EN 378-2:2008

(Main)Refrigerating systems and heat pumps - Safety and environmental requirements - Part 2: Design, construction, testing, marking and documentation

Refrigerating systems and heat pumps - Safety and environmental requirements - Part 2: Design, construction, testing, marking and documentation

This European Standard is applicable to the design, construction and installing of refrigerating systems

including piping, components and materials and including ancillary equipment directly associated with such

systems. It also specifies requirements for testing, commissioning, marking and documentation. In case the

heat transfer fluid is not gaseous at atmospheric pressure, the requirements for circuits for heat transfer fluids

are excluded except for any safety devices associated with the refrigerating system. It is not applicable to

refrigerating systems with air or water as refrigerant and does not cover the requirements for equipment to be

used in a potentially explosive atmosphere.

The following ancillary equipment includes:

- fan and fan motor;

- electrical motor and transmission for open compressor systems.

This European Standard specifies the requirements relating to stationary and mobile refrigerating systems of

all sizes, including heat pumps.

Systems using refrigerants other than those listed in Annex E of EN 378-1:2008 are not covered by this

standard as long as a safety class is not assigned.

Basic safety requirements for refrigerating systems as defined in EN 378-1 are applicable for this standard.

Basic requirements for the installation site as defined in EN 378-3 apply.

This European Standard is not applicable to refrigeration systems and heat pumps which are manufactured

before the date of its publication as EN.

Kälteanlagen und Wärmepumpen - Sicherheitstechnische und umweltrelevante Anforderungen - Teil 2: Konstruktion, Herstellung, Prüfung, Kennzeichnung und Dokumentation

Diese Europäische Norm gilt für die Konstruktion, Herstellung und die Aufstellung von Kälteanlagen, einschließlich Rohrleitungen, Bauteilen und Werkstoffen sowie mit diesen Anlagen direkt verbundenen Zusatzausrüstungen. Diese Norm legt außerdem Anforderungen an die Prüfung, Inbetriebnahme, Kennzeichnung und Dokumentation fest. Wenn der Wärmeträger bei Atmosphärendruck nicht gasförmig ist, sind die Anforderungen an Wärmeträger-Kreisläufe mit Ausnahme aller mit der Kälteanlage verbundenen Sicherheitseinrich¬tungen ausgeschlossen. Diese Europäische Norm gilt nicht für Kälteanlagen mit Luft oder Wasser als Kältemittel und behandelt keine Anforderungen an Geräte zur Verwendung in explosionsgefährdeten Bereichen.

Die nachfolgende Zusatzausrüstung beinhaltet:

Ventilator und Ventilatormotor;

Elektromotor und Getriebe für offene Verdichtersysteme.

Diese Europäische Norm legt die Anforderungen fest für stationäre und ortsveränderliche Kälteanlagen aller Größen, einschließlich Wärmepumpen.

Kälteanlagen mit anderen als in Anhang E in EN 378-1:2008 aufgeführten Kältemitteln sind nicht Gegen¬stand dieser Europäischen Norm, sofern sie keiner Sicherheitsgruppe zugeordnet sind.

Für diese Norm gelten die grundlegenden sicherheitstechnischen Anforderungen nach den Festlegungen in EN 378-1.

Es gelten die grundlegenden Anforderungen für den Aufstellungsort nach den Festlegungen in EN 378-3.

Diese Europäische Norm gilt nicht für Kälteanlagen und Wärmepumpen, die vor dem Datum der Veröffentlichung als EN hergestellt werden.

Systèmes de réfrigération et pompes à chaleur - Exigences de sécurité et d'environnement - Partie 2: Conception, construction, essais, marquage et documentation

La présente Norme européenne est applicable à la conception, construction et installation des systèmes de

réfrigération, y compris les tuyauteries, composants et matériaux utilisés, ainsi que les équipements

auxiliaires directement associés à ces systèmes. Elle spécifie également des exigences pour les essais, la

mise en service, le marquage et la documentation. Dans le cas où le fluide caloporteur n’est pas sous forme

gazeuse à la pression atmosphérique, les exigences relatives aux circuits pour les fluides caloporteurs sont

exclues, excepté pour tout dispositif de sécurité associé au système de réfrigération. Elle n’est pas applicable

aux systèmes de réfrigération avec l’air ou l’eau comme fluide frigorigène et ne couvre pas les exigences pour

les équipements à utiliser en atmosphères explosibles.

Les équipements auxiliaires suivants incluent :

ventilateur et moteur de ventilateur ;

moteur électrique et transmission pour systèmes de compresseurs ouverts.

La présente norme européenne spécifie les exigences relatives aux systèmes de réfrigération mobile et

stationnaire de toute taille, incluant les pompes à chaleur.

Les systèmes utilisant des fluides frigorigènes autres que ceux mentionnés en Annexe E de l'EN 378-1:2008

ne sont pas couverts par la présente norme aussi longtemps qu'une classe de sécurité ne leur ait pas

assignée.

Les exigences de sécurité de base concernant les systèmes de réfrigération comme définies dans l'EN 378-1

sont applicables à la présente norme.

Les exigences de base concernant l’installation in situ comme définies dans l'EN 378-3 s’appliquent.

La présente Norme européenne n’est pas applicable aux systèmes de réfrigération et pompes à chaleur qui

sont fabriquées avant la date de sa publication comme EN.

Hladilni sistemi in toplotne črpalke - Varnostnotehnične in okoljevarstvene zahteve - 2. del: Načrtovanje, izdelava, preskušanje, označevanje in dokumentacija

General Information

- Status

- Withdrawn

- Publication Date

- 19-Feb-2008

- Withdrawal Date

- 21-Apr-2009

- Technical Committee

- CEN/TC 182 - Refrigerating systems, safety and environmental requirements

- Drafting Committee

- CEN/TC 182/WG 6 - Revision of EN 378

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 22-Apr-2009

- Completion Date

- 22-Apr-2009

- Directive

- 97/23/EC - Pressure equipment

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 18-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

EN 378-2:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Refrigerating systems and heat pumps - Safety and environmental requirements - Part 2: Design, construction, testing, marking and documentation". This standard covers: This European Standard is applicable to the design, construction and installing of refrigerating systems including piping, components and materials and including ancillary equipment directly associated with such systems. It also specifies requirements for testing, commissioning, marking and documentation. In case the heat transfer fluid is not gaseous at atmospheric pressure, the requirements for circuits for heat transfer fluids are excluded except for any safety devices associated with the refrigerating system. It is not applicable to refrigerating systems with air or water as refrigerant and does not cover the requirements for equipment to be used in a potentially explosive atmosphere. The following ancillary equipment includes: - fan and fan motor; - electrical motor and transmission for open compressor systems. This European Standard specifies the requirements relating to stationary and mobile refrigerating systems of all sizes, including heat pumps. Systems using refrigerants other than those listed in Annex E of EN 378-1:2008 are not covered by this standard as long as a safety class is not assigned. Basic safety requirements for refrigerating systems as defined in EN 378-1 are applicable for this standard. Basic requirements for the installation site as defined in EN 378-3 apply. This European Standard is not applicable to refrigeration systems and heat pumps which are manufactured before the date of its publication as EN.

This European Standard is applicable to the design, construction and installing of refrigerating systems including piping, components and materials and including ancillary equipment directly associated with such systems. It also specifies requirements for testing, commissioning, marking and documentation. In case the heat transfer fluid is not gaseous at atmospheric pressure, the requirements for circuits for heat transfer fluids are excluded except for any safety devices associated with the refrigerating system. It is not applicable to refrigerating systems with air or water as refrigerant and does not cover the requirements for equipment to be used in a potentially explosive atmosphere. The following ancillary equipment includes: - fan and fan motor; - electrical motor and transmission for open compressor systems. This European Standard specifies the requirements relating to stationary and mobile refrigerating systems of all sizes, including heat pumps. Systems using refrigerants other than those listed in Annex E of EN 378-1:2008 are not covered by this standard as long as a safety class is not assigned. Basic safety requirements for refrigerating systems as defined in EN 378-1 are applicable for this standard. Basic requirements for the installation site as defined in EN 378-3 apply. This European Standard is not applicable to refrigeration systems and heat pumps which are manufactured before the date of its publication as EN.

EN 378-2:2008 is classified under the following ICS (International Classification for Standards) categories: 27.080 - Heat pumps; 27.200 - Refrigerating technology. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 378-2:2008 has the following relationships with other standards: It is inter standard links to EN 378-2:2000, EN 378-2:2008+A1:2009, EN 1736:2008, EN 12693:2008, EN 378-2:2008/prA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 378-2:2008 is associated with the following European legislation: EU Directives/Regulations: 94/9/EC, 97/23/EC, 98/37/EC; Standardization Mandates: M/071, M/079, M/BC/CEN/92/40, M/BC/CEN/92/46. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 378-2:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Refrigerating systems and heat pumps - Safety and environmental requirements - Part 2: Design, construction, testing, marking and documentationPHQWDFLMDSystèmes de réfrigération et pompes à chaleur - Exigences de sécurité et d'environnement - Partie 2: Conception, construction, essais, marquage et documentationKälteanlagen und Wärmepumpen - Sicherheitstechnische und umweltrelevante Anforderungen - Teil 2: Konstruktion, Herstellung, Prüfung, Kennzeichnung und DokumentationTa slovenski standard je istoveten z:EN 378-2:2008SIST EN 378-2:2008en,fr,de27.20027.080ICS:SIST EN 378-2:20001DGRPHãþDSLOVENSKI

STANDARDSIST EN 378-2:200801-april-2008

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 378-2February 2008ICS 27.200; 27.080Supersedes EN 378-2:2000

English VersionRefrigerating systems and heat pumps - Safety andenvironmental requirements - Part 2: Design, construction,testing, marking and documentationSystèmes de réfrigération et pompes à chaleur - Exigencesde sécurité et d'environnement - Partie 2: Conception,construction, essais, marquage et documentationKälteanlagen und Wärmepumpen - Sicherheitstechnischeund umweltrelevante Anforderungen - Teil 2: Konstruktion,Herstellung, Prüfung, Kennzeichnung und DokumentationThis European Standard was approved by CEN on 13 October 2007.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2008 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 378-2:2008: E

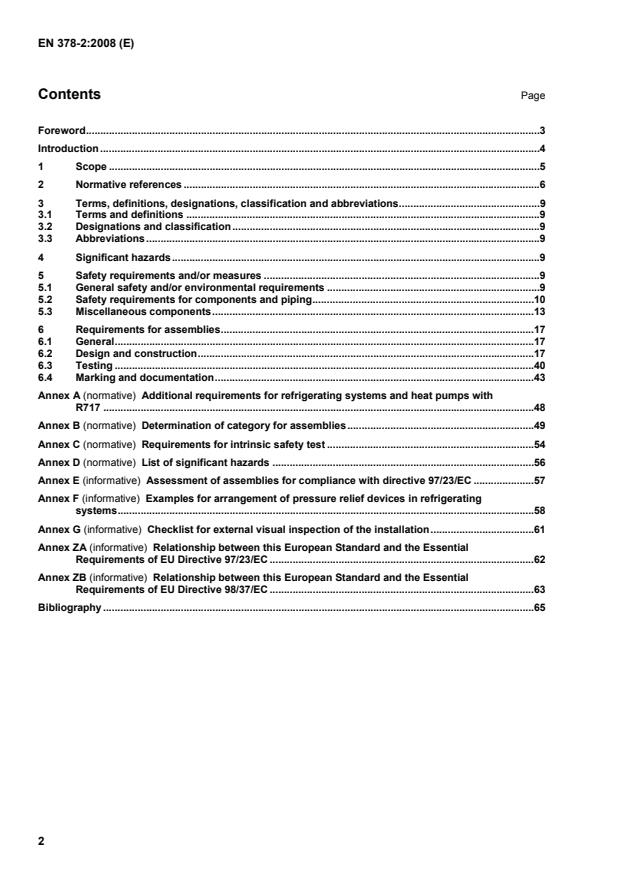

Additional requirements for refrigerating systems and heat pumps with R717.48 Annex B (normative)

Determination of category for assemblies.49 Annex C (normative)

Requirements for intrinsic safety test.54 Annex D (normative)

List of significant hazards.56 Annex E (informative)

Assessment of assemblies for compliance with directive 97/23/EC.57 Annex F (informative)

Examples for arrangement of pressure relief devices in refrigerating systems.58 Annex G (informative)

Checklist for external visual inspection of the installation.61 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 97/23/EC.62 Annex ZB (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC.63 Bibliography.65

(Directive 98/37/EC), which are integral parts of this document. EN 378 consists of the following parts under the general title Refrigerating systems and heat pumps — Safety and environmental requirements: Part 1: Basic requirements, definitions, classification and selection criteria Part 2: Design, construction, installing, testing, marking and documentation Part 3: Installation site and personal protection Part 4: Operation, maintenance, repair and recovery According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

including piping, components and materials and including ancillary equipment directly associated with such systems. It also specifies requirements for testing, commissioning, marking and documentation. In case the heat transfer fluid is not gaseous at atmospheric pressure, the requirements for circuits for heat transfer fluids are excluded except for any safety devices associated with the refrigerating system. It is not applicable to

refrigerating systems with air or water as refrigerant and does not cover the requirements for equipment to be used in a potentially explosive atmosphere. The following ancillary equipment includes: fan and fan motor; electrical motor and transmission for open compressor systems. This European Standard specifies the requirements relating to stationary and mobile refrigerating systems of all sizes, including heat pumps. Systems using refrigerants other than those listed in Annex E of EN 378-1:2008 are not covered by this standard as long as a safety class is not assigned. Basic safety requirements for refrigerating systems as defined in EN 378-1 are applicable for this standard. Basic requirements for the installation site as defined in EN 378-3 apply. This European Standard is not applicable to refrigeration systems and heat pumps which are manufactured before the date of its publication as EN.

refrigeration — Part 1: Tubes for piping systems EN 12735-2:2001, Copper and copper alloys — Seamless, round copper tubes for air conditioning and

refrigeration — Part 2: Tubes for equipment EN 12799:2000, Brazing — Non destructive examination of brazed joints EN 13136:2001, Refrigerating systems and heat pumps — Pressure relief devices and their associated piping — Methods for calculation EN 13313:2001, Refrigerating systems and heat pumps — Competence of personnel EN 13445-1:2002, Unfired pressure vessels — Part 1: General EN 13445-2:2002, Unfired pressure vessels — Part 2: Materials EN 13445-3:2002, Unfired pressure vessels — Part 3: Design EN 13445-4:2002, Unfired pressure vessels — Part 4: Fabrication EN 13445-5:2002, Unfired pressure vessels — Part 5: Inspection and testing EN 13445-6:2002, Unfired pressure vessels — Part 6: Requirements for the design and fabrication of pressure vessels and pressure parts constructed from spheroidal graphite cast iron EN 13445-8:2006, Unfired pressure vessels — Part 8: Additional requirements for pressure vessels of aluminium and aluminium alloys EN 13480-1:2002, Metallic industrial piping — Part 1: General EN 13480-2:2002, Metallic industrial piping — Part 2: Materials EN 13480-3:2002, Metallic industrial piping — Part 3: Design and calculation EN 13480-4:2002, Metallic industrial piping — Part 4: Fabrication and installation EN 13480-5:2002, Metallic industrial piping — Part 5: Inspection and testing EN 13480-6:2004, Metallic industrial piping — Part 6: Additional requirements for buried piping EN 13480-8:2007, Metallic industrial piping — Part 8: Additional requirements for aluminium and aluminium alloy piping EN 14276-1:2006, Pressure equipment for refrigerating systems and heat pumps — Part 1: Vessels — General requirements EN 14276-2:2007, Pressure equipment for refrigerating systems and heat pumps — Part 2: Piping — General requirements EN 60204-1:2006, Safety of machinery — Electrical equipment of machines — Part 1: General requirements (IEC 60204-1:2005, modified)

refrigerating appliances, ice-cream appliances and ice-makers (IEC 60335-2-24:2002) EN 60335-2-34:2002, Household and similar electrical appliances — Safety — Part 2-34: Particular

requirements for motor-compressors (IEC 60335-2-34:2002) EN 60335-2-40:2003, Household and similar electrical appliances — Safety — Part 2-40: Particular requirements for electrical heatpumps, air-conditioners and dehumidifiers (IEC 60335-2-40:2002, modified) EN 60335-2-89:2002, Household and similar electrical appliances — Safety — Part 2-89: Particular

requirements for commercial refrigerating appliances with an incorporated or remote refrigerant condensing unit or compressor (IEC 60335-2-89:2002) EN 61000-6-1:2007, Electromagnetic compatibility (EMC) — Part 6-1: Generic standards — Immunity for

residential, commercial and light-industrial environments (IEC 61000-6-1:2005) EN 61000-6-2:2005, Electromagnetic compatibility (EMC) — Part 6-2: Generic standards — Immunity for

industrial environments (IEC 61000-6-2:2005) EN 61000-6-3:2007, Electromagnetic compatibility (EMC) — Part 6-3: Generic standards — Emission

standard for residential, commercial and light-industrial environments (IEC 61000-3-3:2006) EN 61000-6-4:2007, Electromagnetic compatibility (EMC) — Part 6-4: Generic standards — Emission

standard for industrial environments (IEC 61000-6-4:2006) EN ISO 3744:1995, Acoustics — Determination of sound power levels of noise sources using sound pressure — Engineering method in an essentially free field over a reflecting plane (ISO 3744:1994) EN ISO 3746:1995, Acoustics — Determination of sound power levels of noise sources using sound pressure — Survey method using an enveloping measurement surface over a reflecting plane (ISO 3746:1995) EN ISO 4126-1:2004, Safety devices for protection against excessive pressure — Part 1: Safety valves (ISO 4126-1:2003) EN ISO 4126-2:2003, Safety devices for protection against excessive pressure — Part 2: Bursting disc safety devices (ISO 4126-2:2003) EN ISO 4871:1996, Acoustics — Declaration and verification of noise emission values of machinery and equipment (ISO 4871:1996) EN ISO 11202:1995, Acoustics — Noise emitted by machinery and equipment — Measurement of emission sound pressure levels at a work station and at other specified positions — Survey method in situ (ISO 11202:1995) EN ISO 11688-1:1998, Acoustics — Recommended practice for the design of low-noise machinery and equipment — Part 1: Planning (ISO TR 11688-1:1995) EN ISO 12100-1:2003, Safety of machinery — Basic concepts, general principles for design — Part 1: Basic terminology, methodology (ISO 12100-1:2003) EN ISO 12100-2:2003, Safety of machinery — Basic concepts, general principles for design — Part 2:

Technical principles (ISO 12100-2:2003) EN ISO 13732-1:2006, Ergonomics of the thermal environment —- Methods for the assessment of human responses to contact with surfaces — Part 1: Hot surfaces (ISO 13732-1:2006)

principles for design (ISO/DIS 13849-1:2006) EN ISO 13850:2006, Safety of machinery — Emergency stop — Principles for design (ISO 13850:2006) ISO 817:2005, Refrigerants —Designation system ASTM D 4728:2006, Standard Test Method for Random Vibration Testing of Shipping Containers 3 Terms, definitions, designations, classification and abbreviations 3.1 Terms and definitions For the purposes of this document, the terms and definitions given in EN 378-1:2008 apply. 3.2 Designations and classification Designation and classification of the refrigerant such as: refrigerant number, e.g. R 717 and safety groups A1, A2, A3, B1, B2, B3 are specified in EN 378-1:2008, Annex E. 3.3 Abbreviations DN Nominal size (see EN 378-1:2008, 3.5.17) PS Maximum allowable pressure in bar (1 bar = 0,1 MPa) (see EN 378-1:2008, 3.3.2) LFL Lower flammability limit in kg/m3

4 Significant hazards The list of significant hazards related to the Machinery Directive is given in Annex D. 5 Safety requirements and/or measures 5.1 General safety and/or environmental requirements 5.1.1 General Safety and environmental requirements are specified in 5.2 and Clause 6. Refrigerating appliances complying with the product standards such as EN 60335-2-40 for electrical heat pumps, air-conditioners and dehumidifiers, EN 60335-2-24 for refrigerating appliances, ice-cream appliances and ice-makers and EN 60335-2-89 for commercial refrigerating appliances with an incorporated or remote refrigerant con-densing unit or compressor

possible hazards to persons, property and the environment. Deliberate discharge of refrigerants shall only be permitted in a manner which is not harmful to persons, property and the environment and in accordance with national laws. 5.2 Safety requirements for components and piping 5.2.1 General requirements Components and piping shall comply with the related standards or requirements as indicated in Table 1. Requirements for components not included in Table 1 and which are below category II as defined in B.5 are indicated in 5.3. Where the product standards for components or piping are not harmonised for the EC provisions in relation to pressure or if the essential requirements of such provisions are not covered then, if relevant, compliance of such components or piping shall be proved and by risk assessment assure that the relevant requirements for pressure are met. If the relevant standards for those components listed in Table 1 does not cover requirements for electrical safety, than the electrical parts/ systems of these components shall fulfil the requirements for electrical safety as defined in EN 60335-2-40, EN 60335-2-24, EN 60335-2-89 or EN 60204-1 as relevant.

EN 60335-2-34 or prEN 12693 Open positive displacement compressor prEN 12693 Non positive displacement compressor EN 14276-1 or EN 13445 if applicable combined with EN 60204-1 Pump

General requirements

Additional requirements for pumps in refrigerating systems and heat pumps with R717

EN 809 combined with EN 60204-1, and combined with 5.2.2.2 and 5.2.2.5 of this standard Annex A Piping EN 14276-2 or EN 13480 piping joints permanent joints detachable joints

EN 14276-2 5.2.2.2 and 5.2.2.3 of this standard Flexible piping EN 1736 Valves EN 12284 safety valve EN 13136 and EN ISO 4126-1 combined with 5.2.2 of this standard safety switching devices for limiting the pressure EN 12263 combined with 5.2.2.2 of this standard isolating valves EN 12284 hand operated valves EN 12284 valves with seal cap EN 12284 Bursting disc EN ISO 4126-2 and EN 13136 combined with 5.2.2.2 of this standard Fusible plug EN 13136 combined with 5.2.2.2 and 5.2.2.4 of this standard Liquid level indicators EN 12178 combined with 5.2.2.2 of this standard Gauges EN 837-1, EN 837-2 and EN 837-3 combined with 5.2.2.2 of this standard Brazing and soldering materials 5.3.1.3 e), f) of this standard Welding materials EN 14276-2 If the component contains electrical components, and if the component standard does not cover electrical safety, then the component shall fulfil the electrical requirements of EN 60335-2-40, EN 60335-2-24, EN 60335-2-89 or EN 60204-1 as relevant.

standards also comply with the requirements of this standard. 5.2.2 Specific requirements 5.2.2.1 General In addition to the requirements of 5.2.1, following requirements are applicable for incorporation of specific components and piping into the refrigerating system. 5.2.2.2 Tightness If no test procedure is specified in the component standard, the tightness shall be assured by testing using a test method appropriate for the component and refrigerant, for details see 6.3.4. When required, some or all tests may be executed on the assembly (refer to 6.3). Tightness tests shall be conducted only after the component has passed a strength pressure test or has been verified by a type test. NOTE For guidance refer also to EN 1779:1999. 5.2.2.3 Piping joints Joints shall be designed so that they will not be damaged due to the freezing of water on the outside. They shall be suitable for the pipe, the piping material and the pressure, temperature and fluid. Coated (e.g. galvanized) pipes shall not be welded, unless all coating has been completely removed from the joint area. Welded joints shall be suitably protected. 5.2.2.4 Fusible plugs The nominal melting temperature and work pressure of the fusible material shall be stamped on the non-fusible portion of the plug. 5.2.2.5 Refrigerant liquid pumps Refrigerant liquid pumps shall be provided with the following information as a minimum, which shall be durable and permanently affixed: a) manufacturer; b) type designation; c) serial number; d) year of manufacture; e) design pressure or maximum allowable pressure (PS).

refrigerant systems and heat pumps.

The relevant standards have to be considered. Restrictions for use of dangerous or hazardous substances and preparations shall be taken into account. NOTE For example as required in 76/769/EC ("dangerous substances") and 2002/95/EC (RoHS). 5.3.1.2 Ferrous materials The material of the component shall be suitable for the specified temperature and pressure range and

combination with the refrigerants applicable for that part. a) Cast iron and malleable iron Cast iron and malleable iron shall only be used, when suitable for the particular application in accordance with the requirements of this standard. NOTE 1 Since some grades of cast iron are brittle, their application is dependent on temperature/stress/design

considerations. NOTE 2 Malleable iron has two general classifications with several different grades in each. These can have very different mechanical properties. b) Steel, cast steel, carbon steel and low alloy steel Steel, cast steel, carbon steel and low alloy steel may be used for all parts carrying refrigerant and also for heat transfer medium circuits. Where there is a combination of low temperatures and high pressure and/or where corrosion risks and/or thermal stresses are present, steel with adequate impact strength shall be used paying regard to thickness, the lowest operating temperature and its welding properties. c) High alloy steel High alloy steel may be required where there is a combination of low temperatures and high pressure and/or where corrosion risks and/or thermal stresses are present. The impact strength shall be adequate for the

particular duty and the material suitable for welding, if required. d) Stainless steel When using stainless steel, care shall be taken to ensure that the grade of stainless steel is compatible with the process fluids and possible atmospheric impurities, e.g. sodium chloride (NaCl), sulphuric acid (H2SO4). 5.3.1.3 Non-ferrous materials and their alloys (cast, forged, rolled and drawn) The material of the component shall be suitable for the specified temperature and pressure range and combination with the refrigerants applicable for that part. a) Copper and copper alloys Copper in contact with refrigerants shall be oxygen-free or de-oxidized (refer to EN 12735-1 and EN 12735-2). Copper and alloys with a high percentage of copper shall not be used for parts carrying R717 unless their compatibility has been proved by test or experience.

compatibility has been proved by test or experience. NOTE 4 Copper free lead antimony or lead tin alloys may be used for valve seats. 5.3.1.4 Non-metallic materials a) Gasket and packing materials Gasket and packing materials for sealing joints and for sealing stuffing boxes on valves etc. shall be resistant to the refrigerants, oil and lubricants used and shall be suitable for the pressures and temperatures occurring. b) Glass Glass may be used in refrigerant circuits and for electrical terminal insulators, indicators and sight glasses, but it shall be resistant to the pressures, temperatures and chemical actions which may occur. c) Asbestos Asbestos shall not be used.

designed with a thickness according to standards of similar components of Table 1 and each component is strength pressure tested individually at 1,43 times the maximum allowable pressure, or type approved by testing at 3 times the maximum allowable pressure, or type approved by testing according to the fatigue test as described in 5.3.2.2 d). b) The strength-pressure test shall be carried out preferably by means of air or some other non-hazardous gas. Adequate precautions shall be taken to prevent danger to people and to minimize risk to property. A hydrostatic pressure test by means of water or some other liquid may be accepted under the condition that the refrigeration circuit shall not be contaminated. If the continuous operating temperature is less than or equal to 125 °C for copper or aluminium, or 200 °C for steel, the test temperature of the component part or assembly shall be at least 20 °C. If the continuous operating temperature of the component exceeds 125 °C for copper or aluminium, or 200 °C for steel, the test temperature of the parts or assemblies that are at these temperatures, and subjected to the pressure, shall be at least 150 °C for copper or aluminium and 260 °C for steel. For other materials or higher

temperatures, the effects of temperature on the material fatigue characteristics shall be evaluated. If the continuous operating temperature of the component exceeds 125 °C for copper or aluminium, or 200 °C for steel, the fatigue test temperature of the parts or assemblies that are at these temperatures, shall be at least 10 °K above the continuous operating temperature. Static test pressure shall be in creased by the ratio of allowable stress of material at room temperature to that at the highest continuous operating temperature. For other materials, the effects of temperature on the fatigue characteristics shall be evaluated to determine the test conditions.

1) pressure not less than three times the component’s maximum allowable pressure without

rupture,

or

2) the test as described in 5.3.2.2 d). d) Fatigue test Three test samples shall be filled with fluid, and shall be connected to a pressure-driving source. The pressure shall be raised and lowered between the upper and lower cyclic values at a rate specified by the manufacturer for a total number of 250 000 cycles. The entire specified pressure excursion shall occur during each cycle. Following test pressures shall be applied: NOTE For safety purposes, it is suggested that a non-compressible fluid should be used. For components at the low pressure side you shall apply the maximum PS for the low pressure side for the first cycle. For components at the high pressure side you shall apply the maximum PS for the high pressure side for the first cycle. The pressure for the test cycles shall be as follows: upper pressure value shall not be less than 0,7 × PS and the lower pressure value shall not be greater than 0,2 × PS. The upper pressure shall be 0,9 × PS, for water heat exchangers in heat pump. For the final test cycle, the test pressure shall be increased to 1,4 × PS (2 times 0,7 × PS). The pressure shall be 1,8 × PS (2 times of 0,9 × PS), for water heat exchangers in heat pump. The component shall not rupture, burst or leak during this test. A strength pressure test at 2 × PS is to be performed on three samples, other than the samples used for the fatigue test. The component shall not rupture burst or leak during this test. 5.3.3 Marking For miscellaneous parts no special marking is required.

calculation or testing. Where temperature differences are calculated, the method shall be verified by

testing. For refrigerants used in the low temperature stage (with or without compressor) of a cascade system, the maximum allowable pressure PS shall be determined by the designer. The design shall include provision for normal and emergency standstill conditions. Method 2 Where no specific verification method is used, Table 2 shall apply. The minimum value of the maximum allowable pressure shall be determined by the minimum specified temperatures given in Table 2 to determine the saturated refrigerant pressure. When the evaporators can be subject to high pressure e.g. during hot gas defrosting or reverse cycle operation, the high pressure side specified temperature shall be used.

temperature + 8 K High pressure side with

evaporative condenser

43 °C 43 °C 43 °C 55 °C Low pressure side with heat exchanger exposed to the outdoor ambient temperature 32 °C 38 °C 43 °C 55 °C Low pressure side with heat exchanger exposed to the indoor ambient temperature 27 °C 33 °C 38 °C 38 °C NOTE 1 For the high pressure side, the specified temperatures are considered the maximum which will occur during operation. This temperature is higher than the temperature during compressor shut down (standstill). For the low pressure side and/or intermediate pressure side, it is sufficient to base the calculation of pressure on the expected temperature during compressor standstill period. These temperatures are minimum temperatures and thus determine that the system will not be designed for maximum allowable pressure lower than the saturated refrigerant pressure corresponding to these minimum temperatures. NOTE 2 The use of specified temperatures does not always result in saturated refrigerant pressure within the system, e.g. a limited charge system or a system working at or above critical temperature, CO2 in particular. NOTE 3 For zeotropic blends the maximum allowable pressure (PS) is the pressure at the bubble point.

NOTE 1 The system can be subdivided into several parts (e.g. low and high pressure sides) for each of which there might be a different maximum allowable pressure. NOTE 2 The pressure at which the system or part of the system normally operates will be lower than the maximum allowable pressure PS. NOTE 3 Excessive stress can result from gas pulsations. NOTE 4 For determination of the ambient conditions IEC 60721-2-1 can be used. 6.2.2.2 Component design pressure The design pressure for each component shall not be less than the maximum allowable pressure of the system or part of the system. Compressors which meet the requirements of EN 60335-2-34 or prEN 12693 also comply with the requirements of this subclause. 6.2.2.3 Pressure relationships to maximum allowable pressure Systems and components shall be designed to meet the pressure relationship given in Table 3.

maximum allowable pressure (PS) Design pressure ≥ PS Strength test pressure

according to 6.3.3 Tightness test pressure for assemblies according 6.3.4.2 Safety switching device for limiting the pressure for systems with relief

device, setting ≤ 0,9 × PS Safety switching device for limiting the pressure for systems without relief

device, setting ≤ 1,0 × PS Pressure relief device, setting 1,0 × PS Pressure relief valve achieves the required flow at 1,1 PS ≤ 1,1 × PS

6.2.3 Piping 6.2.3.1 Foreseeable misuse of piping For piping where the risk of misuse can be foreseen adequate measures shall be taken (e.g. by design,

location, protection) to avoid misuse. 6.2.3.2 Piping joints and fittings. 6.2.3.2.1 General Piping joints and fittings shall comply with the requirements of EN 14276-2. Snap-on or push-on connections shall only be used for connecting parts of self-contained systems. 6.2.3.2.2 Permanent joints For permanent joints welding or brazing shall be used in accordance with EN 14276-2. 6.2.3.2.3 Detachable joints 6.2.3.2.3.1 General In general, detachable joints shall only be used where permanent joints for technical reasons are not

appropriate. 6.2.3.2.3.2 Flanged joints Flanged joints shall be arranged so that the connected parts can be dismantled with minimum distortion stress of the piping. NOTE 1 It is preferable to use standardized flanges for steel piping according to EN 1092-1 and copper piping according to EN 1092-3.

EN 12735-2. For flare connections of copper pipes, the appropriate torque and conditions shall apply as indicated in Table 4. The flares shall be tightened with the designated torque by means of a torque wrench and appropriate spanner. The pipe ends shall be cut at a right angle to the axes (perpendicular) and checked to be free of burrs. Table 4 — Standard tightening torque Nominal outside diameter

(according to EN 12735-1 and EN 12735- 2) Imperial series Metric series (mm) (mm) (in) Minimum wall Thickness (mm) Tightening torque (Nm)

0,80 14 —

6,35 ¼ 0,80 14 —

7,94 5⁄16 0,80 33 —

0,80 33 —

9,52 ê 0,80 33 —

42 10

0,80 33 —

42 12

0,80 50 —

12,7

½ 0,80 50 —

62 15

0,80 63 —

15,88 ë 0,95 63 —

77 18

1,00 90 — 110

19,06 ¾ 1,00 90 — 110 NOTE 1 When making flared joints, care sh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...