EN 14958:2006+A1:2009

(Main)Food processing machinery - Machinery for grinding and processing flour and semolina - Safety and hygiene requirements

Food processing machinery - Machinery for grinding and processing flour and semolina - Safety and hygiene requirements

This European Standard deals with the significant hazards, hazardous situations and events relevant to the following machinery for grinding and processing of flour and semolina, as defined in Clause 3: roller mills, plan sifters and rotary separators, air classifiers, rotating machines and impact machines.

The machines in the scope are stationery (not intended to be moved when in operation), have a capacity of at least 100 kg/h, and are intended for use in installations for grain processing, such as flour mills, semolina mills, grain cleaning and flaking plants.

This European Standard deals with the significant hazards during commissioning, operation, cleaning and maintenance of the machines in the scope when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer.

This European Standard is not applicable to:

- machines intended for household use or laboratory use;

- stone mills;

- equipment for dampening and heating;

- auxiliary equipment for conveying, weighting and bagging (without changing the characteristics of the products).

This European Standard is not dealing with the following:

- hazards related to decommissioning;

- the hazards of the installations into which the machines are incorporated other than those directly related to the machines in the scope (e.g. start of the installation, disconnection of energy supply, need from an emergency stop device);

- hazards due to the use of the machinery in a potentially explosive atmosphere (when producing this standard it has been assumed that the machinery in the scope, if designed and used in accordance with this European Standard, is not creating itself a hazardous atmosphere wholly of partly surrounding it).

NOTE If the machine is intended for use in a potentially explosive atmosphere, additional safety measures can be necessary ).

This European Standard is not applicable to machines for grinding and processing of flour and semolina which are ma

Nahrungsmittelmaschinen - Maschinen zum Mahlen und Verarbeiten von Mehl und Grieß - Sicherheits- und Hygieneanforderungen

Dieser Europäische Norm behandelt die signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse, die auf die folgenden Maschinen zum Mahlen und Verarbeiten von Mehl und Grieß zutreffen, wie in 3 definiert: Walzenstühle, Plansichter und Siebmaschinen mit horizontaler Kreisbewegung der Siebe, Windsichter, Maschinen mit Rotoren und feststehenden Trennelementen, Prallmaschinen.

Die im Anwendungsbereich genannten Maschinen sind fest installierte Maschinen (nicht zum Verrücken während des Betriebes vorgesehen), haben einen Durchsatz von 100 kg/h und sind für den Einsatz in der Getreideverarbeitung wie z. B. Mehlmühlen, Grießmühlen, Getreidereinigungsanlagen und in Anlagen zur Herstellung von Getreideflocken vorgesehen.

Diese Europäische Norm behandelt die signifikanten Gefährdungen während der Inbetriebnahme, des Betriebs, der Reinigung und der Wartung der in den Anwendungsbereich fallenden Maschinen, wenn sie bestimmungsgemäß und unter den Bedingungen, die vom Hersteller als Fehlanwendung vernünftigerweise vorhersehbar sind, verwendet werden.

Diese Europäische Norm gilt nicht für:

- Maschinen für den Hausgebrauch und für den Einsatz in Labors,

- Steinmühlen,

- Ausrüstungen für das Netzen und Trocknen,

- Hilfsausrüstungen zum Fördern, Wiegen und Abpacken (ohne Veränderung von Produkteigenschaften).

Diese Europäische Norm behandelt Gefährdungen in den folgenden Zusammenhängen nicht:

- Gefährdungen durch die Außerbetriebstellung,

- Gefährdungen durch die Anlagen, in welche die Maschinen eingebaut wurden, außer die Gefährdungen stehen im direkten Zusammenhang mit den im Anwendungsbereich genannten Maschinen (z. B. Start der Gesamtinstallation, Trennen der Energiezufuhr, Notwendigkeit einer Not-Aus-Einrichtung),

- Gefährdungen durch den Einsatz der Maschinen in gefährlicher explosionsfähiger Atmosphäre. (....)

Machines pour les produits alimentaires - Machines pour la mouture et la transformation de farines et de semoules - Prescriptions relatives à la sécurité et à l'hygiéne

Stroji za obdelavo hrane - Stroji za mletje in obdelavo moke in zdroba - Varnostne in higienske zahteve

General Information

- Status

- Published

- Publication Date

- 07-Apr-2009

- Withdrawal Date

- 27-Dec-2009

- Technical Committee

- CEN/TC 153 - Food processing machinery - Safety and hygiene specifications

- Drafting Committee

- CEN/TC 153/WG 7 - Pasta processing plant

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 04-Mar-2018

- Completion Date

- 04-Mar-2018

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 17-Feb-2009

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 14958:2006+A1:2009 is a CEN (European) standard that specifies safety and hygiene requirements for stationary food processing machinery used to grind and process flour and semolina. It covers machine types such as roller mills, plan sifters and rotary separators, air classifiers, rotating machines and impact machines with a capacity of at least 100 kg/h, intended for use in flour mills, semolina mills, grain cleaning and flaking plants. The standard addresses significant hazards during commissioning, operation, cleaning and maintenance when machines are used as intended or under reasonably foreseeable misuse.

Key topics and technical requirements

- Hazard identification & risk reduction: Lists significant mechanical hazards (crushing, cutting, entanglement, abrasion/impact) and requires appropriate protective measures.

- Mechanical safety: Design and guarding principles to prevent access to danger zones, minimum gaps, interlocks and emergency stop considerations.

- Safety-related control systems: Requirements for control system design and verification to ensure safe operation and machine shutdown.

- Electrical safety & electrostatic phenomena: Protection measures for electrical hazards associated with grain-processing machinery.

- Noise management: Noise measurement and reduction guidance (noise test code in Annex B) to protect operators’ hearing and maintain warning signal intelligibility.

- Dust and hygiene control: Protection against dust emission, cleanability and sanitation principles (normative Annex A), and guidance on harmful substances such as cleaning/disinfecting agents.

- Fire and explosion: Measures and an informative Annex C for evaluating explosion risks in plants that include grain-processing machines.

- Ergonomics and information: Ergonomic requirements, marking, safety signals and comprehensive instruction manuals for use, maintenance and cleaning.

- Verification & documentation: Procedures for verifying the implemented safety measures and providing manufacturer information for conformity assessment.

Practical applications

- Integrating EN 14958 into the design phase ensures machinery meets hygiene and safety expectations for industrial mills.

- Use for risk assessments, machine commissioning checks, operator training, and maintenance planning in flour and semolina production facilities.

- Reference for procurement specifications, conformity assessment, CE marking support and to demonstrate compliance with relevant EU machinery directives (see Annexes ZA/ZB).

Who should use this standard

- Machine designers and manufacturers of flour/semolina processing equipment

- Safety and compliance engineers, notified bodies and certification agencies

- Mill operators, plant managers and maintenance teams

- Food safety and hygiene officers responsible for equipment sanitation

Related standards (selected)

- EN 1672-2 (food machinery hygiene requirements)

- EN ISO 12100 (machine risk assessment & design principles)

- EN ISO 13849-1 (safety-related control systems)

- EN 1127-1 (explosive atmospheres)

- EN 13284-1 (dust measurement)

Keywords: EN 14958:2006+A1:2009, food processing machinery, flour and semolina safety, hygiene requirements, roller mills, plan sifters, machine safety standard, CEN.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

EN 14958:2006+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Food processing machinery - Machinery for grinding and processing flour and semolina - Safety and hygiene requirements". This standard covers: This European Standard deals with the significant hazards, hazardous situations and events relevant to the following machinery for grinding and processing of flour and semolina, as defined in Clause 3: roller mills, plan sifters and rotary separators, air classifiers, rotating machines and impact machines. The machines in the scope are stationery (not intended to be moved when in operation), have a capacity of at least 100 kg/h, and are intended for use in installations for grain processing, such as flour mills, semolina mills, grain cleaning and flaking plants. This European Standard deals with the significant hazards during commissioning, operation, cleaning and maintenance of the machines in the scope when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer. This European Standard is not applicable to: - machines intended for household use or laboratory use; - stone mills; - equipment for dampening and heating; - auxiliary equipment for conveying, weighting and bagging (without changing the characteristics of the products). This European Standard is not dealing with the following: - hazards related to decommissioning; - the hazards of the installations into which the machines are incorporated other than those directly related to the machines in the scope (e.g. start of the installation, disconnection of energy supply, need from an emergency stop device); - hazards due to the use of the machinery in a potentially explosive atmosphere (when producing this standard it has been assumed that the machinery in the scope, if designed and used in accordance with this European Standard, is not creating itself a hazardous atmosphere wholly of partly surrounding it). NOTE If the machine is intended for use in a potentially explosive atmosphere, additional safety measures can be necessary ). This European Standard is not applicable to machines for grinding and processing of flour and semolina which are ma

This European Standard deals with the significant hazards, hazardous situations and events relevant to the following machinery for grinding and processing of flour and semolina, as defined in Clause 3: roller mills, plan sifters and rotary separators, air classifiers, rotating machines and impact machines. The machines in the scope are stationery (not intended to be moved when in operation), have a capacity of at least 100 kg/h, and are intended for use in installations for grain processing, such as flour mills, semolina mills, grain cleaning and flaking plants. This European Standard deals with the significant hazards during commissioning, operation, cleaning and maintenance of the machines in the scope when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer. This European Standard is not applicable to: - machines intended for household use or laboratory use; - stone mills; - equipment for dampening and heating; - auxiliary equipment for conveying, weighting and bagging (without changing the characteristics of the products). This European Standard is not dealing with the following: - hazards related to decommissioning; - the hazards of the installations into which the machines are incorporated other than those directly related to the machines in the scope (e.g. start of the installation, disconnection of energy supply, need from an emergency stop device); - hazards due to the use of the machinery in a potentially explosive atmosphere (when producing this standard it has been assumed that the machinery in the scope, if designed and used in accordance with this European Standard, is not creating itself a hazardous atmosphere wholly of partly surrounding it). NOTE If the machine is intended for use in a potentially explosive atmosphere, additional safety measures can be necessary ). This European Standard is not applicable to machines for grinding and processing of flour and semolina which are ma

EN 14958:2006+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 67.260 - Plants and equipment for the food industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14958:2006+A1:2009 has the following relationships with other standards: It is inter standard links to EN 14958:2006, EN 60529:1991, EN 61310-1:1995, EN ISO 11688-1:1998, EN 1672-2:2005, EN ISO 4871:1996, EN 13284-1:2001, EN 811:1996, EN 1088:1995, EN ISO 12100-2:2003, EN 614-1:2006, EN ISO 11201:2010, EN ISO 3744:1995, EN ISO 13849-1:2008, EN 13478:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14958:2006+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14958:2006+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stroji za obdelavo hrane - Stroji za mletje in obdelavo moke in zdroba - Varnostne in higienske zahteveNahrungsmittelmaschinen - Maschinen zum Mahlen und Verarbeiten von Mehl und Grieß - Sicherheits- und HygieneanforderungenMachines pour les produits alimentaires - Machines à mouture et transformation de farines et de semoule - Prescriptions relatives à la sécurité et à l'hygiéneFood processing machinery - Machinery for grinding and processing flour and semolina - Safety and hygiene requirements67.260Tovarne in oprema za živilsko industrijoPlants and equipment for the food industryICS:Ta slovenski standard je istoveten z:EN 14958:2006+A1:2009SIST EN 14958:2006+A1:2009en,fr01-junij-2009SIST EN 14958:2006+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14958:2006+A1

April 2009 ICS 67.260 Supersedes EN 14958:2006English Version

Food processing machinery - Machinery for grinding and processing flour and semolina - Safety and hygiene requirements

Machines pour les produits alimentaires - Machines à mouture et transformation de farines et de semoule - Prescriptions relatives à la sécurité et à l'hygiéne

Nahrungsmittelmaschinen - Maschinen zum Mahlen und Verarbeiten von Mehl und Grieß - Sicherheits- und Hygieneanforderungen This European Standard was approved by CEN on 10 May 2006 and includes Amendment 1 approved by CEN on 7 March 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 14958:2006+A1:2009: ESIST EN 14958:2006+A1:2009

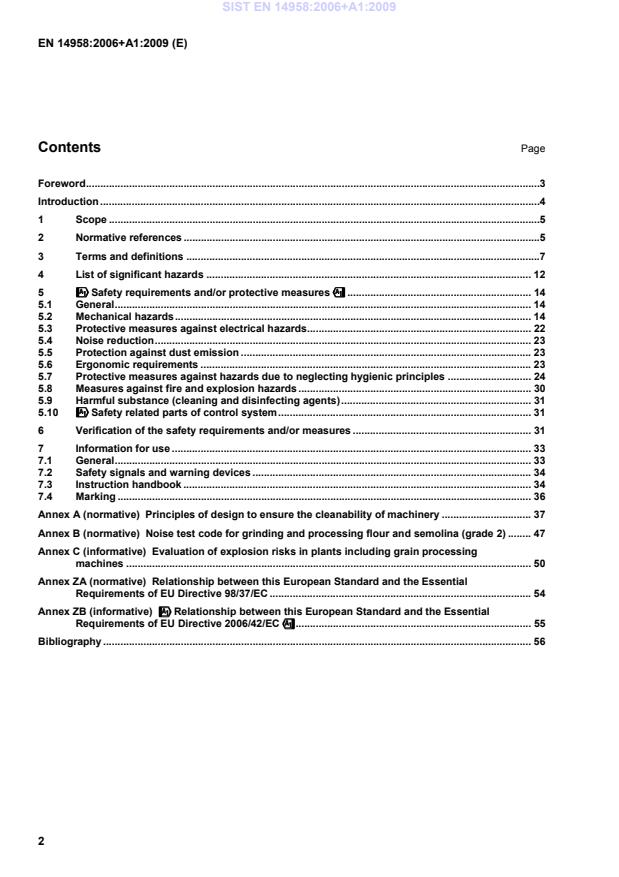

Principles of design to ensure the cleanability of machinery . 37Annex B (normative)

Noise test code for grinding and processing flour and semolina (grade 2) . 47Annex C (informative)

Evaluation of explosion risks in plants including grain processing machines . 50Annex ZA (normative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC . 54Annex ZB (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC"""" . 55Bibliography . 56

This European Standard is not applicable to: machines intended for household use or laboratory use; stone mills; equipment for dampening and heating; auxiliary equipment for conveying, weighting and bagging (without changing the characteristics of the products). This European Standard is not dealing with the following: hazards related to decommissioning; the hazards of the installations into which the machines are incorporated other than those directly related to the machines in the scope (e.g. start of the installation, disconnection of energy supply, need from an emergency stop device); hazards due to the use of the machinery in a potentially explosive atmosphere (when producing this standard it has been assumed that the machinery in the scope, if designed and used in accordance with this European Standard, is not creating itself a hazardous atmosphere wholly of partly surrounding it). NOTE If the machine is intended for use in a potentially explosive atmosphere, additional safety measures can be necessary1). This European Standard is not applicable to machines for grinding and processing of flour and semolina which are manufactured before the date of its publication as EN. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 294:1992, Safety of machinery — Safety distances to prevent danger zones being reached by the upper limbs EN 349:1993, Safety of machinery — Minimum gaps to avoid crushing of parts of the human body

1) For the EU and the EEA the requirements of the EU directive 94/9/EC may apply. SIST EN 14958:2006+A1:2009

(see Figure 4). The following machines are included in this group: vibrating finishers, intensive scourers, rotating sifters, bran finishers, crumblers, de-germinators, de-huskers 3.5 impact machine machine that carry out a physical action on grain and/or grain products by causing a granulometric reduction by impact using rotating components (see Figure 5). The following machines are included in this group: impactors, infestation destroyers SIST EN 14958:2006+A1:2009

Key 1 product inlet 2 grinding rolls 3 product outlet 4 drive motor 5 feeding rolls Figure 1 — Operating principle of roller mill SIST EN 14958:2006+A1:2009

Key 1 product inlet 2 sieves 3 product outlet 4 centrifugal weights 5 suspension rods 6 drive motor Figure 2 — Operating principle of plan sifter and rotary separator SIST EN 14958:2006+A1:2009

Key 1 product inlet 2 air exhaust 3 sieves 4 product outlets 5 supporting springs 6 vibrating devices Figure 3 — Operating principle of air classifier (purifier, gravity separator, aspirator, de-stoner, vibrating separator) SIST EN 14958:2006+A1:2009

Key 1 product inlet 2 air exhaust 3 fixed component (sieve or screen) 4 rotating component 5 product outlet 6 drive motor Figure 4 — Operating principle of rotating machine (vibrating fisher, intensive scourer, rotating sifter, bran finisher, crumbler, de-germinator, de-husker) SIST EN 14958:2006+A1:2009

Key 1 product inlet 2 rotating components 3 drive motor 4 product outlet Figure 5 — Operating principle of impact machine (impactor, infestation destroyer) 4 List of significant hazards This clause contains all the significant hazards, hazardous situations and events, as far as they are dealt with in this European Standard, identified by risk assessment as significant for this type of machinery and which require action to eliminate or reduce the risk. Before using this standard it is important to carry out a risk assessment of the different types of machines to check that it has the hazards identified in this clause. SIST EN 14958:2006+A1:2009

phenomena – 5.3 4.3 Noise hazards e.g. hearing damage, tinnitus, accidents due to a reduced intelligibility of acoustic warning signals, limited speech intelligibility – 5.4 4.4 Hazards resulting from inhalation of dust – 5.5 4.5 Hazards due to neglecting ergonomic principles – 5.6 4.6 Hazards due to neglecting hygienic principles – 5.7.2.1 – 5.7.2.2 – 5.7.2.3 – 5.7.2.4 – 5.7.2.5 – 5.7.2.6 – 5.7.2.7 4.7 Fire and explosion hazards – 5.8 4.8 harmful substances

5.9 SIST EN 14958:2006+A1:2009

Key Zone1: feeding rolls Zone 2: grinding rolls Zone 3: roll drive arrangement Zone 4: pneumatics pistons Zone 5: grinding rolls transmission drive Zone 6: feeding rolls transmission drive Zone 7: scraper Figure 6 — Hazard zones in the roller mill SIST EN 14958:2006+A1:2009

Key Zone 1: centrifugal weights transmission Zone 2: centrifugal weights Zone 8: loss of stability Figure 7 — Hazard zones in the plan sifter

Key Zone 1: vibrating drive Zone 8: loss of stability Figure 8 — Hazard zones at air classifier (purifier) SIST EN 14958:2006+A1:2009

Key Zone 1: rotor Zone 2: motor drive belt transmission Zone 3: screw Zone 4: vibrating drive Figure 9 — Hazard zones in the air classifier (aspirator) SIST EN 14958:2006+A1:2009

Key Zone 1: rotor Zone 2: motor drive belt transmission Figure 10 — Hazard zones in the rotating machine SIST EN 14958:2006+A1:2009

Key Zone 1: rotor Figure 11 — Hazard zones in the impact machine (impactor) SIST EN 14958:2006+A1:2009

Key Zone 1: rotor Zone 2: motor drive transmission Figure 12 — Hazard zones in the impact machine (infestation destroyer) 5.3 Protective measures against electrical hazards 5.3.1 General All electrical equipment associated with the machine shall comply with the requirements of !EN 60204-1:2006" as indicated in this clause. 5.3.2 Protection against electric shock 5.3.2.1 Direct contact Live parts shall be located inside enclosures that provide protection against direct contact of at least IP2X as defined in EN 60529:1991. The opening of enclosure shall only be possible by using a key or tool, or by disconnecting the live parts before opening the enclosure (see 6.2.2 options a and b of !EN 60204-1:2006"). 5.3.2.2 Indirect contact Protection against indirect contact due to insulation failure between live parts and exposed conductive parts, shall be achieved by the connection of exposed conductive parts to the protective bonding circuits and disconnection of the supply in accordance with !EN 60204-1:2006". 5.3.3 !!!!Degrees of protection (see 11.3 of EN 60204-1:2006)"""" Enclosure of control gear shall provide a degree of protection at least IP54. SIST EN 14958:2006+A1:2009

Key

non food area

food area 1 inlet spout 2 feed rolls conveying chute 3 feed valve 4 feed rolls 5 grinding rolls conveying chute 6 grinding rolls 7 brushes/scrapers 8 outlet hopper 9 surfaces close to the feed zone 10, 11 surfaces close to the grinding rolls 12 surfaces close to brushes / scrapers Figure 13

Key

non food area

food area 1 inlet spout 2 sieves compartment upper cover 3 sieves compartment inner surfaces 4 sieve 5 sieve compartment lower cover 6 outlet spout Figure 14 SIST EN 14958:2006+A1:2009

Key

non food area

food area 1 inlet spout 2 feed zone 3 sieves 4 outlet hoppers Figure 15 SIST EN 14958:2006+A1:2009

Key

non food area

food area 1 inlet spout

2 moving body 3 outlet hopper Figure 16 5.7.2.5 Rotating machine (see Figure 17) SIST EN 14958:2006+A1:2009

Key

non food area

food area 1 inlet spout 2 rotor 3 screen / sieve 4 inner surfaces 5 outlet hopper Figure 17 SIST EN 14958:2006+A1:2009

5.7.2.6 Impact machine (impactor) (see Figure 18)

Key

non food area

food area 1 inlet spout 2 pins zone 3 outlet spout Figure 18 SIST EN 14958:2006+A1:2009

5.7.2.7 Impact machine (infestation destroyer) (see Figure 19)

Key

non food area

food area 1 inlet spout 2 pins zone 3 outlet spout Figure 19 5.7.3 Splash area Not present in these machines. 5.7.4 Non food area All parts not mentioned in 5.7.2. 5.8 Measures against fire and explosion hazards 5.8.1 Fire hazard The machines shall be designed and constructed in accordance with the requirements of EN 13478. 5.8.2 Explosion hazard The machines shall be designed and constructed in accordance with the principles and requirements of EN 1127-1, in particular concerning: measures for avoiding or reducing potentially explosive atmospheres; measures against potential ignition sources (static electricity, mechanical sparks, overheating of moving parts,…); SIST EN 14958:2006+A1:2009

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...