ASTM D8408/D8408M-21

(Guide)Standard Guide for Development of Long-Term Monitoring Plans for Vapor Mitigation Systems

Standard Guide for Development of Long-Term Monitoring Plans for Vapor Mitigation Systems

SIGNIFICANCE AND USE

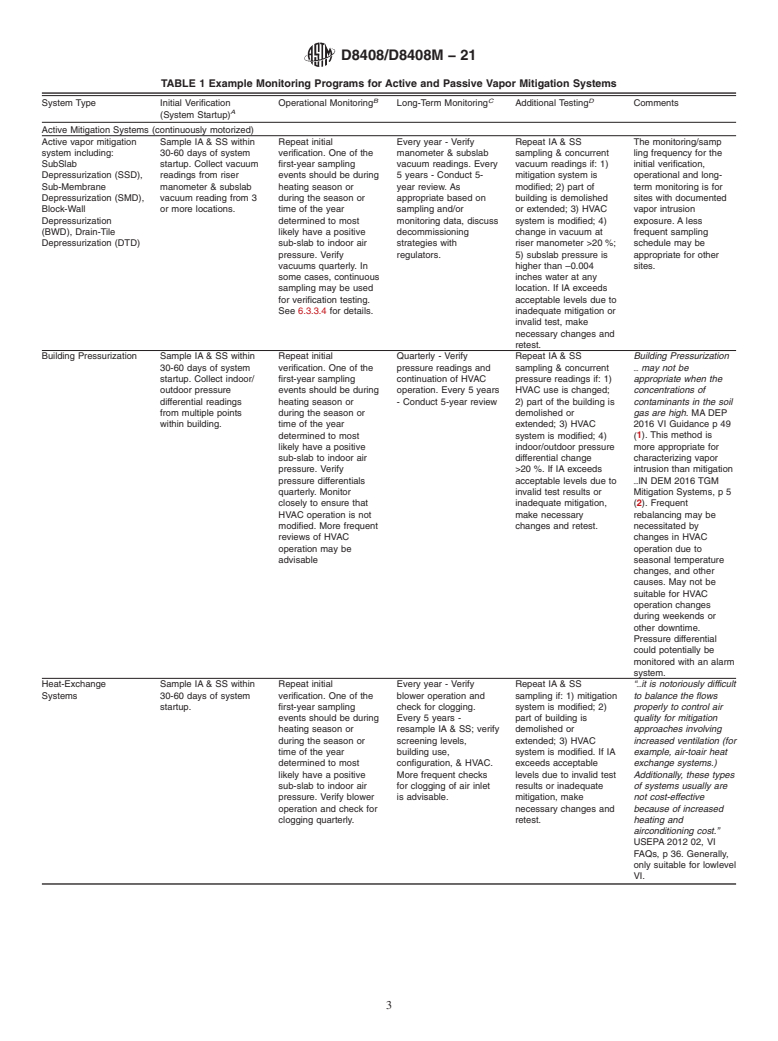

5.1 There are two primary types of vapor mitigation systems: Active and Passive (Table 1). Active vapor mitigation systems include: Sub-Slab Depressurization (SSD), Sub-Membrane Depressurization (SMD), Sub-Membrane Pressurization, Block-Wall Depressurization, Drain-tile Depressurization, Building Pressurization, Heat-Exchange Systems, and Indoor Air Treatment. Passive vapor mitigation systems include: Passive Venting, Floor Sealants, Vapor Barriers, and Increased Ventilation. Vapor mitigation systems may also consist of a combination of active and passive technologies.

5.2 Development and implementation of a LTM Plan is important for ensuring the long-term protectiveness of the mitigation systems.

5.3 The approach presented in this guide is a practical and streamlined process for establishing long-term monitoring requirements, monitoring time frames, and factors needed to determine when the use of a vapor mitigation system is no longer needed.

5.4 This guide is intended to be used by environmental professionals including: consultants, building managers, local or regional governing or regulatory agencies, that are installing vapor mitigation systems, conducting monitoring of the vapor barriers, or developing LTM Plans for vapor mitigation systems. Vapor mitigation system installation and LTM activities should only be carried out by environmental professionals who are trained in the proper application of vapor mitigation systems and experienced in the monitoring described in this guide, as applicable.

Note 1: The quality of the result produced by this standard is dependent on the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D3740 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of this standard are cautioned that compliance with Practice D3740 does not in itself assure reliable results. Reliable results depend...

SCOPE

1.1 This guide presents factors to consider when developing Long-Term Monitoring (LTM) Plans for monitoring the performance of both active and passive vapor mitigation systems in buildings. This guide will also assist in developing appropriate performance standards to make sure that vapor mitigation systems remain protective of human health. Active and passive vapor mitigation systems have been used for a number of years on contaminated properties where residual volatile contaminants remain in the ground. This guide discusses a variety of vapor mitigations systems; however, its focus is on the development of long-term monitoring plans for vapor mitigation systems that are designed to remain in place for multiple years.

1.2 A LTM Plan provides clear performance goals for a vapor mitigation system which help to reduce potential confusion and ineffective project management. The LTM Plan also defines performance monitoring time frames to efficiently test the vapor mitigation systems’ effectiveness without unnecessary and costly over-testing. This will also promote consistent monitoring. Vapor mitigation systems are often installed without adequate consideration of the long-term monitoring requirements necessary to make sure that they remain protective of human health for as long as the system remains in place. This guidance addresses the requirements of the LTM Plan to monitor a vapor mitigation system’s continued effectiveness. Installation verification that the vapor mitigation system was installed correctly is typically addressed in the Remedial Design stage of a contaminated Property Management and is not covered in this document.

1.3 LTM Plan limitations, constraints and potential sources of error are discussed in this standard. This guide does not endorse a mitigation system vendor or testing of vapor mitigation systems. However, this guide does provide a reference for the common procedures for testing vapor miti...

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8408/D8408M − 21

Standard Guide for

Development of Long-Term Monitoring Plans for Vapor

1

Mitigation Systems

This standard is issued under the fixed designation D8408/D8408M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope for the common procedures for testing vapor mitigation sys-

tems and related terms, as appropriate.

1.1 This guide presents factors to consider when developing

Long-Term Monitoring (LTM) Plans for monitoring the per-

1.4 Units—The values stated in either International System

formance of both active and passive vapor mitigation systems

(SI) units or English units are to be regarded separately as

in buildings. This guide will also assist in developing appro-

standard. The values stated in each system may not be exact

priate performance standards to make sure that vapor mitiga-

equivalents;therefore,eachsystemshallbeusedindependently

tion systems remain protective of human health. Active and

of the other. Combining values from the two systems may

passive vapor mitigation systems have been used for a number

result in nonconformance with the standard. Reporting of test

of years on contaminated properties where residual volatile

results in units other than SI shall not be regarded as noncon-

contaminants remain in the ground. This guide discusses a

formance with this standard. The values given in parentheses

variety of vapor mitigations systems; however, its focus is on

are provided for informational purposes only and are not

the development of long-term monitoring plans for vapor

considered standard.

mitigation systems that are designed to remain in place for

1.5 All observed and calculated values shall conform to the

multiple years.

guidelines for significant digits and rounding established in

1.2 A LTM Plan provides clear performance goals for a

Practice D6026. For purposes of comparing a measured or

vapor mitigation system which help to reduce potential confu-

calculated value(s) with specified limits, the measured or

sion and ineffective project management. The LTM Plan also

calculated value(s) shall be rounded to the nearest decimal of

defines performance monitoring time frames to efficiently test

significant digits in the specified limit.

the vapor mitigation systems’ effectiveness without unneces-

sary and costly over-testing. This will also promote consistent

1.6 This guide offers an organized collection of information

monitoring. Vapor mitigation systems are often installed with-

oraseriesofoptionsanddoesnotrecommendaspecificcourse

out adequate consideration of the long-term monitoring re-

of action. This document cannot replace education or experi-

quirements necessary to make sure that they remain protective

ence and should be used in conjunction with professional

of human health for as long as the system remains in place.

judgment. Not all aspects of this guide may be applicable in all

This guidance addresses the requirements of the LTM Plan to

circumstances. This ASTM standard is not intended to repre-

monitor a vapor mitigation system’s continued effectiveness.

sent or replace the standard of care by which the adequacy of

Installation verification that the vapor mitigation system was

a given professional service must be judged, nor should this

installed correctly is typically addressed in the Remedial

document be applied with consideration of a project’s many

Design stage of a contaminated Property Management and is

unique aspects. The word “Standard” in the title of this

not covered in this document.

document means only that the document has been approved

through the ASTM consensus process.

1.3 LTM Plan limitations, constraints and potential sources

of error are discussed in this standard. This guide does not

1.7 This standard does not purport to address all of the

endorse a mitigation system vendor or testing of vapor miti-

safety concerns, if any, associated with its use. It is the

gation systems. However, this guide does provide a reference

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

1

mine the applicability of regulatory limitations prior to use.

This guide is under the jurisdiction ofASTM Committee D18 on Soil and Rock

and is the direct responsibility of Subcommittee D18.21 on Groundwater and

1.8 This international standard was developed in accor-

Vadose Zone Investigations.

dance with internationally recognized pr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.