ASTM D7343-12

(Practice)Standard Practice for Optimization, Sample Handling, Calibration, and Validation of X-ray Fluorescence Spectrometry Methods for Elemental Analysis of Petroleum Products and Lubricants

Standard Practice for Optimization, Sample Handling, Calibration, and Validation of X-ray Fluorescence Spectrometry Methods for Elemental Analysis of Petroleum Products and Lubricants

SIGNIFICANCE AND USE

3.1 Accurate elemental analyses of samples of petroleum and petroleum products are required for the determination of chemical properties, which are in turn used to establish compliance with commercial and regulatory specifications.

SCOPE

1.1 This practice covers information relating to sampling, calibration and validation of X-ray fluorescence instruments for elemental analysis, including all kinds of wavelength dispersive (WDXRF) and energy dispersive (EDXRF) techniques. This practice includes sampling issues such as the selection of storage vessels, transportation, and sub-sampling. Treatment, assembly, and handling of technique-specific sample holders and cups are also included. Technique-specific requirements during analytical measurement and validation of measurement for the determination of trace elements in samples of petroleum and petroleum products are described. For sample mixing, refer to Practice D5854. Petroleum products covered in this practice are considered to be a single phase and exhibit Newtonian characteristics at the point of sampling.

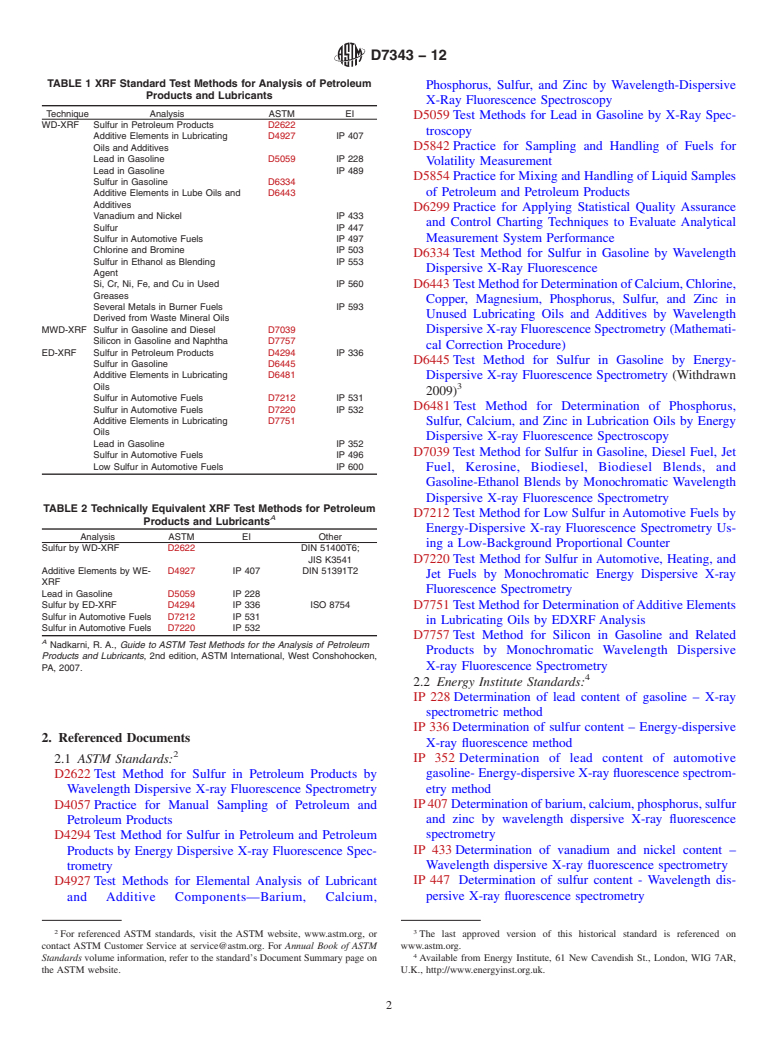

1.2 Applicable Test Methods—This practice is applicable to the XRF methods under the jurisdiction of ASTM Subcommittee D02.03 on Elemental Analysis, and those under the jurisdiction of the Energy Institute’s Test Method Standardization Committee (Table 1). Some of these methods are technically equivalent though they may differ in details (Table 2).TABLE 1 XRF Standard Test Methods for Analysis of Petroleum Products and Lubricants

Technique

Analysis

ASTM

EI

WD-XRF

Sulfur in Petroleum Products

D2622

Additive Elements in Lubricating Oils and Additives

D4927

IP 407

Lead in Gasoline

D5059

IP 228

Lead in Gasoline

IP 489

Sulfur in Gasoline

D6334

Additive Elements in Lube Oils and Additives

D6443

Vanadium and Nickel

IP 433

Sulfur

IP 447

Sulfur in Automotive Fuels

IP 497

Chlorine and Bromine

IP 503

Sulfur in Ethanol as Blending Agent

IP 553

Si, Cr, Ni, Fe, and Cu in Used Greases

IP 560

Several Metals in Burner Fuels Derived from Waste Mineral Oils

IP 593

MWD-XRF

Sulfur in Gasoline and Diesel

D7039

Silicon in Gasoline and Naphtha

D7757

ED-XRF

Sulfur in Petroleum Products

D4294

IP 336

Sulfur in Gasoline

D6445

Additive Elements in Lubricating Oils

D6481

Sulfur in Automotive Fuels

D7212

IP 531

Sulfur in Automotive Fuels

D7220

IP 532

Additive Elements in Lubricating Oils

D7751

Lead in Gasoline

IP 352

Sulfur in Automotive Fuels

IP 496

Low Sulfur in Automotive Fuels

IP 600

TABLE 2 Technically Equivalent XRF Test Methods for Petroleum Products and LubricantsA

Analysis

ASTM

EI

Other

Sulfur by WD-XRF

D2622

DIN 51400T6;

JIS K3541

Additive Elements by WE-XRF

D4927

IP 407

DIN 51391T2

Lead in Gasoline

D5059

IP 228

Sulfur by ED-XRF

D4294

IP 336

ISO 8754

Sulfur in Automotive Fuels

D7212

IP 531

Sulfur in Automotive Fuels

D7220

IP 532

A Nadkarni, R. A., Guide to ASTM Test Methods for the Analysis of Petroleum Products and Lubricants, 2nd edition, ASTM International, West Conshohocken, PA, 2007.

1.3 Applicable Fluids—This practice is applicable to petroleum and petroleum products with vapor pressures at sampling and storage temperatures less than or equal to 101 kPa (14.7 psi). Use Practice D4057 or IP 475 to sample these materials. Refer to Practice D5842 when sampling materials that also require Reid vapor pressure (RVP) determination.

1.4 Non-applicable Fluids—Petroleum products whose vapor pressure at sampling and sample storage conditions are above 101...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7343 − 12

Designation: 558/07

Standard Practice for

Optimization, Sample Handling, Calibration, and Validation

of X-ray Fluorescence Spectrometry Methods for Elemental

1

Analysis of Petroleum Products and Lubricants

This standard is issued under the fixed designation D7343; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* tion Committee (Table 1). Some of these methods are techni-

cally equivalent though they may differ in details (Table 2).

1.1 This practice covers information relating to sampling,

calibration and validation of X-ray fluorescence instruments

1.3 Applicable Fluids—This practice is applicable to petro-

for elemental analysis, including all kinds of wavelength

leum and petroleum products with vapor pressures at sampling

dispersive (WDXRF) and energy dispersive (EDXRF) tech-

and storage temperatures less than or equal to 101 kPa (14.7

niques. This practice includes sampling issues such as the

psi). Use Practice D4057 or IP 475 to sample these materials.

selection of storage vessels, transportation, and sub-sampling.

Refer to Practice D5842 when sampling materials that also

Treatment, assembly, and handling of technique-specific

require Reid vapor pressure (RVP) determination.

sample holders and cups are also included. Technique-specific

1.4 Non-applicable Fluids—Petroleum products whose va-

requirements during analytical measurement and validation of

por pressure at sampling and sample storage conditions are

measurement for the determination of trace elements in

above 101 kPa (14.7 psi) and liquefied gases (that is, LNG,

samples of petroleum and petroleum products are described.

LPG, etc.) are not covered by this practice.

For sample mixing, refer to Practice D5854. Petroleum prod-

ucts covered in this practice are considered to be a single phase

1.5 Sampling Methods—The physical sampling and meth-

and exhibit Newtonian characteristics at the point of sampling.

ods of sampling from a primary source are not covered by this

guide. It is assumed that samples covered by this practice are

1.2 Applicable Test Methods—This practice is applicable to

a representative sample of the primary source liquid. Refer to

the XRF methods under the jurisdiction ofASTM Subcommit-

Practice D4057 or IP 475 for detailed sampling procedures.

tee D02.03 on Elemental Analysis, and those under the

jurisdiction of the Energy Institute’s Test Method Standardiza-

1.6 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

1

This practice is under the jurisdiction ofASTM Committee D02 on Petroleum

only.

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom-

1.7 This standard does not purport to address all of the

mittee D02.03 on Elemental Analysis.

Current edition approved Dec. 1, 2012. Published December 2012. Originally

safety concerns, if any, associated with its use. It is the

approved in 2007. Last previous edition approved in 2007 as D7343–07. DOI:

responsibility of the user of this standard to establish appro-

10.1520/D7343-07.

priate safety and health practices and determine the applica-

This practice was jointly prepared by ASTM International and the Energy

Institute. bility of regulatory limitations prior to use.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7343 − 12

1

---------------------- Page: 2 ----------------------

D7343 − 12

TABLE 1 XRF Standard Test Methods for Analysis of Petroleum

Phosphorus, Sulfur, and Zinc by Wavelength-Dispersive

Products and Lubricants

X-Ray Fluorescence Spectroscopy

Technique Analysis ASTM EI

D5059 Test Methods for Lead in Gasoline by X-Ray Spec-

WD-XRF Sulfur in Petroleum Products D2622

troscopy

Additive Elements in Lubricating D4927 IP 407

D5842 Practice for Sampling and Handling of Fuels for

Oils and Additives

Lead in Gasoline D5059 IP 228

Volatility Measurement

Lead in Gasoline IP 489

D5854 Practice for Mixing and Handling of Liquid Samples

Sulfur in Gasoline D6334

Additive Elements in Lube Oils and D6443 of Petroleum and Petroleum Products

Additives

D6299 Practice for Applying Statistical Quality Assurance

Vanadium and Nickel IP 433

and Control Charting Techniques to Evaluate Analytical

Sulfur IP 447

Sulfur in Automotive Fuels IP 497 Measurement System Performance

Chlorine and Bromine IP 503

D6334 Test Method for Sulfur in Gasoline by Wavelength

Sulfur in Ethano

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7343 − 07 D7343 − 12

Designation: 558/07

Standard Practice for

Optimization, Sample Handling, Calibration, and Validation

of X-ray Fluorescence Spectrometry Methods for Elemental

1

Analysis of Petroleum Products and Lubricants

This standard is issued under the fixed designation D7343; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This practice covers information relating to sampling, calibration and validation of X-ray fluorescence instruments for

elemental analysis, including all kinds of wavelength dispersive (WDXRF) and energy dispersive (EDXRF) techniques. This

practice includes sampling issues such as the selection of storage vessels, transportation, and sub-sampling. Treatment, assembly,

and handling of technique-specific sample holders and cups are also included. Technique-specific requirements during analytical

measurement and validation of measurement for the determination of trace elements in samples of petroleum and petroleum

products are described. For sample mixing, refer to Practice D5854. Petroleum products covered in this practice are considered

to be a single phase and exhibit Newtonian characteristics at the point of sampling.

1.2 Applicable Test Methods—This practice is applicable to the XRF methods under the jurisdiction of ASTM Subcommittee

D02.03 on Elemental Analysis:Analysis, D2622, D4294, D5059, D6334, D6443, D6445, D6481, D7039, D7212, and D7220 and

those under the jurisdiction of the Energy Institute’s Test Method Standardization Committee: IPCommittee (Table 1 228, IP 336,

IP 352, IP 407, IP 433, IP 447, IP 475, IP ). Some of these methods are technically equivalent though they may differ in details

(Table 2489, IP 496, IP 497, IP 503, IP 531, and IP 532.).

1.3 Applicable Fluids—This practice is applicable to petroleum and petroleum products with vapor pressures at sampling and

storage temperatures less than or equal to 101 kPa (14.7 psi). Use Practice D4057 or IP 475 to sample these materials. Refer to

Practice D5842 when sampling materials that also require Reid vapor pressure (RVP) determination.

1.4 Non-applicable Fluids—Petroleum products whose vapor pressure at sampling and sample storage conditions are above 101

kPa (14.7 psi) and liquefied gases (that is, LNG, LPG, etc.) are not covered by this practice.

1.5 Sampling Methods—The physical sampling and methods of sampling from a primary source are not covered by this guide.

It is assumed that samples covered by this practice are a representative sample of the primary source liquid. Refer to Practice

D4057 or IP 475 for detailed sampling procedures.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D2622 Test Method for Sulfur in Petroleum Products by Wavelength Dispersive X-ray Fluorescence Spectrometry

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4294 Test Method for Sulfur in Petroleum and Petroleum Products by Energy Dispersive X-ray Fluorescence Spectrometry

1

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.03 on

Elemental Analysis.

Current edition approved Aug. 1, 2007Dec. 1, 2012. Published September 2007December 2012. Originally approved in 2007. Last previous edition approved in 2007 as

D7343–07. DOI: 10.1520/D7343-07.

This practice was jointly prepared by ASTM International and the Energy Institute. DOI: 10.1520/D7343-07.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- P

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.