EN 16637-1:2023

(Main)Construction products: Assessment of release of dangerous substances - Part 1: Guidance for the determination of leaching tests and additional testing steps

Construction products: Assessment of release of dangerous substances - Part 1: Guidance for the determination of leaching tests and additional testing steps

(1) This document allows the identification of the appropriate leaching test method for the determination of the release of RDS from construction products into soil, surface water and groundwater. This document provides a stepwise procedure for the determination of appropriate release tests, including:

a) determination of the test method based on general product properties;

b) choice of the test method using specific product properties.

(2) Furthermore, this document gives general guidance for CEN Technical Product Committees and EOTA WGs on basic aspects (sampling, sample preparation and storage, eluate treatment, analysis of eluates and documentation) to be specified in the relevant product standards or ETAs.

(3) Metallic products and coatings on metallic products are not considered in the determination scheme of this document since the test methods in prEN 16637 2:—1) (tank test) and prEN 16637 3:—2) (column test) are not appropriate for the testing of these construction products due to a different release mechanism (solubility control).

NOTE See Annex F.

(4) It is assumed that intermittent contact with water (e.g. exposure to rainwater) is tested – by convention – as permanent contact. For some coatings, (e.g. some renders with organic binders according to EN 15824 [7]) in intermittent contact to water, physical and chemical properties might be altered in permanent contact with water. These products are not considered in the determination scheme of this document since the test method in prEN 16637 2 is not appropriate for the testing of these construction products (in this case EN 16105 [8] might be an alternative method).

Bauprodukte - Bewertung der Freisetzung von gefährlichen Stoffen - Teil 1: Leitfaden für die Festlegung von Auslaugprüfungen und zusätzlichen Prüfschritten

Dieses Dokument ermöglicht die Identifizierung des geeigneten Auslaugprüfverfahrens für die Bestimmung der Freisetzung regulierter gefährlicher Stoffe aus Bauprodukten in den Boden, das Oberflächenwasser und das Grundwasser. Dieses Dokument enthält ein schrittweises Verfahren zur Ermittlung geeigneter Freisetzungsprüfungen, einschließlich:

a) Bestimmung des Prüfverfahrens auf der Grundlage allgemeiner Produkteigenschaften;

b) Wahl des Prüfverfahrens durch Anwendung spezieller Produkteigenschaften.

Darüber hinaus enthält dieses Dokument einen Leitfaden für die Technischen Produktkomitees von CEN und Arbeitsgruppen (WG) der Europäischen Organisation für Technische Bewertung EOTA zu grundlegenden Aspekten (Probenahme, Probenvorbereitung und -lagerung, Eluatbehandlung, Analyse von Eluaten und Dokumentation), die in den maßgebenden Produktnormen oder Europäischen Technischen Bewertungen (ETA) festzulegen sind.

Metallische Produkte und Beschichtungen auf metallischen Produkten werden in diesem Dokument nicht berücksichtigt, da die Prüfverfahren in EN 16637 2 (Trog-Prüfverfahren) und EN 16637 3 (Perkolationsprüfung) für die Prüfung dieser Bauprodukte aufgrund eines anderen Freisetzungsmechanismus (Löslichkeitssteuerung) nicht geeignet sind.

ANMERKUNG Siehe Anhang F.

Es wird angenommen, dass der zeitweilige Kontakt mit Wasser (z. B. Beanspruchung durch Regenwasser) nach Vereinbarung als dauerhafter Kontakt geprüft wird. Bei einigen Beschichtungen (z. B. einige Putze mit organischen Bindemitteln nach EN 15824 [7]), die zeitweilig mit Wasser in Berührung kommen, könnten physikalische und chemische Eigenschaften sich bei dauerhaftem Kontakt mit Wasser verändern. Diese Produkte werden nicht in diesem Dokument berücksichtigt, da das Prüfverfahren in EN 16637 2 für die Prüfung dieser Bauprodukte nicht geeignet ist (in diesem Fall könnte EN 16105 [8] ein geeignetes alternatives Prüfverfahren sein.)

Produits de construction - Évaluation du relargage de substances dangereuses - Partie 1 : Guide pour la spécification des essais de lixiviation et des étapes supplémentaires d’essai

Le présent document permet l’identification de la méthode d’essai de lixiviation appropriée pour déterminer le relargage de SDR issues de produits de construction dans le sol, les eaux de surface et les eaux souterraines. Le présent document fournit un mode opératoire par étapes pour la détermination des essais de relargage appropriés, comprenant :

a) la détermination de la méthode d’essai basée sur les propriétés générales du produit ;

b) le choix de la méthode d’essai reposant sur des propriétés spécifiques du produit.

En outre, le présent document donne des recommandations générales pour les Comités techniques de produits du CEN et les groupes de travail de l’EOTA sur des aspects de base (échantillonnage, préparation des échantillons et stockage, traitement des éluats, analyse des éluats et documentation) à spécifier dans les normes de produits ou évaluations techniques européennes (ETE) correspondantes.

Les produits métalliques et revêtements de produits métalliques ne sont pas pris en compte dans le schéma de détermination du présent document, car les méthodes d’essai de l’EN 16637 2 (essai en réacteur) et de l’EN 16637 3 (essai en colonne) ne sont pas appropriées pour les essais de ces produits de construction du fait d’un mécanisme de relargage différent (contrôle de la solubilité).

NOTE Voir l’Annexe F.

Il est présumé que le contact intermittent avec l’eau (par exemple, exposition à l’eau de pluie) est considéré, par convention, comme un contact permanent. Pour certains revêtements (tels que certains enduits de maçonnerie organiques conformément à l’EN 15824[7]) en contact intermittent avec l’eau, certaines propriétés physiques et chimiques peuvent être altérées en cas de contact permanent avec l’eau. Ces produits ne sont pas pris en compte dans le schéma de détermination du présent document, car la méthode d’essai dans l’EN 16637 2 n’est pas appropriée pour les essais de ces produits de construction (dans ce cas, l’EN 16105[8] peut être une méthode alternative).

Gradbeni proizvodi - Ocenjevanje sproščanja nevarnih snovi - 1. del: Navodilo za določanje preskusov izluževanja in dodatnih korakov preskušanja

(1) Ta evropski standard omogoča opredelitev ustrezne preskusne metode izluževanja za določanje sproščanja reguliranih nevarnih snovi (RDS) iz gradbenih proizvodov v tla, površinsko vodo in podtalnico. Ta dokument določa korake postopka za določanje ustreznih preskusov sproščanja, vključno z:

a) določanjem preskusne metode na podlagi splošnih lastnosti proizvodov;

b) izbiro preskusne metode z uporabo posebnih lastnosti proizvodov.

(2) Poleg tega ta evropski standard določa splošna navodila za tehnične odbore za proizvode CEN in delovne skupine EOTA v zvezi z osnovnimi vidiki (vzorčenje, priprava vzorcev in shramba, obdelava izlužkov, analiza izlužkov in dokumentacija), ki se določijo v ustreznih standardih za proizvode ali evropskih tehničnih soglasjih ETA.

(3) Kovinski proizvodi in premazi na kovinskih proizvodih niso obravnavani v shemi določanja te tehnične specifikacije, saj preskusne metode iz standarda EN 16637-2 (preskus s cisterno) in EN 16637-3 (preskus v stolpcu) niso primerne za preskušanje teh gradbenih proizvodov zaradi drugačnega mehanizma sproščanja (nadzor topljivosti).

OPOMBA: glej dodatek F.

4) Domneva se, da je občasen stik z vodo (npr. izpostavljenost deževnici) preskušen – po dogovoru – kot stalen stik.

Pri nekaterih premazih (npr. nekateri ometi z organskimi vezivi v skladu s standardom EN 15824 [4]) v občasnem stiku z vodo se lahko fizikalne in kemijske lastnosti spremenijo ob stalnem stiku z vodo. Ti proizvodi niso obravnavani v shemi določanja te tehnične specifikacije, saj preskusna metoda iz standarda EN 16637-2 ni primerna za preskušanje teh gradbenih proizvodov (v tem primeru je lahko standard EN 16105 alternativna metoda).

General Information

- Status

- Published

- Publication Date

- 31-Oct-2023

- Withdrawal Date

- 09-May-2022

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 01-Nov-2023

- Due Date

- 17-Dec-2021

- Completion Date

- 01-Nov-2023

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 28-Jan-2026

- Refers

EN 16687:2023 - Construction products: Assessment of release of dangerous substances - Terminology - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 16637-1:2023 (CEN) provides guidance to determine appropriate leaching tests for assessing the release of regulated dangerous substances (RDS) from construction products into soil, surface water and groundwater. Part 1 sets out a stepwise determination scheme based on general and product‑specific properties and gives procedural guidance on sampling, sample preparation, eluate handling, analysis and documentation for use in product standards and European Technical Assessments (ETAs).

Key topics and requirements

- Test selection procedure: A two-step approach to identify the correct leaching method

- Determine test family from general product properties (monolithic vs granular, surface-dependent vs percolation).

- Refine test choice using specific product features (permeability, particle size, intended exposure).

- Support modules for standardisation: Guidance modules for inclusion in product‑specific standards covering:

- Sampling plans, transport, chain of custody and reporting

- Preparation of test portions and storage

- Eluate collection, treatment and analytical requirements

- Documentation and data reporting

- Scope limitations and conventions:

- Metallic products and coatings on metals are excluded from the determination scheme (see Annex F) because release is often solubility‑controlled, not suited to horizontal tank/column tests.

- Intermittent water contact (e.g., rain) is conventionally treated as permanent contact for testing purposes. Some coatings affected by permanent immersion may require alternative tests (e.g., EN 16105).

- Quality and applicability:

- Intended to support both type testing (TT) and factory production control (FPC) and to inform impact assessments (Annex A).

- Includes informative annexes on release scenarios, test types, sampling concepts and handling unexpected or heterogeneous test results (Annex G).

Practical applications and users

Who uses EN 16637-1:2023:

- CEN Technical Product Committees and EOTA working groups specifying product standards or ETAs

- Manufacturers and product developers preparing CE marking documentation

- Accredited testing laboratories designing leaching test campaigns

- Notified bodies, conformity assessors and regulators evaluating environmental release of RDS

- Environmental consultants conducting release or impact assessments

Practical benefits:

- Ensures consistent, harmonised selection of leaching tests across product standards

- Improves comparability of leaching data for compliance with national regulations

- Reduces uncertainty in sampling, eluate handling and reporting

Related standards

- EN 16637-2:2023 - Horizontal dynamic surface leaching test (tank test)

- EN 16637-3:2023 - Horizontal up‑flow percolation test (column test)

- EN 16687:2023 - Terminology for assessment of release of dangerous substances

- EN 16105 - Alternative method for some coatings (where applicable)

Keywords: EN 16637-1:2023, leaching tests, construction products, release of dangerous substances, CEN, soil, surface water, groundwater, sampling, eluate analysis.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 16637-1:2023 is a standard published by the European Committee for Standardization (CEN). Its full title is "Construction products: Assessment of release of dangerous substances - Part 1: Guidance for the determination of leaching tests and additional testing steps". This standard covers: (1) This document allows the identification of the appropriate leaching test method for the determination of the release of RDS from construction products into soil, surface water and groundwater. This document provides a stepwise procedure for the determination of appropriate release tests, including: a) determination of the test method based on general product properties; b) choice of the test method using specific product properties. (2) Furthermore, this document gives general guidance for CEN Technical Product Committees and EOTA WGs on basic aspects (sampling, sample preparation and storage, eluate treatment, analysis of eluates and documentation) to be specified in the relevant product standards or ETAs. (3) Metallic products and coatings on metallic products are not considered in the determination scheme of this document since the test methods in prEN 16637 2:—1) (tank test) and prEN 16637 3:—2) (column test) are not appropriate for the testing of these construction products due to a different release mechanism (solubility control). NOTE See Annex F. (4) It is assumed that intermittent contact with water (e.g. exposure to rainwater) is tested – by convention – as permanent contact. For some coatings, (e.g. some renders with organic binders according to EN 15824 [7]) in intermittent contact to water, physical and chemical properties might be altered in permanent contact with water. These products are not considered in the determination scheme of this document since the test method in prEN 16637 2 is not appropriate for the testing of these construction products (in this case EN 16105 [8] might be an alternative method).

(1) This document allows the identification of the appropriate leaching test method for the determination of the release of RDS from construction products into soil, surface water and groundwater. This document provides a stepwise procedure for the determination of appropriate release tests, including: a) determination of the test method based on general product properties; b) choice of the test method using specific product properties. (2) Furthermore, this document gives general guidance for CEN Technical Product Committees and EOTA WGs on basic aspects (sampling, sample preparation and storage, eluate treatment, analysis of eluates and documentation) to be specified in the relevant product standards or ETAs. (3) Metallic products and coatings on metallic products are not considered in the determination scheme of this document since the test methods in prEN 16637 2:—1) (tank test) and prEN 16637 3:—2) (column test) are not appropriate for the testing of these construction products due to a different release mechanism (solubility control). NOTE See Annex F. (4) It is assumed that intermittent contact with water (e.g. exposure to rainwater) is tested – by convention – as permanent contact. For some coatings, (e.g. some renders with organic binders according to EN 15824 [7]) in intermittent contact to water, physical and chemical properties might be altered in permanent contact with water. These products are not considered in the determination scheme of this document since the test method in prEN 16637 2 is not appropriate for the testing of these construction products (in this case EN 16105 [8] might be an alternative method).

EN 16637-1:2023 is classified under the following ICS (International Classification for Standards) categories: 91.100.01 - Construction materials in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16637-1:2023 has the following relationships with other standards: It is inter standard links to CEN/TS 16637-1:2018, EN 16637-3:2023, EN 16687:2023, EN 16637-2:2023, CEN/TS 16637-3:2016, EN 17516:2023, CEN/TS 16637-2:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16637-1:2023 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/366. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16637-1:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-april-2024

Nadomešča:

SIST-TS CEN/TS 16637-1:2019

Gradbeni proizvodi - Ocenjevanje sproščanja nevarnih snovi - 1. del: Navodilo za

določanje preskusov izluževanja in dodatnih korakov preskušanja

Construction products - Assessment of release of dangerous substances - Part 1:

Guidance for the determination of leaching tests and additional testing steps

Bauprodukte - Bewertung der Freisetzung von gefährlichen Stoffen - Teil 1: Leitfaden für

die Festlegung von Auslaugprüfungen und zusätzlichen Prüfschritten

Produits de construction - Évaluation du relargage de substances dangereuses - Partie 1

: Guide pour la spécification des essais de lixiviation et des étapes supplémentaires

d’essai

Ta slovenski standard je istoveten z: EN 16637-1:2023

ICS:

13.020.99 Drugi standardi v zvezi z Other standards related to

varstvom okolja environmental protection

91.100.01 Gradbeni materiali na Construction materials in

splošno general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 16637-1

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2023

EUROPÄISCHE NORM

ICS 91.100.01 Supersedes CEN/TS 16637-1:2018

English Version

Construction products: Assessment of release of

dangerous substances - Part 1: Guidance for the

determination of leaching tests and additional testing

steps

Produits de construction - Évaluation du relargage de Bauprodukte - Bewertung der Freisetzung von

substances dangereuses - Partie 1 : Guide pour la gefährlichen Stoffen - Teil 1: Leitfaden für die

spécification des essais de lixiviation et des étapes Festlegung von Auslaugprüfungen und zusätzlichen

supplémentaires d'essai Prüfschritten

This European Standard was approved by CEN on 30 July 2023.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 16637-1:2023 E

worldwide for CEN national Members.

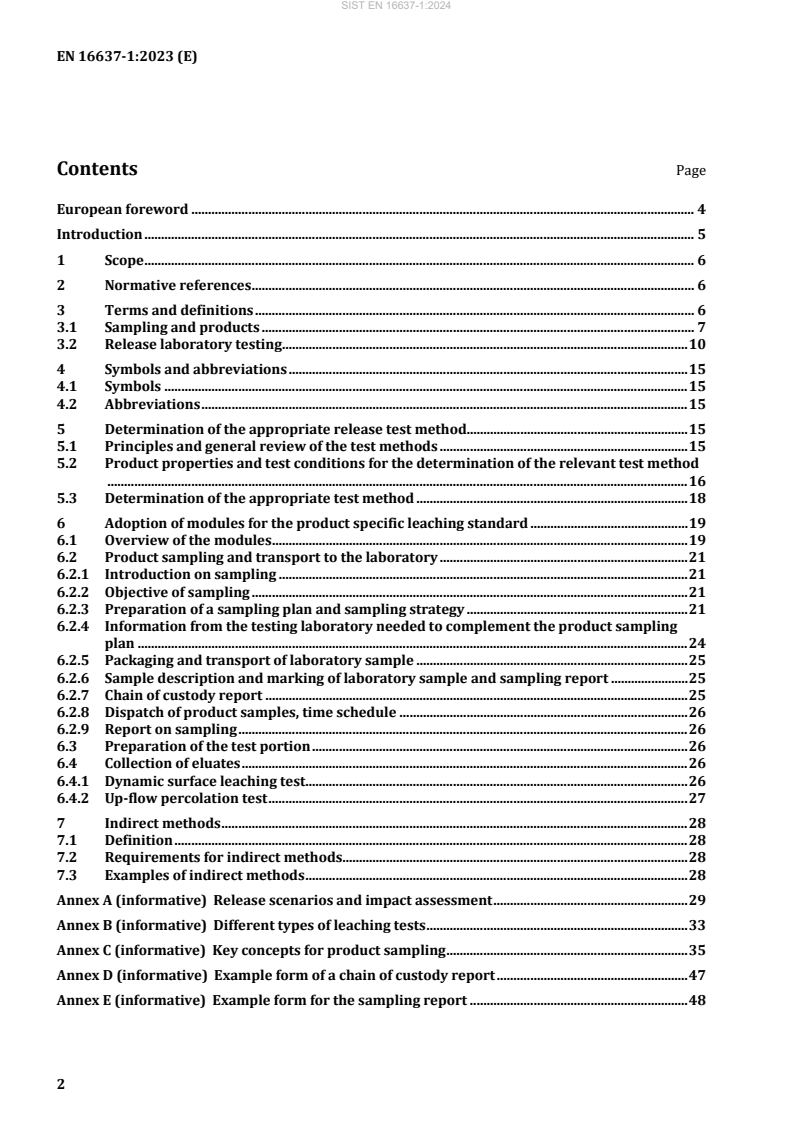

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

3.1 Sampling and products . 7

3.2 Release laboratory testing . 10

4 Symbols and abbreviations . 15

4.1 Symbols . 15

4.2 Abbreviations . 15

5 Determination of the appropriate release test method. 15

5.1 Principles and general review of the test methods . 15

5.2 Product properties and test conditions for the determination of the relevant test method

............................................................................................................................................................................. 16

5.3 Determination of the appropriate test method . 18

6 Adoption of modules for the product specific leaching standard . 19

6.1 Overview of the modules . 19

6.2 Product sampling and transport to the laboratory . 21

6.2.1 Introduction on sampling . 21

6.2.2 Objective of sampling . 21

6.2.3 Preparation of a sampling plan and sampling strategy . 21

6.2.4 Information from the testing laboratory needed to complement the product sampling

plan . 24

6.2.5 Packaging and transport of laboratory sample . 25

6.2.6 Sample description and marking of laboratory sample and sampling report . 25

6.2.7 Chain of custody report . 25

6.2.8 Dispatch of product samples, time schedule . 26

6.2.9 Report on sampling . 26

6.3 Preparation of the test portion . 26

6.4 Collection of eluates . 26

6.4.1 Dynamic surface leaching test . 26

6.4.2 Up-flow percolation test . 27

7 Indirect methods . 28

7.1 Definition . 28

7.2 Requirements for indirect methods. 28

7.3 Examples of indirect methods . 28

Annex A (informative) Release scenarios and impact assessment . 29

Annex B (informative) Different types of leaching tests . 33

Annex C (informative) Key concepts for product sampling . 35

Annex D (informative) Example form of a chain of custody report . 47

Annex E (informative) Example form for the sampling report . 48

Annex F (informative) Metallic products . 49

Annex G (informative) Guidance on how to identify and handle unexpected test results and how

to recognize heterogeneous products . 50

Bibliography . 53

European foreword

This document (EN 16637-1:2023) has been prepared by Technical Committee CEN/TC 351

“Construction products: Assessment of release of dangerous substances”, the secretariat of which is held

by NEN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by May 2024 and conflicting national standards shall be

withdrawn at the latest by May 2024.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes CEN/TS 16637-1:2018.

The main changes compared to the previous edition are as follows:

— transfer of technical specification into a European Standard;

— addition of guidance on how to identify and handle unexpected test results and how to recognize

heterogeneous products (see Annex G);

— updating of normative and informative cross-references.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

This document deals with the determination and use of test methods for leaching of construction

products taking specific situations into account. It specifies preconditions under which leaching tests for

monolithic products and for granular products need to be selected.

EN 16637, Construction products: Assessment of release of dangerous substances, consists of the following

parts:

— Part 1: Guidance for the determination of leaching tests and additional testing steps;

— Part 2: Horizontal dynamic surface leaching test;

— Part 3: Horizontal up-flow percolation test.

Background information on characterization of leaching behaviour of construction products can be found

in Technical Reports provided by CEN/TC 351 (i.e. CEN/TR 16098 [1], CEN/TR 16496 [2]).

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

The European Standards EN 16637-1, EN 16637-2 and EN 16637-3 are developed to assess the release

of regulated dangerous substances (RDS) from construction products into soil, surface water and

groundwater in the framework of Mandate M/366. The horizontal test methods developed under the

Mandate M/366 are intended to be used to show compliance with notified regulations. The tests cover

the release of substances from construction products and in particular, those that are regulated in

notified regulations in one or more EU Member States.

EN 16637-1 specifies how the CEN Technical Product Committees and EOTA experts should determine

the appropriate leaching test for the determination of the release of RDS from a construction product into

soil, surface water and groundwater. EN 16637-1 gives background information for CEN Technical

Product Committees on the following aspects:

— description of the intended conditions of use of the construction product (e.g. above ground exposed

to the precipitation, or shielded from direct infiltration, in surface or groundwater) with respect to

the release of RDS into soil, surface water and groundwater;

— identification of main release mechanisms, and the appropriate leaching test for a given construction

product.

EN 16637-2 specifies a horizontal test to assess surface dependent release from monolithic, plate-like or

sheet-like construction products (tank test).

EN 16637-3 specifies a horizontal test to assess release from granular construction products.

The test methods can be used for both steps in the hierarchy (type testing (TT) and factory production

control (FPC)) and form the reference tests for the intended uses and conditions specified in EN 16637-1.

In this hierarchy of testing conditionally “indirect tests” can be used, but are not specified.

The release of substances upon contact with water results in a potential risk to the environment during

the intended use of construction products. The intent of these tests is to identify the leaching behaviour

of construction products and thereby allow assessments of the release of RDS from such products to soil,

surface water and groundwater under intended conditions of use in relation to CE marking and

assessment and verification of constancy of performance.

This document does not address impact assessment. However, since the test methods described in the

document may be used in the context of impact assessments and regulation based on impact assessments,

some guidance on this issue is provided in this document in Annex A (informative).

In addition to existing validation results, in 2011 CEN/TC 351 began an extensive research program on

robustness validation of the existing tank leaching and percolation tests. This was carried out by a

consortium of European experts on 20 construction products to unify differences from the protocols of

the different CEN Members and to check the influence of testing conditions on the test result (e.g.

temperature, flow rate, renewal scheme). The results ([3], [4]) of the research program confirmed the

robustness of the horizontal tests known from former works. Conclusions from the program have been

implemented into the Technical Specifications for the test methods. The performance of the leaching tests

regarding repeatability and reproducibility was deduced from a second validation step and respective

data ([5], [6]) are included in EN 16637-2 and EN 16637-3.

1 Scope

This document allows the identification of the appropriate leaching test method for the determination of

the release of RDS from construction products into soil, surface water and groundwater. This document

provides a stepwise procedure for the determination of appropriate release tests, including:

a) determination of the test method based on general product properties;

b) choice of the test method using specific product properties.

Furthermore, this document gives general guidance for CEN Technical Product Committees and

EOTA WGs on basic aspects (sampling, sample preparation and storage, eluate treatment, analysis of

eluates and documentation) to be specified in the relevant product standards or ETAs.

Metallic products and coatings on metallic products are not considered in the determination scheme of

this document since the test methods in EN 16637-2 (tank test) and EN 16637-3 (column test) are not

appropriate for the testing of these construction products due to a different release mechanism

(solubility control).

NOTE See Annex F.

It is assumed that intermittent contact with water (e.g. exposure to rainwater) is tested – by convention –

as permanent contact. For some coatings (e.g. some renders with organic binders according to

EN 15824 [7]) in intermittent contact with water, physical and chemical properties might be altered in

permanent contact with water. These products are not considered in the determination scheme of this

document since the test method in EN 16637-2 is not appropriate for the testing of these construction

products (in this case EN 16105 [8] might be an alternative method).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 16637-2:2023, Construction products: Assessment of release of dangerous substances — Part 2:

Horizontal dynamic surface leaching test

EN 16637-3:2023, Construction products: Assessment of release of dangerous substances — Part 3:

Horizontal up-flow percolation test

EN 16687:2023, Construction products: Assessment of release of dangerous substances — Terminology

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 16687:2023 and the following

apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1 Sampling and products

3.1.1

compacted granular product

granular product with a low permeability, due to very small pores between the particles

Note 1 to entry: Compacted granular products are usually tested by a test method for granular construction

products with low hydraulic conductivity, because the percolation test is not applicable due to the low permeability

of the products (e.g. fine aggregates that do not allow significant percolation of water through the solid material in

a regular percolation test). The compacted granular tank test may also apply to granular products to be placed in

stagnant water or in use scenarios with very low flow gradients

[SOURCE: EN 16687:2023, 3.1.2.2 — modified: brackets and second sentence added to Note to Entry]

3.1.2

composite sample

average sample

aggregated sample

two or more increments, mixed together in appropriate proportions, either discretely or continuously,

from which the mean value of a desired characteristic may be obtained

[SOURCE: EN 16687:2023, 3.2.1.1]

3.1.3

curing

hardening of freshly prepared mixtures under well-defined conditions (time, temperature, humidity, etc.)

specified in harmonized product standards

[SOURCE: EN 16687:2023, 3.2.2.6]

3.1.4

curing time

minimal time defined necessary for curing before a release/emission test can be executed to obtain test

results, that are relevant to in use conditions

[SOURCE: EN 16687:2023, 3.2.2.7 — modified: addition of “release/”]

3.1.5

granular product

product composed of solid particles with a particle size smaller than a specified size or grading

Note 1 to entry: Granular products are usually tested by a percolation test.

[SOURCE: EN 16687:2023, 3.1.2.1]

3.1.6

increment

portion of product collected by a single operation of a sampling device which will not be tested as a single

entity, but will be mixed or combined with other increments in a composite sample

[SOURCE: EN 16687:2023, 3.2.1.2]

3.1.7

laboratory sample

sample or sub-sample(s) sent to or received by the laboratory

Note 1 to entry: When the laboratory sample is further prepared by subdividing, cutting, sawing, coring, mixing,

drying, grinding, and curing or by combinations of these operations, the result is the test sample. When no

preparation of the laboratory sample is required, the laboratory sample is the test sample. A test portion is removed

from the test sample for the performance of the test/analysis or for the preparation of a test specimen.

Note 2 to entry: The laboratory sample is the final sample from the point of view of sample collection but it is the

initial sample from the point of view of the laboratory.

[SOURCE: EN 16687:2023, 3.2.2.1]

3.1.8

monolithic granular product

granular product with specific requirements on the grain size distribution to be tested in the dynamic

surface leaching test (DSLT)

[SOURCE: EN 16687:2023, 3.1.2.3]

3.1.9

monolithic product

product which has certain minimum dimensions and physical and mechanical properties that ensure its

integrity over a certain period of time in the considered intended conditions of use

Note 1 to entry: Monolithic products are usually tested by a dynamic surface leaching test.

[SOURCE: EN 16687:2023, 3.1.2.4]

3.1.10

plate-like product

product formed as a semi-rigid or rigid plate, which has certain minimum dimensions and physical and

mechanical properties that ensure its integrity over a certain period of time in the intended conditions of

use

Note 1 to entry: Plate-like products are usually tested by a dynamic surface leaching test.

[SOURCE: EN 16687:2023, 3.1.2.5]

3.1.11

population

totality of items under consideration

Note 1 to entry: See also the term “sub-population”.

[SOURCE: EN 16687:2023, 3.2.1.3]

3.1.12

sample

portion of material selected from a larger quantity of material

Note 1 to entry: The manner of selection of the sample should be described in a sampling plan.

Note 2 to entry: The term “sample” is often accompanied by a prefix (e.g. laboratory sample, test sample) specifying

the type of sample and/or the specific step in the sampling process to which the obtained material relates.

[SOURCE: EN 16687:2023, 3.2.1.5]

3.1.13

sampling plan

predetermined procedure for the selection, withdrawal, on-site pre-treatment — if necessary,

preservation and transportation of samples to be removed from a population

[SOURCE: EN 16687:2023, 3.2.1.6]

3.1.14

scale

minimum quantity (dimension, mass or volume) of the product for which test results are obtained

Note 1 to entry: Information on characteristics of the product, including emission and variations therein, for a

quantity of product smaller than the defined scale, is judged to be unimportant.

[SOURCE: EN 16687:2023, 3.2.1.7]

3.1.15

sheet-like product

product formed as a flexible or semi-flexible sheet, which has certain minimum dimensions and physical

and mechanical properties that ensure its integrity over a certain period of time in the considered

intended conditions of use

Note 1 to entry: Sheet-like products are usually tested by the dynamic surface leaching test.

[SOURCE: EN 16687:2023, 3.1.2.6]

3.1.16

sub-population

defined part of the population that is targeted for the purposes of sampling

EXAMPLE Consider a continuous production process that results in a specific product. The population for that

product is all the individual products produced between the moment the production process started (this may be

years ago) and the moment the production process ends (this may be years ahead). From the perspective of testing,

this definition does not provide a practical concept. Products produced in the past are no longer available for testing,

while products that might be produced in the (far) future are also not available. The term sub-population provides

a workable alternative, as the ‘start’ and ’end’ of the sub-population can be defined in a practical way. For the same

product, already in production for a number of years, the sub-population might be the production for a year, the

production for a month, or another definition that is practical.

Note 1 to entry: See also the term “population”.

[SOURCE: EN 16687:2023, 3.2.1.8]

3.1.17

test portion

analytical portion

amount of the test sample taken for testing/analysis purposes, usually of known dimension, mass or

volume

EXAMPLE A bag of aggregates is delivered to the laboratory (the laboratory sample). For test purposes a

certain amount of the aggregate is dried, the result is the test sample. Afterwards the column for a percolation test

is filled with a test portion of dried aggregate.

[SOURCE: EN 16687:2023, 3.2.2.3 — modified: EXAMPLE 2 deleted]

3.1.18

test sample

analytical sample

sample, prepared from the laboratory sample, from which test portions are removed for testing or for

analysis

[SOURCE: EN 16687:2023, 3.2.2.2]

3.1.19

test specimen

test portion specially prepared for emission/release/radiation testing in a test facility in order to

simulate the emission/release/radiation behaviour of the product under intended conditions of use

EXAMPLE Cement is used in construction as a constituent of concrete. For testing purposes, a test specimen of

concrete is prepared for the release test, using cement and adding additional constituents (like aggregates) with a

well-known leaching behaviour.

[SOURCE: EN 16687:2023, 3.2.2.4 — modified: EXAMPLE 1 for emission testing into indoor air has been

deleted]

3.2 Release laboratory testing

3.2.1

test method for granular construction products with low hydraulic conductivity

GLHC

release test method in which a granular construction product with low hydraulic conductivity is exposed

with one defined surface to a leachant renewed at subsequent time intervals

Note 1 to entry: See also the term “tank leaching test”.

[SOURCE: EN 16687:2023, 3.3.2.4]

3.2.2

dynamic surface leaching test

DSLT

release test method in which a test portion of a monolithic, sheet-like or plate-like product is immersed

in a leachant renewed at determined time intervals

Note 1 to entry: See also the term “tank leaching test”.

[SOURCE: EN 16687:2023, 3.3.2.3]

3.2.3

eluate

solution obtained from a leaching test

Note 1 to entry: See also the term “leachate”.

[SOURCE: EN 16687:2023, 3.3.2.8]

3.2.4

impact assessment

entire process of assessing the concentrations of regulated dangerous substances, or parameters, at the

point of compliance based on the leaching test results, the source term, (or, where applicable, the façade

emission function) and the modelling of environmental transport taking into account the intended

conditions of use

Note 1 to entry: The final step after the impact assessment is the comparison of the predicted environmental

concentrations with the environmental limit values at the point(s) of compliance, see “impact evaluation”.

Note 2 to entry: Impact assessment is not part of the standardization work in CEN/TC 351. The regulator is

responsible for the definition of relevant intended conditions of use, modelling of the environmental transport, the

point of compliance and the limit values at the point of compliance.

[SOURCE: EN 16687:2023, 3.3.2.23]

3.2.5

impact evaluation

assessment of emissions/immissions

comparison of (predicted) environmental concentrations of substances/parameters with regulatory

limit values (or other assessment criteria) in soil, surface water or groundwater at a point of compliance

as a result of release from construction products

Note 1 to entry: Such predictions are based on the results of release tests which are translated to intended

conditions of use by modelling the source term and the environmental transport.

Note 2 to entry: The translation of test results to environmental concentrations is not part of standardization work

in CEN/TC 351.

[SOURCE: EN 16687:2023, 3.3.2.22]

3.2.6

intended use

intended use of the construction product as defined in the applicable harmonized standard or European

assessment document

3.2.7

intended conditions of use

conditions that a product may undergo during service life and that influence its release/emission

behaviour

Note 1 to entry: These conditions are expressed in parameters such as temperature, amount of water during

exposure, wetting/drying; intended conditions of use may vary for instance as a function of time, location,

orientation, geographical location, etc. For simplification, intended conditions of use are transferred into release

scenarios for test purposes.

[SOURCE: EN 16687:2023, 3.3.1.16 — modified: “release/” added]

3.2.8

leachant

liquid that is brought into contact with the test portion in the leaching procedure

Note 1 to entry: Usually demineralized water is used as leachant for laboratory leaching tests.

[SOURCE: EN 16687:2023, 3.3.2.7]

3.2.9

leaching behaviour

release and change with time in release from a solid product in contact with a leachant as a function of

major release controlling factors

Note 1 to entry: Such factors are diffusion, pH, L/S-ratio or time.

[SOURCE: EN 16687:2023, 3.3.2.10]

3.2.10

liquid to surface area-ratio

L/A

ratio between the volume of liquid (L) which in a given step of the test is in contact with the exposed

surface area (A) of the test portion

Note 1 to entry: L/A is expressed in l/m .

[SOURCE: EN 16687:2023, 3.3.2.14 — modified: deleted]

3.2.11

liquid to solid-ratio

L/S

ratio between the total volume of liquid (L) percolated through the solid product and

of solid product (S) packed into the column

Note 1 to entry: L/S is expressed in l/kg dry matter.

[SOURCE: EN 16687:2023, 3.3.2.15]

3.2.12

modelling of environmental transport

modelling of environmental path

transport term

modelling of immissions

theoretical estimation of the transport of substances in the environment under specific intended

conditions of use based on test results or the source term for release of these substances

[SOURCE: EN 16687:2023, 3.3.2.23]

3.2.13

percolation test

PT

column test

release test method to determine the release of substances from a granular construction product packed

in a column with a leachant percolating through it

[SOURCE: EN 16687:2023, 3.3.2.5]

3.2.14

point of compliance

POC

point in an environmental medium where substance concentrations/parameters should comply with

regulatory limit values for soil, groundwater and/or surface water at a certain distance from the source

[SOURCE: EN 16687:2023, 3.3.2.26]

3.2.15

regulated dangerous substances

RDS

in the context of the CPR dangerous/hazardous substances, ions and radioactive substances that may

present a danger for man or the environment during normal use of construction products when installed

in works and for which at least one European Member State has notified a law, regulation or

administrative provision or the European Union has a Community provision

[SOURCE: EN 16687:2023, 3.1.1.6]

3.2.16

release

emission

liberation of chemical substances (e.g. non-volatile organic compounds, heavy metals, salts)

from a construction product into soil, surface water or groundwater or into the leachant of a test facility

Note 1 to entry: Release to soil, surface water and groundwater may be expressed in terms of area related release

(tank leaching test, e.g. mg/m ) or in terms of mass related release (percolation test, e.g. mg/kg).

Note 2 to entry: The terms “emission” and “release” have fundamentally the same meaning. However, it is often a

tradition to use the term “emission” when describing liberation of chemical substances or radiation into air and to

use the term “release” when describing the liberation of chemical substances into soil or water.

[SOURCE: EN 16687:2023, 3.3.2.16]

3.2.17

release mechanism

physical-chemical processes that control the release of substances from a solid construction product into

a leachant

Note 1 to entry: In the case of monolithic products, the main release mechanisms for substances are diffusion of

substances, dissolution of substances, initial surface wash-off of substances and/or dissolution of the matrix. In case

of granular products the main release mechanisms are washout and solubility. Additional factors like pH or DOC

also have an influence on the mechanism of the release.

Note 2 to entry: Under appropriate conditions the release mechanism of every substance can be determined using

the results of the release test (tank leaching test, percolation test). Determination of the release mechanism is

relevant for modelling of the source term and so for determination of the effects on soil and water over a time

period.

[SOURCE: EN 16687:2023, 3.3.2.18]

3.2.18

release scenario

emission scenario

model description of the release from construction products into their immediate

soil and water environments and of the chemical, physical and geometrical parameters that influence this

release and which forms the basis for defining the test methods as a function of the products and its

intended use

Note 1 to entry: For soil, groundwater and surface water, two release scenarios have been defined for

impermeable, low permeable and permeable construction products. Release scenario should not be confused with

modelling of environmental transport.

[SOURCE: EN 16687:2023, 3.3.2.21]

3.2.19

source term

calculated, long term release or release function of a substance from a product related to intended

conditions of use, which is used for modelling of environmental transport

[SOURCE: EN 16687:2023, 3.3.2.24]

3.2.20

tank leaching test

tank test

leaching test where a test portion/test specimen is immersed in a leachant and the leachant is renewed

at determined time intervals

Note 1 to entry: Currently CEN/TC 351 has developed two versions of the tank leaching test: the dynamic surface

leaching test (DSLT) and the test method for granular construction products with low hydraulic conductivity

(GLHC).

[SOURCE: EN 16687:2023, 3.3.2.2]

4 Symbols and abbreviations

4.1 Symbols

For the purposes of this document, the following symbols apply.

A geometric area of the test portion exposed surface of test piece(s), in m ;

L volume of liquid in contact with the test portion, in l;

S amount of solid product packed into the column, in kg.

4.2 Abbreviations

For the purposes of this document, the following abbreviations apply.

DSLT dynamic surface leaching test

EOTA European organization for technical assessment

ETA European technical assessment

FPC factory production control

GLHC test method for granular products with low hydraulic conductivity

hEN harmonized European Standard

POC point of compliance

PT percolation test

PTD product type determination

RDS regulated dangerous substances

TT type testing

5 Determination of the appropriate release test method

5.1 Principles and general review of the test methods

The user of this document shall determine the appropriate test methods for the respective product(s) in

applying the stepwise procedure given in this document. Furthermore, the CEN Product Technical

Committees or the EOTA WGs shall determine the appropriate test methods for the respective product(s)

in close cooperation with CEN/TC 351 applying the stepwise procedure given in this document.

To determine the release of RDS from construction products into soil, surface water and groundwater

generally two different test set-ups are applicable:

a) The dynamic surface leaching test (DSLT) according to EN 16637-2.

EN 16637-2 specifies a method to determine as a function of time the release of substances from

a monolithic, plate-like or sheet-like product or from granular construction products with low

hydraulic conductivity into a leachant in contact with its surface. A test portion of the product is

placed in a reactor/leaching vessel and the exposed surface is completely submerged in a leachant.

The leachant is introduced in the reactor up to a given volume of liquid to surface area ratio

(L/A ratio), at a given temperature. The concentration of the relevant RDS is analysed in the

individual fractions of the eluate. Annex A describes a test set-up for granular products with low

hydraulic conductivity.

b) The percolation test (PT) according to EN 16637-3.

Typically, granular construction products are subjected to percolation with water as a function of

liquid to solid ratio (L/S ratio) under specified percolation conditions. The construction products are

leached under hydraulically dynamic conditions. The eluates are collected in different fractions and

the concentrations of the relevant RDS are analysed in the individual fractions. The method is a once-

through column leaching test and the test results establish the distinction between different release

patterns, for instance wash-out and release under the influence of interaction with the matrix, when

approaching local equilibrium between construction product and leachant (for inorganic

substances).

The point of departure for test determination is that the test method reflects the presumed dominant

release mechanism in practice. The basic distinction is made on whether the construction product in its

intended use is expected to show release mainly through diffusion or percolation. The determination

scheme (Figure 1) is set up in such a way that it will be possible to test a given product “as it is produced”.

To ensure that the test takes into account the appropriate substance release mechanism, the choice to

test a product “as it is produced” may require the use of specific test conditions and product properties.

The dominant release mechanism in practice is linked to general product properties allowing the choice

of the appropriate test method. The product properties are easy to determine characteristics such as

composition, shape, size and durability/stability of the construction product, as it appears during

intended use. These general properties of a product lead to one of two “release scenarios” as explained

in the informative Annex A. The release scenario is a description of the dominant release mechanisms

expected in practice for a certain product category with the same general properties. Each release

scenario is associated with one test method:

c) Release scenario I (impermeable or low permeable “monolithic”, “sheet-like” or “plate-like” non-

metallic products; mainly diffusion controlled release): Dynamic surface leaching test according to

EN 16637-2 (standard procedure or method for granular construction products with low hydraulic

conductivity according to EN 16637-2:2023, Annex A for a few products with specific properties);

d) Release scenario II (permeable “granular” products; release mainly controlled by equilibrium-like

conditions and percolation): Percolation test according to EN 16637-3.

5.2 Product properties and test conditions for the determination of the relevant test

method

Monolithic products:

a) Monolithic products to be tested according to EN 16637-2 are:

3 3

1) products with all dimensions > 40 mm or a volume > 64 000 mm (64 cm );

2 2

2) flat products (sheet-like, plate-like) with an area > 10 000 mm (100 cm) and one

dimension < 40 mm (4 cm);

3) monolithic granular products fulfilling the requirements of Table 1. The dimensions of the test

pieces shall be in line with 5.2, a), 1). Armour stone and railway ballast may be tested according

to EN 16637-3.

Table 1 — Requirements on monolithic granular products

Sieve size

Percentage passing by

mass

mm

63 ≤ 100

40 ≤ 75

22,4 ≤ 7

b) For tiles that are produced in smaller entities that do not fulfil the size requirements for testing as a

monolithic or plate-like product but are intended to be used as larger, combined entities that do fulfil

the criteria, the test can be carried out on larger samples prepared from the smaller entities in

accordance with intended use.

Examples of construction products (impermeable products or products of low permeability) to be

tested according to EN 16637-2 are:

1) facade (e.g. bricks, concrete, treated wood, glazed products, coated products);

2) roof (e.g. flexible roofing covers);

3) bound paving materials (e.g. concrete, paving stone, asphalt, concrete slabs);

4) foundation (e.g. concrete, blocks);

5) coastal protection (e.g. armour stone or large concrete blocks withstanding wave action);

6) railway ballast;

7) glass tiles.

Monolithic products draining water in their intended use:

c) Although products draining water have a high internal surface exposed to draining water, the

situation may be rather comparable to that of a monolithic product. The surface area in contact with

the water phase is much larger than the outer surface and can hardly be determined. These products

shall be tested in a tank test (DSLT) according to EN 16637-2 after preparing test specimens by

cutting, coring or moulding. The external geometric surface of the specimen shall be used for the

calculation of the release.

Examples for these types of products are:

1) porous asphalt (EN 13108-7) used in road construction and in water works;

2) drainage tiles.

Example of granular products to be tested according to EN 16637-3 are:

d) natural, manufactured or recycled aggregate (e.g. slag, recycled concrete aggregate) for road

shoulders or road-base;

e) unbound aggregate for e.g. parking lots, forest tracks;

f) crushed clay masonry for road construction.

Granular construction products with low hydraulic conductivity:

g) In cases where fine aggregates do not allow significant percolation of water through the solid material

in a regular percolation test, the method for granular products with low hydraulic

conductivity (GLHC) according to EN 16637-2:2023, Annex A, shall be used.

NOTE 1 The method for granular products with low hydraulic conductivity according to EN 16637-2:2023,

Annex A, is a special mode of the dynamic surface leaching test.

NOTE 2 Previous studies have indicated that the point at which a regular percolation test becomes

−8

infeasible for these products is at hydraulic conducti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...