EN 12547:1999+A1:2009

(Main)Centrifuges - Common safety requirements

Centrifuges - Common safety requirements

1.1 This European Standard applies to centrifuges aiming at separation of liquid/liquid/solid/solid or at least two of these substances. It gives requirements to minimise the risks caused by the hazards specified in 1.2.

The Standard deals with the significant hazards associated with the operation of centrifuges.

1.2 The Standard gives requirements for minimising the risks caused by the following hazards:

- mechanical hazards common to all types of centrifuges, except those specified in 1.3;

- ergonomical hazards;

- electrical hazards.

The standard also covers requirements for noise measurements.

1.3 Types of centrifuges and hazards excluded

1.3.1 Types of centrifuges excluded:

- centrifuges with a kinetic energy of rotation less than 200 Joule;

- centrifuges designated by their manufacturers for domestic use;

- centrifuges designated by their manufacturers as laboratory centrifuges according to EN 61010-2-020, including Amendment 1;

- centrifuges designated by their manufacturers for forming, i.e. centrifugal hot metal casting machines.

1.3.2 Hazards excluded:

- thermal hazards;

- hazards specific to processing radioactive products;

- hazards specific to microbiological processing - including viral and parasitic hazards;

- hazards from processing corrosive and/or erosive materials;

- hazards from processes involving flammable or explosive substances;

- hazards caused by leakage of hazardous substances;

- hazards caused by unsuitable hygienic design for applications involving food products;

- other application specific hazards which must be dealt with, either according to application specific standards (e.g. prEN 12505), or EN 292.

1.4 This standard applies to centrifuges which are manufactured after the date of issue of this standard.

Zentrifugen - Allgemeine Sicherheitsanforderungen

1.1 Diese europäische Norm gilt für Zentrifugen, die der Trennung von Flüssig- / Flüssig- / Fest- / Festoder

mindestens zwei dieser Stoffe dienen. Sie legt die Anforderungen zur Minimierung von Risiken fest, die

aus den in 1.2 aufgeführten Gefährdungen entstehen.

Diese Norm behandelt signifikante, mit dem Betrieb von Zentrifugen verbundene Gefährdungen.

1.2 Diese Norm legt die Anforderungen zur Minimierung der durch die folgenden Gefährdungen entstehenden

Risiken fest:

- Allen Zentrifugenarten gemeinsame mechanische Gefährdungen, ausgenommen die unter 1.3

aufgeführten Gefährdungen;

- ergonomische Gefährdungen;

- elektrische Gefährdungen.

Die Norm umfasst ebenfalls Anforderungen hinsichtlich der Geräuschmessung.

1.3 Vom Anwendungsbereich ausgenommene Zentrifugenarten und Gefährdungen:

1.3.1 Ausgenommene Zentrifugenarten

- Zentrifugen mit einer kinetischen Rotationsenergie von weniger als 200 Joule;

- Zentrifugen, die vom Hersteller zur Anwendung im Haushalt bestimmt sind;

- Zentrifugen die vom Hersteller gemäß EN 61010-2-020, einschließlich Anhang 1, als Laborzentrifugen

bezeichnet sind;

- Zentrifugen die vom Hersteller zum Formen bestimmt sind, z. B. Schleudergussmaschinen.

1.3.2 Ausgenommene Gefährdungen

- Thermische Gefährdungen;

- Spezielle Gefährdungen bei der Verarbeitung radioaktiver Produkte;

- Spezielle Gefährdungen mikrobiologischer Einsatzfälle – einschließlich Gefährdungen durch Viren und

Parasiten;

- Gefährdungen aus der Verarbeitung von korrosiven und/oder erosiven Stoffen;

- Gefährdungen durch Verfahren, bei denen brennbare oder explosive Substanzen eingesetzt werden;

- Gefährdungen durch Leckage gefährlicher Substanzen;

- Gefährdungen durch ungeeignete hygienische Konstruktion für Anwendungen bei der Lebensmittelherstellung;

- Spezielle Gefährdungen, entsprechend anderen Anwendungen, die entweder entsprechend

anwendungsspezifischen Normen (z. B. EN 12505) oder EN 292 berücksichtigt werden müsse

Centrifugeuses - Prescriptions communes de sécurité

1.1 La présente norme européenne s'applique aux centrifugeuses destinées à la séparation de plusieurs phases liquides, d'une phase solide contenue dans une ou plusieurs phases liquides ou d'au moins deux de ces substances. Elle donne des prescriptions pour minimiser les risques dus aux phénomènes dangereux spécifiés en 1.2.

La présente norme traite des phénomènes dangereux significatifs liés à l'utilisation des centrifugeuses.

1.2 La présente norme donne des prescriptions pour minimiser les risques causés par les phénomènes dangereux suivants :

- phénomènes dangereux mécaniques communs à tous les types de centrifugeuses, excepté ceux spécifiés en 1.3 ;

- phénomènes dangereux dus au non-respect des principes ergonomiques ;

- phénomènes dangereux électriques.

La présente norme précise également les prescriptions concernant les mesures du bruit.

1.3 Types de centrifugeuses et de phénomènes dangereux exclus

1.3.1 Types de centrifugeuses exclus :

- centrifugeuses dont l'énergie cinétique de rotation est inférieure à 200 joules ;

- centrifugeuses conçues par leur constructeur comme machines à usage domestique ;

- centrifugeuses conçues par leur constructeur comme des centrifugeuses de laboratoire selon l'EN 61010-2-020, amendement 1 compris ;

- centrifugeuses conçues par leur constructeur, comme machines de mise en forme de métaux ou d'alliages par centrifugation.

1.3.2 Phénomènes dangereux exclus :

- phénomènes dangereux thermiques ;

- phénomènes dangereux liés au bruit ;

- phénomènes dangereux liés au traitement de produits radioactifs ;

- phénomènes dangereux liés à des traitements microbiologiques, y compris les phénomènes dangereux liés aux virus et aux parasites ;

- phénomènes dangereux liés au traitement de matériaux corrosifs et/ou érosifs ;

- phénomènes dangereux provenant de traitements mettant en œuvre des substances inflammables ou explosives ;

- phénomènes dangereux dus à la fuite de substances dangereuses ;

Centrifuge - Splošne varnostne zahteve

General Information

- Status

- Withdrawn

- Publication Date

- 24-Mar-2009

- Withdrawal Date

- 20-Jan-2026

- Technical Committee

- CEN/TC 313 - Centrifuges - Safety requirements

- Drafting Committee

- CEN/TC 313 - Centrifuges - Safety requirements

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 15-Oct-2014

- Completion Date

- 28-Jan-2026

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 13-Nov-2010

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Eurofins Food Testing Global

Global leader in food, environment, and pharmaceutical product testing.

Intertek Bangladesh

Intertek certification and testing services in Bangladesh.

Intertek Textile Testing

Global textile testing and certification.

Sponsored listings

Frequently Asked Questions

EN 12547:1999+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Centrifuges - Common safety requirements". This standard covers: 1.1 This European Standard applies to centrifuges aiming at separation of liquid/liquid/solid/solid or at least two of these substances. It gives requirements to minimise the risks caused by the hazards specified in 1.2. The Standard deals with the significant hazards associated with the operation of centrifuges. 1.2 The Standard gives requirements for minimising the risks caused by the following hazards: - mechanical hazards common to all types of centrifuges, except those specified in 1.3; - ergonomical hazards; - electrical hazards. The standard also covers requirements for noise measurements. 1.3 Types of centrifuges and hazards excluded 1.3.1 Types of centrifuges excluded: - centrifuges with a kinetic energy of rotation less than 200 Joule; - centrifuges designated by their manufacturers for domestic use; - centrifuges designated by their manufacturers as laboratory centrifuges according to EN 61010-2-020, including Amendment 1; - centrifuges designated by their manufacturers for forming, i.e. centrifugal hot metal casting machines. 1.3.2 Hazards excluded: - thermal hazards; - hazards specific to processing radioactive products; - hazards specific to microbiological processing - including viral and parasitic hazards; - hazards from processing corrosive and/or erosive materials; - hazards from processes involving flammable or explosive substances; - hazards caused by leakage of hazardous substances; - hazards caused by unsuitable hygienic design for applications involving food products; - other application specific hazards which must be dealt with, either according to application specific standards (e.g. prEN 12505), or EN 292. 1.4 This standard applies to centrifuges which are manufactured after the date of issue of this standard.

1.1 This European Standard applies to centrifuges aiming at separation of liquid/liquid/solid/solid or at least two of these substances. It gives requirements to minimise the risks caused by the hazards specified in 1.2. The Standard deals with the significant hazards associated with the operation of centrifuges. 1.2 The Standard gives requirements for minimising the risks caused by the following hazards: - mechanical hazards common to all types of centrifuges, except those specified in 1.3; - ergonomical hazards; - electrical hazards. The standard also covers requirements for noise measurements. 1.3 Types of centrifuges and hazards excluded 1.3.1 Types of centrifuges excluded: - centrifuges with a kinetic energy of rotation less than 200 Joule; - centrifuges designated by their manufacturers for domestic use; - centrifuges designated by their manufacturers as laboratory centrifuges according to EN 61010-2-020, including Amendment 1; - centrifuges designated by their manufacturers for forming, i.e. centrifugal hot metal casting machines. 1.3.2 Hazards excluded: - thermal hazards; - hazards specific to processing radioactive products; - hazards specific to microbiological processing - including viral and parasitic hazards; - hazards from processing corrosive and/or erosive materials; - hazards from processes involving flammable or explosive substances; - hazards caused by leakage of hazardous substances; - hazards caused by unsuitable hygienic design for applications involving food products; - other application specific hazards which must be dealt with, either according to application specific standards (e.g. prEN 12505), or EN 292. 1.4 This standard applies to centrifuges which are manufactured after the date of issue of this standard.

EN 12547:1999+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 71.040.20 - Laboratory ware and related apparatus. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12547:1999+A1:2009 has the following relationships with other standards: It is inter standard links to EN 12547:1999, EN 12547:2014, EN ISO 3746:1995, EN 294:1992, EN 1050:1996, EN 954-1:1996, EN 894-2:1997, EN ISO 11688-1:1998, EN ISO 3744:1995, EN 894-3:2000, EN 292-1:1991, EN 292-2:1991, EN 792-3:2000, EN ISO 4871:1996, ENV 1402-2:1997. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12547:1999+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12547:1999+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Centrifuge - Splošne varnostne zahteveZentrifugen - Allgemeine SicherheitsanforderungenCentrifugeuses - Prescriptions communes de sécuritéCentrifuges - Common safety requirements71.120.99Druga oprema za kemijsko industrijoOther equipment for the chemical industryICS:Ta slovenski standard je istoveten z:EN 12547:1999+A1:2009SIST EN 12547:2000+A1:2009en,fr01-maj-2009SIST EN 12547:2000+A1:2009SLOVENSKI

STANDARDSIST EN 12547:20001DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12547:1999+A1

March 2009 ICS 71.040.20 Supersedes EN 12547:1999English Version

Centrifuges - Common safety requirements

Centrifugeuses - Prescriptions communes de sécurité

Zentrifugen - Allgemeine Sicherheitsanforderungen This European Standard was approved by CEN on 6 November 1998 and includes Amendment 1 approved by CEN on 22 February 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12547:1999+A1:2009: ESIST EN 12547:2000+A1:2009

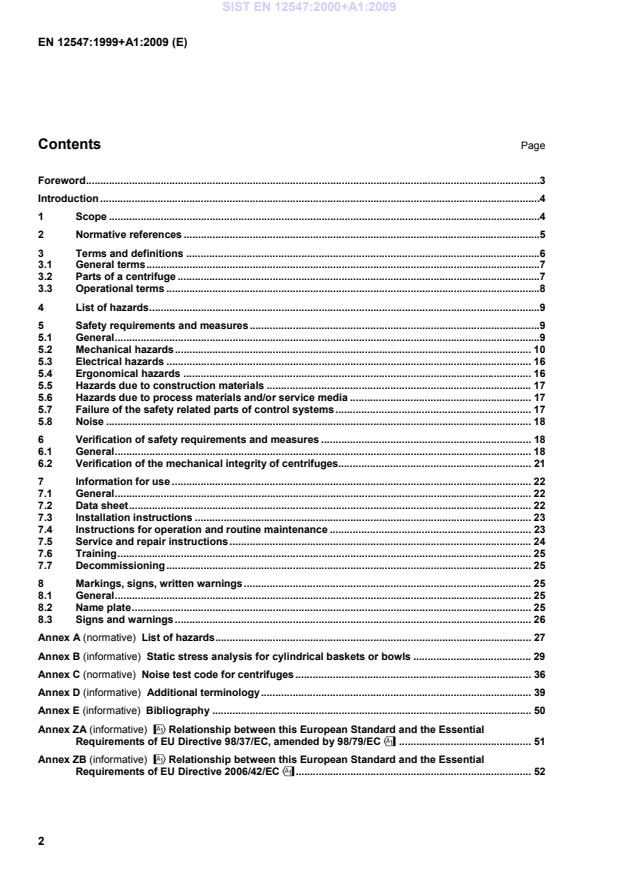

List of hazards . 27 Annex B (informative)

Static stress analysis for cylindrical baskets or bowls . 29 Annex C (normative)

Noise test code for centrifuges . 36 Annex D (informative)

Additional terminology . 39 Annex E (informative)

Bibliography . 50 Annex ZA (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC, amended by 98/79/EC" . 51 Annex ZB (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC" . 52

EN 729-3:1994, Quality requirements for welding - Fusion welding of metallic materials – Part 3: Standard quality requirements EN 894-2:1997, Ergonomics - Requirements for the design of displays and control actuators. Part 2: Displays. prEN 894-3:1992, Ergonomics - Requirements for the design of displays and control actuators. Part 3: Control actuators. EN 953:1997, Safety of machinery - General requirements for the design and construction of guards (fixed and moveable) EN 954-1:1996, Safety of machinery - Safety related parts of control systems – Part 1: General principles for design prEN 1005-2:1993, Safety of machinery - Human physical performance – Part 2: Manual handling of objects associated to machinery EN 1037:1995, Safety of machinery - Prevention of unexpected start-up EN 1050:1996, Safety of machinery - Principles for risk assessment SIST EN 12547:2000+A1:2009

3.2.10 critical components parts of a centrifuge that cause significant hazardous situations to develop when they fail or rupture 3.2.11 special lifting tools tools tailored to the lifting and other handling requirements of a centrifuge or specific components of the centrifuge 3.3 Operational terms 3.3.1 process material substances fed to a centrifuge for separation and other purposes, for example washing, purging or drying the load 3.3.2 filling mass total mass of process materials in the drum at any instant 3.3.3 maximum filling mass filling mass determined by the limiting features of the centrifuge - for example either drum strength or linear dimensions 3.3.4 cleaning in place (CIP) cleaning of equipment by impingement or circulation of flowing chemical solutions and water rinses into, onto and over surfaces in equipment or systems without dismantling, using equipment designed and installed for that purpose 3.3.5 kinetic energy of total rotating system total kinetic energy of the rotor together with the filling mass at operating speed 3.3.6 maximum/minimum (allowable) temperature maximum allowable or minimum allowable temperature of the process material declared by the manufacturer 3.3.7 normal operation operating condition of the centrifuge, determined by specification and design, considering feed and wash rates, load, vibration, rotational speeds, etc 3.3.8 operating speed of a centrifuge rotational speed measured in revolutions per unit time at which the rotor is expected to revolve either continuously or at each part of a multispeed programme 3.3.9 purging removal of unwanted material from a centrifuge by means of a flushing media 3.3.10 throughput actual feed rate in the case of centrifuges with a continuous process material flow, or; SIST EN 12547:2000+A1:2009

b) there is no risk of a rotor rupture. To support the latter case centrifuge rotors shall be manufactured from suitable materials with verified properties considering the operating environment (e.g. temperature, corrosion and erosion) and steady and/or cyclic loading: Case 1 - Steady loading The rotor shall be designed according to procedures specified by the manufacturer. The manufacturer shall ensure a safety margin against general yielding and rupture, taking into account the steady loading due to the rotation of the rotor mass and the maximum filling mass.

The strength of cylindrical baskets or bowls may be determined using the method of analysis specified in annex B provided that the loading, geometry and material of construction satisfies the requirements stated in the annex. For stress analysis of more complex geometry’s an elastic-plastic FEM (Finite Element Method) or BEM (Boundary Element Method) calculation is considered to be the most suitable. lf a drive mechanism is employed which would drive the centrifuge at a speed higher than its maximum permissible speed, such as a frequency converter and a hydraulic drive, a speed control and an overspeed prevention device to prevent the rotor from exceeding the maximum permitted speed shall be provided, see 5.7. Case 2 - Cyclic loading The rotor shall be designed with a safety margin against fatigue failure. Stresses which shall be considered in a fatigue evaluation are: bending stresses in horizontal rotors caused by the weight of the rotor; bending stresses in rotors caused by external forces such as loads from belt drives etc; stresses caused by cyclic loading of the centrifuge (for example related to intermittent loading and discharging of process materials); stresses caused by unbalanced forces of rotors, in particular in the case of dual rotor systems; All other cyclic loads acting on the rotor, known by the manufacturer, shall be considered. The operating load acting on a rotor as a result of the start/stop cycle of a centrifuge shall be considered as a cyclic load. The load and expected number of cycles shall be assessed to determine if this will lead to fatigue failure during the foreseeable life of the centrifuge. Stress raisers such as sharp edges, perforations, rough surfaces (scores, grinding cracks etc.) and bores shall be avoided in regions subjected to high cyclic stresses. All peak stresses at perforations or discontinuities shall be considered in the evaluation of the safety margin against fatigue failure. The difference in the condition of the actual rotor material and the test material shall be considered in the evaluation of the safety margin against fatigue failure. The differences in actual service and test conditions SIST EN 12547:2000+A1:2009

Figure 1 — Example of indication on crates SIST EN 12547:2000+A1:2009

Dangerous run down timeb

Guard requirement

Access during normal operation e.g. to feed or remove product at stop (4.1.3 of EN 292-2:1991)

Yes Guard, requiring tool for opening, with interlocking device, or: interlocking guard with guard locking if frequent access is needed

No

Interlocking guard

Maintenance or repair, not during normal operationa

(4.1.2 and 4.1.4 of EN 292-2:1991)

No

Fixed guard c

a Provided that these openings are clearly defined in the instructions for use, and that warnings are applied. b See definition in 3.3.15. c Fixed guards in compliance with EN 953. The fixing element shall remain attached to the guard or machine when the guard is removed. " SIST EN 12547:2000+A1:2009

The selection of control and indicating equipment shall take into account the environment in which the equipment will operate. The protection class of the equipment shall be according to the requirements in EN 60529. The following choices for centrifuges as permitted by EN 60204-1 shall be followed (see also 5.4 and 5.7): Control gear shall be protected to a minimum of IP54 of EN 60529. Control devices shall be protected to a minimum of IP55 of EN 60529, but all safety related control devices installed in locations, which are flushed with water or subjected to water and/or other liquids during operation of the centrifuge shall be protected to a minimum of IP56 of EN 60529. !Centrifuges shall have sufficient immunity from electromagnetic disturbances to enable them to operate safely as intended and not fail to danger when exposed to the levels and types of disturbances intended by the manufacturer.

The manufacturer of the machines shall design, install and wire the equipment and sub-assemblies taking into account the instructions of the suppliers of these sub-assemblies." The use of the Enquiry Form in Annex B of EN 60204-1 is strongly recommended. 5.3.2 Specific Hazards Access to electrical equipment associated with the drive motor shall be prevented or prohibited until the rotor is known to be stopped. 5.3.3 Movement and vibration A centrifuge or centrifuge part may move relative to the foundation due to out of balance. Centrifuges which are rigidly mounted, and centrifuges which are set-up on vibration isolators, are subject to relative movements. This relative movement shall be considered when electrical cables are fitted to: sensors and actuators; electric drives; other electrical equipment. Cables shall be selected and installed so that they can withstand predictable movement and/or vibration. See 15.4.3 of EN 60204-1:1997, for connection and table C.5 of EN 60204-1:1997 for classification of conductors 5.4 Ergonomical hazards The manufacturer shall provide the centrifuge with additional equipment to avoid personal manual lifting of heavy or awkward loads (see 5.2.5), or if this cannot be avoided, the manufacturer shall provide instructions for use (see clause 7) which will enable all the essential actions to be performed safely. The manufacturer shall also provide:

procedures associated with maintenance operations; SIST EN 12547:2000+A1:2009

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...