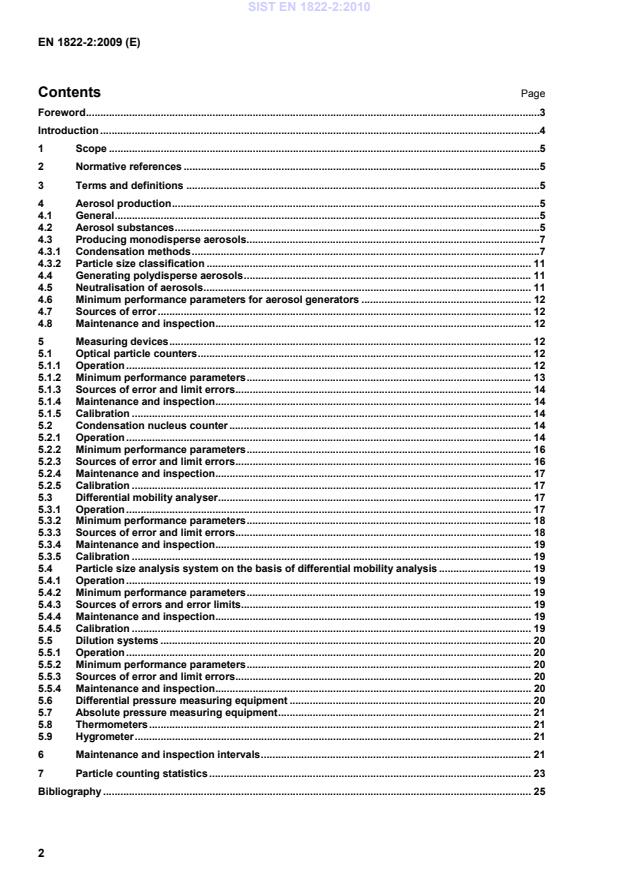

EN 1822-2:2009

(Main)High efficiency air filters (EPA, HEPA and ULPA) - Part 2: Aerosol production, measuring equipment, particle counting statistics

High efficiency air filters (EPA, HEPA and ULPA) - Part 2: Aerosol production, measuring equipment, particle counting statistics

This European Standard applies to efficient particulate air filters (EPA), high efficiency particulate air filters (HEPA) and ultra low penetration air filters (ULPA) used in the field of ventilation and air conditioning and for technical processes, e.g. for applications in clean room technology or pharmaceutical industry.

It establishes a procedure for the determination of the efficiency on the basis of a particle counting method using a liquid (or alternatively a solid) test aerosol, and allows a standardized classification of these filters in terms of their efficiency, both local and integral efficiency.

This European Standard describes the measuring instruments and aerosol generators used in the course of this testing. With regard to particle counting it specifies the statistical basis for the evaluation of counts with only small numbers of counted events.

Schwebstofffilter (EPA, HEPA und ULPA) - Teil 2: Aerosolerzeugung, Messgeräte, Partikelzählstatistik

Diese Europäische Norm gilt für Hochleistungs-Partikelfilter und Hochleistungs-Schwebstofffilter (EPA, HEPA

und ULPA) im Bereich der Raum- und Prozesslufttechnik, z. B. Anwendungen in der Reinraumtechnik oder in

der pharmazeutischen Industrie.

Sie legt ein Verfahren zur Prüfung des Abscheidegrades auf Basis von Partikelzählverfahren unter

Verwendung eines flüssigen (oder alternativ eines festen) Prüfaerosols fest und ermöglicht eine einheitliche

Klassifizierung der Schwebstofffilter nach dem Abscheidegrad, sowohl nach dem integralen als auch nach

dem lokalen Abscheidegrad.

Diese Europäische Norm beschreibt die im Rahmen dieser Prüfung verwendeten Messgeräte und

Aerosolgeneratoren. Darüber hinaus beschreibt sie für Partikelzählungen die statistischen Grundlagen zur

Auswertung von Zählergebnissen bei nur geringer Anzahl von Zählereignissen.

Filtres à air à haute efficacité (EPA, HEPA et ULPA) - Partie 2: Production d'aérosol, équipement de mesure et statistiques de comptage de particules

La présente Norme européenne s'applique aux filtres à air à haute efficacité (EPA), aux filtres à très haute efficacité et aux filtres à air à très faible pénétration (ULPA) utilisés dans le domaine de la ventilation et de l'air conditionné, ainsi que dans des procédés techniques, par exemple pour des application de technique en salle blanche ou dans l'industrie pharmaceutique.

Elle définit une méthode de détermination de l'efficacité, à partir d'une méthode du comptage de particules à l'aide d'un aérosol d'essai liquide (ou à particules solides) et permet une classification normalisée de ces filtres en fonction de leur efficacité, locale et globale.

La présente Norme européenne décrit les instruments de mesure et les générateurs d'aérosol utilisés au cours de ces essais. Pour ce qui est du comptage de particules, elle spécifie les bases statistiques de l'évaluation des comptages effectués sur un nombre limité d'événements.

Visoko učinkoviti zračni filtri (EPA, HEPA in ULPA) - 2. del: Proizvodnja aerosola, merilna oprema, statistika štetja delcev

Ta evropski standard velja za učinkovite zračne filtre drobnih delcev (EPA), visoko učinkovite zračne filtre drobnih delcev (HEPA) in zračne filtre z ultra nizko penetracijo (ULPA), ki se uporabljajo na področju prezračevanja in klimatizacije ter za tehnične postopke, npr. za naprave v tehnologiji čistega prostora ali farmacevtski industriji. Vzpostavlja postopek za določitev učinkovitosti na osnovi metode štetja delcev z uporabo tekočega testnega aerosola (ali v trdnem stanju kot druga možnost) ter omogoča standardizirano klasifikacijo teh filtrov glede na njihovo učinkovitost, tako lokalno kot celovito učinkovitosti. Ta evropski standard opisuje merilne instrumente in aerosolne razpršilce, ki se uporabljajo pri tem preskušanju. Kar se tiče štetja delcev, določa statistično osnovo za vrednotenje štetja pri le majhnem številu štetih dogodkov.

General Information

- Status

- Withdrawn

- Publication Date

- 17-Nov-2009

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 195 - Air filters for general air cleaning

- Drafting Committee

- CEN/TC 195/WG 2 - HEPA and ULPA filters

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 10-Oct-2018

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 17-Oct-2018

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 1822-2:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "High efficiency air filters (EPA, HEPA and ULPA) - Part 2: Aerosol production, measuring equipment, particle counting statistics". This standard covers: This European Standard applies to efficient particulate air filters (EPA), high efficiency particulate air filters (HEPA) and ultra low penetration air filters (ULPA) used in the field of ventilation and air conditioning and for technical processes, e.g. for applications in clean room technology or pharmaceutical industry. It establishes a procedure for the determination of the efficiency on the basis of a particle counting method using a liquid (or alternatively a solid) test aerosol, and allows a standardized classification of these filters in terms of their efficiency, both local and integral efficiency. This European Standard describes the measuring instruments and aerosol generators used in the course of this testing. With regard to particle counting it specifies the statistical basis for the evaluation of counts with only small numbers of counted events.

This European Standard applies to efficient particulate air filters (EPA), high efficiency particulate air filters (HEPA) and ultra low penetration air filters (ULPA) used in the field of ventilation and air conditioning and for technical processes, e.g. for applications in clean room technology or pharmaceutical industry. It establishes a procedure for the determination of the efficiency on the basis of a particle counting method using a liquid (or alternatively a solid) test aerosol, and allows a standardized classification of these filters in terms of their efficiency, both local and integral efficiency. This European Standard describes the measuring instruments and aerosol generators used in the course of this testing. With regard to particle counting it specifies the statistical basis for the evaluation of counts with only small numbers of counted events.

EN 1822-2:2009 is classified under the following ICS (International Classification for Standards) categories: 13.040.40 - Stationary source emissions; 23.120 - Ventilators. Fans. Air-conditioners. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1822-2:2009 has the following relationships with other standards: It is inter standard links to EN 1822-2:1998, EN ISO 29463-2:2018, EN 14799:2007, EN ISO 29463-3:2018, EN 1822-3:2009, EN 15695-2:2017, EN 1822-5:2009, EN 1822-1:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1822-2:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Schwebstofffilter (EPA, HEPA und ULPA) - Teil 2: Aerosolerzeugung, Meßgeräte, PartikelzählstatistikFiltres à air à haute efficacité (EPA, HEPA et ULPA) - Partie 2: Production d'aérosol, équipement de mesure et statistiques de comptage de particulesHigh efficiency air filters (EPA, HEPA and ULPA) - Part 2: Aerosol production, measuring equipment, particle counting statistics23.120QDSUDYHVentilators. Fans. Air-conditionersICS:Ta slovenski standard je istoveten z:EN 1822-2:2009SIST EN 1822-2:2010en,fr01-januar-2010SIST EN 1822-2:2010SLOVENSKI

STANDARDSIST EN 1822-2:20001DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1822-2

November 2009 ICS 13.040.40 Supersedes EN 1822-2:1998English Version

High efficiency air filters (EPA, HEPA and ULPA) - Part 2: Aerosol production, measuring equipment, particle counting statistics

Filtres à air à haute efficacité (EPA, HEPA et ULPA) - Partie 2: Production d'aérosol, équipement de mesure et statistiques de comptage de particules

Schwebstofffilter (EPA, HEPA und ULPA) - Teil 2: Aerosolerzeugung, Meßgeräte, Partikelzählstatistik This European Standard was approved by CEN on 17 October 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1822-2:2009: ESIST EN 1822-2:2010

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom.

DEHS PAO a Paraffin oil (low visc.) Chemical designation Sebacic acid-bis(2-ethylhexyl) ester Poly-Alpha-Olephin (e.g. CAS b No. 68649-12-7) Mixture (e.g. CAS # 64742-46-7)Trivial name Diethylhexylsebacyte Polyalphaolefin Paraffinoil Density (kg/m3) 912 800 – 820 (820 c) 843 Melting point (K) 225 ~ 280 259 Boiling point (K) 529 650 – 780 (674 c)

Flash point (K) > 473 445 – 500 453 Vapour pressure at 293 K (µPa) 1,9 100 – 130

Dynamic viscosity (kg/m s) 0,022 to 0,024 0,003 1 – 0,004 at 373 K (0,013 at 313 K c) (Kinematic viscosity at 373 K: 3,8 – 4,1 mm2/s) 0,026 Index of refraction/ wavelength (nm) 1,450/650 1,452/600 1,453 5/550 1,454 5/500 1,458 5/450 1,475/400 (1,455 6 c)

a

US Patents 5,059,349 [3] and 5,059,352 [4] describe and restrict the use of PAO for filter testing. Material properties of PAO as per Japan JACA Standard No. 37-2001: “The guideline of substitute materials to DOP” [5], Japan JISZ Standard No. 8901-206 [6] and ISO Standard No. 14644-3 [7]. b

CAS #, Chemical Abstracts Service Registry Number, substances have been registered in Chemical Abstracts, issued by American Chemical Society [8]. c

Data for “Emery 3004” as a specific example of a PAO. Source: Crosby, David W., Concentration produced by a Laskin nozzle generator, a comparison of substitute materials and DOP, 21st DOE/NRC Nuclear Air Cleaning Conference [9].

4.3 Producing monodisperse aerosols 4.3.1 Condensation methods 4.3.1.1 General Condensation methods are preferred for the creation of monodisperse aerosols, i.e. the particles are formed by condensation from the vapour phase. It is necessary to distinguish between heterogeneous and homogeneous condensation. SIST EN 1822-2:2010

A simple nebuliser operated with nitrogen nebulises a weak aqueous solution of sodium chloride. After large water drops have been excluded in a drop eliminator, the smaller droplets are passed into a diffusion drier where they vaporise. The resultant sodium chloride aerosol is then passed into a vessel containing the actual aerosol substance, where it becomes saturated with the vapour of this substance. The aerosol vapour mixture is then passed through a re-heater, and then on through a condensation chimney, where the vapour condenses on the salt particles, forming a homogeneous droplet aerosol (see also [10]).

Key 1 Nitrogen supply 2 Nebuliser 3 Drop eliminator 4 Diffusion drier 5 Thermostatic oven 6 By-pass valve 7 Flow meter 8 Re-heater 9 Condensation chimney 10 Aerosol Figure 1 — Structure of the Sinclair-LaMer aerosol generator The vessel containing the aerosol substance is contained in a thermostatic oven, whose temperature can be adjusted so as to regulate the amount of vapour and the diameter of the particles. A part of the sodium SIST EN 1822-2:2010

The rates of particle production which can be achieved by means of this type of generator are in the order of 108 s-1; the particle diameter can be adjusted between approximately 0,1 µm and 4 µm. 4.3.1.2.3 Rapaport-Weinstock generator (Figure 2) An aerosol substance is nebulised through a nozzle, either as a pure substance or in solution, and the resultant polydisperse aerosol is then vaporised along the heated section of a glass tube. Residual nuclei of the impurities in the material remain.

Key 1 Liquid reservoir 2 Compressed air 3 Nebuliser 4 Vaporisation section 5 Thermostat 6 Condensation section 7 Aerosol Figure 2 — Structure of the Rapaport and Weinstock aerosol generator In the subsequent condensation section the aerosol substance then condenses on these nuclei to form a mondisperse aerosol (see also [11]). The particle diameter of this aerosol is determined by the mixing ratio of aerosol substance and solvent. The final aerosol contains the solvent used (e.g. Propanol) as a vapour. SIST EN 1822-2:2010

Key 1 DEHS tank 2 Pump 3 Flow controller 4 Nitrogen 5 Ultra-sonic nebuliser 6 Thermostat 7 Vaporisation pipe with heater and insulation 8 Sheath air 9 Nozzle 10 Sintered metal plate 11 Coagulation section 12 Aerosol Figure 3 — Set-up of a free-jet condensation aerosol generator SIST EN 1822-2:2010

It is comparatively simple to increase the particle production rate by using a number of jets in parallel. The maximum rate of particle production which can be achieved using one nozzle is 5 x 1010 s-1.

NOTE A typical jet nebuliser is described for example in [13]. 4.5 Neutralisation of aerosols

Since electrically charged particles are removed more effectively by filters than are uncharged particles, electrically neutral particles should be used for testing filters. A neutral state of charge is generally understood to be the stationary equilibrium achieved when charged aerosol particles are brought together with a sufficient number of positive and negative gas ions. This is usually carried out by ionising the carrier gas of the aerosol using a radioactive source or by corona discharge. The low level of residual charge in the aerosol after this neutralisation can be neglected for the filtration process. Aerosol particles become electrically charged when there is a division of charges in the course of production (e.g. nebulisation).

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...