EN 15746-2:2020

(Main)Railway applications - Track - Road-rail machines and associated equipment - Part 2: General safety requirements

Railway applications - Track - Road-rail machines and associated equipment - Part 2: General safety requirements

This document specifies the significant hazards, hazardous situations and events, common to self-propelled road-rail machines - henceforward referred to as machines - and associated equipment, arising due to the adaptation for their use on railway networks and urban rail networks. These machines are intended for construction, maintenance and inspection of the railway infrastructure, shunting and emergency rescue vehicles, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer; see Clause 4.

This document deals with the common hazards during assembly and installation, commissioning, travelling on and off track, use including setting, programming, and process changeover, operation, cleaning, fault finding, maintenance and de-commissioning of the machines.

NOTE Specific measures for exceptional circumstances are not dealt with in this document. They can be subject to negotiation between manufacturer and the machine operator.

The common hazards dealt with include the general hazards presented by the machines, also the hazards presented by the following specific machine functions:

a) excavation;

b) ballast tamping, ballast cleaning, ballast regulating, ballast consolidating;

c) track construction, renewal, maintenance and repair;

d) lifting;

e) overhead contact line system renewal / maintenance;

f) maintenance of the components of the infrastructure;

g) inspection and measurement of the components of the infrastructure;

h) working in tunnels;

i) shunting;

j) vegetation control;

k) emergency rescue and recovery;

during commissioning, use, maintenance and servicing.

For a road-rail machine it is assumed that an EU road permissible host vehicle will offer an accepted safety level for its designed basic functions before conversion. Unless explicitly stated otherwise in a particular clause this specific aspect is not dealt with in this document.

This document does not deal with:

1) requirements with regard to the quality of work and the performance of the machine;

2) machines that utilize the contact line system for traction purposes;

3) specific requirements established by a railway Infrastructure Manager or Urban Rail Manager;

4) negotiations between the manufacturer and the machine operator for additional or alternative requirements;

5) requirements for use and travel of the machine on public highway;

6) hazards due to air pressure caused by the passing of high-speed trains at more than 190 km/h;

7) requirements which could be necessary in case of use in extreme conditions, such as extreme ambient temperatures (tropical or polar); see 5.30;

8) highly corrosive or contaminating environment, e.g. due to the presence of chemicals;

9) potentially explosive atmospheres.

Other special machines used on railway tracks are dealt with in other European Standards, see Annex E.

Bahnanwendungen - Oberbau - Zweiwege-Maschinen und zugehörige Ausrüstungen - Teil 2: Allgemeine Sicherheitsanforderungen

Dieses Dokument legt die signifikanten Gefährdungen, gefährlichen Situationen und Ereignisse fest, die durch die Anpassung für den Einsatz auf dem Eisenbahnnetz und auf Schienennahverkehrssystemen von selbstangetriebenen Zweiwege Maschinen – im Folgenden als Maschinen bezeichnet – und von deren Ausrüstungen entstehen. Diese Maschinen sind vorgesehen für Bau, Instandhaltung und Inspektion der Eisenbahninfrastruktur, für Rangier- und Notfallfahrzeuge, sofern sie bestimmungsgemäß und unter den Bedingungen der vernünftigerweise vorhersehbaren Fehlanwendungen durch den Hersteller verwendet werden, siehe Abschnitt 4.

Dieses Dokument behandelt die allgemeinen Gefährdungen beim Aufrüsten und Einrichten, bei Inbetriebnahme, Versetzfahrten auf dem Gleis und außerhalb des Gleises, Gebrauch einschließlich Einstellen, Programmieren und Umrüsten, Betrieb, Reinigung, Fehlersuche, Instandhaltung und Außerbetriebnahme der Maschinen.

ANMERKUNG Besondere Maßnahmen für außergewöhnliche Umstände werden in diesem Dokument nicht behandelt. Sie können in einem Vertrag zwischen Hersteller und Maschinenbetreiber vereinbart werden.

Die behandelten üblichen Gefährdungen umfassen die allgemeinen von der Maschine ausgehenden Gefährdungen sowie auch die Gefährdungen, die durch die folgenden spezifischen Maschinenfunktionen während der Inbetriebnahme, des Gebrauchs, der Instandhaltung und der Wartung entstehen:

a) Aushubarbeiten;

b) Schotter stopfen, Schotter reinigen, Schotter profilieren, Schotter verdichten;

c) Gleisbau, -erneuerung, -wartung und -instandsetzung;

d) Kranbetrieb;

e) Oberleitungsanlagenerneuerung/-instandhaltung;

f) Instandhaltung der Infrastrukturkomponenten;

g) Überprüfung und Messung der Infrastrukturkomponenten;

h) Arbeiten im Tunnel;

i) Rangieren;

j) Vegetationskontrolle;

k) Notfallrettung und -bergung.

Für eine Zweiwege-Maschine wird vorausgesetzt, dass ein EU-Straßen-zugelassenes Basisfahrzeug ein akzeptiertes Sicherheitsniveau für seine vorgesehenen Grundfunktionen vor der Umrüstung bietet. Sofern in einem bestimmten Abschnitt nicht ausdrücklich etwas anderes festgelegt ist, wird dieser besondere Aspekt in diesem Dokument nicht behandelt.

Dieses Dokument behandelt nicht:

1) Anforderungen an die Qualität der Arbeit und an die Leistung der Maschine;

2) Maschinen, die die Oberleitungsanlage zur Traktion nutzen;

3) spezifische Anforderungen, die vom Infrastruktur- oder Nahverkehrsinfrastrukturbetreiber festgelegt werden;

4) Vereinbarungen zwischen dem Hersteller und dem Maschinenbetreiber hinsichtlich zusätzlicher oder alternativer Anforderungen;

5) Anforderungen an den Gebrauch und an die Fahrt der Maschine auf öffentlichen Straßen;

6) Gefährdungen durch aerodynamische Lasten, verursacht durch das Vorbeifahren von Hoch-geschwindigkeitszügen mit mehr als 190 km/h;

7) Anforderungen, die für den Einsatz unter extremen Bedingungen notwendig sein könnten, wie beispielsweise extreme Umgebungstemperaturen (tropisch oder polar), siehe 5.30;

8) hochkorrosive oder kontaminierende Umgebung, z. B. durch vorhandene Chemikalien;

9) explosionsgefährdete Bereiche.

Andere Spezialfahrzeuge für den Einsatz auf Eisenbahngleisen werden in anderen Europäischen Normen behandelt, siehe Anhang E.

Applications ferroviaires - Voie - Machines rail-route et équipements associés - Partie 2 : Exigences générales pour la sécurité

Le présent document spécifie les phénomènes, situations et événements dangereux significatifs, communs aux machines rail-route automotrices (ci-après désignées les « machines ») et équipements associés, qui sont consécutifs à leur utilisation sur les réseaux ferroviaires et les réseaux ferroviaires urbains. Ces machines sont destinées à la construction, à la maintenance et à l'inspection de l'infrastructure ferroviaire, aux manœuvres et aux véhicules de secours d'urgence. Le présent document s'applique aux machines rail-route automotrices lorsqu'elles sont utilisées normalement et dans les conditions prévues par le fabricant (voir Article 4).

Le présent document traite des phénomènes dangereux communs qui se produisent durant l'assemblage et l'installation, la mise en service, le déplacement en voie et hors voie, l'utilisation (y compris montage, programmation et changement de procédés, nettoyage, localisation des défauts, entretien et mise hors service des machines).

NOTE Les mesures spécifiques en cas de circonstances exceptionnelles ne sont pas traitées dans le présent document. Celles-ci peuvent faire l'objet de négociations entre le fabricant et l'opérateur de la machine.

Les phénomènes dangereux communs traitent des phénomènes dangereux généraux représentés par les machines, ainsi que ceux dus aux fonctions spécifiques de la machine :

a) excavation ;

b) bourrage, criblage, régalage et consolidation du ballast ;

c) construction, renouvellement, maintenance et réparation des voies ;

d) levage-relevage ;

e) renouvellement/maintenance des systèmes caténaires ;

f) maintenance des constituants de l'infrastructure ;

g) inspection et mesure des constituants de l'infrastructure ;

h) travail dans les tunnels ;

i) manœuvres ;

j) maîtrise de la végétation ;

k) secours d'urgence et dépannage ;

pendant la mise en service, l'utilisation, l'entretien et la maintenance.

Pour une machine rail-route, il est supposé qu'un véhicule-hôte autorisé à circuler sur le réseau routier au sein de l'Union européenne offrira un niveau de sécurité acceptable pour ses fonctions de base avant conversion. Sauf spécification contraire explicite dans un article particulier, cet aspect spécifique n'est pas traité dans le présent document.

Le présent document ne s'applique pas :

1) aux prescriptions relatives à la qualité du travail et aux performances de la machine ;

2) aux machines utilisant le système caténaire pour la traction ;

3) aux prescriptions spécifiques établies par le gestionnaire de l'infrastructure ferroviaire ou le gestionnaire du réseau ferroviaire urbain ;

4) aux négociations entre le fabricant et l'opérateur de la machine pour des prescriptions supplémentaires ou alternatives ;

5) aux prescriptions d'utilisation et de déplacement de la machine sur voie publique ;

6) aux risques dus à la pression de l'air causée par le passage des trains à grande vitesse à plus de 190 km/h ;

7) aux prescriptions qui pourraient être nécessaires en cas d'utilisation dans des conditions extrêmes, telles que des températures ambiantes extrêmes (tropicales ou polaires), voir 5.30 ;

8) à un environnement hautement corrosif ou contaminant, par exemple provoqué par la présence de produits chimiques ;

9) aux atmosphères potentiellement explosives.

Les autres machines spéciales empruntant également les voies ferrées sont couvertes par d'autres Normes européennes (voir Annexe E).

Železniške naprave - Zgornji ustroj proge - Dvopotna železniška vozila in oprema - 2. del: Splošne varnostne zahteve

General Information

- Status

- Published

- Publication Date

- 22-Dec-2020

- Withdrawal Date

- 29-Jun-2021

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 1/WG 5 - Track construction and maintenance machines

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 23-Dec-2020

- Completion Date

- 23-Dec-2020

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

ISO 15817:2012 - Earth-moving machinery — Safety requirements for remote operator control systems - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

Overview

EN 15746-2:2020 - Railway applications - Track - Road-rail machines and associated equipment - Part 2: General safety requirements - sets out the significant hazards, hazardous situations and events common to self-propelled road‑rail machines (RRMs) and associated equipment when adapted for use on railway and urban rail networks. It covers hazards arising during assembly, installation, commissioning, travelling on and off track, use (including setting/programming), maintenance, fault finding and de‑commissioning. The standard supports safe design and operation for machines used in construction, maintenance, inspection, shunting and emergency rescue.

Key technical topics and requirements

The standard addresses a comprehensive list of safety topics (some highlighted below are drawn from the document structure):

- Hazard identification: list of significant hazards and hazardous situations specific to RRMs.

- Access and egress: safe cab and workplace access, walkways and emergency exits.

- Ergonomics and visibility: cab layout, operator seating, minimum dimensions and sightlines.

- Stability and derailment prevention: stability in road and rail configurations and measures to avoid overturning and derailment.

- Controls and protection: operator controls, indicators, prevention of accidental activation, remote controls and emergency stopping devices.

- Braking and traction: braking system requirements for running and working modes, including holding on gradients and trailing vehicles.

- Electrical systems & EMC: safe electrical design, bonding, batteries, antennae and electromagnetic compatibility.

- Fire, noise and vibration: fire detection/extinguishing, noise mitigation and whole‑body/hand‑arm vibration controls.

- Moving parts & lifting: guarding, conveyors, cranes and safe transport of loads.

- Maintenance and servicing: design for safe maintenance, support devices and prevention of unauthorized access.

- Special functions: requirements for excavation, ballast handling, overhead contact line works, tunnel working, shunting, vegetation control, emergency recovery, inspection and measurement.

The document also lists explicit exclusions (e.g., machine performance/quality, machines using contact line for traction, public highway use, extreme climates, explosive atmospheres, hazards from trains >190 km/h aerodynamic pressure).

Practical applications - who uses this standard

- Machine manufacturers and designers - to design RRMs that comply with European safety expectations.

- System integrators and converters - for safe conversion of road vehicles to rail operation.

- Railway Infrastructure Managers & Urban Rail Operators - to define safety expectations, procurement requirements and interfaces (note: specific IM/URM requirements may be additional).

- Safety assessors and certification bodies - for risk assessments and conformity checks.

- Maintenance teams and operators - to implement safe procedures and machine selection for track works, shunting and emergency rescue.

Related standards

- This Part 2 forms part of the EN 15746 series; other parts and European standards cover special machines and further technical detail (see Annex E of the standard for cross‑references). National and Infrastructure Manager requirements may apply in addition.

Keywords: EN 15746-2:2020, road-rail machines, railway safety, track maintenance, general safety requirements, rail machinery standards.

Get Certified

Connect with accredited certification bodies for this standard

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 15746-2:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Track - Road-rail machines and associated equipment - Part 2: General safety requirements". This standard covers: This document specifies the significant hazards, hazardous situations and events, common to self-propelled road-rail machines - henceforward referred to as machines - and associated equipment, arising due to the adaptation for their use on railway networks and urban rail networks. These machines are intended for construction, maintenance and inspection of the railway infrastructure, shunting and emergency rescue vehicles, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer; see Clause 4. This document deals with the common hazards during assembly and installation, commissioning, travelling on and off track, use including setting, programming, and process changeover, operation, cleaning, fault finding, maintenance and de-commissioning of the machines. NOTE Specific measures for exceptional circumstances are not dealt with in this document. They can be subject to negotiation between manufacturer and the machine operator. The common hazards dealt with include the general hazards presented by the machines, also the hazards presented by the following specific machine functions: a) excavation; b) ballast tamping, ballast cleaning, ballast regulating, ballast consolidating; c) track construction, renewal, maintenance and repair; d) lifting; e) overhead contact line system renewal / maintenance; f) maintenance of the components of the infrastructure; g) inspection and measurement of the components of the infrastructure; h) working in tunnels; i) shunting; j) vegetation control; k) emergency rescue and recovery; during commissioning, use, maintenance and servicing. For a road-rail machine it is assumed that an EU road permissible host vehicle will offer an accepted safety level for its designed basic functions before conversion. Unless explicitly stated otherwise in a particular clause this specific aspect is not dealt with in this document. This document does not deal with: 1) requirements with regard to the quality of work and the performance of the machine; 2) machines that utilize the contact line system for traction purposes; 3) specific requirements established by a railway Infrastructure Manager or Urban Rail Manager; 4) negotiations between the manufacturer and the machine operator for additional or alternative requirements; 5) requirements for use and travel of the machine on public highway; 6) hazards due to air pressure caused by the passing of high-speed trains at more than 190 km/h; 7) requirements which could be necessary in case of use in extreme conditions, such as extreme ambient temperatures (tropical or polar); see 5.30; 8) highly corrosive or contaminating environment, e.g. due to the presence of chemicals; 9) potentially explosive atmospheres. Other special machines used on railway tracks are dealt with in other European Standards, see Annex E.

This document specifies the significant hazards, hazardous situations and events, common to self-propelled road-rail machines - henceforward referred to as machines - and associated equipment, arising due to the adaptation for their use on railway networks and urban rail networks. These machines are intended for construction, maintenance and inspection of the railway infrastructure, shunting and emergency rescue vehicles, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer; see Clause 4. This document deals with the common hazards during assembly and installation, commissioning, travelling on and off track, use including setting, programming, and process changeover, operation, cleaning, fault finding, maintenance and de-commissioning of the machines. NOTE Specific measures for exceptional circumstances are not dealt with in this document. They can be subject to negotiation between manufacturer and the machine operator. The common hazards dealt with include the general hazards presented by the machines, also the hazards presented by the following specific machine functions: a) excavation; b) ballast tamping, ballast cleaning, ballast regulating, ballast consolidating; c) track construction, renewal, maintenance and repair; d) lifting; e) overhead contact line system renewal / maintenance; f) maintenance of the components of the infrastructure; g) inspection and measurement of the components of the infrastructure; h) working in tunnels; i) shunting; j) vegetation control; k) emergency rescue and recovery; during commissioning, use, maintenance and servicing. For a road-rail machine it is assumed that an EU road permissible host vehicle will offer an accepted safety level for its designed basic functions before conversion. Unless explicitly stated otherwise in a particular clause this specific aspect is not dealt with in this document. This document does not deal with: 1) requirements with regard to the quality of work and the performance of the machine; 2) machines that utilize the contact line system for traction purposes; 3) specific requirements established by a railway Infrastructure Manager or Urban Rail Manager; 4) negotiations between the manufacturer and the machine operator for additional or alternative requirements; 5) requirements for use and travel of the machine on public highway; 6) hazards due to air pressure caused by the passing of high-speed trains at more than 190 km/h; 7) requirements which could be necessary in case of use in extreme conditions, such as extreme ambient temperatures (tropical or polar); see 5.30; 8) highly corrosive or contaminating environment, e.g. due to the presence of chemicals; 9) potentially explosive atmospheres. Other special machines used on railway tracks are dealt with in other European Standards, see Annex E.

EN 15746-2:2020 is classified under the following ICS (International Classification for Standards) categories: 93.100 - Construction of railways. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15746-2:2020 has the following relationships with other standards: It is inter standard links to EN 15746-2:2010+A1:2011, EN 62262:2002, EN 61310-1:2008, EN 60529:1991, EN 61508-3:2010, ISO 3864-4:2011, EN 60529:1991/A2:2013, ISO 10263-5:2009, EN 61310-2:2008, ISO 3864-1:2011, ISO 15817:2012, ISO 12117-2:2008, EN 60204-1:2018, ISO 3864-3:2012, ISO 12508:1994. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15746-2:2020 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 2008/57/EC; Standardization Mandates: M/396, M/483. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15746-2:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2021

Nadomešča:

SIST EN 15746-2:2010+A1:2012

Železniške naprave - Zgornji ustroj proge - Dvopotna železniška vozila in oprema -

2. del: Splošne varnostne zahteve

Railway applications - Track - Road-rail machines and associated equipment - Part 2:

General safety requirements

Bahnanwendungen - Oberbau - Zweiwege-Maschinen und zugehörige Ausrüstungen -

Teil 2: Allgemeine Sicherheitsanforderungen

Applications ferroviaires - Voie - Machines rail-route et équipements associés - Partie 2 :

Exigences générales pour la sécurité

Ta slovenski standard je istoveten z: EN 15746-2:2020

ICS:

45.060.01 Železniška vozila na splošno Railway rolling stock in

general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 15746-2

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2020

EUROPÄISCHE NORM

ICS 93.100 Supersedes EN 15746-2:2010+A1:2011

English Version

Railway applications - Track - Road-rail machines and

associated equipment - Part 2: General safety

requirements

Applications ferroviaires - Voie - Machines rail route et Bahnanwendungen - Oberbau - Zweiwege-Maschinen

équipements associés - Partie 2 : Prescriptions und zugehörige Ausrüstungen - Teil 2: Allgemeine

générales pour la sécurité Sicherheitsanforderungen

This European Standard was approved by CEN on 9 November 2020.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 15746-2:2020 E

worldwide for CEN national Members.

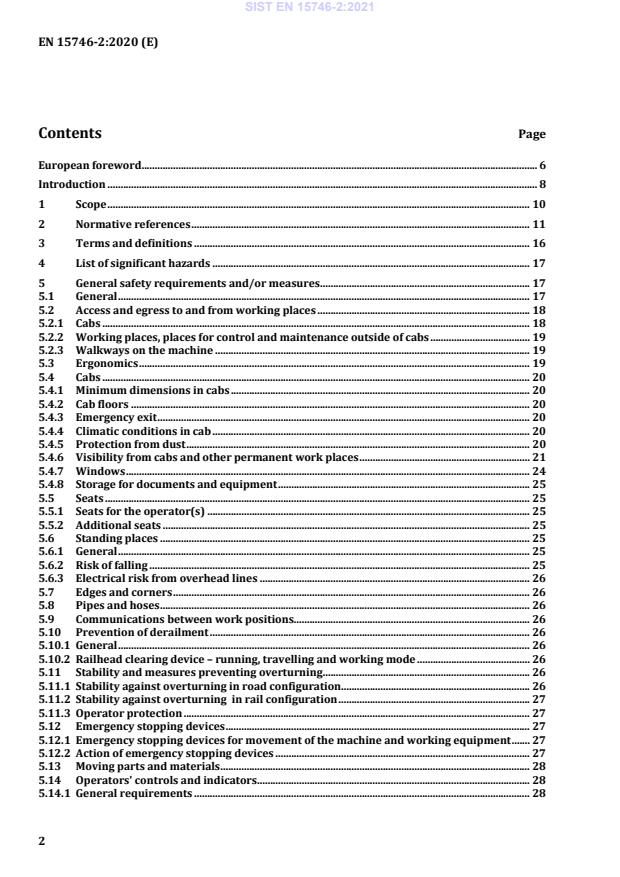

Contents Page

European foreword . 6

Introduction . 8

1 Scope . 10

2 Normative references . 11

3 Terms and definitions . 16

4 List of significant hazards . 17

5 General safety requirements and/or measures . 17

5.1 General . 17

5.2 Access and egress to and from working places . 18

5.2.1 Cabs . 18

5.2.2 Working places, places for control and maintenance outside of cabs . 19

5.2.3 Walkways on the machine . 19

5.3 Ergonomics . 19

5.4 Cabs . 20

5.4.1 Minimum dimensions in cabs . 20

5.4.2 Cab floors . 20

5.4.3 Emergency exit . 20

5.4.4 Climatic conditions in cab . 20

5.4.5 Protection from dust . 20

5.4.6 Visibility from cabs and other permanent work places . 21

5.4.7 Windows . 24

5.4.8 Storage for documents and equipment . 25

5.5 Seats . 25

5.5.1 Seats for the operator(s) . 25

5.5.2 Additional seats . 25

5.6 Standing places . 25

5.6.1 General . 25

5.6.2 Risk of falling . 25

5.6.3 Electrical risk from overhead lines . 26

5.7 Edges and corners . 26

5.8 Pipes and hoses . 26

5.9 Communications between work positions. 26

5.10 Prevention of derailment . 26

5.10.1 General . 26

5.10.2 Railhead clearing device – running, travelling and working mode . 26

5.11 Stability and measures preventing overturning . 26

5.11.1 Stability against overturning in road configuration. 26

5.11.2 Stability against overturning in rail configuration . 27

5.11.3 Operator protection . 27

5.12 Emergency stopping devices . 27

5.12.1 Emergency stopping devices for movement of the machine and working equipment . 27

5.12.2 Action of emergency stopping devices . 27

5.13 Moving parts and materials . 28

5.14 Operators' controls and indicators . 28

5.14.1 General requirements . 28

5.14.2 Control systems . 30

5.14.3 Starting system . 32

5.14.4 Accidental activation . 32

5.14.5 Pedals . 32

5.14.6 Protection against uncontrolled motion in working mode . 32

5.14.7 Control panels and indicators . 32

5.14.8 Remote controls . 32

5.15 Thermal hazards . 33

5.16 Electrical system . 34

5.16.1 Electrical equipment . 34

5.16.2 Disconnection devices . 34

5.16.3 Working environment . 34

5.16.4 Conductors, cables and wiring practices . 34

5.16.5 Batteries . 34

5.16.6 Overhead contact line systems . 35

5.16.7 Equipotential bonding . 36

5.16.8 Specific requirements for urban rail machines for working with live overhead

contact line systems . 36

5.16.9 Antennae . 37

5.17 Machine safety requirements related to electromagnetic compatibility . 37

5.18 Emission of gas and particles . 37

5.19 Pressurized systems . 38

5.20 Fuel tanks and hydraulic tanks . 38

5.21 Noise . 39

5.22 Vibration . 39

5.22.1 General . 39

5.22.2 Whole body vibration. 40

5.22.3 Hand arm vibration . 40

5.23 Protection from the risks of fire . 40

5.23.1 Fire fighting equipment . 40

5.23.2 Material requirements . 40

5.23.3 Fire detection devices . 41

5.23.4 Fire extinguishing devices . 41

5.23.5 Self-rescue devices . 41

5.23.6 Built in fire extinguishing system . 41

5.24 Braking systems . 41

5.24.1 General . 41

5.24.2 Special case for machines in running mode . 43

5.24.3 Special case for machines on urban rail . 43

5.24.4 Holding on gradients . 44

5.24.5 Braking of trailing machines/vehicles . 44

5.24.6 Continuous service air brake for trailing machines/vehicles . 45

5.24.7 Remote application of brakes . 45

5.25 Lighting . 45

5.25.1 Lighting general . 45

5.25.2 Lighting inside the machine . 45

5.25.3 Lighting for working places/areas beside the machine . 45

5.26 Warning systems . 46

5.27 Maintenance . 47

5.27.1 General . 47

5.27.2 Frequent maintenance . 47

5.27.3 Support devices . 47

5.27.4 Unauthorized access to the engine compartment . 47

5.28 Safe handling. 47

5.29 Moveable machine components . 47

5.30 Environmental temperature conditions . 47

5.31 Storage of substances hazardous to health . 48

6 Additional safety requirements or measures for specific machine functions . 48

6.1 Conveyors. 48

6.2 Cranes and lifting devices fixed on the machine . 49

6.3 Transport of loads by machines used for lifting . 49

6.4 Elevating work platforms . 49

6.5 Rail profiling machines (grinding, milling or planing) . 49

7 Verification of the conformity to the requirements and/or particular safety

measures . 49

7.1 General . 49

7.2 Methods of verification . 50

7.2.1 General . 50

7.2.2 Visual check . 50

7.2.3 Measurement . 50

7.2.4 Functional test . 50

7.2.5 Load test(s) . 50

7.2.6 Specific verification/measurements and other controls . 50

8 Information for use . 50

8.1 General . 50

8.2 Instruction handbook . 51

8.2.1 Specific information in instruction handbook . 51

8.2.2 Restrictions of use. 52

8.2.3 Mass of the machine in working condition . 53

8.2.4 Stability of the machine . 53

8.2.5 Conformance to the lateral limit of work . 53

8.2.6 Opening and closing the machine . 53

8.2.7 Locking of tools and equipment . 53

8.2.8 Devices to prevent access to an operating track . 54

8.2.9 Work places situated outside the running gauge . 54

8.2.10 Warning systems . 54

8.2.11 Testing of warning systems . 54

8.2.12 Information for maintenance . 54

8.2.13 Trailing loads . 55

8.3 Warning signs and written warnings . 55

8.4 Marking . 55

Annex A (normative) List of significant hazards . 57

Annex B (normative) Check list for conformity . 60

Annex C (normative) Noise test code (grade of accuracy 2) . 66

C.1 Scope . 66

C.2 Definitions . 66

C.3 Determination of the emission sound pressure level at the working place and other

specified positions . 66

C.4 Sound power level determination . 67

C.5 Installation and mounting conditions . 67

C.6 Working conditions . 67

C.7 Measurement uncertainties . 70

C.8 Information to be recorded . 70

C.9 Information to be reported . 70

C.10 Declaration and verification of noise emission values . 71

Annex D (normative) Vibration test code . 75

D.1 Scope . 75

D.2 Measurement and degree of uncertainty (K) of whole body vibration (WBV) . 75

D.2.1 General . 75

D.2.2 WBV Vibration measurement . 75

D.2.3 Reporting whole body vibration data . 75

D.3 Measurement and degree of uncertainty (K) of hand arm vibration (HAV) . 76

D.3.1 General . 76

D.3.2 HAV Vibration measurement . 76

D.3.3 Reporting hand arm vibration data . 76

Annex E (informative) Structure of European Standards for track construction and

maintenance machines . 77

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of EU Directive 2006/42/EC aimed to be covered . 79

Bibliography . 85

European foreword

This document (EN 15746-2:2020) has been prepared by Technical Committee CEN/TC 256 “Railway

applications”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2021, and conflicting national standards shall be

withdrawn at the latest by June 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 15746-2:2010+A1:2011.

Principal amended clauses compared to EN 15746-2:2010+A1:2011:

— general All references updated to latest issue;

— 5.2.3 Requirements for walkways simplified;

— 5.4.6 Visibility requirements separated for running, travelling and working modes;

— 5.6.2 New requirements for risk of falling;

— 5.11.3 New requirements for operator protection;

— 5.12 Greater clarity provided for emergency stopping devices;

— 5.14.2 Requirements for control systems enhanced;

— 5.16.8 Alternative requirements for equipotential bonding on urban rail added;

— 5.18 Requirements for emissions enhanced;

— 5.20 Requirements for tanks enhanced;

— 5.23 Protection from risk of fire revised;

— 5.24 Braking requirements amended to accommodate urban rail;

— 5.29 New requirements for moveable components;

— 5.30 New requirements for environment;

— 5.31 New requirements for substances hazardous to health;

— 6.5 New requirements for rail profiling machines;

— Annexes All annexes reviewed and updated;

— Annex C Noise test code amended;

— Annex D New annex for vibration test.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this

document.

EN 15746, Railway applications — Track — Road-rail machines and associated equipment, is currently

composed with the following parts:

— Part 1: Technical requirements for travelling and working;

— Part 2: General safety requirements;

— Part 3: Technical requirements for running;

— Part 4: Technical requirements for running, travelling and working on urban rail.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

Introduction

This document is the second of a series of four parts of the European Standard: Railway applications —

Track — Road-rail machines and associated equipment, dealing with railway specific risks of the road-

rail machines when running, travelling and working on railway infrastructures:

— Part 1 covers the technical requirements for the machines in travelling and working modes, and is

applicable for all machines.

— Part 2 covers the safety requirements for the machines in travelling and working modes; this is a

document harmonized with the European Machinery Directive 2006/42/EC.

— Part 3 covers the essential requirements for the machines that have a running mode and run on

tracks within the scope of the Railway Directive 2007/58/EC; this is a document harmonized with

the Railway Interoperability Directive 2008/57/EC and its associated Technical Specifications for

Interoperability (TSI).

— Part 4 covers the technical requirements for the machines that have a running mode on urban rail

and/or for machines intended to have travelling and working modes on urban rail.

Part 1 defines requirements for approval of the machine for use on the railway. Depending on the

decision of the Infrastructure Manager or National rules, the assessment of conformance could be by

the Infrastructure Manager concerned, by a third party assessor or declaration of conformity by the

manufacturer.

Part 2 defines requirements for the machine to be declared conformant by the manufacturer, except in

the case of machines classified under Annex 4 of the Machinery Directive, which requires a conformity

check in conjunction with a notified body.

Part 3 defines requirements for running on the European railway network. Assessment of conformity is

by a notified body as prescribed in the Railway Interoperability Directive.

Part 4 defines requirements for approval of the machine for use on urban rail. Depending on the

decision of the Urban Rail Manager or National rules the assessment of conformance could be by the

Urban Rail Manager concerned, by a third party assessor or declaration of conformity by the

manufacturer.

This document is a type C standard as stated in EN ISO 12100:2010. This document is of relevance, in

particular, for the following stakeholder groups representing the market players with regard to

machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance, etc.)

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e.g. for maintenance (small, medium and large enterprises);

— consumers (in case of machinery intended for use by consumers).

The above-mentioned stakeholder groups have been given the possibility to participate in the drafting

process of this document.

The machinery concerned and the extent to which hazards, hazardous situations and hazardous events

are covered are indicated in the scope of this document.

When provisions of this type C standard are different from those which are stated in type B standards,

the provisions of this type C standard take precedence over the provisions of the other standards, for

machines that have been designed and built according to the provisions of this type C standard.

As far as possible this document sets out only the requirements that materials and equipment need to

meet in the interest of safety, and it is assumed that persons operating machines are adequately trained.

1 Scope

This document specifies the significant hazards, hazardous situations and events, common to self-

propelled road-rail machines – henceforward referred to as machines – and associated equipment,

arising due to the adaptation for their use on railway networks and urban rail networks. These

machines are intended for construction, maintenance and inspection of the railway infrastructure,

shunting and emergency rescue vehicles, when they are used as intended and under conditions of

misuse which are reasonably foreseeable by the manufacturer; see Clause 4.

This document deals with the common hazards during assembly and installation, commissioning,

travelling on and off track, use including setting, programming, and process changeover, operation,

cleaning, fault finding, maintenance and de-commissioning of the machines.

NOTE Specific measures for exceptional circumstances are not dealt with in this document. They can be

subject to negotiation between manufacturer and the machine operator.

The common hazards dealt with include the general hazards presented by the machines, also the

hazards presented by the following specific machine functions:

a) excavation;

b) ballast tamping, ballast cleaning, ballast regulating, ballast consolidating;

c) track construction, renewal, maintenance and repair;

d) lifting;

e) overhead contact line system renewal / maintenance;

f) maintenance of the components of the infrastructure;

g) inspection and measurement of the components of the infrastructure;

h) working in tunnels;

i) shunting;

j) vegetation control;

k) emergency rescue and recovery;

during commissioning, use, maintenance and servicing.

For a road-rail machine it is assumed that an EU road permissible host vehicle will offer an accepted

safety level for its designed basic functions before conversion. Unless explicitly stated otherwise in a

particular clause this specific aspect is not dealt with in this document.

This document does not deal with:

1) requirements with regard to the quality of work and the performance of the machine;

2) machines that utilize the contact line system for traction purposes;

3) specific requirements established by a railway Infrastructure Manager or Urban Rail Manager;

4) negotiations between the manufacturer and the machine operator for additional or alternative

requirements;

5) requirements for use and travel of the machine on public highway;

6) hazards due to air pressure caused by the passing of high-speed trains at more than 190 km/h;

7) requirements which could be necessary in case of use in extreme conditions, such as extreme

ambient temperatures (tropical or polar); see 5.30;

8) highly corrosive or contaminating environment, e.g. due to the presence of chemicals;

9) potentially explosive atmospheres.

Other special machines used on railway tracks are dealt with in other European Standards, see Annex E.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 2:1992, Classification of fires

EN 3-7:2004+A1:2007, Portable fire extinguishers — Part 7: Characteristics, performance requirements

and test methods

EN 280:2013+A1:2015, Mobile elevating work platforms — Design calculations — Stability criteria —

Construction - Safety - Examinations and tests

EN 403:2004, Respiratory protective devices for self-rescue — Filtering devices with hood for escape from

fire — Requirements, testing, marking

EN 474-1:2006+A6:2019, Earth-moving machinery — Safety — Part 1: General requirements

EN 547-1:1996+A1:2008, Safety of machinery — Human body measurements — Part 1: Principles for

determining the dimensions required for openings for whole body access into machinery

EN 547-2:1996+A1:2008, Safety of machinery — Human body measurements — Part 2: Principles for

determining the dimensions required for access openings

EN 547-3:1996+A1:2008, Safety of machinery — Human body measurements — Part 3: Anthropometric

data

EN 614-1:2006+A1:2009, Safety of machinery — Ergonomic design principles — Part 1: Terminology and

general principles

EN 614-2:2000+A1:2008, Safety of machinery — Ergonomic design principles — Part 2: Interactions

between the design of machinery and work tasks

EN 618:2002+A1:2010, Continuous handling equipment and systems — Safety and EMC requirements for

equipment for mechanical handling of bulk materials except fixed belt conveyors

EN 619:2002+A1:2010, Continuous handling equipment and systems — Safety and EMC requirements for

equipment for mechanical handling of unit loads

EN 620:2002+A1:2010, Continuous handling equipment and systems — Safety and EMC requirements for

fixed belt conveyors for bulk materials

EN 842:1996+A1:2008, Safety of machinery — Visual danger signals — General requirements, design and

testing

EN 894-1:1997+A1:2008, Safety of machinery — Ergonomics requirements for the design of displays and

control actuators — Part 1: General principles for human interactions with displays and control actuators

EN 894-2:1997+A1:2008, Safety of machinery — Ergonomics requirements for the design of displays and

control actuators — Part 2: Displays

EN 894-3:2000+A1:2008, Safety of machinery — Ergonomics requirements for the design of displays and

control actuators — Part 3: Control actuators

EN 981:1996+A1:2008, Safety of machinery — System of auditory and visual danger and information

signals

EN 1032:2003+A1:2008, Mechanical vibration — Testing of mobile machinery in order to determine the

vibration emission value

EN 1837:1999+A1:2009, Safety of machinery — Integral lighting of machines

EN 12999:2011+A2:2018, Cranes — Loader cranes

EN 13000:2010+A1:2014, Cranes — Mobile cranes

EN 13135:2013+A1:2018, Cranes — Safety — Design — Requirements for equipment

EN 14033-1:2017, Railway applications — Track — Railbound construction and maintenance machines

— Part 1: Technical requirements for running

EN 14033-2:2017, Railway applications — Track — Railbound construction and maintenance machines

— Part 2: Technical requirements for travelling and working

EN 14033-3:2017, Railway applications — Track — Railbound construction and maintenance machines

— Part 3: General safety requirements

EN 15153-2:2020, Railway applications — External visible and audible warning devices — Part 2:

Warning horns for heavy rail

EN 15746-1:2020, Railway applications — Track — Road-rail machines and associated equipment —

Part 1: Technical requirements for travelling and working

EN 15746-3:2020, Railway applications — Track — Road-rail machines and associated equipment —

Part 3: Technical requirements for running

EN 15877-1:2012+A1:2018, Railway applications — Marking on railway vehicles — Part 1: Freight

wagons

EN 16704-2-1:2016, Railway applications — Track — Safety protection on the track during work — Part

2-1: Common solutions and technologies — Technical requirements for Track Warning Systems (TWS)

EN 28662-1:1992, Hand-held portable power tools — Measurement of vibrations at the handle — Part 1:

General (ISO 8662-1:1988)

EN 45545-2:2020, Railway applications — Fire protection on railway vehicles — Part 2: Requirements for

fire behaviour of materials and components

EN 50153:2014, Railway applications — Rolling stock — Protective provisions relating to electrical

hazards

EN 60204-1:2018, Safety of machinery — Electrical equipment of machines — Part 1: General

requirements (IEC 60204-1:2016)

EN 60204-32:2008, Safety of machinery — Electrical equipment of machines — Part 32: Requirements for

hoisting machines (IEC 60204-32:2008)

EN 60529:1991, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989)

EN 61310-1:2008, Safety of machinery — Indication, marking and actuation — Part 1: Requirements for

visual, acoustic and tactile signals (IEC 61310-1:2007)

EN 61310-2:2008, Safety of machinery — Indication, marking and actuation — Part 2: Requirements for

marking (IEC 61310-2:2007)

EN 61310-3:2008, Safety of machinery — Indication, marking and actuation — Part 3: Requirements for

the location and operation of actuators (IEC 61310-3:2007)

EN 61496-1:2013, Safety of machinery — Electro-sensitive protective equipment — Part 1: General

requirements and tests (IEC 61496-1:2012)

EN 61508-3:2010, Functional safety of electrical/electronic/programmable electronic safety-related

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...