FprEN 13813

(Main)Screed material and floor screeds - Screed material - Properties and requirements

Screed material and floor screeds - Screed material - Properties and requirements

This document specifies requirements for the following types of screed material as defined in EN 13318:

- cementitious;

- calcium sulfate;

- magnesite;

- mastic asphalt;

- synthetic resin.

All types of screed material can be used for internal applications. However, cementitious screed materials can also be used for internal and external applications.

This document specifies the properties for fresh and hardened screed materials.

The floor screed materials could be installed as monolayer or multilayer products.

This document specifies designation of the screed materials as well as designation and classification of their characteristics. Furthermore, it also specifies the assessment and verification of constancy of performance, marking and labelling of the screed materials.

This document does not provide criteria or recommendations for the design and installation of screed materials.

Estrichmörtel, Estrichmassen und Estriche - Estrichmörtel und Estrichmassen - Eigenschaften und Anforderungen

Diese Europäische Norm legt Anforderungen an folgende Arten von Estrichmörtel fest, wie in EN 13318 definiert:

- Zement;

- Calciumsulfat;

- Magnesit;

- Gussasphalt;

- Synthetisches Reaktionsharz.

Alle Arten Estrichmörtel dürfen innen angewendet werden.

Zementestrichmörtel darf sowohl innen als auch außen angewendet werden.

Diese Europäische Norm legt die Leistung für frischen und nicht erhärteten Estrichmörtel fest.

Estrichmörtel kann einzelschichtig oder mehrschichtig sein.

Diese Europäische Norm legt die Bewertung und Überprüfung der Konstanz der Leistung und die Klassifizierung und Bezeichnung von Estrichmörtel fest.

Diese Europäische Norm gibt keine Kriterien oder Empfehlungen für die Gestaltung und den Einbau von Estrichmörtel an.

Matériau de chape et chapes - Matériau de chapes - Propriétés et exigences

La présente Norme européenne spécifie les exigences relatives aux types de matériaux pour chape suivants, définis dans l'EN 13318 :

- à base de ciment ;

- à base de sulfate de calcium ;

- à base de magnésie ;

- en asphalte coulé ;

- à base de résine synthétique.

Tous les types de matériau pour chape peuvent être utilisés pour des applications en intérieur.

Les matériaux pour chape à base de ciment peuvent être utilisés tant pour les applications en intérieur que pour les applications en extérieur.

La présente Norme européenne spécifie les performances des matériaux pour chape frais et durcis.

Les matériaux pour chape peuvent être monocouches ou multicouches.

La présente Norme européenne spécifie l'évaluation et la vérification de la constance des performances, ainsi que la classification et la désignation des matériaux pour chape.

La présente Norme européenne ne fournit pas de critères ni de recommandations en matière de conception et d'installation des matériaux pour chape.

Estrihi - Materiali za estrihe - Lastnosti in zahteve

General Information

- Status

- Not Published

- Technical Committee

- CEN/TC 303 - Floor screeds and in-situ floorings in buildings

- Drafting Committee

- CEN/TC 303/WG 1 - General

- Current Stage

- 5098 - Decision to abandon - Formal Approval

- Start Date

- 07-Jun-2023

- Completion Date

- 11-Feb-2026

Relations

- Revises

EN 13813:2002 - Screed material and floor screeds - Screed material - Properties and requirements - Effective Date

- 18-Jan-2023

Overview

FprEN 13813 - Screed material and floor screeds: Screed material - Properties and requirements (CEN) defines performance requirements and classification for screed materials used in floor construction. It covers five binder-based screed types: cementitious, calcium sulfate, magnesite, mastic asphalt, and synthetic resin. The standard specifies properties for both fresh and hardened screed materials, designation and classification of characteristics, assessment and verification of constancy of performance (AVCP), and marking and labelling. It does not cover design or installation methods.

Key topics and technical requirements

- Scope of materials:

- Types defined by EN 13318: CT (cementitious), CA (calcium sulfate), MA (magnesite), AS (mastic asphalt), SR (synthetic resin).

- All types suitable for internal applications; cementitious can also be used externally.

- Product characteristics and testing:

- Performance specified for fresh (e.g., consistency, setting time) and hardened materials (e.g., compressive strength, flexural strength, wear resistance, surface hardness).

- Detailed list of characteristics includes: compressive stress at 10% strain, density, Böhme/BCA wear resistance, resistance to indentation, impact resistance, bond strength, shrinkage, modulus of elasticity, vertical water permeability, freeze–thaw resistance, pH value, and several special characteristics (chemical resistance, water vapour permeability, electrical and thermal resistance, rolling wheel resistance with/without floor coverings).

- Test methods and specimen preparation are referenced (e.g., EN 13892 series, EN 13501-1 for reaction to fire, EN 13454-2 for calcium sulfate binders).

- Classification and designation:

- Characteristic abbreviations (examples): C (compressive strength), F (flexural), A/AR/RWA (wear resistance variants), SH (surface hardness), B (bond strength), SK (shrinkage), EM (elastic modulus), WP (water permeability), CDF (freeze–thaw).

- Conformity & factory control:

- Requirements for type testing, factory production control (FPC), initial inspection, continuous surveillance and reporting as part of AVCP.

- Regulatory alignment:

- Includes informative Annex ZA relating the standard to Regulation (EU) No 305/2011 (construction products).

Applications and who uses it

- Practical users:

- Manufacturers of screed materials and binders for product specification, labelling and CE marking.

- Specifiers, architects and engineers who require standardized performance classes for floor screeds.

- Test laboratories performing type tests and FPC verifications.

- Regulatory authorities and certification bodies verifying AVCP compliance.

- Typical applications:

- Internal floor systems (all types), external floor screeds (cementitious), monolayer or multilayer screed products, and projects requiring documented material performance.

Related standards

- EN 13318 (definitions for screed materials)

- EN 13892 series (test methods for screed materials)

- EN 13501-1 (reaction to fire classification)

- EN 13454-2 and various referenced EN and ISO test standards included in the normative references.

Keywords: FprEN 13813, screed material, floor screeds, screed properties, cementitious screeds, calcium sulfate screed, AVCP, factory production control, EN 13318.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

FprEN 13813 is a draft published by the European Committee for Standardization (CEN). Its full title is "Screed material and floor screeds - Screed material - Properties and requirements". This standard covers: This document specifies requirements for the following types of screed material as defined in EN 13318: - cementitious; - calcium sulfate; - magnesite; - mastic asphalt; - synthetic resin. All types of screed material can be used for internal applications. However, cementitious screed materials can also be used for internal and external applications. This document specifies the properties for fresh and hardened screed materials. The floor screed materials could be installed as monolayer or multilayer products. This document specifies designation of the screed materials as well as designation and classification of their characteristics. Furthermore, it also specifies the assessment and verification of constancy of performance, marking and labelling of the screed materials. This document does not provide criteria or recommendations for the design and installation of screed materials.

This document specifies requirements for the following types of screed material as defined in EN 13318: - cementitious; - calcium sulfate; - magnesite; - mastic asphalt; - synthetic resin. All types of screed material can be used for internal applications. However, cementitious screed materials can also be used for internal and external applications. This document specifies the properties for fresh and hardened screed materials. The floor screed materials could be installed as monolayer or multilayer products. This document specifies designation of the screed materials as well as designation and classification of their characteristics. Furthermore, it also specifies the assessment and verification of constancy of performance, marking and labelling of the screed materials. This document does not provide criteria or recommendations for the design and installation of screed materials.

FprEN 13813 is classified under the following ICS (International Classification for Standards) categories: 91.100.10 - Cement. Gypsum. Lime. Mortar. The ICS classification helps identify the subject area and facilitates finding related standards.

FprEN 13813 has the following relationships with other standards: It is inter standard links to EN 13813:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

FprEN 13813 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/119, M/132. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

FprEN 13813 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

oSIST prEN 13813:2017

01-marec-2017

Estrihi - Materiali za estrihe - Lastnosti in zahteve

Screed material and floor screeds - Screed material - Properties and requirements

Estrichmörtel, Estrichmassen und Estriche - Estrichmörtel und Estrichmassen -

Eigenschaften und Anforderungen

Matériau de chape et chapes - Matériau de chapes - Propriétés et exigences

Ta slovenski standard je istoveten z: prEN 13813

ICS:

91.100.10 Cement. Mavec. Apno. Malta Cement. Gypsum. Lime.

Mortar

oSIST prEN 13813:2017 en,fr,de

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

oSIST prEN 13813:2017

oSIST prEN 13813:2017

DRAFT

EUROPEAN STANDARD

prEN 13813

NORME EUROPÉENNE

EUROPÄISCHE NORM

January 2017

ICS 91.100.10 Will supersede EN 13813:2002

English Version

Screed material and floor screeds - Screed material -

Properties and requirements

Matériau de chape et chapes - Matériau de chapes - Estrichmörtel, Estrichmassen und Estriche -

Propriétés et exigences Estrichmörtel und Estrichmassen - Eigenschaften und

Anforderungen

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 303.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2017 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 13813:2017 E

worldwide for CEN national Members.

oSIST prEN 13813:2017

prEN 13813:2017 (E)

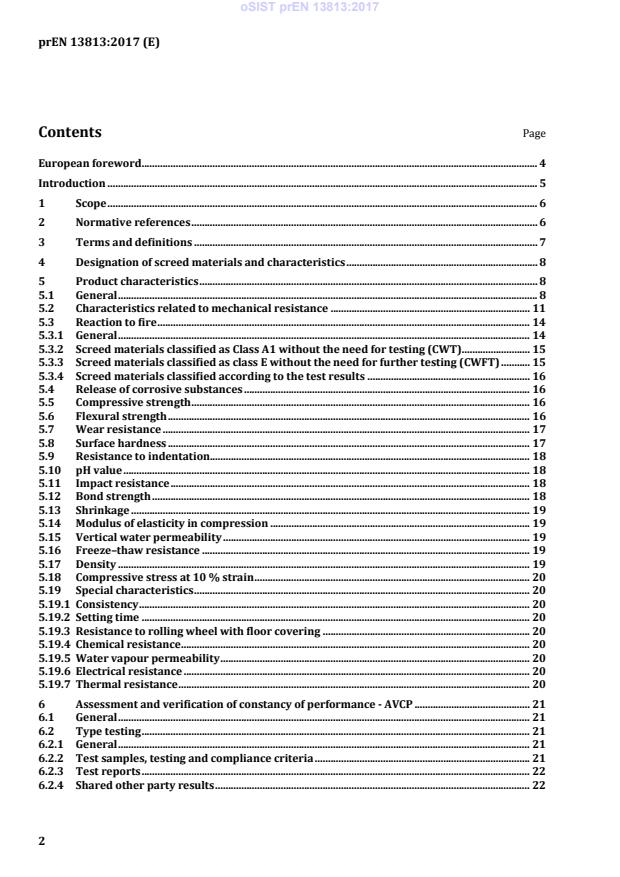

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Designation of screed materials and characteristics . 8

5 Product characteristics . 8

5.1 General . 8

5.2 Characteristics related to mechanical resistance . 11

5.3 Reaction to fire . 14

5.3.1 General . 14

5.3.2 Screed materials classified as Class A1 without the need for testing (CWT) . 15

5.3.3 Screed materials classified as class E without the need for further testing (CWFT) . 15

5.3.4 Screed materials classified according to the test results . 16

5.4 Release of corrosive substances . 16

5.5 Compressive strength . 16

5.6 Flexural strength . 16

5.7 Wear resistance . 17

5.8 Surface hardness . 17

5.9 Resistance to indentation. 18

5.10 pH value . 18

5.11 Impact resistance . 18

5.12 Bond strength . 18

5.13 Shrinkage . 19

5.14 Modulus of elasticity in compression . 19

5.15 Vertical water permeability . 19

5.16 Freeze–thaw resistance . 19

5.17 Density . 19

5.18 Compressive stress at 10 % strain . 20

5.19 Special characteristics . 20

5.19.1 Consistency . 20

5.19.2 Setting time . 20

5.19.3 Resistance to rolling wheel with floor covering . 20

5.19.4 Chemical resistance . 20

5.19.5 Water vapour permeability . 20

5.19.6 Electrical resistance . 20

5.19.7 Thermal resistance . 20

6 Assessment and verification of constancy of performance - AVCP . 21

6.1 General . 21

6.2 Type testing . 21

6.2.1 General . 21

6.2.2 Test samples, testing and compliance criteria . 21

6.2.3 Test reports . 22

6.2.4 Shared other party results . 22

oSIST prEN 13813:2017

prEN 13813:2017 (E)

6.3 Factory production control (FPC) . 23

6.3.1 General . 23

6.3.2 Requirements . 24

6.3.3 Product specific requirements . 27

6.3.4 Initial inspection of factory and of FPC . 28

6.3.5 Continuous surveillance of FPC . 28

6.3.6 Procedure for modifications . 28

6.3.7 One-off products, pre-production products (e.g. prototypes) and products produced

in very low quantity . 29

7 Marking and labelling . 29

Annex ZA (informative) Relationship between this European Standard with Regulation (EU)

No 305/2011 . 31

Bibliography . 42

oSIST prEN 13813:2017

prEN 13813:2017 (E)

European foreword

This document (prEN 13813:2017) has been prepared by Technical Committee CEN/TC 303 “Floor

screeds and screed materials”, the secretariat of which is held by UNI.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 13813:2002.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports basic work requirements for construction works of

Regulation (EU) No 305/2011 on construction products.

For relationship with the Regulation, see informative Annex ZA, which is an integral part of this

document.

The significant technical changes between this European Standard and the previous edition are listed

herewith:

— Clause 1;

— Clause 4;

— Clause 5;

— Clause 6;

— Annex ZA (informative).

oSIST prEN 13813:2017

prEN 13813:2017 (E)

Introduction

The properties required of a screed are related to its use.

They are considered in two groups: those relating to the fresh, unhardened screed material and those

relating to the hardened screed material.

The properties achieved depend essentially on the type or types of binder used and their respective

proportions. The type of aggregates, admixtures and/or additions used can achieve special properties.

oSIST prEN 13813:2017

prEN 13813:2017 (E)

1 Scope

This European Standard specifies requirements for the following types of screed material as defined in

EN 13318:

— Cementitious;

— Calcium sulphate;

— Magnesite;

— Mastic asphalt;

— Synthetic resin.

All types of screed material may be used for internal applications.

Cementitious screed material may be used for both internal and external applications.

This European Standard specifies the performance for fresh and hardened screed materials.

The floor screed materials could be monolayer or multilayer.

This European Standard specifies the assessment and verification of the constancy of performance and

the classification and designation of screed materials.

This European Standard does not provide criteria or recommendations for the design and installation of

screed materials.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

EN 826, Thermal insulating products for building applications — Determination of compression behaviour

EN 1015-10, Methods of test for mortar for masonry — Part 10: Determination of dry bulk density of

hardened mortar

EN 1081, Resilient floor coverings — Determination of the electrical resistance

EN 12086, Thermal insulating products for building applications — Determination of water vapour

transmission properties

CEN/TS 12390-9, Testing hardened concrete — Part 9: Freeze-thaw resistance - Scaling

EN 12664, Thermal performance of building materials and products — Determination of thermal

resistance by means of guarded hot plate and heat flow meter methods — Dry and moist products of

medium and low thermal resistance

EN 12697-19 Bituminous mixtures — Test methods for hot mix asphalt — Part 19: Permeability of

specimen

EN 12697-20, Bituminous mixtures — Test methods for hot mix asphalt — Part 20: Indentation using

cube or cylindrical specimens (CY)

oSIST prEN 13813:2017

prEN 13813:2017 (E)

EN 13318, Screed material and floor screeds — Definitions

EN 13412, Products and systems for the protection and repair of concrete structures — Test methods —

Determination of modulus of elasticity in compression

EN 13454-2, Binders, composite binders and factory made mixtures for floor screeds based on calcium

sulfate — Part 2: Test methods

EN 13501-1, Fire classification of construction products and building elements — Part 1: Classification

using data from reaction to fire tests

EN 13529, Products and systems for the protection and repair of concrete structures — Test methods —

Resistance to severe chemical attack

EN 13892-1, Methods of test for screed materials — Part 1: Sampling, making and curing specimens for

test

EN 13892-2, Methods of test for screed materials — Part 2: Determination of flexural and compressive

strength

EN 13892-3, Methods of test for screed materials — Part 3: Determination of wear resistance - Böhme

EN 13892-4, Methods of test for screed materials — Part 4: Determination of wear resistance-BCA

EN 13892-5, Methods of test for screed materials — Part 5: Determination of wear resistance to rolling

wheel of screed material for wearing layer

EN 13892-6, Methods of test for screed materials — Part 6: Determination of surface hardness

EN 13892-7, Methods of test for screed materials — Part 7: Determination of wear resistance to rolling

wheel of screed material with floor coverings

EN 13892-8, Methods of test for screed materials — Part 8: Determination of bond strength

prEN 13892-9:2017, Methods of test for screed materials — Part 9: Shrinkage and swelling

EN ISO 178, Plastics - Determination of flexural properties (ISO 178)

EN ISO 6272-1, Paints and varnishes — Rapid-deformation (impact resistance) tests — Part 1: Falling-

weight test, large-area indenter (ISO 6272-1)

EN ISO 10456, Building materials and products — Hygrothermal properties —Tabulated design values

and procedures for determining declared and design thermal values (ISO 10456)

3 Terms and definitions

For the purpose of this document, the terms and definitions described in EN 13318 apply.

oSIST prEN 13813:2017

prEN 13813:2017 (E)

4 Designation of screed materials and characteristics

Screed materials shall be designated as one of the following types, according to the binder used and to

the definitions given in EN 13318:

CT cementitious screeds

CA calcium sulfate screeds

MA magnesite screeds

AS mastic asphalt screeds

SR synthetic resin screeds

For each type it is possible to have different classes, related to the different characteristics, designated

with the following abbreviations:

C for compressive strength

σ for compressive stress at 10 % strain

F for flexural strength

D for density

A for wear resistance “Böhme”

AR for wear resistance “BCA”

RWA for wear resistance to rolling wheel

SH for surface hardness

IC for resistance to indentation

IR for impact resistance

B for bond strength

SK for shrinkage

EM for elastic modulus

WP for water permeability

CDF for freeze–thaw resistance

5 Product characteristics

5.1 General

The requirements and properties specified in this standard shall be defined in terms of the test methods

and procedures referred to in this standard. For these tests the screed material shall be sampled and

the test specimens made and cured in accordance with EN 13892-1.

The conformity criteria given in the following subclauses relate to type tests and production control.

The following classes for screed materials in this clause are definitive and may not be defined using

intermediate values.

NOTE 1 The screed properties under site conditions cannot always be directly comparable with the screed

material properties obtained under laboratory conditions, due for instance to variations of mixing, compaction or

curing.

oSIST prEN 13813:2017

prEN 13813:2017 (E)

In Table 1 there are three different types of characteristics given.

Basic characteristics (B) and relevant characteristics (R) may be relevant for intended uses.

NOTE 2 Basic characteristics (B) generally identify a product whereas relevant characteristics (R) provide

further information relevant to specific applications.

Special characteristics (S) provide further information about its general performance.

Table 1 — Type related for physico-mechanical characteristics

Screed material

Internal use

Characteristic Test method

Characteristics for all intended uses

Compressive Strength EN 13892–2 C B B B B - R

U

EN 13892–2 B B B B - R

U

Flexural Strength F

c

EN ISO 178 - - - - - R

Density EN 1015–10 D R R R R R R

a

Wear Resistance :

“Böhme“ EN 13892–3 A R R R R R -

A A A A A

“BCA“ EN 13892–4 AR R R R R R R

A A A A A A

“rolling wheel“ EN 13892–5 RWA R R R R R R

A A A A A A

Surface Hardness EN 13892–6 SH - - - R - -

A

Resistance to

EN 12697–20 IC - - - - B -

indentation

pH value EN 13454–2 pH - - B - - -

Impact resistance EN ISO 6272-1 IR - - - - - R

A

Bond strength EN 13892–8 B R R R R - R

prEN 13892–

Shrinkage SK R R R R - R

9:2017

Modulus of elasticity in

EN 13412 EM R R R R - R

compression

Vertical Water

b

EN 12697–19 WP B - - - - -

U

Permeability

Abbreviation

Cementitious

External

use

CT

Cementitious

CT

Calcium sulfate

CA

Magnesite

MA

Mastic asphalt

AS

Synthetic resin

SR

oSIST prEN 13813:2017

prEN 13813:2017 (E)

b

Freeze–thaw resistance CEN/TS 12390–9 CDF B - - - - -

d d

Compressive Stress EN 826 σ R R R R R

Special Characteristics

Consistency EN 13454–2 CON S S S S - S

Setting time EN 13454–2 SET S S S S - -

Resistance to rolling

RWF

wheel with floor EN 13892–7 S S S S S S

C

covering

Chemical resistance EN 13529 CR S S S S S S

Water vapour

EN 12086 WVP S S S S S S

permeability

Electrical resistance EN 1081 ER S S S S S S

Thermal resistance EN 12664 TR S S S S S S

Other characteristic Indicate method used S S S S S S

Key:

- = not applicable characteristic

A = screed material intended for wearing surface

U = screed material intended for underlying layer

a

The use of one of the wear resistance tests is sufficient.

b

For underlying layers, the use of one of the two tests is sufficient.

c

Only for synthetic resin with layer thickness < 5 mm.

d

Only for the identification of the lightweight screed material.

oSIST prEN 13813:2017

prEN 13813:2017 (E)

5.2 Characteristics related to mechanical resistance

In Tables 2 to 6 characteristics for mechanical resistance of different types of screed materials and

different intended use are indicated.

Table 2 — Characteristics for mechanical resistance of cementitious screed materials (CT)

BASIC CHARACTERISTICS (B)

2 a INTERNAL USE

Characteristic Abbreviation Test Method

Compressive strength C EN 13892–2

Flexural strength F EN 13892–2

c

Density D EN 1015–10

2 b EXTERNAL USE

Characteristic Abbreviation Test Method

Compressive strength C EN 13892–2

Flexural strength F EN 13892–2

Vertical Water Permeability (only for underlying

WP EN 12697–19

a

layer)

a

Freeze–thaw resistance CDF CEN/TS 12390–9

2 c RELEVANT CHARACTERISTICS (R)

Characteristic Abbreviation Test Method

b

Wear resistance (intended for wearing surface)

“Bohme” A EN 13892–3

“BCA” AR EN 13892–4

“rolling wheel RWA EN 13892–5

Bond strength (intended for bonded screed) B EN 13892–8

prEN 13892–

Shrinkage SK

9:2017

Modulus of elasticity in compression EM EN 13412

d

Compressive stress at 10 % strain σ EN 826

a

For underlying layer use one of the two tests.

b

Use one of three wear resistance tests.

c

Only for the identification of the lightweight screed material.

d

Only for the identification of the lightweight screed material instead of testing compressive strength.

oSIST prEN 13813:2017

prEN 13813:2017 (E)

Table 3 — Characteristics for mechanical resistance of calcium sulfate screed materials (CA)

BASIC CHARACTERISTICS (B)

3 a INTERNAL USE

Characteristic Abbreviation Test Method

Compressive strength C EN 13892–2

Flexural strength F EN 13892–2

pH value PH EN 13454–2

b

Density D EN 1015–10

3 b RELEVANT CHARACTERISTICS (R)

Characteristic Abbreviation Test Method

a

Wear resistance (intended for wearing surface)

“Bohme” A EN 13892–3

“BCA” AR EN 13892–4

“rolling wheel RWA EN 13892–5

Bond strength (intended for bonded screed) B EN 13892–8

prEN 13892–

Shrinkage SK

9:2017

Modulus of elasticity in compression EM EN 13412

c

Compressive stress at 10 % strain σ EN 826

a

Use one of three wear resistance tests

b

Only for the identification of the lightweight screed material

c

Only for the identification of the lightweight screed material instead of testing compressive strength

oSIST prEN 13813:2017

prEN 13813:2017 (E)

Table 4 — Characteristics for mechanical resistance of magnesite screed materials (MA)

BASIC CHARACTERISTICS (B)

4 a INTERNAL USE

Characteristic Abbreviation Test Method

Compressive strength C EN 13892–2

Flexural strength F EN 13892–2

Surface hardness (only for wearing surfaces) SH EN 13892–6

b

Density D EN 1015–10

4 b RELEVANT CHARACTERISTICS (R)

Characteristic Abbreviation Test Method

a

Wear resistance (intended for wearing surface)

“Bohme” A EN 13892–3

“BCA” AR EN 13892–4

“rolling wheel RWA EN 13892–5

Bond strength (intended for bonded screed) B EN 13892–8

prEN 13892–

Shrinkage SK

9:2017

Modulus of elasticity in compression EM EN 13412

c

Compressive stress at 10 % strain σ EN 826

a

Use one of three wear resistance tests.

b

Only for the identification of the lightweight screed material.

c

Only for the identification of the lightweight screed material instead of testing compressive strength.

Table 5 — Characteristics for mechanical resistance of mastic asphalt screed materials (AS)

BASIC CHARACTERISTICS (B)

5 a INTERNAL USE

Characteristic Abbreviation Test Method

Resistance to indentation IC EN 12697–20

a

Density D EN 1015–10

RELEVANT CHARACTERISTICS (R)

b

Compressive stress at 10 % strain σ EN 826

a

Only for the identification of the lightweight screed material.

b

Only for the identification of the lightweight screed material instead of testing compressive strength.

oSIST prEN 13813:2017

prEN 13813:2017 (E)

Table 6 — Characteristics for mechanical resistance of synthetic resin screed materials (SR)

6 a BASIC CHARACTERISTICS (B)

Characteristic Abbreviation Test Method

Compressive strength (only for underlying layer) C EN 13892–2

Flexural strength (only for underlying layer) F EN 13892–2

Bond strength (only for wearing surface) B EN 13892–8

b

Density D EN 1015–10

6 b RELEVANT CHARACTERISTICS (R)

Characteristic Abbreviation Test Method

a

Wear resistance (intended for wearing surface)

“Bohme” A EN 13892–3

“BCA” AR EN 13892–4

“rolling wheel RWA EN 13892–5

Impact resistance (intended for wearing surface) IR EN 13892–6

prEN 13892–

Shrinkage SK

9:2017

Flexural strength (intended for layer

F EN ISO 178

thickness < 5 mm)

Bond strength (intended for bonded underlying

B EN 13892–8

layer)

c

Compressive stress at 10 % strain σ EN 826

a

Use one of three wear resistance tests.

b

Only for the identification of the lightweight screed material.

c

Only for the identification of the lightweight screed material instead of testing compressive strength.

5.3 Reaction to fire

5.3.1 General

Where use of a screed material is subject to regulatory requirements on reaction to fire, its reaction to

fire performance shall be declared as the class in accordance with EN 13501-1, based on one of the

following options:

a) either without the need for testing (CWT) according to 4.4.2 or without the need for further testing

(CWFT) according to 4.4.3, when meeting the requirements, specified in therein, or otherwise

b) based on results of the test method(s), relevant to specific reaction to fire class, and carried out in

accordance with the standard(s) referred to in EN 13501-1, as specified in 4.4.4.

oSIST prEN 13813:2017

prEN 13813:2017 (E)

5.3.2 Screed materials classified as Class A1 without the need for testing (CWT)

1)

The reaction to fire performance of a given type of screed material may be declared as Class A1

without the need for testing, provided that it contains not more than 1 % of homogeneously distributed

organic material, by mass or volume (whichever is the most onerous).

5.3.3 Screed materials classified as class E without the need for further testing (CWFT)

The reaction to fire performance of a given type of screed material may be declared as class given in

2)

Tables 7 and 8 , when meeting the requirements for specific type of screed material, specified therein.

Table 7 — Classes of reaction-to-fire performance for cementitious and calcium sulphate screeds

Organic content Maximum layer

a b

Product Class

(% in weight) thickness (mm)

Cementitious screeds according to prEN 13813

< 20 30 E

Calcium sulphate screeds according to prEN 13813

a 3

Mounted on any substrate of at least class D-s2, d0 and with density ≥ 680 kg/m .

b

Class E as provided for in Table 1 of the Annex to Commission Decision 2000/147/EC when the screed is

used as underlying layer.

Table 8 — Classes of reaction-to-fire performance for synthetic resin screeds

Organic content Maximum layer

a b

Product Class

(% in weight) thickness (mm)

Unfilled synthetic resin floor screeds with binder

made of epoxy resin or polyurethane resin or

100 4

polymethylmethacrylates resin or vinylester resin

in accordance with prEN 13813

Filled synthetic resin floor screeds with binder

made of epoxy resin or polyurethane resin or

polymethylmethacrylates resin or vinylester resin < 75 10

E or E

fl

and filled with mineral aggregates in accordance

with prEN 13813

Filled synthetic resin floor screeds scattered with

silica sand with binder made of epoxy resin or

polyurethane resin or polymethylmethacrylates < 75 10

resin or vinylester resin and filled with mineral

aggregates in accordance with prEN 13813

a

Mounted on a substrate of at least class A2-s1,d0 with minimum thickness 6 mm and with minimum

density 1 800 kg/m 3 .

b

Class E as provided for in Table 1 of the Annex to Commission Decision 2000/147/EC when the screed is

used as underlying layer, or Class E as provided for in Table 2 of the Annex to Commission Decision

fl

2000/147/EC when the screed is used as wearing layer.

1) See Decision of the Commission 96/603/EC of 1996-10-04 (see OJEU L267 of 1996-10-19), as amended by

2000/605/EC of 2000-09-26 (see OJEU L258 of 2000-10-12) and 2003/424/EC of 2003-06-06 (see OJEU L144 of

2003-06-12).

2) These tables are the same as Tables of the Commission Decision 2010/85/EU of 2010-02-09 (see OJEU L038

of 2010-02-11).

oSIST prEN 13813:2017

prEN 13813:2017 (E)

5.3.4 Screed materials classified according to the test results

The reaction to fire performance of a given type of screed material shall be declared as class (including

the additional classification for smoke production and flaming droplets/particles, if any), determined on

a base of results of the tests carried out on the specimens prepared in accordance with the relevant

methods, which are specified for considered class in the standards referred in EN 13501-1.

5.4 Release of corrosive substances

Release of corrosive substances or corrosiveness of screed materials will be dealt with by a declaration

of the material type according to the symbols given in Clause 4.

5.5 Compressive strength

The compressive strength, for cementitious screed, calcium sulfate screed, magnesite screed materials

and synthetic resin screed materials shall be declared by the manufacturer.

The compressive strength shall be determined in accordance with EN 13892-2.

The compressive strength shall be designated by a “C” (for Compression) followed by the compressive

strength class in N/mm , in accordance with Table 9.

Table 9 — Compressive strength classes for screed materials

Class C5 C8 C12 C16 C20 Higher in

multiples of 5

Compressive strength in ≥ 5 ≥ 8 ≥ 12 ≥ 16 ≥ 20

≥ 25 - ≥ 30-etc

N/mm and < 8 and < 12 and < 16 and < 20 and < 25

5.6 Flexural strength

The flexural strength, for cementitious screed, calcium sulfate screed and magnesite screed materials

shall be determined in accordance with EN 13892-2.

The flexural strength of synthetic resin screed materials shall be determined in accordance with

EN ISO 178 for screed materials intended to be applied at a thickness of 5 mm or less, or with

EN 13892-2 for other screed materials.

The flexural strength is designated with “F” (for Flexural) followed by the flexural strength in N/mm , in

accordance with Table 10.

Table 10 — Flexural strength classes for screed materials

F1 F1 F1 F1 Higher in

Class F1 F2 F3 F4 F5 F6 F7 F8 F9

0 1 2 5 multiples of 5

≥ 1 ≥ 1 ≥ 1

≥ 1 ≥ 2 ≥ 3 ≥ 4 ≥ 5 ≥ 6 ≥ 7 ≥ 8 ≥ 9 ≥ 2

Flexural 0 1 5

an an an an an an an an an an ≥ 20 - ≥ 25-

strength in an an an

d < d < d < d < d < d < d < d < d < d < etc

N/mm d < d < d <

2 3 4 5 6 7 8 9 10 15

11 12 20

oSIST prEN 13813:2017

prEN 13813:2017 (E)

5.7 Wear resistance

The wear resistance for cementitious screed materials and for synthetic resin screed materials, to be

used as wearing surfaces, shall be determined in accordance with EN 13892-3 (wear resistance Böhme)

or with EN 13892-4 (wear resistance BCA) or with EN 13892-5 (wear resistance to rolling wheel) and

shall be declared by the manufacturer. To declare the wear resistance for cementitious screed

materials, the manufacturer may choose between the three test methods and for synthetic resin screed

materials between the wear resistance BCA and the wear resistance to rolling wheel.

A manufacturer of a screed material other than cementitious or synthetic resin screed material to be

used as a wearing surface may choose to determine and declare the appropriate wear class utilizing

these methods.

Another test method may be used, if a correlation with EN 13892-3, with EN 13892-4 or with

EN 13892-5 is proven with the screed material.

The wear resistance Böhme is designated by “A” (for Abrasion) followed by the abrasion quantity in

3 2

cm /50 cm , in accordance with Table 11.

Table 11 — Wear resistance Böhme classes for cementitious and other screed materials

Class A22 A18 A15 A12 A9 A6 A3 A1,5

Abrasion quantity > 18 > 15 > 12 > 9 > 6 > 3 > 1,5

≤ 1,5

3 2

in cm /50 cm and ≤ 22 and ≤ 18 and ≤ 15 and ≤ 12 and ≤ 9 and ≤ 6 and ≤ 3

The wear resistance BCA is designated by an “AR” (for Abrasion Resistance) followed by the maximum

wear depth in 100 μm, in accordance with Table 12.

Table 12 — Wear resistance BCA classes for cementitious and other screed materials

Class AR6 AR4 AR2 AR1 AR0,5

≤ 600 and ≤ 400 and ≤ 200 and ≤ 100 and

Maximum wear depth

≤ 50

in μm

> 400 > 200 > 100 > 50

The wear resistance to rolling wheel is designated by “RWA” (for Rolling Wheel Abrasion) followed by

the abrasion quantity in cm , in accordance with Table 13.

Table 13 — Wear resistance to rolling wheel classes for cementitious and other screed materials

Class RWA300 RWA100 RWA50 RWA20 RWA 10 RWA5 RWA1

≤ 300

≤ 5 and

Abrasion quantity ≤ 100 ≤ 50 ≤ 20 ≤ 10

and > 10 ≤ 1

in cm and > 50 and > 20 and > 10 and > 5

> 1

5.8 Surface hardness

The surface hardness for magnesite screed materials, to be used as wearing surfaces, shall be declared

by the manufacturer and as an option may be declared for other types of screed materials with fine

aggregates (<4 mm). The surface hardness shall be determined in accordance with EN 13892-6.

The surface hardness is designated with “SH” (for Surface Hardness) followed by the surface hardness

in N/mm , in accordance with Table 14.

oSIST prEN 13813:2017

prEN 13813:2017 (E)

Table 14 — Surface hardness

Higher in

Class SH30 SH40 SH50 SH60 SH70 SH80 SH100 SH120 SH150 multiples

of 50

≥ 30 ≥ 40 ≥ 50 ≥ 60 ≥ 70 ≥ 80 ≥ 100 ≥ 120 ≥ 150

Surface

≥ 200-

and and and and and and and and and

hardness in

≥ 250-etc

N/mm

< 40 < 50 < 60 < 70 < 80 < 100 < 120 < 150 < 200

5.9 Resistance to indentation

The manufacturer shall declare the resistance to indentation of mastic asphalt screed materials. The

resistance to indentation shall be determined on cubes in accordance with EN 12697-20 The resistance

to indentation of mastic asphalt screed materials shall be designated by “I” (for Indentation), “C” (for

Cube), followed by the maximum indentation value in 0,1 mm, in accordance with Table 15.

The designation “H” signifies material for use in heated screeds.

Table 15 — Hardness classes on cubes − Load applied 525 N − Indentation in units of 0,1 mm

Class

Test conditions

IC H10 IC 10 IC 15 IC 40 IC 100

(22 ± 1) °C; 100 mm ;

≤ 10 ≤ 10 > 10 and ≤ 15 — —

5 h

(40 ± 1) °C; 100 mm ;

≤ 20 ≤ 40 > 40 and ≤ 60 — —

2 h

(40 ± 1) °C; 500 mm ;

— — — > 15 and ≤ 40 > 40 and ≤ 100

0,5 h

5.10 pH value

For calcium sulfate screed material the pH value shall be greater than or equal to 7, for cementitious

and magnesite screed material a manufacturer may declare the pH value.

The pH is designated as pH followed by the pH value.

The pH shall be determined in accordance with EN 13454-2.

5.11 Impact resistance

The impact resistance shall be declared by the manufacturer for synthetic resin screed materials,

intended for wearing surfaces. The impact resistance for the screed material, applied to a concrete

surface, shall be determined in accordance with EN ISO 6272-1.

The impact resistance shall be designated by “IR” (for Impact Resistance) followed by the impact

resistance in Nm.

5.12 Bond strength

The bond strength shall be declared by the manufacturer for synthetic resin screed materials, and,

where relevant, shall be declared for cementitious, calcium sulfate and magnesite screed materials. The

bond strength shall be determined in accordance with EN 13892-8.

oSIST prEN 13813:2017

prEN 13813:2017 (E)

The bond strength shall be designated by “B” (for Bond) followed by the bond strength in N/mm , in

accordance with Table 16.

Table 16 — Bond strength classes for cementitious, calcium sulfate, magnesite and synthetic

resin screed material

Higher in

multiples of 0,5

Class B0,2 B0,5 B1,0 B1,5 B2,0

Bond strength in ≥ 0,2 ≥ 0,5 ≥ 1,0 ≥ 1,5 ≥ 2,0 ≥ 2,5 and ≥ 3,0,

N/mm and < 0,5 and < 1,0 and < 1,5 and < 2,0 and < 2,5 etc

5.13 Shrinkage

The shrinkage of cementitious, calcium sulfate, magnesite and synthetic resin screed materials shall be

declared by the manufacturer and designated by “SK” (for ShrinKage) followed by the change of length

in mm/m.

The shrinkage shall be determined in accordance with prEN 13892-9:2017.

5.14 Modulus of elasticity in compression

The modulus of elasticity in compression of a screed material other than mastic asphalt shall be

declared by the manufacturer and designated by “EM” followed by the modulus of elasticity in kN/mm2.

The modulus of elasticity shall be determined in accordance with EN 13412.

5.15 Vertical water permeability

The vertical water permeability of cementitious screed materials, intended for external use, shall be

determined in accordance with the test method described in EN 12697-19.

The vertical water permeability shall be designated by “WP” (for Water Permeability) followed by the

−4

value in in 10 m/s.

5.16 Freeze–thaw resistance

The freeze–thaw resistance of cementitious screed materials, intended for external use, shall be

declared by the manufacturer and designated by “CDF” (for Capillary suction of De-icing solution and

Freeze-thaw) followed by the loss of material in g/m .

The freeze - thaw resistance shall be determined in accordance with CEN/TS 12390-9. The sample

should be prepared in accordance with the manufacturer’s guideline. The loss of material should be

measured after 28 freeze–thaw cycles.

5.17 Density

The density of screed materials shall be declared by the manufacturer and designated by “D” followed

by the density in g/dm .

The density shall be determined in accordance with EN 1015-10. The sample should be prepared in

accordance with the manufacturer’s guideline.

oSIST prEN 13813:2017

prEN 13813:2017 (E)

5.18 Compressive stress at 10 % strain

The compressive stress at 10 % strain of lightweight screed materials shall be declared by the

manufacturer and designated by “σ ” followed by the value in kPa.

The compressive stress at 10 % strain shall be determined in accordance with EN 826. The sample

should be prepared in accordance with the manufacturer’s guideline.

5.19 Special characteristics

5.19.1 Consistency

A manufacturer of a screed material, other than mastic asphalt, may declare the consistency, in mm,

determined in accordance with EN 13454-2; where the consistency value is greater than 300 mm, it

may be determined in accordance with EN 12706.

5.19.2 Setting time

A manufacturer of cementitious or calcium sulfate screed material may declare the setting time of the

screed material determined in accordance with EN 13454-2.

5.19.3 Resistance to rolling wheel with floor covering

The resistance to rolling wheel, for all screed materials for screeds intended to be covered with floor

covering, may be declared by the manufacturer.

The resistance to rolling wheel is designated by “RWFC” (for Rolling Wheel Floor Covering) followed by

the rolling wheel load in N.

The resistance to rolling wheel shall be determined in accordance with EN 13892-7.

5.19.4 Chemical resistance

The chemical resistance shall be determined in accordance with EN 13529 and is indicated by “CR” (for

Chemical Resistance) followed by a list of those chemical groups to which resistance has been

demonstrated, with the class of resistance (class 1 or 2), for example CR1 to 8 (class 2), 12 (class 1), 14

(class 2).

5.19.5 Water vapour permeability

Where the intended use of the screed material is for moisture diffusion control, the permeability to

water vapour of the screed material shall be determined in accordance with EN 12086.

5.19.6 Electrical resistance

The electrical resistance shall be determined in accordance with EN 1081 and is indicated by “ER” (for

Electrical Resistance) followed with the electrical resistance in Ohm, for instance ER105.

5.19.7 Thermal resistance

Where the intended use of the screed material is to contribute to thermal resistance in building

construction works (floor screeds), either the design values of thermal resistance for screed material

given in EN ISO 10456 may be used or the product shall be tested in accordance with EN 12664.

oSIST prEN 13813:2017

prEN 13813:2017 (E)

6 Assessment and verification of constancy of performance - AVCP

6.1 General

The compliance of the screed material with the requirements of this standard and with the

performances declared by the manufacturer in the DoP shall be demonstrated by:

— determination of the product-type on the base of type testing

— factory production control by the manufacturer, including product assessment.

The manufacturer shall always retain the overall control and shall have the necessary means to take

responsibility for the conformity of the product with its declared performances.

6.2 Type testing

6.2.1 General

All performances related to characteristics included in this standard shall be determined when the

manufacturer intends to declare the respective performances unless the standard gives provisions for

declaring them without performing tests (e.g. use of previously existing data, CWFT and conventionally

accepted performance).

Assessment previously performed in accordance with the provisions of this standard, may be taken into

account provided that they were made to the same or a more rigorous test method, under the same

AVCP system on the same product or products of similar design, construction and functionality, such

that the results are applicable to the product in question.

Reference to the assessment method standards should be made to allow the selection of a suitable

repr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...