EN 12952-6:2002

(Main)Water-tube boilers and auxiliary installations - Part 6: Inspection during construction; documentation and marking of pressure parts of the boiler

Water-tube boilers and auxiliary installations - Part 6: Inspection during construction; documentation and marking of pressure parts of the boiler

This Part of this European Standard specifies requirements for the inspection during construction, documentation and marking of water-tube boilers as defined in EN 12952 1.

Wasserrohrkessel und Anlagenkomponenten - Teil 6: Prüfung während der Herstellung; Dokumentation und Kennzeichnung für drucktragende Kesselteile

Chaudières à tubes d'eau et installations auxiliaires - Partie 6: Contrôle en cours de construction, documentation et marquage des parties sous pression de la chaudière

Cette partie de la norme européenne spécifie les règles d'inspection durant la construction, de documentation et de marquage des chaudières à tubes d'eau telles que définies dans l'EN 12952-1.

Vodocevni kotli in pomožne napeljave - 6. del: Preskušanje pri proizvajalcu - Dokumentacija in žigosanje tlačnih delov kotla

General Information

- Status

- Withdrawn

- Publication Date

- 21-May-2002

- Withdrawal Date

- 09-Aug-2011

- Technical Committee

- CEN/TC 269 - Shell and water tube boilers

- Drafting Committee

- CEN/TC 269 - Shell and water tube boilers

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 10-Aug-2011

- Completion Date

- 10-Aug-2011

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 13-Aug-2011

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

EN 12952-6:2002 is a standard published by the European Committee for Standardization (CEN). Its full title is "Water-tube boilers and auxiliary installations - Part 6: Inspection during construction; documentation and marking of pressure parts of the boiler". This standard covers: This Part of this European Standard specifies requirements for the inspection during construction, documentation and marking of water-tube boilers as defined in EN 12952 1.

This Part of this European Standard specifies requirements for the inspection during construction, documentation and marking of water-tube boilers as defined in EN 12952 1.

EN 12952-6:2002 is classified under the following ICS (International Classification for Standards) categories: 27.040 - Gas and steam turbines. Steam engines. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12952-6:2002 has the following relationships with other standards: It is inter standard links to EN 12952-6:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12952-6:2002 is associated with the following European legislation: EU Directives/Regulations: 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12952-6:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Wasserrohrkessel und Anlagenkomponenten - Teil 6: Prüfung während der Herstellung; Dokumentation und Kennzeichnung für drucktragende KesselteileChaudieres a tubes d'eau et installations auxiliaires - Partie 6: Contrôle en cours de construction, documentation et marquage des parties sous pression de la chaudiereWater-tube boilers and auxiliary installations - Part 6: Inspection during construction; documentation and marking of pressure parts of the boiler27.060.30Grelniki vode in prenosniki toploteBoilers and heat exchangersICS:Ta slovenski standard je istoveten z:EN 12952-6:2002SIST EN 12952-6:2002en01-november-2002SIST EN 12952-6:2002SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12952-6May 2002ICS 27.040English versionWater-tube boilers and auxiliary installations - Part 6: Inspectionduring construction; documentation and marking of pressureparts of the boilerChaudières à tubes d'eau et installations auxiliaires - Partie6: Contrôle en cours de construction, documentation etmarquage des parties sous pression de la chaudièreWasserrohrkessel und Anlagenkomponenten - Teil 6:Prüfung während der Herstellung; Dokumentation undKennzeichnung für drucktragende KesselteileThis European Standard was approved by CEN on 15 May 2002.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2002 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12952-6:2002 ESIST EN 12952-6:2002

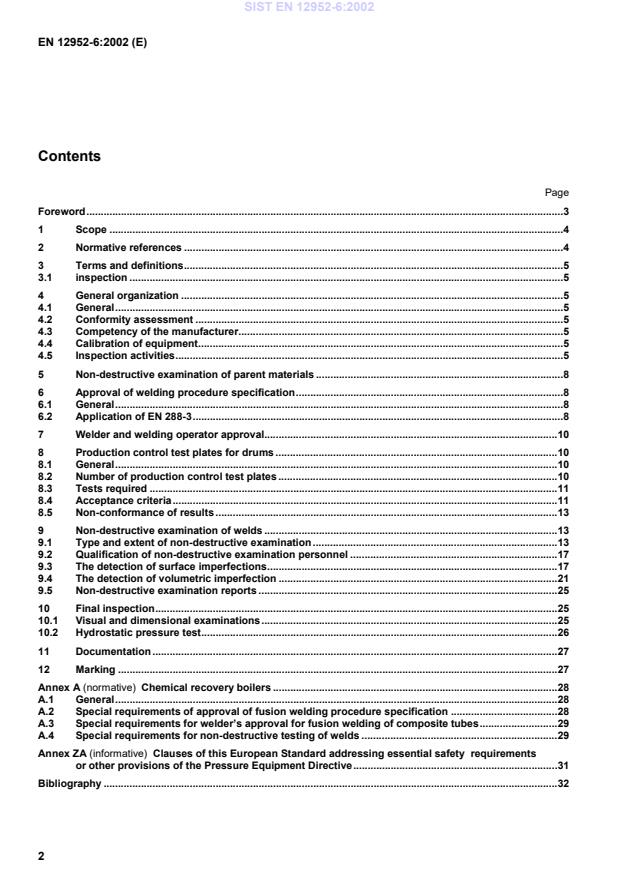

Chemical recovery boilers.28A.1General.28A.2Special requirements of approval of fusion welding procedure specification.28A.3Special requirements for welder’s approval for fusion welding of composite tubes.29A.4Special requirements for non-destructive testing of welds.29Annex ZA (informative)

Clauses of this European Standard addressing essential safety

requirementsor other provisions of the Pressure Equipment Directive.31Bibliography.32SIST EN 12952-6:2002

1: General. Part

2: Materials for pressure parts of boilers and accessories. Part

3: Design and calculation for pressure parts. Part

4: In-service boiler life expectancy calculations. Part

5: Workmanship and construction of pressure parts of the boiler. Part

6: Inspection during construction, documentation and marking of pressure parts of the boiler. Part

7: Requirements for equipment for the boiler. Part

8: Requirements for firing systems for liquid and gaseous fuels for the boiler. Part

9: Requirements for firing systems for pulverized solid fuels for the boiler. Part 10: Requirements for safeguards against excessive pressure. Part 11: Requirements for limiting devices

of the boiler and accessories. Part 12: Requirements for boiler feedwater and boiler water quality. Part 13: Requirements for flue gas cleaning systems. Part 14: Requirements for flue gas DENOX-systems. Part 15: Acceptance tests. Part 16: Requirements for grate and fluidized bed firing systems for solid fuels for the boiler.CR 12952 Part 17: Guideline for the involvement of an inspection body independent of the manufacturer.Although these Parts can be obtained separately, it should be recognized that the Parts are inter-dependent. Assuch, the design and manufacture of water-tube boilers requires the application of more than one Part in order forthe requirements of the standard to be satisfactorily fulfilled.NOTEParts 4 and

15 are not applicable during the design, construction and installation stages.Annex A is normative.According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following coun-tries are bound to implement this European Standard: Austria, Belgium, Czech Republic, Denmark, Finland,France, Germany, Greece, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Swe-den, Switzerland and the United Kingdom.SIST EN 12952-6:2002

the materials and the field of welding application,and that they have been approved by a responsibleauthority3.3Welder approvalVerify that the welder approvals have been approvedby a responsible authority and that they are availableand valid3.4Forming proceduresVerify that forming procedures are available, whereapplicable, and their contents are appropriate to theproduct to be formed3.5Weld preparationsExamine material cut edges where thermal cuttinghas been used and confirm machined preparationsare to the correct profileSIST EN 12952-6:2002

25 mm (full penetration)100 %—100 % e15 mm

ed < 25 mm (full penetration)100 %—

10 % eAll other welds, including seal welds

10 %——Attachments weldsLoad carrying100 %——Non-load carrying

10 %——aMagnetic particle inspection.bFor steel group 1 and mechanized welding, if the thickness d0

25 mm : 10 % plus T-junctions (over a length of 250 mmfor T-junctions).cFor steel group 4 only ultrasonic examination is permitted.de is the thickness of pressure connection.eNo ultrasonic examination is required if do < 142 mm.SIST EN 12952-6:2002

25 mm (full penetration)100 % e100 % c, fOR100 % c, f15 mm

ed < 25 mm (full penetration)100 % e

10 % c, fOR

10 % c, fAll other welds, including seal welds

10 % g——Attachments weldsLoad carrying100 %——Non-load carrying

10 %——End plate welds100 %—100 % haMagnetic particle inspection, but dye penetrant inspection is acceptable for steel groups 1 and 8.bFor steel groups 1 and 8 with a thickness do

25 mm : 10 % of circumferential welds.cFor steel groups 4 and 6 only ultrasonic examination is permitted.de is the thickness of the pressure connection.eOnly 10 % for steel groups 1 and 8.fNo volumetric imperfection detection is required if do < 142 mm.gDye penetrant examination is also acceptable for tube stubs in steel groups 2 and 5 with a nominal diameter e

80 mm.hOnly for outside diameter e > 70 mm and for end plate thickness do > 8 mm.SIST EN 12952-6:2002

25 mm (full penetration)100 % b100 % c, e, fOR100 % e, f15 mm

ed < 25 mm (full penetration)100 % b

10 % c, e, fOR10 % e, fAll other welds10 %——Attachments weldsLaod carrying100 %——Non-load carrying

10 %——Welds between fins and tubes for panelconstructiong——aMagnetic particle inspection, dye penetrant inspection is acceptable for steel groups 1 and 8.bOnly 10 % for steel groups 1 and 8.cFor outside diameters above 80 mm in steel groups 4 and 6 only ultrasonic examination is permitted.de is the thickness of the pressure connection.eRadiographic examination is acceptable instead of ultrasonic examination when ultrasonic examination is not possible.fNo volumetric imperfecton detection is required if do < 142 mm.gLimited to 100 % visual examination.9.1.5 Extension procedure of random examination in case of repairsWhen performing a 10 % rate of non-destructive examination, as permitted in 9.1.2, 9.1.3 and 9.1.4, and when theresult of the examination is not acceptable in accordance with the requirements of 9.3 or 9.4, the principle for theextension of the rate of that NDE shall be as follows:a) the basis for an extension of the rate of examination shall always be related to each individual component, toeach welder involved in the manufacture of this component, and to the same type of welds (referring to anidentical welding procedure specification);b) when performing the random examination, if one weld, or more than one weld, is (are) revealed as not beingacceptable according to the requirements of 9.3 or 9.4, the examination shall be extended to two additionalwelds of the same type, for each rejected weld;c) if all the examined welds of that extension are acceptable, then the initial rate of 10 % may be resumed;SIST EN 12952-6:2002

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...