EN 12320:2021

(Main)Building hardware - Padlocks and padlock fittings - Requirements and test methods

Building hardware - Padlocks and padlock fittings - Requirements and test methods

This document applies to mechanical padlocks and padlock fittings used on buildings and general use and specifies the test methods to be used.

This document specifies performance and other requirements for strength, security, durability, performance, and corrosion resistance of padlocks. It establishes one category of use, two categories of durability, six categories for corrosion resistance and six grades for security based on performance tests that simulate attack.

Limited manual attack testing is included in this document because the machine testing does not replicate all known manual attacks.

Baubeschläge - Hangschlösser und Hangschlossbeschläge - Anforderungen und Prüfverfahren

Dieses Dokument gilt für mechanische Hangschlösser und Hangschlossbeschläge zur Verwendung in Gebäuden und für den allgemeinen Gebrauch und legt die anzuwendenden Prüfverfahren fest.

Dieses Dokument legt Anforderungen an die Leistungsfähigkeit und weitere Anforderungen an Festigkeit, Sicherheit, Dauerhaftigkeit, Leistung und Korrosionsbeständigkeit von Hangschlössern fest. Sie legt eine Gebrauchsklasse, zwei Klassen für die Dauerhaftigkeit, sechs Klassen für die Korrosionsbeständigkeit und sechs Klassen für die Sicherheit fest. Letztere basieren auf Leistungsprüfungen, in denen Angriffe simuliert werden.

In diesem Dokument ist eine begrenzte manuelle Angriffsprüfung enthalten, da die maschinelle Prüfung nicht alle bekannten Möglichkeiten eines manuellen Angriffs nachbildet.

Quincaillerie pour le bâtiment - Cadenas et porte-cadenas - Prescriptions et méthodes d'essai

Le présent document s’applique aux cadenas mécaniques et aux porte-cadenas utilisés dans le bâtiment et pour une utilisation générale et il spécifie les méthodes d’essai à utiliser.

Le présent document spécifie les performances et autres exigences relatives à la résistance, à la sécurité des biens, l’endurance, au fonctionnement et à la résistance à la corrosion des cadenas. Il définit une catégorie d’utilisation, deux catégories d’endurance, six catégories pour la résistance à la corrosion et six grades pour la sécurité des biens.

Des essais limités d'attaque manuelle sont inclus dans le présent document du fait que la machine d’essai ne reproduit pas toutes les attaques manuelles connues.

Stavbno okovje - Obešanke in dodatki za obešanke - Zahteve in preskusne metode

Ta dokument obravnava mehanske obešanke in dodatke za obešanke za uporabo na stavbah in splošno uporabo ter določa preskusne metode zanje.

Ta dokument določa lastnosti in druge zahteve glede trdnosti, varnosti, trajnosti, zmogljivosti in odpornosti obešank na korozijo. Določa eno kategorijo uporabe, dve kategoriji trajnosti, šest kategorij odpornosti na korozijo in šest varnostnih stopenj na podlagi preskusov delovanja s simulacijo napada.

V dokument je vključeno omejeno ročno preskušanje napada, ker strojno preskušanje ne ponovi vseh znanih ročnih napadov.

General Information

- Status

- Published

- Publication Date

- 30-Nov-2021

- Withdrawal Date

- 29-Jun-2022

- Technical Committee

- CEN/TC 33 - Doors, windows, shutters and building hardware

- Drafting Committee

- CEN/TC 33/WG 4 - Building hardware

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 01-Dec-2021

- Due Date

- 07-Jun-2022

- Completion Date

- 01-Dec-2021

Relations

- Replaces

EN 12320:2012 - Building hardware - Padlocks and padlock fittings - Requirements and test methods - Effective Date

- 08-Dec-2021

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 12320:2021 - published by CEN - specifies requirements and test methods for mechanical padlocks and padlock fittings used on buildings and for general use. The standard defines objective performance criteria for strength, security, durability, functionality and corrosion resistance, and sets classification rules that allow manufacturers and specifiers to compare products consistently across Europe. EN 12320:2021 replaces the 2012 edition and includes normative annexes for sampling and test rig illustrations, plus an informative manufacturer’s declaration of compliance.

Key Topics and Requirements

- Scope: Applies to mechanical padlocks and padlock fittings (excluding cables and chains) and specifies the test methods to be used.

- Classification structure: Products are classified by four digits:

- 1st digit - category of use

- 2nd digit - durability (Grade 0 or Grade 1 - 10 000 cycles)

- 3rd digit - corrosion resistance (6 grades, aligned with EN 1670)

- 4th digit - security grade (6 grades based on attack-resistance tests)

- Security tests: Performance-based tests simulate attacks and include machine and limited manual-attack testing. Key test areas:

- Minimum number of effective key differs

- Non-interpassing of adjacent keys

- Force and torque resistance on cylinder/locking mechanism

- Pull, twist and cutting resistance of shackle and staple

- Impact resistance at low temperature

- Resistance to drilling and sawing

- Manual tool attack resistance (timed)

- Durability and corrosion: Durability test requires 10 000 operating cycles for Grade 1; corrosion categories follow EN 1670 salt-spray test durations (up to 480 h).

- Marking and documentation: The standard defines marking and requires manufacturers to provide drawings and, optionally, a declaration of compliance (Annex C).

Applications and Who Uses EN 12320:2021

- Manufacturers - design, test and certify padlocks to meet market expectations and claim security/durability grades.

- Testing laboratories - perform reproducible tests (force, torque, impact, corrosion, cutting, drilling, sawing, manual attack).

- Architects, specifiers and procurement officers - select padlocks and fittings to meet performance requirements for buildings, doors, gates and external fittings.

- Facility managers and security consultants - choose products with appropriate corrosion resistance and security grades for site conditions (outdoor exposure, temperature, threat level).

- Regulatory bodies and installers - ensure installed hardware complies with European standardization for building hardware.

Related Standards

- EN 1670:2007 - corrosion resistance test methods and requirements

- EN 1303:2015 - cylinders for locks (relevant for key/cylinder aspects)

- EN 10025‑2 and various EN ISO fastener standards - referenced for component materials and fasteners

Keywords: EN 12320:2021, padlocks, padlock fittings, test methods, corrosion resistance, security grades, durability, building hardware, CEN.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 12320:2021 is a standard published by the European Committee for Standardization (CEN). Its full title is "Building hardware - Padlocks and padlock fittings - Requirements and test methods". This standard covers: This document applies to mechanical padlocks and padlock fittings used on buildings and general use and specifies the test methods to be used. This document specifies performance and other requirements for strength, security, durability, performance, and corrosion resistance of padlocks. It establishes one category of use, two categories of durability, six categories for corrosion resistance and six grades for security based on performance tests that simulate attack. Limited manual attack testing is included in this document because the machine testing does not replicate all known manual attacks.

This document applies to mechanical padlocks and padlock fittings used on buildings and general use and specifies the test methods to be used. This document specifies performance and other requirements for strength, security, durability, performance, and corrosion resistance of padlocks. It establishes one category of use, two categories of durability, six categories for corrosion resistance and six grades for security based on performance tests that simulate attack. Limited manual attack testing is included in this document because the machine testing does not replicate all known manual attacks.

EN 12320:2021 is classified under the following ICS (International Classification for Standards) categories: 91.190 - Building accessories. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12320:2021 has the following relationships with other standards: It is inter standard links to EN 12320:2012, EN 1303:2015, EN ISO 10666:1999, EN ISO 15483:1999, EN ISO 15481:1999, EN 1670:2007, EN 10025-2:2019, EN ISO 15480:2019, EN ISO 15482:1999, EN 17610:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12320:2021 is associated with the following European legislation: EU Directives/Regulations: 305/2011. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12320:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2022

Nadomešča:

SIST EN 12320:2013

Stavbno okovje - Obešanke in dodatki za obešanke - Zahteve in preskusne metode

Building hardware - Padlocks and padlock fittings - Requirements and test methods

Baubeschläge - Hangschlösser und Hangschlossbeschläge - Anforderungen und

Prüfverfahren

Quincaillerie pour le bâtiment - Cadenas et porte-cadenas - Prescriptions et méthodes

d'essai

Ta slovenski standard je istoveten z: EN 12320:2021

ICS:

91.190 Stavbna oprema Building accessories

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12320

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2021

EUROPÄISCHE NORM

ICS 91.190 Supersedes EN 12320:2012

English Version

Building hardware - Padlocks and padlock fittings -

Requirements and test methods

Quincaillerie pour le bâtiment - Cadenas et porte- Baubeschläge - Hangschlösser und

cadenas - Prescriptions et méthodes d'essai Hangschlossbeschläge - Anforderungen und

Prüfverfahren

This European Standard was approved by CEN on 21 September 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12320:2021 E

worldwide for CEN national Members.

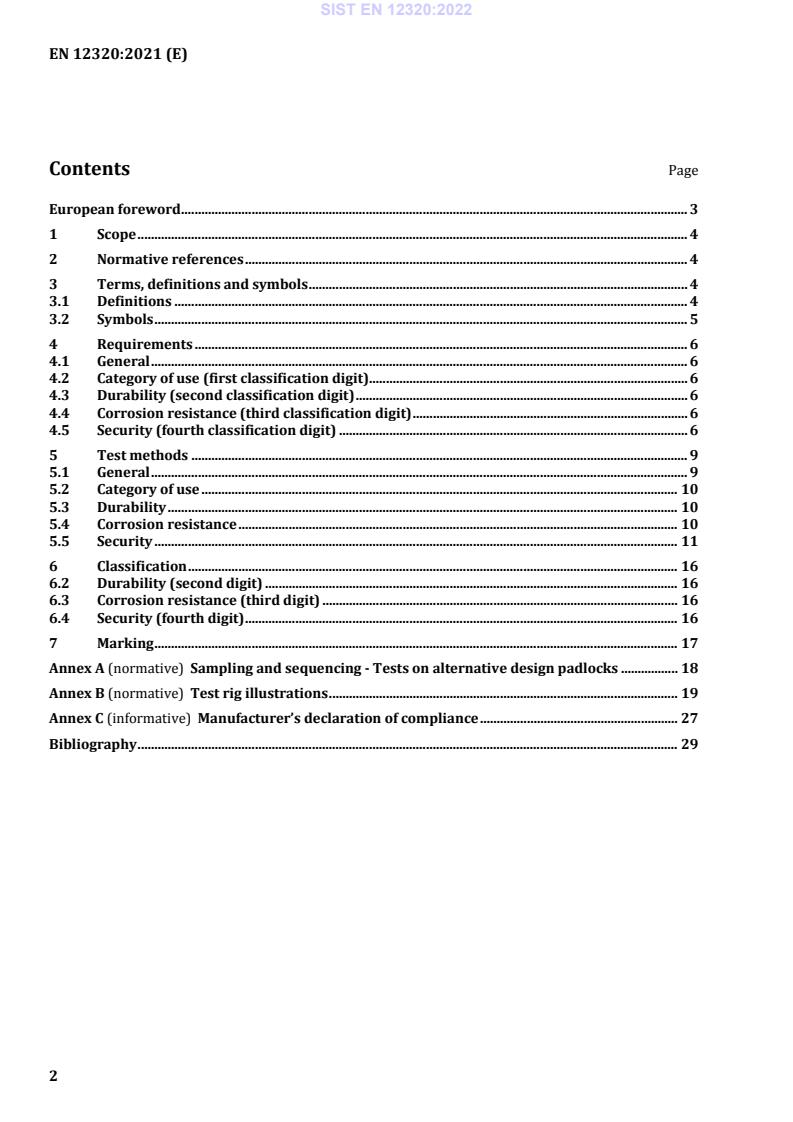

Contents Page

European foreword . 3

1 Scope . 4

2 Normative references . 4

3 Terms, definitions and symbols . 4

3.1 Definitions . 4

3.2 Symbols . 5

4 Requirements . 6

4.1 General . 6

4.2 Category of use (first classification digit) . 6

4.3 Durability (second classification digit) . 6

4.4 Corrosion resistance (third classification digit) . 6

4.5 Security (fourth classification digit) . 6

5 Test methods . 9

5.1 General . 9

5.2 Category of use . 10

5.3 Durability . 10

5.4 Corrosion resistance . 10

5.5 Security . 11

6 Classification . 16

6.2 Durability (second digit) . 16

6.3 Corrosion resistance (third digit) . 16

6.4 Security (fourth digit) . 16

7 Marking . 17

Annex A (normative) Sampling and sequencing - Tests on alternative design padlocks . 18

Annex B (normative) Test rig illustrations . 19

Annex C (informative) Manufacturer’s declaration of compliance . 27

Bibliography . 29

European foreword

This document (EN 12320:2021) has been prepared by Technical Committee CEN/TC 33 “Doors,

windows, shutters, building hardware and curtain walling”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2022, and conflicting national standards shall be

withdrawn at the latest by June 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 12320:2012.

This document is one of a series of European Standards dedicated to building hardware products.

Annexes A and B are normative.

In comparison with the previous edition, the following significant technical modifications have been

made:

— Annex C, Manufacturer’s declaration of compliance.

Test methods are specified in detail to ensure reproducibility at any testing establishment within Europe,

and acceptance criteria are defined objectively to ensure consistency of assessment.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

1 Scope

This document applies to mechanical padlocks and padlock fittings used on buildings and general use and

specifies the test methods to be used.

This document specifies performance and other requirements for strength, security, durability,

performance, and corrosion resistance of padlocks. It establishes one category of use, two categories of

durability, six categories for corrosion resistance and six grades for security based on performance tests

that simulate attack.

Limited manual attack testing is included in this document because the machine testing does not replicate

all known manual attacks.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1670:2007, Building hardware - Corrosion resistance - Requirements and test methods

EN 10025-2:2019, Hot rolled products of structural steels - Part 2: Technical delivery conditions for non-

alloy structural steels

EN 1303:2015, Building hardware - Cylinders for locks - Requirements and test methods

EN ISO 10666, Drilling screws with tapping screw thread - Mechanical and functional properties

(ISO 10666)

EN ISO 15480, Fasteners - Hexagon washer head drilling screws with tapping screw thread (ISO 15480)

EN ISO 15481, Cross recessed pan head drilling screws with tapping screw thread (ISO 15481)

EN ISO 15482, Cross recessed countersunk head drilling screws with tapping screw thread (ISO 15482)

EN ISO 15483, Cross recessed raised countersunk head drilling screws with tapping screw thread

(ISO 15483)

3 Terms, definitions and symbols

3.1 Definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1.1

cam

part of the key and cylinder mechanism which operates the locking mechanism

3.1.2

effective key differ

difference between key mechanism of similar design, achieved only by the movable detainer, which

allows each key mechanism to be operated only by its own key

Note 1 to entry: The number of effective differs is equal to the number of theoretical differs after deduction of the

differs suppressed by the manufacturer due to technical constraints and those differs suppressed in accordance

with the restraints of 4.5.1.

3.1.3

hasp

part of the padlock fitting which goes over the staple

3.1.4

key mechanism

part of the mechanism which recognises a correct key

3.1.5

locking mechanism

part of the mechanism which is operated by the key mechanism to lock/unlock the padlock

3.1.6

padlock

independent locking device comprising a body, a key mechanism, a locking mechanism and a shackle

3.1.7

padlock fitting

device fitted to the object which is to be locked with a padlock excluding cables and chains

3.1.8

shackle

part of the padlock which passes through and secures the padlock fitting

3.1.9

staple

part of the padlock fitting through which the padlock shackle is passed

3.2 Symbols

For the purposes of this document, the symbols described in Table 1 apply.

Table 1

Symbol Unit Definition

d mm Diameter of shackle

F1 kN Push/pull force on cylinder plug/locking mechanism

F2 kN Pull force on shackle or staple

F3 kN Cutting force on shackle or staple

F4 kN Maximum possible push/pull force on cylinder plug/locking

mechanism

h mm Height through which weight is dropped (impact test)

Symbol Unit Definition

M1 Nm Torque on key to test for interpassing

M2 Nm Torque on cylinder plug/locking mechanism

M3 Nm Twisting torque on shackle or staple

n Minimum number of effective key differs

t min Drilling/sawing resistance time

T °C Temperature of product for impact testing

m g Drop mass for impact test

4 Requirements

4.1 General

The structure of this clause reflects the classification as given in Clause 6.

4.2 Category of use (first classification digit)

Grade 1: according to requirements in 5.2.

4.3 Durability (second classification digit)

Grade 0: no requirements

Grade 1: 10 000 cycles

When tested in accordance with 5.3, it shall be possible to operate the padlock.

The padlock fittings are excluded from the durability test.

4.4 Corrosion resistance (third classification digit)

Products shall be classified in accordance with EN 1670.

— Grade 0: no defined corrosion resistance

+1h/-0 h

— Grade 1: 24h ;

+1h/-0 h

— Grade 2: 48h ;

+1h/-0 h

— Grade 3: 96h ;

+1h/-0 h

— Grade 4: 240h ;

+1h/-0 h

— Grade 5: 480h .

When tested in accordance with 5.4, it shall be possible to operate the padlock.

This corrosion test shall apply to the functionality only (not appearance).

4.5 Security (fourth classification digit)

4.5.1 General

4.5.1.1 Some of the requirements can be confirmed with a certificate and test report according to

EN 1303.

4.5.1.2 In grades 4, 5 and 6 it shall not be possible to remove the key until the shackle is deadlocked in

the closed position, key retained in open position.

4.5.2 Minimum number of effective key differs

Padlocks shall have a minimum of n effective key differs (Table 2).

For a mechanical padlock the maximum number of steps on the same level shall be 60 %, maximum two

adjacent and a minimum of three levels.

4.5.3 Non-interpassing of keys with just one interval effective differ

When tested in accordance with 5.5.3, it shall not be possible to operate the padlock with keys differing

from the correct key by one interval, i.e. the next closest key. The next closest key shall be defined by the

manufacturer according to its key coding system.

4.5.4 Resistance to force on cylinder plug or locking mechanism

When tested in accordance with 5.5.4, the cylinder plug or the locking mechanism shall resist a force F1

(Table 2).

4.5.5 Resistance to torque on cylinder plug or locking mechanism

When tested in accordance with 5.5.5, the cylinder plug or the locking mechanism shall resist a torque

M2 (Table 2).

4.5.6 Resistance to pulling of shackle or staple

When tested in accordance with 5.5.6, the shackle and the staple shall each resist a force F2 (Table 2).

4.5.7 Resistance to twisting of shackle or staple

When tested in accordance with 5.5.7, the shackle and the staple shall each resist a torque M3 (Table 2).

4.5.8 Resistance to cutting of shackle or staple

When tested in accordance with 5.5.8, the shackle and the staple shall each resist a force F3 (Table 2).

4.5.9 Resistance to impact on padlock body, shackle and staple at low temperature

When tested in accordance with 5.5.9, the padlock body, the shackle and the staple cooled to temperature

T, shall each resist the blows from the steel pole with the mass m and from the height h (Table 2).

4.5.10 Resistance to drilling of padlock body, shackle and staple

When tested in accordance with 5.5.10, the padlock body, the shackle and the staple shall each resist

drilling for a time t (Table 2).

4.5.11 Resistance to sawing of padlock body, shackle and staple

When tested in accordance with 5.5.11, the padlock body, the shackle and the staple shall each resist

sawing for a time t (Table 2).

4.5.12 Manual attack resistance

When tested in accordance with 5.5.12, the padlock shall resist attacks with manual tools for a time t (see

Table 2).

Table 2 — Security requirements

Requirement Requirement Test Test Grade Unit

clause method parameter

number clause

1 2 3 4 5 6

number

4.5.1.2 Key retained in open 5.5.1 yes/no - - - yes yes yes

position

4.5.2 Minimum number of 5.5.2 n 300 1 000 2 500 5 000 10 20 -

effective key differs 000 000

4.5.3 Non-interpassing of 5.5.3 M1 1 1 1,5 1,5 1,5 1,5 Nm

keys with just one

interval differ -

Torque on key

4.5.4 Resistance to force 5.5.4 F1 - - 4 5 10 15 kN

on cylinder plug or

locking mechanism

4.5.5 Resistance to torque 5.5.5 M2 - 2,5 5 15 20 30 Nm

on cylinder plug or

locking mechanism

4.5.6 Resistance to pulling 5.5.6 F2 3 5 15 30 70 100 kN

of shackle or staple

4.5.7 Resistance to 5.5.7 M3 40 100 200 600 1 200 2 500 Nm

twisting of shackle

or staple

4.5.8 Resistance to cutting 5.5.8 F3 6 15 25 45 70 100 kN

of shackle or staple

4.5.9 Resistance to impact 5.5.9 T - - - 20 - 20 - 40 - 40 °C

on padlock body,

m - - 1 250 3 050 6 550 7 150 g

shackle and staple at

h - - 800 1 000 1 400 1 500 mm

low temperature

4.5.10 Resistance to drilling 5.5.10 t - - - 2 4 8 min

of padlock body,

shackle and staple

4.5.11 Resistance to sawing 5.5.11 t - - - 2 4 8 min

of padlock body,

shackle and staple

4.5.12 Manual attack 5.5.12 t - - - 3 5 10 min

resistance

toolsets

5 Test methods

5.1 General

The manufacturer will provide assembly and component drawings to enable the tester to carry out a

preliminary product assessment prior to testing.

The padlock shall be tested in the locked position with the key removed.

It is not necessary for the correct key to operate the padlock after testing.

Padlocks/padlock fittings and their original keys shall be taken at random and submitted for each test.

In the event of one of the original two samples failing the test, the padlocks/padlock fittings shall be

deemed to have failed and a further two shall be tested, both of which shall pass the test.

If the parts to be tested are inaccessible when the product is correctly mounted in accordance with the

manufacturer's instructions, the product shall be considered to have passed that test.

A padlock shall be deemed to have been opened when a bar, of equal cross-section to that of its shackle,

can be released. Ability to open can be checked at any time during the test by manipulation with a

screwdriver or similar implement (maximum length 200 mm) for a period of 5 s max.

5.1.1 Tolerances

Unless otherwise stated, the following tolerances shall apply:

— force ±2 %;

— torque ±2 %;

— mass/weight ±2 %;

— distance ±2 %;

— time ±5 s;

— temperature ±2 °C.

Unless otherwise stated, the forces shall be applied progressively and without shock to the required load

within 1 min.

5.1.2 Test environment

The ambient temperature of the test environment shall be controlled throughout the test from 15 °C to

30 °C unless otherwise stated.

5.1.3 Test tools

Specification of steel for cutting and impact tests as required in 5.5.8.1 and 5.5.9 shall be structural steel

E335 defined in EN 10025-2:2019, heat treated to have a hardness of 60 HRC to 64 HRC.

5.1.4 Sampling

Test sampling and sequencing shall be in accordance with Annex A.

5.2 Category of use

5.2.1 Operational unlocking test

Mount the padlock in a suitable holding fixture and apply a torque to a fully inserted correct key using a

torquemeter, as shown in Figure B.1. At no point between locked and unlocked shall the torque exceed

1 Nm.

5.2.2 Key strength

Requirements for key strength shall meet the requirements of EN 1303:2015, 5.2.

5.3 Durability

The durability test shall be carried out using suitable apparatus that allows the full operational locking

and unlocking sequence of the padlock to include the release of the shackle. (It is not necessary for the

shackle to be turned). Repeat the sequence at a speed of five to twenty cycles per minute

During the operational cycle the key may remain partially inserted in the locking mechanism but shall

have cleared all movable detainers.

The key used for the durability test can be cleaned and the padlock shall be lubricated in accordance with

the manufacturer’s instructions at the start of the test and after each 5000 cycles using the lubricant

recommended by the manufacturer.

After completing the required number of cycles, the operation of the padlock shall be tested using a new

original key. The rotation shall be achieved with a maximum torque of 1,5 Nm.

If the padlock should jam and cease to operate during the test, then provided the padlock continues to

operate in the proper manner when released, the test shall be allowed to continue.

No durability requirements for padlock fittings.

5.4 Corrosion resistance

5.4.1 Preparation

The padlock is locked on a plastic bar and placed in the chamber for salt spray test. The padlock without

a key is oriented in the manner that it would assume to be in use.

Padlock shall be exposed to a neutral salt spray test in accordance with EN 1670:2007.

— Grade 0: no defined corrosion resistance

+1h/-0 h

— Grade 1: 24h ;

+1h/-0 h

— Grade 2: 48h ;

+1h/-0 h

— Grade 3: 96h ;

+1h/-0 h

— Grade 4: 240h ;

+1h/-0 h

— Grade 5: 480h .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...