EN 13617-2:2012

(Main)Petrol filling stations - Part 2: Safety requirements for construction and performance of safe breaks for use on metering pumps and dispensers

Petrol filling stations - Part 2: Safety requirements for construction and performance of safe breaks for use on metering pumps and dispensers

This European Standard specifies safety requirements for the construction and performance of safe breaks to be fitted to metering pumps and dispensers installed at filling stations and used to dispense liquid fuels into the tanks of motor vehicles, boats and light aircraft and into portable containers at flow rates up to 200 l min-1.

The requirements apply to safe breaks at ambient temperatures from –20 °C to +40 °C with the possibility for an extended temperature range.

It pays particular attention to electrical, mechanical and hydraulic characteristics of, and electrical apparatus incorporated within or mounted on, the safe break.

This European Standard applies mainly to hazards related to the ignition of liquid fuels being dispensed or their vapour. This European Standard also addresses electrical and mechanical hazards.

NOTE 1 This European Standard does not apply to equipment for use with liquefied petroleum gas (LPG) or liquefied natural gas (LNG) or compressed natural gas (CNG).

NOTE 2 Fuels other than of Explosion Group IIA are excluded from this European Standard.

Tankstellen - Teil 2: Sicherheitstechnische Anforderungen an Bau- und Arbeitsweise von Abreißkupplungen für Zapfsäulen und druckversorgte Zapfsäulen

Diese Europäische Norm legt die sicherheitstechnischen Anforderungen an den Bau und die Arbeitsweise von Abreißkupplungen an Zapfsäulen und druckversorgten Zapfsäulen fest, die an Tankstellen installiert werden für die Abgabe von flüssigen Kraftstoffen in Tanks von Kraftfahrzeugen, Booten und Leichtflugzeugen sowie in tragbare Behälter bei Durchflussraten bis zu 200 l min1.

Die Anforderungen gelten für Abreißkupplungen bei Umgebungstemperaturen zwischen –20 °C und 40 °C, wobei ein erweiterter Temperaturbereich möglich ist.

Es berücksichtigt insbesondere die elektrischen, mechanischen und hydraulischen Eigenschaften von Abreiß-kupplungen und der zugehörigen oder an ihnen angebrachten elektrischen Betriebsmittel.

Diese Europäische Norm ist hauptsächlich auf die Gefährdungen durch Entzünden von abzufüllenden flüssigen Kraft¬stoffen oder deren Dämpfen anwendbar. Diese Europäische Norm berücksichtigt auch die elektrischen und mecha¬nischen Gefährdungen.

ANMERKUNG 1 Diese Europäische Norm gilt nicht für Ausrüstung für Anwendungen mit Flüssiggas (LPG, en: liquefied petroleum gas) oder Flüssigerdgas (LNG, en: liquefied natural gas) oder komprimiertem Erdgas (CNG, en: compressed natural gas).

ANMERKUNG 2 Diese Europäische Norm gilt nicht für Kraftstoffe, die nicht zur Explosionsgruppe IIA gehören.

Stations-service - Partie 2: Exigences de sécurité relatives à la construction et aux performances des raccords cassants utilisés pour les distributeurs de carburant

La présente Norme européenne spécifie les exigences relatives à la construction et aux performances en matière de sécurité des raccords cassants montés sur les distributeurs installés en stations-service et utilisés pour distribue des carburants liquides dans des réservoirs de véhicules à moteur, de bateaux, d’avions légers et dans des réservoirs portables, dont les débits sont inférieurs à 200 l∙min-1.

Les exigences s'appliquent aux raccords cassants à des températures comprises entre –20 °C et +40 °C avec la possibilité d'étendre la plage de température.

Elle accorde une attention toute particulière aux caractéristiques électriques, mécaniques et hydrauliques ainsi qu’aux appareillages électriques installés dans ou montés sur les raccords cassants.

La présente Norme européenne concerne principalement les phénomènes dangereux liés à l’inflammation des carburants liquides distribués ou de leurs vapeurs. La présente Norme européenne concerne également les risques de nature électrique ou mécanique.

NOTE 1 La présente Norme européenne ne s’applique pas aux équipements mettant en œuvre du gaz de pétrole liquéfié (GPL) ou du gaz naturel liquéfié (GNL) ou du gaz naturel compressé (GNC).

NOTE 2 Les carburants autres que ceux du Groupe d’Explosion IIA sont exclus de la présente Norme européenne.

Bencinski servisi - 2. del: Varnostne zahteve za izdelavo in lastnosti varnostnih zapor za tlačne in sesalne naprave za točenje goriva

Ta dokument določa varnostne zahteve za izdelavo in lastnosti varnostnih zapor, nameščenih na tlačne in sesalne naprave za točenje goriva, ki so postavljene na bencinskih servisih in se uporabljajo za točenje tekočih goriv v rezervoarje motornih vozil, čolnov in lahkih letal ter v premične rezervoarje s pretokom do 200 l×min-1.

Posebej se osredotoča na električne, mehanske in hidravlične lastnosti varnostnih zapor ter električne naprave, ki so vgrajene vanje ali nanje.

Ta dokument se uporablja predvsem za nevarnosti, povezane z vžigom tekočih goriv, ki se točijo, ali njihovih hlapov. V tem dokumentu so obravnavane tudi električne in mehanske nevarnosti.

OPOMBA: Utekočinjen naftni plin (LPG) ni tekočina v smislu tega dokumenta.

General Information

- Status

- Withdrawn

- Publication Date

- 13-Mar-2012

- Withdrawal Date

- 20-Jan-2026

- Technical Committee

- CEN/TC 393 - Equipment for storage tanks and for service stations

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 15-Sep-2021

- Completion Date

- 28-Jan-2026

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 16507:2014 - Railway applications - Ground based service - Diesel refuelling equipment - Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ABS Group Brazil

ABS Group certification services in Brazil.

Bureau Veritas Kuwait

Bureau Veritas certification services in Kuwait.

Bureau Veritas Nigeria

Bureau Veritas certification services in Nigeria.

Sponsored listings

Frequently Asked Questions

EN 13617-2:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Petrol filling stations - Part 2: Safety requirements for construction and performance of safe breaks for use on metering pumps and dispensers". This standard covers: This European Standard specifies safety requirements for the construction and performance of safe breaks to be fitted to metering pumps and dispensers installed at filling stations and used to dispense liquid fuels into the tanks of motor vehicles, boats and light aircraft and into portable containers at flow rates up to 200 l min-1. The requirements apply to safe breaks at ambient temperatures from –20 °C to +40 °C with the possibility for an extended temperature range. It pays particular attention to electrical, mechanical and hydraulic characteristics of, and electrical apparatus incorporated within or mounted on, the safe break. This European Standard applies mainly to hazards related to the ignition of liquid fuels being dispensed or their vapour. This European Standard also addresses electrical and mechanical hazards. NOTE 1 This European Standard does not apply to equipment for use with liquefied petroleum gas (LPG) or liquefied natural gas (LNG) or compressed natural gas (CNG). NOTE 2 Fuels other than of Explosion Group IIA are excluded from this European Standard.

This European Standard specifies safety requirements for the construction and performance of safe breaks to be fitted to metering pumps and dispensers installed at filling stations and used to dispense liquid fuels into the tanks of motor vehicles, boats and light aircraft and into portable containers at flow rates up to 200 l min-1. The requirements apply to safe breaks at ambient temperatures from –20 °C to +40 °C with the possibility for an extended temperature range. It pays particular attention to electrical, mechanical and hydraulic characteristics of, and electrical apparatus incorporated within or mounted on, the safe break. This European Standard applies mainly to hazards related to the ignition of liquid fuels being dispensed or their vapour. This European Standard also addresses electrical and mechanical hazards. NOTE 1 This European Standard does not apply to equipment for use with liquefied petroleum gas (LPG) or liquefied natural gas (LNG) or compressed natural gas (CNG). NOTE 2 Fuels other than of Explosion Group IIA are excluded from this European Standard.

EN 13617-2:2012 is classified under the following ICS (International Classification for Standards) categories: 75.200 - Petroleum products and natural gas handling equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13617-2:2012 has the following relationships with other standards: It is inter standard links to EN 13617-2:2004, EN 13617-2:2021, EN ISO 6878:2004, EN ISO 1825:2017, EN 13463-1:2009, EN ISO 9013:2002/A1:2003, EN 1360:2013, EN 228:2025, EN 572-7:2004, EN 13483:2022, EN 1127-1:2019, EN ISO 8031:2009, EN ISO 228-1:2003, EN 13617-1:2012, EN 16507:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13617-2:2012 is associated with the following European legislation: EU Directives/Regulations: 2014/34/EU, 94/9/EC; Standardization Mandates: M/079. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13617-2:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Tankstellen - Teil 2: Sicherheitstechnische Anforderungen an Bau- und Arbeitsweise von Abreißkupplungen für Zapfsäulen und druckversorgte ZapfsäulenStations-service - Partie 2: Exigences de sécurité relatives à la construction et aux performances des raccords cassants utilisés pour distributeurs de carburantsPetrol filling stations - Part 2: Safety requirements for construction and performance of safe breaks for use on metering pumps and dispensers75.200Petroleum products and natural gas handling equipmentICS:Ta slovenski standard je istoveten z:EN 13617-2:2012SIST EN 13617-2:2012en,fr,de01-maj-2012SIST EN 13617-2:2012SLOVENSKI

STANDARDSIST EN 13617-2:20041DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13617-2

March 2012 ICS 75.200 Supersedes EN 13617-2:2004English Version

Petrol filling stations - Part 2: Safety requirements for construction and performance of safe breaks for use on metering pumps and dispensers

Stations-service - Partie 2: Exigences de sécurité relatives à la construction et aux performances des raccords cassants utilisés pour les distributeurs de carburant

Tankstellen - Teil 2: Sicherheitstechnische Anforderungen an Bau- und Arbeitsweise von Abreißkupplungen für Zapfsäulen und druckversorgte Zapfsäulen This European Standard was approved by CEN on 28 January 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13617-2:2012: ESIST EN 13617-2:2012

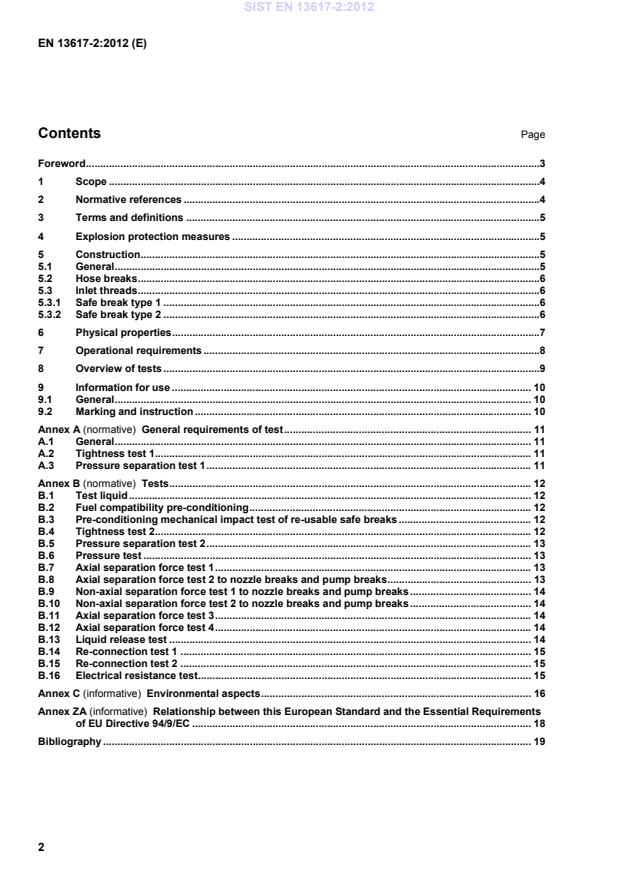

General requirements of test . 11A.1General . 11A.2Tightness test 1 . 11A.3Pressure separation test 1 . 11Annex B (normative)

Tests . 12B.1Test liquid . 12B.2Fuel compatibility pre-conditioning . 12B.3Pre-conditioning mechanical impact test of re-usable safe breaks . 12B.4Tightness test 2 . 12B.5Pressure separation test 2 . 13B.6Pressure test . 13B.7Axial separation force test 1 . 13B.8Axial separation force test 2 to nozzle breaks and pump breaks . 13B.9Non-axial separation force test 1 to nozzle breaks and pump breaks . 14B.10Non-axial separation force test 2 to nozzle breaks and pump breaks . 14B.11Axial separation force test 3 . 14B.12Axial separation force test 4 . 14B.13Liquid release test . 14B.14Re-connection test 1 . 15B.15Re-connection test 2 . 15B.16Electrical resistance test . 15Annex C (informative)

Environmental aspects . 16Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 94/9/EC . 18Bibliography . 19 SIST EN 13617-2:2012

(ISO 1825) EN ISO 8031:2009, Rubber and plastics hoses and hose assemblies — Determination of electrical resistance and conductivity (ISO 8031:2009) ISO 261, ISO general-purpose metric screw threads — General plan ISO 965-2, ISO general purpose metric screw threads — Tolerances — Part 2: Limits of sizes for general purpose external and internal screw threads — Medium quality ISO 11925-3, Reaction to fire tests — Ignitability of building products subjected to direct impingement of flame — Part 3: Multi-source test SIST EN 13617-2:2012

EN 13463–1. The safe break shall fulfil the requirements for temperature class T3 and Group IIA to EN 60079-0 or EN 13463–1. 5 Construction 5.1 General 5.1.1 All electrical and non-electrical equipment and components, intended for use in potentially explosive atmospheres, shall be designed and constructed according to good engineering practice and in conformity with the required categories for group II equipment to ensure avoidance of any ignition source. To classify the category of the equipment it shall be subjected to an ignition hazard assessment in accordance with 5.2 of EN 13463-1:2009. 5.1.2 All materials used in the construction shall be chemically and dimensionally stable under known service conditions. Materials likely to come into contact with fuels in both liquid and vapour phases shall be resistant to attack by these fuels. Compliance shall be demonstrated by manufacturer's declaration and compliance with the tests B.1 to B.16 inclusive. SIST EN 13617-2:2012

MALE THREADSb

Maximum thread depth mm Minimum thread length mm ¾” 12,5 11,0 1” 15,5 14,0 1 1/4” 15,5 17,5 1 1/2” 15,5 18,0 a The thread depth is measured from the outer to the metallic inner sealing face. b The stated minimum lengths does only apply if the female thread of the hose fitting includes an inner flat gasket. In case of using an outer flat gasket, the male threads may be shorter as stated.

5.3.2 Safe break type 2 Threads shall comply with Form 2: Form 2. M 34 × 1,5 female or male according to ISO 261 and ISO 965–2. The total thread depth shall be not less than 15,0 mm. The inlet end shall be controlled to a diameter of (35,0 ± 0,05) mm for a length (6,0 ± 0,1) mm. SIST EN 13617-2:2012

Physical properties The physical properties of the safe break shall be according to Table 2. Table 2 — Physical properties of safe break PROPERTY REQUIREMENT TEST METHOD Electrical resistance of inlet thread to outlet thread when fully assembled. All readings to be < 105 Ω B.16 Electrostatic properties 6.7 of EN 13463-1:2009 EN 13463-1 Fuel compatibility Clause 7 B.2 Ignitability of composites on safe break, Ignition source C; Effect time 20 s; Surface flame impingement The material tested shall not afterflame ISO 11925–3 Characteristics of safe break body and/or cover to prevent dangerous, mechanically generated, sparks (resistance to sparking). 6.4.4.2 of EN 13463-1:2009

EN 13463-1 SIST EN 13617-2:2012

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...