EN 15430-1:2007+A1:2011

(Main)Winter and road service area maintenance equipments - Data acquisition and transmission - Part 1: In vehicle data acquisition

Winter and road service area maintenance equipments - Data acquisition and transmission - Part 1: In vehicle data acquisition

This European Standard specifies a standardized protocol for downloading data from the equipment control box to an in vehicle board computer to ensure interchangeability between a vehicle and different equipments that the same vehicle can carry.

It specifies the interface connection as well as variables, records and reports which permit standardized protocol to cover applications with the greatest possible variety of equipments for performing winter maintenance and road service area maintenance.

Winterdienst- und Straßenbetriebsdienstausstattung - Datenerfassung und -übertragung - Teil 1: Datenerfassung im Fahrzeug

Dieses Europäische Norm legt ein genormtes Protokoll für das Übertragen von Betriebsdaten von der Anbau-Gerätesteuerung (Steuergerät) zu einem im Fahrzeug befindlichen Bord-Computer fest, um die Kompatibilität zwischen dem Fahrzeug und den verschiedenen Anbau-Geräten, die an diesem Fahrzeug betrieben werden können, sicherzustellen. Diese Norm legt sowohl Schnittstellen (Anschlüsse) fest wie auch Variablen, Datensätze und Meldungen, die es in dem genormten Protokoll ermöglichen, eine größtmögliche Vielfalt bei Anwendungen von Anbau-Geräten beim Straßenbetriebs- und Winterdienst abzudecken.

Matériels de viabilité hivernale et d'entretien des dépendances routières - Acquisition et transmission des données - Partie 1 : Acquisition des données véhiculaires

Cette Norme européenne spécifie un protocole normalisé pour le téléchargement de données à partir du boîtier de commande d'un matériel vers un ordinateur embarqué afin d'assurer l'interchangeabilité entre un véhicule et les différents matériels que ce véhicule peut embarquer.

Elle spécifie l'interface de connexion, ainsi que les variables, les enregistrements et les rapports qui permettent au protocole normalisé de couvrir des applications avec des matériels les plus variés pour réaliser la viabilité hivernale et l'entretien des dépendances routières.

Oprema za vzdrževalna dela zimske službe in službe za vzdrževanje cest - Zajem in prenos podatkov - 1. del: Zajem podatkov v vozilu

Ta evropski standard določa standardiziran protokol za snemanje podatkov iz škatle za nadzor opreme do računalnika, vgrajenega v vozilu, za zagotovitev zamenljivosti med vozilom in različnimi opremami, ki jih lahko ista vozila prenašajo.

Določa vmesniško povezavo in spremenljivke, zapise in poročila, ki dovoljujejo standardiziran protokol z uporabo največje mogoče raznolikosti opreme za izvajanje zimske službe in službe za vzdrževanje cest.

General Information

- Status

- Withdrawn

- Publication Date

- 01-Feb-2011

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 337 - Winter maintenance and road service area maintenance equipment

- Drafting Committee

- CEN/TC 337/WG 3 - Interface between tools and vehicle

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 05-Aug-2015

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 04-Dec-2010

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Sponsored listings

Frequently Asked Questions

EN 15430-1:2007+A1:2011 is a standard published by the European Committee for Standardization (CEN). Its full title is "Winter and road service area maintenance equipments - Data acquisition and transmission - Part 1: In vehicle data acquisition". This standard covers: This European Standard specifies a standardized protocol for downloading data from the equipment control box to an in vehicle board computer to ensure interchangeability between a vehicle and different equipments that the same vehicle can carry. It specifies the interface connection as well as variables, records and reports which permit standardized protocol to cover applications with the greatest possible variety of equipments for performing winter maintenance and road service area maintenance.

This European Standard specifies a standardized protocol for downloading data from the equipment control box to an in vehicle board computer to ensure interchangeability between a vehicle and different equipments that the same vehicle can carry. It specifies the interface connection as well as variables, records and reports which permit standardized protocol to cover applications with the greatest possible variety of equipments for performing winter maintenance and road service area maintenance.

EN 15430-1:2007+A1:2011 is classified under the following ICS (International Classification for Standards) categories: 35.240.60 - IT applications in transport; 43.160 - Special purpose vehicles. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15430-1:2007+A1:2011 has the following relationships with other standards: It is inter standard links to EN 15430-1:2007/FprA1, EN 15430-1:2007, EN 15430-1:2015, CEN/TS 15430-2:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15430-1:2007+A1:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Oprema za vzdrževalna dela zimske službe in službe za vzdrževanje cest - Zajem in prenos podatkov - 1. del: Zajem podatkov v voziluWinterdienst- und Straßenbetriebsdienstausstattung - Datenerfassung und -übertragung - Teil 1: Datenerfassung im FahrzeugMatériels de viabilité hivernale et d'entretien des dépendances routières - Acquisition et transmission des données - Partie 1 : Acquisition des données véhiculairesWinter and road service area maintenance equipments - Data acquisition and transmission - Part 1: In vehicle data acquisition43.160Vozila za posebne nameneSpecial purpose vehicles35.240.60Uporabniške rešitve IT v transportu in trgoviniIT applications in transport and tradeICS:Ta slovenski standard je istoveten z:EN 15430-1:2007+A1:2011SIST EN 15430-1:2008+A1:2011en,fr,de01-maj-2011SIST EN 15430-1:2008+A1:2011SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15430-1:2007+A1

February 2011 ICS 35.240.60; 43.160 Supersedes EN 15430-1:2007English Version

Winter and road service area maintenance equipments - Data acquisition and transmission - Part 1: In vehicle data acquisition Matériels de viabilité hivernale et d'entretien des dépendances routières - Acquisition et transmission des données - Partie 1: Acquisition des données véhiculaires

Winterdienst- und Straßenbetriebsdienstausstattung - Datenerfassung und -übertragung - Teil 1: Datenerfassung im Fahrzeug This European Standard was approved by CEN on 21 October 2007 and includes Amendment 1 approved by CEN on 27 December 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15430-1:2007+A1:2011: ESIST EN 15430-1:2008+A1:2011

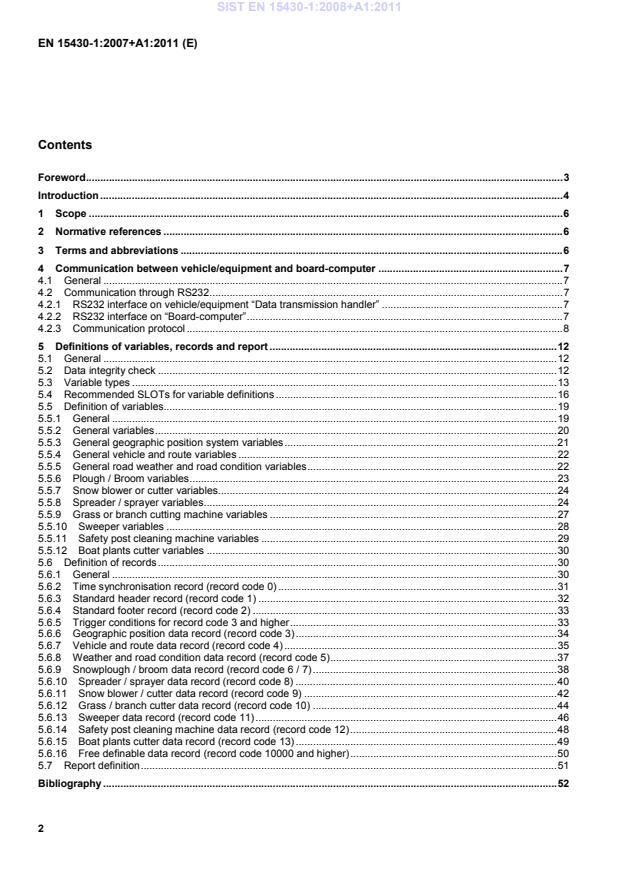

2 ContentsForeword . 3Introduction . 41Scope . 62Normative references . 63Terms and abbreviations . 64Communication between vehicle/equipment and board-computer . 74.1General . 74.2Communication through RS232 . 74.2.1RS232 interface on vehicle/equipment “Data transmission handler” . 74.2.2RS232 interface on “Board-computer” . 74.2.3Communication protocol . 85Definitions of variables, records and report . 125.1General . 125.2Data integrity check . 125.3Variable types . 135.4Recommended SLOTs for variable definitions . 165.5Definition of variables. 195.5.1General . 195.5.2General variables . 205.5.3General geographic position system variables . 215.5.4General vehicle and route variables . 225.5.5General road weather and road condition variables . 225.5.6Plough / Broom variables . 235.5.7Snow blower or cutter variables . 245.5.8Spreader / sprayer variables . 245.5.9Grass or branch cutting machine variables . 275.5.10Sweeper variables . 285.5.11Safety post cleaning machine variables . 295.5.12Boat plants cutter variables . 305.6Definition of records . 305.6.1General . 305.6.2Time synchronisation record (record code 0) . 315.6.3Standard header record (record code 1) . 325.6.4Standard footer record (record code 2) . 335.6.5Trigger conditions for record code 3 and higher . 335.6.6Geographic position data record (record code 3) . 345.6.7Vehicle and route data record (record code 4) . 355.6.8Weather and road condition data record (record code 5) . 375.6.9Snowplough / broom data record (record code 6 / 7) . 385.6.10Spreader / sprayer data record (record code 8) . 405.6.11Snow blower / cutter data record (record code 9) . 425.6.12Grass / branch cutter data record (record code 10) . 445.6.13Sweeper data record (record code 11) . 465.6.14Safety post cleaning machine data record (record code 12) . 485.6.15Boat plants cutter data record (record code 13) . 495.6.16Free definable data record (record code 10000 and higher) . 505.7Report definition . 51Bibliography . 52 SIST EN 15430-1:2008+A1:2011

Foreword This document (EN 15430-1:2007+A1:2011) has been prepared by CEN/TC 337/WG 3 "Interface between tools and vehicle", the secretariat of which is held by UNI-CUNA, under the direction of Technical Committee

CEN/TC 337 "Winter maintenance and road service area maintenance equipment", the secretariat of which is held by AFNOR. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by August 2011, and conflicting national standards shall be withdrawn at the latest by August 2011. Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights. This document includes Amendment 1, approved by CEN on 2010-12-27. This document supersedes EN 15430-1:2007. The start and finish of text introduced or altered by amendment is indicated in the text by tags

!". According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom. SIST EN 15430-1:2008+A1:2011

4 Introduction This protocol is meant to be used for data acquisition in fleet management applications in the field of municipal vehicles. The purpose of the protocol is to define how data of a vehicle or equipment is generated, stored and transferred to a board-computer system in the vehicle and from the board-computer to the software application in the office (refer to Figure 1). On the equipment or vehicle the data is generated by a “Data generator”. This data is stored, if present, into a buffer-memory. The “Data transmission handler” will send the data present in the buffer-memory to the “Board-computer” or “Data Acquisition System”. The buffer-memory is there to ensure that data does not get lost in case there is no transmission possible. The size or type of the buffer is not defined in this proposal. If there is no buffer or the buffer is too small to store new data, data will get lost. To synchronise time-stamps of the vehicle/equipment with the Board-computer, a special record for time synchronisation is defined. In this part the data acquisition and communication from vehicle/equipment to the Board-computer is defined.

Figure 1 – Architecture

In general, the data is a semi-colon (“;”) separated ASCII text for separation of record codes and values of variables. CR+LF is used for separation of records (one record is one line of text).

Figure 2 – Diagram of possible connections SIST EN 15430-1:2008+A1:2011

6 1 Scope This European Standard specifies a standardized protocol for downloading data from the equipment control box to an in-vehicle board computer to ensure interchangeability between a vehicle and different equipments that the same vehicle can carry. It specifies the interface connection as well as variables, records and reports which permit standardized protocol to cover applications with the greatest possible variety of equipments for performing winter maintenance and road service area maintenance. 2 Normative references !The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies." !ISO/IEC 8859-1", Information technology — 8-bit single-byte coded graphic character sets — Part 1: Latin alphabet No. 1 NMEA 0183, Interface Standard TIA-232-F, Interface between data terminal equipment and data circuit-terminating equipment employing serial binary data interchange (RS232) SAE J1939/71, Recommended practice for serial control and communications vehicle network — Vehicle application layer 3 Terms and abbreviations ACK Acknowledge (ASCII control code 06h) ASCII American national Standard Code for Information Interchange Bps Bits per second CRC-16 Cyclic Redundancy Code with 16 bits !CRC-32

Cyclic Redundancy Code with 32 bits" CR Carriage Return (ASCII control code 0Dh) EOT End Of Transmission (ASCII control code 04h) h Number before h is in hexadecimal notation IEEE Institute of Electrical and Electronics Engineers LF Line Feed (ASCII control code 0Ah) NAK Negative acknowledge (ASCII control code 15h) SOH Start Of Header (ASCII control code 01h) TBD To Be Defined ↵ CR + LF (carriage return + line feed) SIST EN 15430-1:2008+A1:2011

“Data transmission handler”

has to supply a RS232 interface , if in the future other standard interfaces will be defined

(e.g. CAN BUS, USB .) a compliant EN 15430 future “Data transmission handler” will have to supply at least one of the communication standard until that time is defined. 4.2 Communication through RS232 4.2.1 RS232 interface on vehicle/equipment “Data transmission handler” • Connector: SUB-D 9p female o Pin 2 = Transmit Data

o Pin 3 = Receive Data o Pin 5 = Signal Ground • Baud rate: 1 200 Bps.115 200 Bps, default 9 600 Bps. Rate can be programmable (optional) Remark: the baud rate must be sufficient for a worst case amount of data to be send with retries. • Data bits: 8 • Stop bits: 1 • Parity: No • Data format: according to !ISO/IEC 8859-1" (ASCII) • Handshaking: by software with ACK, NAK ASCII control codes, refer to 4.2.3 • Transmission control by SOH and EOT ASCII control codes, refer to 4.2.3 • Data validity check: CRC-16/CCITT, refer to 4.2.3

4.2.2 RS232 interface on “Board-computer” • Connector: SUB-D 9p male o Pin 2 = Receive Data o Pin 3 = Transmit Data o Pin 5 = Signal Ground • Baud rate: 1 200 Bps.115 200 Bps, default 9 600 Bps. Rate must be programmable or automatically detected (autobaud) • Data bits: 8 • Stop bits: 1 SIST EN 15430-1:2008+A1:2011

8 • Parity: No • Data format: according to !ISO/IEC 8859-1" (ASCII) • Handshaking: by software with ACK, NAK ASCII control codes, refer to 4.2.3 • Transmission control by SOH and EOT ASCII control codes, refer to 4.2.3 • Data validity check: CRC-16/CCITT, refer to 4.2.3

4.2.3 Communication protocol ! Transmission of a record. In this definition a message to be communicated consists of one record. Records are terminated by CR+LF (a record is one line of text). In general, a message is sent by the sender (e.g. the “Data transmission handler” of a spreader) and received by the receiver (e.g. the Board-computer). After power up, communication is always started by the vehicle/equipment “Data transmission handler” sending its first message (this is the time synchronisation record). Refer to Figure 4 for flow charts of the sender and receiver algorithms. The receiver will check the validity of a message by testing if the CRC-16 value corresponds to the data in the message received. If the data is valid, the receiver sends an ACK. The sender can now send a new message. If the data is invalid, the receiver sends a NAK. Then, the sender will try to send the same message again for a maximum of 2 times. If the message still fails, the message is considered to be lost. Preferably, a notification is given to the user (operator) that data has been lost by the sender and/or the receiver. NOTE 1 The receiver sends an ACK or a NAK as a single character without other data. The ACK or NAK refers to the latest message sent by the sender. To avoid record synchronisation problems between sender and receiver, the sender must ignore any ACK or NAK received during the transmission of a message until the last byte is sent (EOT character). Also, the receiver is not allowed to send an ACK or NAK during the reception of a message until the last byte is received (EOT character). NOTE 2 Numerical values have to be transmitted with ASCII characters in decimal code. Calculation of the CRC-16 value. The CRC value is calculated according to the CCITT definition. The CRC value is calculated over all record bytes, starting with the record code, ending with CR+LF. The polynomial used is x16 + x12 + x5 + x0 = 11021h (i.e. XOR mask 1021 h) and initial value FFFFh. NOTE 3 The value is written in ASCII characters in hexadecimal code with capitals (0.9,A.F). Calculation of the CRC-32 value. The CRC-32 value is calculated according to the CCITT definition. The CRC-32 value is calculated over all record bytes, starting with the record code, ending with CR+LF. The polynomial used is x32 + x26 + x23 + x22 + x16 + x12 + x11 + x10 + x8 + x7 + x5 + x4 + x2 + x + 1

NOTE 4 The value is written in ASCII characters in hexadecimal code with capitals (0.9,A.F). Sender without receiving options for handshaking. For old vehicle/equipment “Data transmission handlers”, it may be impossible to receive data. In this case the sender cannot respond to an ACK or NAK, i.e. there is no handshaking feature. Hence, the sender will send a new message. This may cause in the result that data gets lost, e.g. in case the Board-computer was not started up yet SIST EN 15430-1:2008+A1:2011

10 ASCII characters in hexadecimal notation: 01 31 3B 31 30 3B 31 36 30 32 30 34 38 3B 30 34 36 31 30 32 31 3B 35 3B 41 62 63 3B 45 71 75 69 70 31 3B 3B 3B 0D 0A 36 36 44 39 04 " Communication example:

Figure 3 – Flow diagram SIST EN 15430-1:2008+A1:2011

Sender algorithm:

Receiver algorithm:

Figure 4 - Flow chart

12 5 Definitions of variables, records and report 5.1 General A report is a file of records which in general is used to describe one ride. A report starts with a header record, one or more status records of the vehicle/equipment(s) and a footer record. A record is a structure of coherent variables in a predefined order. A member of a record is called a “field”. Table 1 - Application or equipment types Equipment Source ref.nr.RemarkBoard computer 1

Vehicle 2 On board vehicle electronic generating data Snow plough or broom 3 It is assumed that if there is more than one snow-plough, the data is generated by one source only. Snow blower or cutter 4

Spreader or sprayer 5 Remark: this equipment could also generate the data for example for a snow plough, however, the source reference number stays 5 (as the spreader is the data generator). Road weather and road condition information system 6

Grass or branch cutting machine 7

Sweeper 8

Safety post cleaning machine 9

Boat plants cutter 10 Used for cutting plants in canals or rivers Other 11 To be used for any equipment not defined ! 5.2 Data integrity check There are at least two methods required to assure integrity: a) Data have to be checked for manipulation of the contents themselves. b) Data have to be checked for completeness: Data have to be checked against any deletion of any parts of them. In the present standard these two requirements lead to the following methods of covering: - Data manipulation (a) is checked by CRC. - Data deletion (b) is checked by including the previously calculated CRC value into the new CRC value. SIST EN 15430-1:2008+A1:2011

14 Table 2 - Ranges Range Name 1 byte2 bytes4 bytesASCIIValid Signal 0 to 250 0 to 64 255 0 to 4211081215 1 to 254 00h to FAh 0000h to FAFFh 00000000h to FAFFFFFFh 01h to FEh Parameter specific indicator 251 64256 to 64 511 4211081216 to 4227858431 None FBh FB00h to FBFFh FBxxxxxxh Reserved range for future indicator bits 252 to 253 64512 to 65 023 4227858432 to 4261412863 None FCh to FDh FC00h to FDFFh FC000000h to FDFFFFFFh Error indicator 254 65 024 to 65 279 4261412864 to 4278190079 0 FEh FExxh FExxxxxxh 00h Not available or not requested 255 65280 to 65 535 4278190080 to 4294967294255 255 FFh FFxxh FFxxxxxxh FFh Table 3 - Basic variable types Type Range LengthFormatRemarkBOOLEAN 0, 1 2 Bits 00 = Value is 0, no errors 01 = Value is 1, no errors 10 = Error 11 = not available Definition taken from SAE J1939 CHAR -125.+125 1 byte 0.250, Offset -125 254 = Error 255 = not available Definition taken from SAE J1939 UNSIGNED CHAR 0.250 1 byte 0.250, Offset 0 254 = Error 255 = not available Definition taken from SAE J1939 SIGNED SHORT -32 127.+ 32 127 2 bytes 0.64255, Offset 32768 65024.65279 = Error 65280.65535 = not available Definition taken from SAE J1939 UNSIGNED SHORT 0.64255 2 bytes 0.64255, Offset 0 65024.65279 = Error 65280.65535 = not available Definition taken from SAE J1939 SIGNED LONG - 2105540608 .

+2105540608 4 bytes 0 to 4211081215,

Offset -2105540608, 4261412864 to 4278190079 = Error, 4278190080 to Definition taken from SAE J1939 SIST EN 15430-1:2008+A1:2011

Offset -2105540608, 4261412864 to 4278190079 = Error, 4278190080 to 4294967295 = not available Definition taken from SAE J1939 BASIC_DATE 1.31,75 day 1.12 month 1985.2235 year 3 bytes 0,25 day/bit, 0 day offset 1 month/bit, 0 month offs. 1 year/bit, +1985 offset Definition taken from SAE J1939 Remarks: day = 0 is forbidden day = 1,2,3,4 are first day of month day = 5,6,7,8 are second day of month. month = 0 is forbidden year = 0 is 1985, year = 1 is 1986, . BASIC_TIME 0.23 h 0.59 min 0.59,75 s 3 bytes 1 h/bit, 0 h offset 1 min/bit, 0 min offset 0,25 s/bit, 0 s offset Definition taken from SAE J1939 STRING_X

ASCII-characters (character set is ISO Latin I) The string length must be <=

X Allowed char values: 01h.FEh 00h = Error FFh = not available Definition taken from SAE J1939 SAEat1728 Any string with max. 255 characters. NOTE The STRING_X type has to follow these additional rules: • If a transmission handler returns a valid string field the first character may not be 00h or FFh.

The predefined string length has to be covered completely with valid characters.

• If the valid string content is shorter than the predefined length ( X characters), the rest of the predefined length has to be filled with FFh characters to indicate that these characters are not valid. • If a transmission handler cannot supply the string filed the first character has to be either 00h, when the contents are incorrect, or FFh, when the contents are not available. In these two special cases the string length may be only one character in size, although it is also allowed to fill the rest of the predefined string length with FFh characters. SIST EN 15430-1:2008+A1:2011

16 Table 4 - ISO LATIN I Character set definition

x0 x1 x2 x3 x4 x5 x6 x7 x8 x9 xA xB xC xD xE xF 0x ------------------------------------------- Should not be displayed ------------------------------------------- 1x ----------------------------------------------------------------------------------------------------------------------- 2x SP ! " # $ % & ' ( ) * + , - . / 3x 0 1 2 3 4 5 6 7 8 9 : ; <

= >

? 4x @ A B C D E F G H I J K L M N O 5x P Q R S T U V W X Y Z [ \ ] ^ _ 6x ` a b c d e f g h i j k l m n o 7x p q r s t u v w x y z { | } ~

8x ------------------------------------------- Should not be displayed ------------------------------------------- 9x ----------------------------------------------------------------------------------------------------------------------- Ax NBSP ¡ ¢ £ ¤ ¥ ¦ § ¨ © ª « ¬ SHY ® ¯ Bx ° ± ² ³ ´ µ ¶ · ¸ ¹ º » ¼ ½ ¾ ¿ Cx À Á Â Ã Ä Å Æ Ç È É Ê Ë Ì Í Î Ï Dx Ð Ñ Ò Ó Ô Õ Ö × Ø Ù Ú Û Ü Ý Þ ß Ex à á â ã ä å æ ç è é ê ë ì í î ï Fx Ð ñ ò ó ô õ ö ÷ ø ù ú û ü ý þ ÿ

!Example of BASIC_TIME and BASIC_DATE format: BASIC_TIME EXAMPLE 16:02:12 (hh:mm:ss). As the seconds are to be stated in quarters of a second these have to be written as 48. Combined value 16 | 02 | 48. Because the maximum of the last value can be 239 (59,75 seconds * 4) 3 characters are reserved for this value. Combined value of BASIC_TIME = 16|02|048 = 1602048. BASIC_DATE

EXAMPLE 11-10-2006 (October 11th 2006). The day value has to be stated in quarters. The time is 16:02, being in the third quarter of the day, so the total value is 11,5 (= 46 quarters). Because the maximum of this value can be 127 (31,75 days * 4) 3 characters are reserved for this value. The month value is 10. The year value has to be stated in years since 1985: 2006-1985 = 21. Combined value of BASIC_DATE = 046|10|12 = 0461012." 5.4 Recommended SLOTs for variable definitions This section is intended to define a set of recommended SLOTs (Scaling, Limit, Offset, and Transfer Function), which can be used when parameters are added to this standard. This permits data consistency is to be maintained as much as possible between parameters of a given type (temperature, pressure, speed, etc.). Each SLOT is intended to provide a range and resolution suitable for most parameters within a given type. When necessary, a different scaling factor or offset can be used. All SLOTs should be based on a power of 2 scaling from another SLOT. This will minimize the math required for any internal scaling and reduce the opportunity for misinterpreted values. Offsets should be selected preferably on the following basis: SIST EN 15430-1:2008+A1:2011

mto 21055406 km 0 32 Bit SAEds09 Distance 6 0,1 mm/bit 0 m to 6425.5 mm 0 16 Bit SAEds04 Economy 1/512 km/L per bit 0 m to 125.5 km/L 0 16 Bit SAEel01 Electrical Current 1 1 A/bit -125 A to 125 A -125 8 Bit SAEec02 Electrical Current 2 1 A/bit 0 A to 250 A 0 8 Bit SAEec03 Electrical Potential 0,05 V/bit 0 V to 3212.75 V 0 16 Bit SAEev01 Flow Rate 1 0,05 L/h per bit 0 L/h to 3212.75 L/h 0 16 Bit SAEful01 Flow Rate 2 0,05 L/h per bit 0 L/h to 21055406 L/h 0 32 Bit CENful01 Force 5 N/bit 0 N to 321275 N 0 16 Bit SAEfr01 Governor Gain 1/1280 %/rpm per bit 0 %/rpm to 0.19 %/rpm 0 8 Bit SAEgg01 Mass (cargo) 1 0,5 kg/bit 0 kg to 32127.5 kg 0 16 Bit SAEmc01 Mass (cargo) 2 2 kg/bit 0 kg to 128510 kg 0 16 Bit SAEmc02 Mass (cargo) 3 0,5 kg/bit 0 kg to 2105540608kg 0 32 Bit CENmc01 Percent 1 (Position/Level) 0,4%/bit 0 % to 100% 0 8 Bit SAEpc03 SIST EN 15430-1:2008+A1:2011

18 Parameter Scaling (Resolution) Limits (Range)OffsetParameter Size SLOT-NamePercent 2 (Position/Level) 1%/bit -125 % to 125% -125 8 Bit SAEpc05 Percent 3 (Position/Level) 0,5%/bit 0 % to 100% 0 8 Bit CENpc01 Power 0,5 kW/bit 0 kW to 32127,5 kW 0 16 Bit SAEpw03 Pressure 1 4 kPa/bit 0 kPa to 1000 kPa 0 8 Bit SAEpr10 Pressure 2 0,05 kPa/bit 0 kPa to 12,5 kPa 0 8 Bit SAEpr02 Pressure 3 16 kPa/bit 0 kPa to 4000 kPa 0 8 Bit SAEpr14 Pressure 4 0,125 kPa/bit 0 kPa to 8031,875 kPa 0 16 Bit SAEpr04 Pressure 5 1/256 MPa/bit 0 MPa to 251 MPa 0 16 Bit SAEpr09 Pressure 6 1/128 kPa/bit - 250 kPa to 251,99 kPa -250 16 Bit SAEpr01 Pressure 7 2 kPa/bit 0 kPa to 500 kPa 0 8 Bit SAEpr07 Pressure 8 0,5 kPa/bit 0 kPa to 125 kPa 0 8 Bit SAEpr05 Ratio 1 0.1/bit 0 to 25,0 0 8 Bit SAEr02 Ratio 2 0,001/bit 0 to 64,255 0 16 Bit SAEr01 Ratio 3 1/bit 0 to 250 0 8 Bit SAEr03 Revolutions 1 000 r/bit 0 to 4211081215000 r 0 32 Bit SAErv01 Temperature 1 1 °C/bit - 40 °C to 210 °C -40 8 Bit SAEtp01 Temperature 2 0,03125 °C/bit -273 °Cto 1735 °C -273 16 Bit SAEtp02 Time 1 0,25 s/bit 0 s to 62.5 s 0 8 Bit SAEtm04 Time 2 1 s/bit 0 s to 64255 s 0 16 Bit SAEtm05 Time 3 1 min/bit 0 min to 250 min 0 8 Bit SAEtm08 Time 4 1 h/bit 0 h to 250 h 0 8 Bit SAEtm11 Time 5 0,05 h/bit 0 h to 210554060,75 h 0 32 Bit SAEtm09 Time 6 0,25 day/bit 0 days to 62,5 days 0 8 Bit SAEcd01 Time 7 1 month/bit 0 months to 250 months 0 8 Bit SAEcm01 Time 8 1 year/bit 1985 years to 2235 years +1.985 8 Bit SAEcy01 SIST EN 15430-1:2008+A1:2011

(speed) 1/256 kph/bit

(1 kph/bit for upper byte) 0 kph to 250,996 kph 0 16 Bit SAEvl02 Velocity 2, linear

(speed) 1/128 kph/bit - 250 kph to 251,992 kph -250 16 Bit SAEvl03 Velocity 3, linear

(speed) 1 kph/bit 0 kph to 250 kph 0 8 Bit SAEvl05 Velocity 1, Rotational 0.125 rpm/bit (32 rpm/bit for upper byte) 0 rpm to 8031,875 rpm 0 16 Bit SAEvr01 Velocity 2, Rotational 4 rpm/bit 0 rpm to 257020 rpm 0 16 Bit SAEvr03 Velocity 3, Rotational 0,5 rpm/bit 0 rpm to 32127,5 rpm 0 16 Bit SAEvr02 Velocity 4, Rotational 10 rpm/bit 0 rpm to 2500 rpm 0 8 Bit SAEvr04 Volume 0,5 L/bit 0 L to 2105540608 L 0 32 Bit SAEvm1 Acceleration 0,03125 m/s² 0 m/s²to 2007,8 m/s² 0 16 Bit CENac1 Dosage 1 0,03125 g/m² 0 g/m² to 2007,8 g/m² 0 16 Bit CENdos01 Dosage 2 0,03125 ml/m² 0 ml/m to 2007,8 ml/m² 0 16 Bit CENdos02 5.5 Definition of variables 5.5.1 General Variables are grouped by application. General variables apply to non application specific variables. Some application specific variables may be generated by other applications (e.g. spreader generates plough data and/or road weather information as well). If a variable is a field of a record being generated, then its value at the moment of generation is written as defined by the basic type format in 5.3 or the SLOT definition in 5.4. The following variables are defined: SIST EN 15430-1:2008+A1:2011

20 5.5.2 General variables Table 6 - General variables !!!! No Name Description BASIC data format or SLOT 1 Version Protocol version number. A positive value indicates a released version. A negative value means that the version with its absolute value is not released yet. Before the very first release the version number will be 0. STRING_10 2 SysTime Time (local time or system time of the equipment under consideration) BASIC_TIME 3 SysDate Date (local date or system date of the equipment under consideration) BASIC_DATE 4 Source Data generation source. UNSIGNED CHAR

Refer to (Table 1 – Application or equipement types) 5 ManufID Manufacturer identification. STRING_20 6 EquipID Vehicle / equipment identification. In order to insure the identification of every single equipments, it is a mandatory that the EquipID must include the manufactures serial identification code. STRING_20 7 DriverID Driver identification. STRING_40 8 Driver2ID 2nd driver identification. STRING_40 9 RunHrs Total of hours the system has run (time that control system is switched on); (can start at any value at power-up, can overrun, can be reset when counters are reset) SAEtm09 10 BeaconOn Beacon light is switched on (0=off, 1=on) BOOLEAN 11 DeviceEntity If more than one implement is mounted on the vehicle, this indicator allows to differentiate between the individual implements. UNSIGNED CHAR 12 CRC_REC See Clause 5. STRING_8 13 CRC_STREAM See Clause 5. STRING_8 14 FreeDef1 This variable is free definable. It can be used for any parameter which is not defined in this norm. It is up to the user to process this data in the office application software. The type is STRING to provide easy conversion in any other type. STRING_20 15 FreeDef2 Free definable variable (see FreeDef1) STRING_20 16 FreeDef3 Free definable variable (see FreeDef1) STRING_20 " SIST EN 15430-1:2008+A1:2011

5.5.3

General geographic position system variables Table 7 - General geographic position system variables No Name Description BASIC data format or SLOT 30 GeoLat Geographic position latitude in NMEA-0183 format: DDMM.mmmmR (two fixed digits of degrees, two fixed digits of minutes and a variable number of digits for decimal-fraction of minutes, R = reference - latitude direction: N=north, S=south). Example: 3339,7334 N = 33 º 39,7334’ north STRING_10 31 GeoLon Geographic position longitude in NMEA-0183 format: DDDMM.mmmmR (three fixed digits of degrees, two fixed digits of minutes and a variable number of digits for decimal-fraction of minutes, R = reference - longitude direction: E=east, W=west). Example: 11751,7598 W = 117 º 51,7598’ west STRING_11 32 GeoAlt Geographic position altitude CENds01 33 GeoSpd Speed over ground by geographic position system SAEvl02 34 GeoCours Course over ground by geographic position system

(0 º.360 º, 0 º = northern direction) SAEad05 35 GeoTime Time by geographic position system (UTC) BASIC_TIME 36 GeoDate Date by geographic position system (UTC) BASIC_DATE 37 GeoSQ Geographic position system signal quality

(0=no fix, 1=2D, 2=3D, 3=differential correction active) UNSIGNED CHAR 38 GeoSats Number of satellites tracked by geographic position system UNSIGNED CHAR

22 5.5.4 General vehicle and route variables Table 8 - General vehicle and route variables No Name Description BASIC data format or SLOT 50 RouteID Route identification. STRING_20 51 DrivenLen Driven length as interpreted and generated by the source (can start at any value at power-up, can overrun, can be reset when counters are reset). SAEds09 52 VehSpd Vehicle speed (0 = not driving; any other value = driving) SAEvl02 53 VehAcc Vehicle acceleration CENac1 54 VehHydrLev Level of hydraulic tank of the vehicle (0%=empty, 100%=full) CENpc01 55 VehHydrTemp Hydraulic oil temperature SAEtp01 56 VehHydrBlock Blockage of hydraulic oil filter (0= no, 1=yes) BOOLEAN 5.5.5 General road weather and road condition variables The variables refer to the weather and road conditions at the time and position (including altitude) of the in-vehicle information system. Table 9 - General road weather and road condition specific variables No Name Description BASIC data format or SLOT 70 AirHum Relative air humidity CENpc01 71 AirTemp Air temperature SAEtp01 72 WindDir Wind direction (0 º.360 º), 0= from the north, 90= from the east, 180 = from the south, 270 = from the west, etc. SAEad05 73 WindSpd Wind speed SAEvl05 74 AtmPress Atmospheric pressure SAEpr04 75 DewPoint Dew point SAEtp01 76 RoadTemp Road surface temperature SAEtp01 77 RoadFrict Friction coefficient of road (value between 0 = no friction and 1 = max. friction) SAEr01 78 WeatherC Weather condition (supplier specific code) STRING_20 79 RoadC Road condition (supplier specific code) STRING_20

Plough / Broom variables Table 10 - Front plough variables No Name DescriptionBASIC data format or SLOT 100 PBPos Plough /broom position 1= front-mounted, 2=side left, 3= side right, 4=between axes) UNSIGNED CHAR 101 PBPresent Plough or broom is mounted (0=no, 1=yes) BOOLEAN 102 PBMode Plough / broom in working position (0=no, 1=yes (with standard scraper blade), 2= yes with second scraper blade) UNSIGNED CHAR 103 PBRelease Plough release: plough weight passed onto vehicle (0=floating, 1=released) BOOLEAN 104 PBRelPerc Plough / broom release pressure %

(0%=floating, 100%=fully released) CENpc01 105 PBInfo Extra plough / broom information e.g. orientation (left, right), enlargement (adding extra section(s)), deflector (up, down), etc. – supplier specific code STRING_20 106 BrmRotSpd Broom Rotation speed as a percentage of the maximum speed CENpc01 107 PBOilT Oil temperature of plough / broom SAEtp01 108 PBOilP Oil working pressure on rotor SAEpr10 109 PBOilQ Oil flow through rotor CENful01 110 PBCntLen Total driven length in working position (can start at any value at power-up, can overrun, can be reset when counters are reset). SAEds05 111 PBCntHrs Total working hours in working position (can start at any value at power-up, can overrun, can be reset when counters are reset). SAEtm09

24 5.5.7 Snow blower or cutter variables Table 11 - Snow blower or cutter variables No Name Description BASIC data format or SLOT 120 SBCMode Snow blower or cutter is working (0=no: in transport position , 1=yes, with direct ejection, 2=yes, controlled ejection by chute). UNSIGNED CHAR 121 SBCBlwSpd Rotation speed of snow blower as a percentage of the maximum speed. CENpc01 122 SBCCutSpd Rotation speed of snow cutter drum as a percentage of the maximum speed. CENpc01 123 SBCDir Snow ejection direction – supplier specific code (e.g. left, right). STRING_20 124 SBCOilT Oil temperature of snow blower or cutter SAEtp01 125 SBCOilP Oil working pressure on rotor SAEpr10 126 SBCOilQ Oil flow through rotor CENful01

5.5.8 Spreader / sprayer variables SIST EN 15430-1:2008+A1:2011

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...