ASTM F744M-97

(Test Method)Standard Test Method for Measuring Dose Rate Threshold for Upset of Digital Integrated Circuits

Standard Test Method for Measuring Dose Rate Threshold for Upset of Digital Integrated Circuits

SCOPE

1.1 This test method covers the measurement of the threshold level of radiation dose rate that causes upset in digital integrated circuits under static operating conditions. The radiation source is either a flash X-ray machine (FXR) or an electron linear accelerator (LINAC).

1.2 The precision of the measurement depends on the homogeneity of the radiation field and on the precision of the radiation dosimetry and the recording instrumentation.

1.3 The test may be destructive either for further tests or for purposes other than this test if the integrated circuit being tested absorbs a total radiation dose exceeding some predetermined level. Because this level depends both on the kind of integrated circuit and on the application, a specific value must be agreed upon by the parties to the test (6.9).

1.4 Setup, calibration, and test circuit evaluation procedures are included in this test method.

1.5 Procedures for lot qualification and sampling are not included in this test method.

1.6 Because of the variability of the response of different device types, the initial dose rate for any specific test is not given in this test method but must be agreed upon by the parties to the test.

1.7 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For more specific hazard statements, see 7.7.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 744M – 97

METRIC

Standard Test Method for

Measuring Dose Rate Threshold for Upset of Digital

Integrated Circuits [Metric]

This standard is issued under the fixed designation F 744M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 666 Practice for Calculating Absorbed Dose from Gamma

or X Radiation

1.1 This test method covers the measurement of the thresh-

E 668 Practice for Application of Thermoluminescence-

old level of radiation dose rate that causes upset in digital

Dosimetry (TLD) Systems for Determining Absorbed Dose

integrated circuits under static operating conditions. The radia-

in Radiation-Hardness Testing of Electronic Devices

tion source is either a flash X-ray machine (FXR) or an electron

F 526 Test Method for Measuring Dose for Use in Linear

linear accelerator (LINAC).

Accelerator Pulsed Radiation Effects Tests

1.2 The precision of the measurement depends on the

homogeneity of the radiation field and on the precision of the

3. Terminology

radiation dosimetry and the recording instrumentation.

3.1 Definitions of Terms Specific to This Standard:

1.3 The test may be destructive either for further tests or for

3.1.1 determined integrated circuit—integrated circuit

purposes other than this test if the integrated circuit being

whose output is a unique function of the inputs; the output

tested absorbs a total radiation dose exceeding some predeter-

changes if and only if the input changes (for example, AND-

mined level. Because this level depends both on the kind of

and OR-gates).

integrated circuit and on the application, a specific value must

3.1.2 dose rate—energy absorbed per unit time and per unit

be agreed upon by the parties to the test (6.8).

mass by a given material from the radiation to which it is

1.4 Setup, calibration, and test circuit evaluation procedures

exposed.

are included in this test method.

3.1.3 dose rate threshold for upset—minimum dose rate that

1.5 Procedures for lot qualification and sampling are not

causes either: (1) the instantaneous output voltage of an

included in this test method.

operating digital integrated circuit to be greater than the

1.6 Because of the variability of the response of different

specified maximum LOW value (for a LOW output level) or

device types, the initial dose rate for any specific test is not

less than the specified minimum HIGH value (for a HIGH

given in this test method but must be agreed upon by the parties

output level), or (2) a change of state of any stored data.

to the test.

3.1.4 nondetermined integrated circuit—integrated circuit

1.7 This standard does not purport to address all of the

whose output or internal operating conditions are not unique

safety concerns, if any, associated with its use. It is the

functions of the inputs (for example, flip-flops, shift registers,

responsibility of the user of this standard to establish appro-

and RAMs).

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Summary of Test Method

4.1 The test device and suitable dosimeters are irradiated by

2. Referenced Documents

either an FXR or a LINAC. The test device is operating but

2.1 ASTM Standards:

under static conditions. The output(s) of the test device and of

E 665 Practice for Determining Absorbed Dose Versus

the dosimeters are recorded.

Depth in Materials Exposed to the X-Ray Output of Flash

2 4.2 The dose rate is varied to determine the rate which

X-Ray Machines

results in upset of the test device.

4.3 For the purposes of this test method, upset is considered

to be either of the following:

This test method is under the jurisdiction of ASTM Committee F-1 on

4.3.1 An output voltage transient exceeding a predeter-

Electronics and is the direct responsibility of Subcommittee F01.11 on Quality and

Hardness Assurance. mined value, or

Current edition approved Feb. 10, 1997. Published April 1997. Originally

published as F 744 – 81. Last previous edition F 744 – 92.

2 3

Annual Book of ASTM Standards, Vol 12.02. Annual Book of ASTM Standards, Vol 10.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 744M – 97

4.3.2 For devices having output logic levels which are not effects can be made based on the area of metallic target

unique functions of the input logic levels, such as flip-flops, a materials irradiated (see Note 1). Values generally range

−11 −10 2

change in the logic state of an output. between 10 and 10 A·s/cm ·Gy, but the use of a scatter

4.3.3 For nondetermined integrated circuits, a change of plate with an intense beam may increase this current (7.7.2).

state of an internal storage element or node.

NOTE 1—For dose rates in excess of 10 Gy(Si)/s, the photocurrents

4.4 A number of factors are not defined in this test method,

developed by the package may dominate the device photocurrent. Care

and must be agreed upon beforehand by the parties to the test:

should be taken in the interpretation of the measured photoresponse for

4.4.1 Total dose limit (see 1.3),

these high dose rates.

4.4.2 Transient values defining an upset (see 4.3.1),

6.3 Orientation—The effective dose to a semiconductor

4.4.3 Temperature at which the test is to be performed (see

junction can be altered by changing the orientation of the test

6.7),

device with respect to the irradiating beam. Most integrated

4.4.4 Details of the test circuit, including output loading,

circuits may be considered “thin samples” (in terms of the

power supply levels, and other operating conditions (see 7.4,

range of the radiation). However, some devices may have

10.3, and 10.4),

cooling studs or thick-walled cases that can act to scatter the

4.4.5 Choice of radiation pulse source (see 7.7),

incident beam, thereby modifying the dose received by the

4.4.6 Radiation pulse width (see 7.7.2),

semiconductor chip. Care must be taken in the positioning of

4.4.7 Sampling (see 8.1),

such devices.

4.4.8 Need for total dose measurement (see 6.8, 7.6, and

6.4 Dose Enhancement—High atomic number materials

10.1),

near the active regions of the integrated circuit (package,

4.4.9 Desired precision of the upset threshold (see 10.8),

metallization, die attach materials, etc.) can cause an enhanced

and

dose to be delivered to the sensitive regions of the device when

4.4.10 Initial dose rate (see 1.6 and 10.5).

it is irradiated with bremsstrahlung. Therefore, when an FXR is

used as the radiation source, calculations should be performed

5. Significance and Use

to determine the possibility and extent of this effect.

5.1 Digital integrated circuits are specified to operate with

6.5 Electrical Noise—Since radiation test facilities are in-

their inputs and outputs in either a logical 1 or a logical 0 state.

herent sources of r-f electrical noise, good noise-minimizing

The occurrence of signals having voltage levels not meeting

techniques such as single-point ground, filtered d-c supply

the specifications of either of these levels (an upset condition)

lines, etc., must be used in these measurements.

may cause the generation and propagation of erroneous data in

6.6 Temperature—Device characteristics are dependent on

a digital system.

junction temperature; hence, the temperature of the test should

5.2 Knowledge of the radiation dose rate that causes upset

be controlled. Unless the parties to the test agree otherwise,

in digital integrated circuits is essential for the design, produc-

measurements shall be made at room temperature (23 6 5°C).

tion, and maintenance of electronic systems that are required to

6.7 Beam Homogeneity and Pulse-to-Pulse Repeatability—

operate in the presence of pulsed radiation environments.

The intensity of a beam from an FXR or a LINAC is likely to

vary across its cross section. Since the pulse-shape monitor is

6. Interferences

placed at a different location than the device under test, the

6.1 Air Ionization—A spurious component of the signal

measured dose rate may be different from the dose rate to

measured during a test can result from conduction through air

which the device was exposed. The spatial distribution and

ionized by the radiation pulse. The source of such spurious

intensity of the beam may also vary from pulse to pulse. The

contributions can be checked by measuring the signal while

beam homogeneity and pulse-to-pulse repeatability associated

irradiating the test fixture in the absence of a test device. Air

with a particular radiation source should be established by a

ionization contributions to the observed signal are generally

thorough characterization of its beam prior to performing a

proportional to the applied field, while those due to secondary

measurement.

emission effects (6.2) are not. The effects of air ionization

6.8 Total Dose—Each pulse of the radiation source imparts

external to the device may be minimized by coating exposed

a dose to both the device under test and the device used for

leads with a thick layer of paraffin, silicone rubber, or noncon-

dosimetry. The total dose deposited in a semiconductor device

ductive enamel or by making the measurement in a vacuum.

can change its operating characteristics. As a result, the

6.2 Secondary Emission —Another spurious component of

response that is measured after several pulses may be different

the measured signal can result from charge emission from, or

from that characteristic of an unirradiated device. Care should

charge injection into, the test device and test circuit. This may

be exercised to ensure that the total dose delivered to the test

be minimized by shielding the surrounding circuitry and

device is less than the agreed-upon maximum value. Care must

irradiating only the minimum area necessary to ensure irradia-

also be taken to ensure that the characteristics of the dosimeter

tion of the test device. Reasonable estimates of the magnitude

have not changed due to the accumulated dose.

to be expected of current resulting from secondary-emission

7. Apparatus

7.1 Regulated d-c Power Supplies, with floating outputs to

Sawyer, J. A., and van Lint, V. A. J., “Calculations of High-Energy Secondary

produce the voltages required to bias the integrated circuit

Electron Emission,” Journal of Applied Physics, Vol 35, No. 6, June 1964, pp.

1706–1711. under test.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 744M – 97

7.2 Recording Devices—A single dual-beam, or two single- is the termination for the coaxial cable and has a value within

beam oscilloscopes, equipped with cameras; or transient digi- 2 % of the characteristic cable impedance. All unused inputs to

tizers with appropriate displays. The bandwidth capabilities of the test device are connected as agreed upon between the

the recording devices shall be such that the radiation responses parties to the test. The output of the test device may be loaded,

of the integrated circuit and the pulse-shape monitor (7.6) are as agreed upon between the parties to the test. To prevent

accurately displayed and recorded. loading of the output of the test device by the coaxial cable,

7.3 Cabling, to complete adequately the connection of the one may use a line driver that has a high input impedance and

test circuit in the exposure area with the power supply and adequate bandwidth and voltage swing to reproduce accurately

oscilloscopes in the data area. Shielded twisted pair or coaxial at the output end of the coaxial cable, the waveforms appearing

cables may be used to connect the power supplies to the bias at the line-driver input.

points of the test circuit; however, coaxial cables properly 7.5 Radiation Pulse-Shape Monitor—Use one of the fol-

terminated at the oscilloscope input are required for the signal lowing to develop a signal proportional to the dose rate

leads. delivered to the test device:

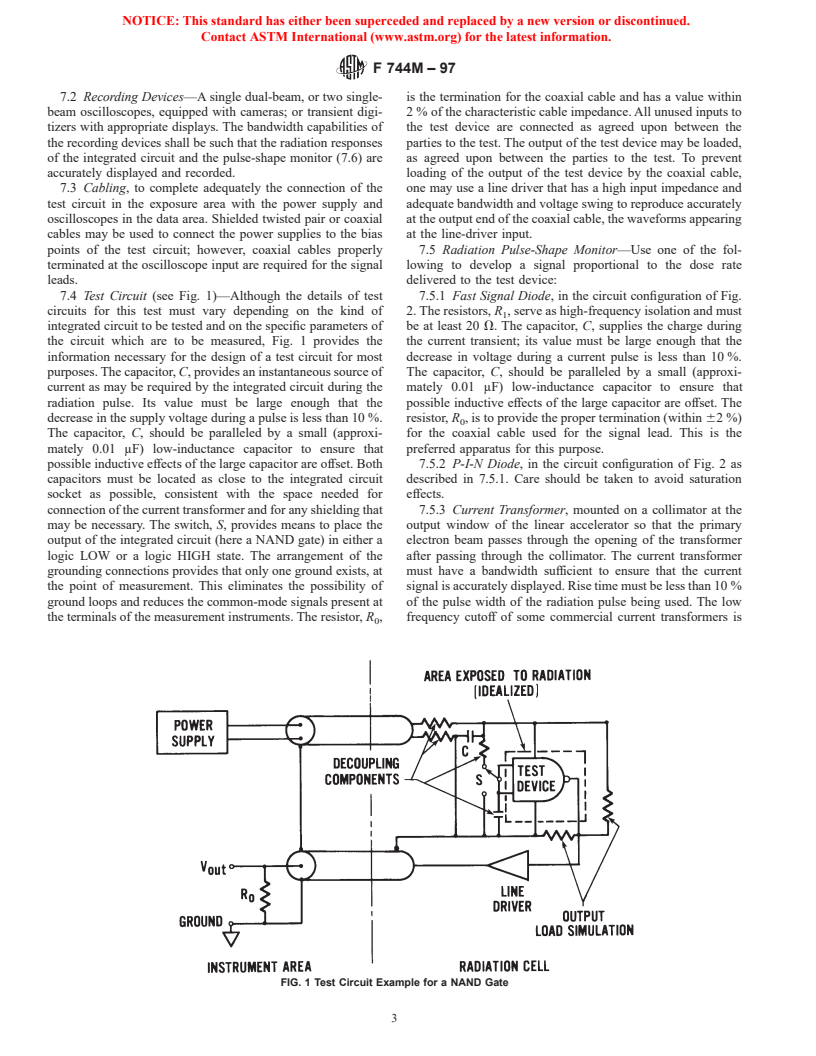

7.4 Test Circuit (see Fig. 1)—Although the details of test 7.5.1 Fast Signal Diode, in the circuit configuration of Fig.

circuits for this test must vary depending on the kind of 2. The resistors, R , serve as high-frequency isolation and must

integrated circuit to be tested and on the specific parameters of be at least 20 V. The capacitor, C, supplies the charge during

the circuit which are to be measured, Fig. 1 provides the the current transient; its value must be large enough that the

information necessary for the design of a test circuit for most decrease in voltage during a current pulse is less than 10 %.

purposes. The capacitor, C, provides an instantaneous source of The capacitor, C, should be paralleled by a small (approxi-

current as may be required by the integrated circuit during the mately 0.01 μF) low-inductance capacitor to ensure that

radiation pulse. Its value must be large enough that the possible inductive effects of the large capacitor are offset. The

decrease in the supply voltage during a pulse is less than 10 %. resistor, R , is to provide the proper termination (within 62%)

The capacitor, C, should be paralleled by a small (approxi- for the coaxial cable used for the signal lead. This is the

mately 0.01 μF) low-inductance capacitor to ensure that preferred apparatus for this purpose.

possible inductive effects of the large capacitor are offset. Both 7.5.2 P-I-N Diode, in the circuit configuration of Fig. 2 as

capacitors must be located as close to the integrated circuit described in 7.5.1. Care should be taken to avoid saturation

socket as possible, consistent with the space needed for effects.

connection of the current transformer and for any shielding that 7.5.3 Current Transformer, mounted on a collimator at the

may be necessary. The switch, S, provides means to place the output window of the linear accelerator so that the primary

output of the integrated circuit (here a NAND gate) in either a electron beam passes through the opening of the transformer

logic LOW or a logic HIGH state. The arrangement of the after passing through the collimator. The current transformer

grounding connections provides that only one ground exists, at must have a bandwidth sufficient to ensure that the current

the point of measurement. This eliminates the possibility of signal is accurately displayed. Rise time must be less than 10 %

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.