for each geometrical configuration, e.g. circular, rectangular, square, also for each material mix, method of manufacture and wall thickness. For circular flue liners the size to be tested shall be (200 ± 50) mm internal transverse dimension. For other geometrical configurations the flue liner shall have an equivalent cross-sectional area. Table 5 — Heat stress test temperature Temperature class Temperature of flue gas

°C T 600 700

T 450 550

T 400 500

T 300 350

T 250 300

T 200 250

T 160 190

T 140 170

T 120 150

T 100 120

T 080 100

8.1.2 Flue liner bends or fittings made of the same material mix and by the same method of manufacture as the tested straight flue liner shall be deemed to conform to the requirement in 8.1.1.

12 8.1.3 Flue liner bends or fittings made of a different material mix or using a different method of manufacture from those described in 8.1.1, shall be checked for heat stress resistance by testing a straight test sample in accordance with 8.1.1. This straight test sample shall be made using the same material mix and manufacturing method as the bend or fitting.

8.2 Heat shock resistance 8.2.1 Following the heat stress resistance test in 8.1, when a liner designated as soot fire resistant is tested as described in A.4.4 to a flue gas temperature of 1 000 °C for a period of (30 ± 1) min the flue liner shall subsequently meet the requirements of 8.3. 8.2.2 Flue liner bends or fittings made of the same material mix and by the same method of manufacture as the tested straight flue liner shall be deemed to conform to the requirement in 8.2.1. 8.2.3 Flue liner bends or fittings made of a different material mix or using a different method of manufacture from those described in 8.2.1, shall be checked for heat shock by testing a straight test sample in accordance with 8.2.1. This straight test sample shall be made using the same material mix and manufacturing method as the bend or fitting.

8.3 Gas tightness When tested in accordance with A.6 the gas tightness, expressed as a leakage rate of the walls of the flue liner, shall not be greater than the values specified in Table 3 for the relevant pressure class. 8.4 Abrasion resistance All flue liners having satisfied the gas tightness requirements of 8.3, when tested according to A.7 the weight of the deposit collected shall not exceed 0,03 kg/m2 of the total area of the inner surface of the flue, and shall subsequently meet the gas tightness requirements of 8.3. 8.5 Compressive strength 8.5.1 The manufacturer shall declare the structural height. When tested according to A.8, flue liners and straight fittings shall withstand an intensity of loading equivalent to four times the manufacturer’s declared structural height.

NOTE The manufacturers’ declared structural height may be derived from the ultimate compressive strength determined by the method in A.11 8.5.2 Flue liner bends or other fittings made of the same material mix and by the same method of manufacture as the tested straight flue liner shall be deemed to conform to the requirement in 8.5.1.

8.5.3 Flue liner bends or fittings made of a different material mix or using a different method of manufacture from those described in 8.5.2, shall be checked for compressive strength by testing a special straight test sample in accordance with 8.5.1. This special straight test sample shall be made using the same material mix and manufacturing method as the bend or fitting.

8.6 Flexural strength There is no requirement for flexural strength as flue liners are not stand alone elements but are built with an outer wall to form a chimney.

8.9 Bulk density When flue liners are tested as described in A.10 each bulk density value shall be within a limit deviation of ± 10 % of the manufacturers declared bulk density for the flue liner.

8.10 Thermal resistance Thermal resistance shall be measured according to the method given in A.5 or calculated according to the method given in Annex C and its value declared by the manufacturer. 8.11 Resistance to freeze/thaw !Where national regulations require freeze/thaw resistance of flue liners, they shall be tested according to EN 14297. The product shall not present any damage of type 7, 8, 9 and 10 in accordance with EN 14297:2004, Table 1". 8.12 Flow resistance 8.12.1 Flow resistance of flue liners The manufacturer shall declare the mean value of roughness for a flue liner determined either: a) by testing in accordance with EN 1859 or b) from the data obtained in EN 13384-1. 8.12.2 Flow resistance of fittings The manufacturer shall declare the coefficient of flow resistance due to a directional and/or cross sectional and/or mass flow change which shall be determined according to the method of EN 1859 or obtained from the data in EN 13384-1.

9 Designation All concrete flue liners to this standard shall be designated in accordance with 4.2, for which an example of a designation system is given below:

EN 1857

T 400

N1

D

G The number of this standard

Flue gas temperature class

Negative/positive pressure class

Resistance to condensate

Corrosion resistance

Fire resistance (Sootfire resistance G or O)

10 Marking A minimum of 20 % of flue liners or fittings in each consignment shall be legibly and indelibly marked or labelled with the following information:

a) the name or trademark of the manufacturer; b) the manufacturers batch or date code; c) the number of this European Standard; d) the class or classes or full designation; e) an arrow indicating direction of flue gas flow. NOTE For CE marking and labelling, see ZA.3. 11 Product information The manufacturer's printed literature for the product shall include the following: a) the manufacturer's product description; b) manufacturer's declared sizes; c) the product designation; d) manufacturer's declared structural height; e) detailed installation instructions including method of jointing. NOTE For CE marking requirements for information on the product, see ZA.3.

Item Factory production control 12.3 a Type tests 12.1 and 12.2 Straight flue liners 4.1; 5; 6; 7.1, 7.2; 7.3; 8.3; 8.5 and 8.9 8.1; 8.2; 8.3; 8.4; 8.5; 8.6; 8.7; 8.8; 8.10 and 8.11, 8.12 a The tests carried out during FPC are intended to verify that the performance requirements assessed through the initial type testing are maintained.

12.3 Factory production control To achieve compliance with this standard, the manufacturer shall establish and maintain an effective documented quality system. Factory production control tests are carried out following manufacture to monitor the quality of product (see Table 6). Sampling and testing of any batch shall be completed prior to removal from the works and shall be in accordance with ISO 2859-1 at an AQL of 10 % and inspection level S2. Isolated batches of units shall be assessed in accordance with tightened inspection procedures, with a maximum batch size of 2 500 (see Annex D). Batches rejected under the factory production control procedure may be resubmitted once, after removal of units with previously undetected visible defects, under the tightened inspection procedures, in respect only of the defect that caused initial rejection. NOTE A quality system assessed by a certification body which complies with the requirements of !EN ISO/IEC 17021" may be applied to ensure that the requirements of EN ISO 9001 and clause 12 are complied with.

16 Annex A (normative)

Test methods A.1 Measurement of dimensions A.1.1 Transverse dimensions The maximum and minimum internal transverse dimensions of the flue liner shall be those calculated from the manufacturer’s declared tolerances and the tolerances specified in 7.1. If direct measurement is to be carried out, two measurements should be taken at the observed maximum and minimum diameters. The test also can be carried out using two gauges whose diameters are set at the minimum and maximum diameters. The minimum gauge should be able to be turned through 360° within the whole length of the flue liner. The maximum gauge should not be able to enter the flue liner when turned through a rotation of 360°. For

square and rectangular flue liners, the internal transverse dimensions shall be measured between the mid points of opposite sides of the flue liner. A.1.2 Declared length The maximum and minimum declared lengths of a flue liner shall be those calculated from the manufacturer’s declared dimensions and the tolerances specified in 7.1. If direct measurement is to be carried out, two measurements should be taken at the observed maximum and minimum internal lengths. The test can also be carried out by using two gauges whose heights are set at the minimum and maximum internal lengths. The minimum gauge should not be able to fit over the internal length of the flue liner. The maximum gauge should be able to fit over the internal length of the flue liner. A.1.3 Wall thickness The maximum and minimum wall thickness dimensions shall be those calculated from the manufacturer’s declared dimensions and the tolerances specified in 7.1 or direct measurement is to be carried out at the observed maximum and minimum thickness. A.2 Straightness A.2.1 Apparatus

A straightness measuring device, such as a straight edge, having a length 100 mm less than the nominal length of the flue liner under test.

A.2.2 Procedure A.2.2.1 Place the measuring device along the line LT as shown in Figure A.1

A.2.2.2 Measure the maximum distance from the centre of the straight line created by the apparatus in A.2.1 spanning any concave curve on the outside of the flue liner to the flue liner surface (DS) as shown in Figure A.1

1000 mm in length, any case where DS is greater than 0,5 % of the declared length. LT/2LT/2LTDSLN Key LN

is the nominal length of the flue liner in mm; LT

is the test length in mm; DS

is the deviation from straightness in mm; LN - LT = 100 mm. Figure A.1 — Straightness test A.3

Squareness of ends test A.3.1 Apparatus A level test bench with a fixed upright at 90°, see Figure A.2 a);

A square having one arm 300 mm long and second arm 400 mm long. A.3.2 First procedure Place the flue liner upright on the test bench with the base of the liner touching the collar. Rotate the liner through 360°. A.3.3 Result Record any case where the flue liner touches the upright.

A.3.4 Second procedure Place the flue liner upright on the test bench and apply one arm of the square along its side with the other arm touching the end of the liner. Rotate the square across the end of the liner. Rotate the square across the end of the liner as shown in Figure A.2 b).

A.3.5 Result Record any case where the dimension at 'G' exceeds 5 mm.

312G5G450 min. 90û

a) First procedure

b) Second procedure Key 1 Adjustable 2 Adjustable cantilevered straight edge 3 Level test surface Figure A.2 — Apparatus for squareness test A.4 Heat stress resistance and heat shock test NOTE The heat shock test is the method to assess the flue liner for soot fire resistance A.4.1 Apparatus A heat generator capable of delivering completely combusted hot gas at the test temperature specified in Table 5, having a CO/CO2 ratio not greater than 0,01, with the appropriate volume flow for the cross section specified in Table A.1.

The temperature of the products of combustion and the surface of the flue liner assembly shall be measured by a type K (Nickel-chromium/Nickel-aluminium) thermocouple, or similar, with an unsheathed junction located as shown in Figure A.3. Limit deviation for temperatures up to 600 °C ± 3oC and for temperatures over 600 °C ± 0,75 %. A.4.2 Test assembly Construct a test assembly of liners containing a minimum of one complete liner and two joints for flue liners less than or equal to 1,0 m manufacturer’s declared length to give a minimum overall height of 2,0 m jointed in accordance with the manufacturer's instructions. Flue liners of manufacturer's declared length greater than 1,0 m may be cut and the test assembly formed from two cut pieces, each having a length greater than 0,5 m and having only one joint near the centre of the assembly, jointed in accordance with the manufacturer's instructions. For thermal testing (heat stress and heat shock) the flue liner shall be insulated with a flexible material having a thermal resistance of 0,4 m2K/W ± 10 % at a temperature of 200 °C. The insulation material shall be capable of withstanding a temperature of CC°°+

1000500.

Draughts into the test room : ≤ 0,5 m/s;

NOTE This requirement is assumed to be met by a closed room environment. Location of measurements : minimum height of 1,0 m above the floor and at least 1,0 m from the test room walls; Minimum distance between test chimneys and other structures (i.e. walls, .): 1,0 m ; Free connecting space if the laboratory is divided in several levels. These ambient air conditions are measured a maximum of 1,0 m from the test assembly. Limit deviation of measurements shall be: a) ± 1,5 °C for the ambient temperature; b) ± 0,05 m/s for the velocity of draughts; c) ± 0,05 m for the distances. A.4.3.2 Assembly conditioning Condition the test assembly for a minimum of 28 days at ambient temperature unless otherwise specified by the manufacturer, then remove all loose materials by conducting 20 brush cycles as in clause A.7 and carry out a gas tightness test as in clause A.6. A.4.3.3 Drying/conditioning phase Unless otherwise specified by the manufacturer deliver flue gases into the test assembly in such a way that the temperature, measured as described in A.4.4.1, rises to 200 °C or the nominated test temperature whichever is the lower in 60 min ± 5 min. A.4.4 Procedure A.4.4.1 Establish an Overall Temperature Distribution Factor (OTDF) not exceeding 1,05 by taking five measurements of temperature along two traverses at right angles across the section of the flue liner within 50 mm of the entry. The locations for temperature measurement shall be positioned in the flue according to Figure A.3. Point E shall be central to the flue, points A to D shall be 20 mm

± 2 mm from the inner surface of the flue. The OTDF is calculated by : E A to points measuring of re temperatuAverageE toA

points measuringat

mperatureHighest te A.4.4.2 Deliver completely combusted gas, according to the flow rate specified in Table A.1, into the test sample and within 10 min, raise the temperature of the gas uniformly to the appropriate test temperature (see Table 5) measured at the location giving the highest temperature as described in A.4.4.1. Values for gas flow rate shall be interpolated for sizes between those in Table A.1 and

20 extrapolated for larger values. The gas flow for liners other than circular shall be determined on an equivalent hydraulic diameter basis. A.4.4.3 Maintain the delivery of gas until the temperature of the outer surface of the mid point of the flue liner test assembly does not rise by more than 2 °C in 30 min (equilibrium) or to a maximum time of 4 h.

The point of measurement shall be at the mid point of a complete flue liner near the centre of the assembly or at least 100 mm from a joint. For rectangular sections the measurement shall be taken at the mid point of the longer side. Allow the test sample to cool to ambient without assistance e.g. without forced ventilation.

A.4.4.4 For the heat shock test maintain the flue gas temperature at C

C

150+ 0 °° for a period of (30 ± 1) min.

A.4.4.5 Subject the test sample to the test described in clause A.6.

Table A.1 —

Hot gas volume flow rates Vs test temperature and flue diameter A. Thermal performance - negative pressure chimneys (Volume flow in m3/h)

Test temperature in °C Diameter

mm 100 120 150 170 190 250 300 350 500 550 700

42,1

42,9

43,9

45,1

46,3

50,2

53,7

57,2

67,4

68,2

80,6 100 65,8 66,9 68,5 70,4 72,3 78,5 83,9 89,3 105 110 126 125 102 104 107 110 113 123 132 140 164 172 197 150 148 150 154 159 163 177 189 201 237 238 283 175 201 205 210 216 221 240 257 274 322 338 386 200 263 266 274 282 289 314 337 357 421 439 504 B. Thermal performance - positive pressure chimneys (Volume flow in m3/h)

Test temperature in °C Diameter mm 100 120 150 170 190 250 300 350 500 550 700

22,0

22,8

24,0

25,0

26,0

28,0

30,0

32,0

37,0

38,8

44,1 80 64,0 66,0 69,0 72,0 74,0 80,0 85,5 91,0 107 112 126 100 105 109 115 119 122 133 142 151 177 185 209 125 174 180 189 196 202 220 235 249 292 305 345 150 262 271 285 295 304 331 353 375 440 460 520 175 370 383 404 417 430 468 500 531 622 651 736 200 500 518 545 564 580 632 675 717 840 879 994 C. Thermal shock - negative and positive pressure chimneys (Volume flow in m3/h) Diameter (in mm) 80 100 125 150 175 200 Temperature

1 000 °C 108 144 252 360 468 612

NOTE The flow rates are for heat generation from natural gas combustion.

22 ˜ 12345 BCDAE

BCDAE

Key 1 flue liner assembly 2 insulation 3 outer surface of flue liner assembly 4 position of measurement points 5 flue gas entry

Figure A.3 — Temperature measuring points™™™™

A.5 Thermal resistance A.5.1 Test assembly Use a test assembly consisting of two fans, two electric heaters and interconnecting tubes so that heated air can pass around the test assembly. A schematic diagram is given in Figure A.4. Install in each arm of the test assembly a minimum of 2 m of test chimney sections including at least two joints. A.5.2 Test procedure Circulate hot gas around the test assembly. The velocity of the hot gas shall be a minimum of 4 m/s and the hot gas temperature at the ends of the test sections measured within 100 mm of the ends of the liner with the test section shall not differ by more than 10 °C. For negative pressure chimneys maintain the pressure in the test chimney between 0 Pa and -10 Pa. Measure the internal and external surface temperature of the chimney sections as specified in A.4.1. For chimneys designated suitable for wet conditions, the hot gas shall be water vapour saturated and shall have a heat content and temperature so that the inner surface reaches a temperature of 70 °C. For chimneys designated suitable for dry conditions, the hot gas shall have a heat content and temperature so that the inner surface reaches a temperature of 20 % below the designated temperature (nominal working temperature), but not more than 200 °C. Adjust the temperature and heat content of the hot gas until equilibrium conditions exist. Equilibrium is reached when the difference between the outer surface temperature of the chimney sections and ambient temperature does not change by more than 1 % in 60 min. Undertake the test twice with one temperature rise from a lower temperature level and one drop from a higher level. Reassemble the test assembly without the test chimney sections. Repeat the test as described before until the hot gas temperature is the same as during the tests with the chimney sections in place, and until equilibrium. Equilibrium is reached when the difference between the outer surface temperature of the chimney sections and ambient temperature does not change by more than 1 % in 3 h. A.5.3 Results For the assembly with two test arms calculate the thermal resistance (1/λ) (m2 x K/W) from the equation:

1/λ = Ai (ti - to)/(Q1 - Q2) where

Q1 is the total heat input with the chimney section (W);

Q2 is the total heat input without the chimney section (W);

ti is the inner surface temperature (°C);

to is the outer surface temperature (°C);

Ai is the total inner surface area of the chimney (m2).

32218432265567471ABA-B Key 1 Experimental chimney 5 Electric heater 2 Flue conductor 6 Connecting pipe 3 Radial ventilator 7 Base 4 Electric fan 8 Measuring points for pressure, the flue gas velocity and working temperature – Outside Figure A.4 — Recirculating test assembly

A.6 Gas tightness test A.6.1 Apparatus A.6.1.1 A test assembly as described in A.4.2, without the insulation. For sampling at the factory only one liner may be used. A.6.1.2 A means of creating an airtight seal at each end of the test flue assembly. A.6.1.3 Two pieces of tubing passing through and sealed into one of the airtight seals (see Figure A.5). A.6.1.4 A fan capable of producing at least the required differential pressure, a flow meter and a manometer shall be used. The air supply for the test shall be measured by a flow meter with a limit deviation of ± 5 % of full scale. The full scale reading shall be approximately the flow rate for the maximum air permeability rate for the appropriate class of flue liner. A.6.1.5 A pressure gauge capable of measuring a pressure to a limit deviation of ± 5 %.

A.6.2 Test environment and conditioning A.6.2.1 Test room As A.4.3.1 A.6.2.2 Assembly and conditioning

Condition the test assembly for a minimum of 28 days at ambient temperature unless otherwise specified by the manufacturer.

A.6.3 Procedure A.6.3.1 Plug both ends of the test assembly with an airtight seal. At one end insert two lengths of tubing (A.6.1.3), see Figure A.5. A.6.3.2 Blow air through one of the tubes at a rate sufficient to achieve and maintain the pressure specified in 8.3 measured on the pressure gauge (A.6.1.5).

26 243615 Key 1 Seal 2 Flow meter 3 Fan 4 Seal 5

Jointed flue liners 6 Pressure gauge Figure A.5 — Gas tightness test apparatus

A.6.4 Result Calculate the gas tightness "E" of the assembly using the following equation:

t SQ = E⋅

where

E

is gas tightness, in litres per second per square metre;

Q

is air volume passing through the test assembly during test, in litres;

t

is test duration, in seconds;

S

is inside surface area of the flue liner, in square metres.

A.7 Abrasion resistance test

A.7.1 Test assembly The assembly of flue liners as described in A.4.2 of 200 mm diameter (or closest size in manufacturers range), which have been subjected to the heat stress and the shock test according to their appropriate temperature group designation.

1415121111181716171620191310 Key 1

Height of funnel not less than 200 mm 2

Tight fitting sleeve projecting 20 mm to 40 mm into opening 3

Bottom plate attached to bottom sleeve 4

Height sufficient to allow brush to pass through

bottom of test assembly 5

Catchment funnel attached to sleeve 6

Collection box 7

Plan of linear opening area 8

Plan of brush area 9

Round liner 10

Square or rectangular liner 11

Rod Figure A.6 — Abrasion resistance test apparatus

A.7.2 Preparation Fit a tight fitting metal sleeve attached to a catchment funnel into the top opening of the test flue. Fit a tight fitting metal sleeve attached to a plate which has an opening matching the area of the opening of the flue into the bottom of the test flue as shown in Figure A.6.

A.7.3 Test brush The sweeping brush shall have flat spring-steel bristles of stainless steel in accordance with EN 10088-2, grade X9 CR NI 18-8, steel number 1.4310, with a cross section of (2,0 mm ± 0,1) mm × (0,3 ± 0,1) mm.

28 The overall dimension of the brush shall be (25 ± 5) mm greater than the internal dimensions of the flue.

The bristles shall be arranged so that there are 5 per 10 mm length of the perimeter of the plan area of the brush.

The brush shall be held securely between plates having a plan dimension (100 ± 5) mm less than the cross sectional internal transverse dimension of the flue being tested. The brush shall be attached to a rod. A.7.4 Test procedure Pass the brush down through the total length of the test assembly at a rate of (0,4 ± 0,1) m/s and then at the same rate pull the brush up through the total length of the test assembly. Repeat this cycle 100 times.

A.7.5 Result Record the weight of any material that has been dislodged from the internal surface of the test assembly and calculate the total area of the internal surface of the flue between the sleeves.

A.8 Compressive strength test A.8.1 Apparatus A machine having a verified accuracy as specified in ISO 7500-1 Class 3, capable of applying the test load at the rate specified in A.8.3. A.8.2 Preparation of test sample A.8.2.1

Prepare a section of liner at least 150 mm in length, by sawing each end to produce flat and parallel ends, to within the tolerances specified in 7.3, square to the axis. If the samples are wet cut, condition by drying in an oven for (48 h ± 30 min) at (70 ± 3) °C. For liners having external transverse dimensions greater than 300 mm, cut by sawing a section as indicated in Figure A.7, and saw the upper and lower ends to produce flat and parallel ends, square to the axis. Dimension ‘a’ shall be greater than three times the declared wall thickness. A.8.2.2

Determine by calculation, the gross cross sectional area of the section and the position of the vertical axis of the centre of the gravity of the test sample.

A.8.2.3

Prepare the ends of the sample with cement mortar (one part calcium aluminate cement and two parts ordinary Portland cement) to achieve flat and parallel end square to the axis. Allow 24 h to harden or more if specified by the manufacturer.

A.8.2.4

Place sample between the test plates so that the axis of the plates corresponds with the axis of the centre of gravity of the test sample, with a tolerance of 1 mm.

A.8.3 Test procedure Apply a load without shock to the test sample and increase at a rate of (0,3 ± 0,05) MPa/s until the required load as specified in 8.5 is reached.

Record the result.

aaaa

a) par

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...