ASTM D5708-00

(Test Method)Standard Test Methods for Determination of Nickel, Vanadium, and Iron in Crude Oils and Residual Fuels by Inductively Coupled Plasma (ICP) Atomic Emission Spectrometry

Standard Test Methods for Determination of Nickel, Vanadium, and Iron in Crude Oils and Residual Fuels by Inductively Coupled Plasma (ICP) Atomic Emission Spectrometry

SCOPE

1.1 These test methods cover the determination of nickel, vanadium, and iron in crude oils and residual fuels by inductively coupled plasma (ICP) atomic emission spectrometry. Two different test methods are presented.

1.2 Test Method A (Sections 7-11 and 18-22)—ICP is used to analyze a sample dissolved in an organic solvent. This test method uses oil-soluble metals for calibration and does not purport to quantitatively determine or detect insoluble particulates.

1.3 Test Method B (Sections 12-22)—ICP is used to analyze a sample that is decomposed with acid.

1.4 The concentration ranges covered by these test methods are determined by the sensitivity of the instruments, the amount of sample taken for analysis, and the dilution volume. A specific statement is given in 15.2. Typically, the low concentration limits are a few tenths of a mg/kg. Precision data are provided for the concentration ranges specified in Section 21.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5708 – 00 An American National Standard

Standard Test Methods for

Determination of Nickel, Vanadium, and Iron in Crude Oils

and Residual Fuels by Inductively Coupled Plasma (ICP)

Atomic Emission Spectrometry

This standard is issued under the fixed designation D 5708; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 4177 Practice for Automatic Sampling of Petroleum and

Petroleum Products

1.1 These test methods cover the determination of nickel,

D 5185 Test Method for the Determination of Additive

vanadium, and iron in crude oils and residual fuels by

Elements, Wear Metals, and Contaminants in Used Lubri-

inductively coupled plasma (ICP) atomic emission spectrom-

cating Oils by Inductively Coupled Plasma Atomic Emis-

etry. Two different test methods are presented.

sion Spectrometry

1.2 Test Method A (Sections 7-11 and 18-22)—ICP is used

D 6299 Practice for Applying Statistical Quality Assurance

to analyze a sample dissolved in an organic solvent. This test

Techniques to Evaluate Analytical Measurement System

method uses oil-soluble metals for calibration and does not

Performance

purport to quantitatively determine or detect insoluble particu-

lates.

3. Summary of Test Method

1.3 Test Method B (Sections 12-22)—ICP is used to analyze

3.1 Test Method A—Approximately 10 g of the sample are

a sample that is decomposed with acid.

dissolved in an organic solvent (Warning—Combustible. Va-

1.4 The concentration ranges covered by these test methods

por is harmful.) to give a specimen solution containing 10 %

are determined by the sensitivity of the instruments, the

(m/m) of sample. The solution is nebulized into the plasma,

amount of sample taken for analysis, and the dilution volume.

and the intensities of the emitted light at wavelengths charac-

A specific statement is given in Note 4. Typically, the low

teristic of the analytes are measured sequentially or simulta-

concentration limits are a few tenths of a mg/kg. Precision data

neously. The intensities are related to concentrations by the

are provided for the concentration ranges specified in Section

appropriate use of calibration data.

21.

3.2 Test Method B—One to 20 g of sample are weighed into

1.5 The values stated in SI units are to be regarded as the

a beaker and decomposed with concentrated sulfuric acid

standard. The values given in parentheses are provided for

(Warning—Poison. Causes severe burns. Harmful or fatal if

information only.

swallowed or inhaled.) by heating to dryness. Great care must

1.6 This standard does not purport to address all of the

be used in this decomposition because the acid fumes are

safety concerns, if any, associated with its use. It is the

corrosive and the mixture is potentially flammable. The re-

responsibility of the user of this standard to establish appro-

sidual carbon is burned off by heating at 525°C in a muffle

priate safety and health practices and determine the applica-

furnace. The inorganic residue is digested with nitric acid

bility of regulatory limitations prior to use.

(Warning—Poison. Causes severe burns. Harmful or fatal if

2. Referenced Documents swallowed or inhaled.), evaporated to incipient dryness, dis-

solved in dilute nitric acid, and made up to volume. The

2.1 ASTM Standards:

solution is nebulized into the plasma of an atomic emission

D 1193 Specification for Reagent Water

spectrometer. The intensities of light emitted at characteristic

D 1548 Test Method for Vanadium in Navy Special Fuel

wavelengths of the metals are measured sequentially or simul-

Oil

taneously. These intensities are related to concentrations by the

D 4057 Practice for Manual Sampling of Petroleum and

appropriate use of calibration data.

Petroleum Products

4. Significance and Use

This test method is under the jurisdiction of ASTM Committee D02 on

4.1 These test methods cover, in single procedures, the

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

determination of Ni, V, and Fe in crude oils and residual oils.

D02.03.0B on Spectrometric Methods.

These test methods complement Test Method D 1548, which

Current edition approved Nov. 10, 2000. Published December 2000. Originally

published as D 5708 – 95. Last previous edition D 5708 – 95a.

Annual Book of ASTM Standards, Vol 11.01.

3 5

Annual Book of ASTM Standards, Vol 05.01. Annual Book of ASTM Standards, Vol 05.03.

4 6

Annual Book of ASTM Standards, Vol 05.02. Annual Book of ASTM Standards, Vol 05.04.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 5708

covers only the determination of vanadium. 6 h exposure to the solvent. Fluoroelastomer copolymer tubing

4.2 When fuels are combusted, vanadium present in the fuel is recommended.

can form corrosive compounds. The value of crude oils can be 7.4 Specimen Solution Containers, glass or plastic vials or

determined, in part, by the concentrations of nickel, vanadium, bottles with screw caps and a capacity of between 50 to 100

and iron. Nickel and vanadium, present at trace levels in mL. One hundred millilitre glass bottles are satisfactory.

petroleum fractions, can deactivate catalysts during processing.

8. Reagents

These test methods provide a means of determining the

8.1 Dilution Solvent—Mixed xylenes, o-xylene, tetralin and

concentrations of nickel, vanadium, and iron.

mixed paraffin-aromatic solvents are satisfactory. Solvent pu-

5. Purity of Reagents

rity can affect analytical accuracy when the sample contains

low concentrations (typically, a few mg/kg) of the analytes.

5.1 Reagent grade chemicals shall be used in all tests.

8.2 Mineral Oil—A high-purity oil such as U.S.P. white oil.

Unless otherwise indicated, it is intended that all reagents

8.3 Organometallic Standards—Pre-prepared multielement

conform to the specifications of the Committee on Analytical

concentrates containing 100 mg/kg concentrations of each

Reagents of the American Chemical Society where such

element are satisfactory.

specifications are available. Other grades may be used, pro-

8.4 Quality Control (QC) Samples, preferably are portions

vided it is first ascertained that the reagent is of sufficiently

of one or more liquid petroleum materials that are stable and

high purity to permit its use without lessening the accuracy of

representative of the samples of interest. These QC samples

the determination.

can be used to check the validity of the testing process as

5.2 When determining metals at concentrations less than 1

described in Section 19.

mg/kg, use ultra-pure reagents.

5.3 Purity of Water—Unless otherwise indicated, reference

9. Preparation of Standards and Specimens

to water shall be understood to mean reagent water conforming

9.1 Blank—Prepare a blank by diluting mineral oil with

to Type II of Specification D 1193.

dilution solvent. The concentration of mineral oil must be 10 %

(m/m). Mix well.

6. Sampling and Sample Handling

9.2 Check Standard—Using organometallic standards, min-

6.1 The objective of sampling is to obtain a sample for

eral oil, and dilution solvent, prepare a check standard to

testing purposes that is representative of the entire quantity.

contain analyte concentrations approximately the same as

Thus, take samples in accordance with the instructions in

expected in the specimens. The concentration of oil in the

Practice D 4057 or D 4177. Do not fill the sample container

check standard must be 10 % (m/m).

more than two-thirds full.

9.3 Test Specimen—Weigh a portion of well-mixed sample

6.2 Prior to weighing, stir the sample and manually shake

into a container and add sufficient solvent to achieve a sample

the sample container. If the sample does not readily flow at

concentration of 10 % (m/m). Mix well.

room temperature, heat the sample in a drying oven at 80°C or

9.4 Working Standard—Prepare an instrument calibration

at another safe temperature.

standard that contains 10 mg/kg each of vanadium, nickel, and

iron. Combine the organometallic standard, dilution solvent

TEST METHOD A—

and, if necessary, mineral oil so that the oil content of the

ICP WITH AN ORGANIC SOLVENT SPECIMEN

calibration standard is 10 % (m/m).

SOLUTION

9.5 Quality Control (QC) Samples—Weigh a portion of the

7. Apparatus

well-mixed QC sample into a container and add sufficient

solvent to achieve a sample concentration of 10 % (m/m).

7.1 Inductively Coupled Plasma Atomic Emission

Spectrometer—Either a sequential or simultaneous spectrom-

10. Preparation of Apparatus

eter, equipped with a quartz torch and radio-frequency genera-

10.1 Consult the manufacturer’s instructions for the opera-

tor to form and sustain the plasma, is suitable.

tion of the ICP instrument. This test method assumes that good

7.2 Nebulizer—The use of a high-solids nebulizer is op-

operating procedures are followed. Design differences between

tional but strongly recommended. This type of nebulizer

instruments make it impractial to specify required parameters.

minimizes the probability of clogging. A concentric glass

10.2 Assign the appropriate operating parameters to the

nebulizer can also be used.

instrument taskfile so that the desired analytes can be deter-

7.3 Peristaltic Pump—This pump is required for non-

mined. Parameters include: (1) element, (2) analytical wave-

aspirating nebulizers and optional for aspirating nebulizers.

length, (3) background correction wavelengths (optional), (4)

The pump must achieve a flow rate in the range of 0.5 to 3

interelement correction factors (refer to 10.3), (5) integration

mL/min. The pump tubing must be able to withstand at least a

time of 1 to 10 s, (6) two to five consecutive repeat integra-

tions. Suggested wavelengths are listed in Table 1.

10.3 Spectral Interferences—Check all spectral interfer-

Reagent Chemicals, American Chemical Society Specifications, American

ences expected for the analytes. If interference corrections are

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, Viton (a trademark owned by E. I. duPont de Nemours) has been found

MD. satisfactory. An equivalent can be used.

D 5708

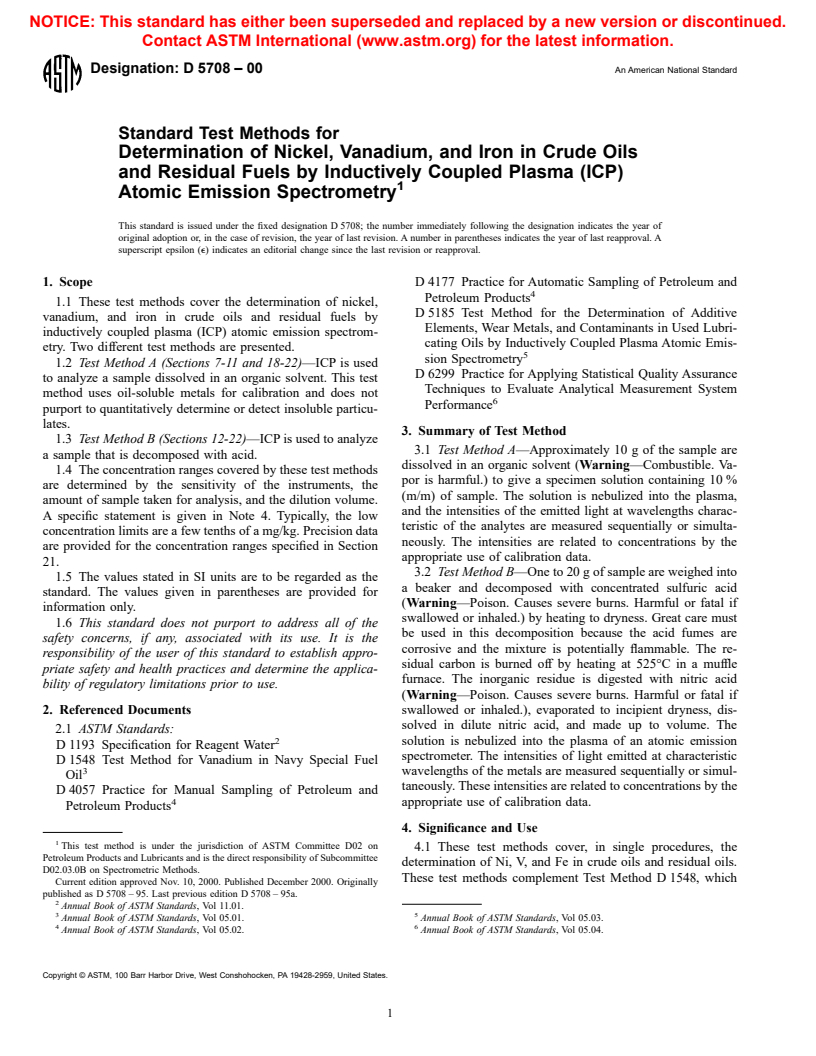

TABLE 1 Elements Determined and Suggested Wavelengths

11.6 The use of spectral background correction is highly

recommended, particularly when the test specimen solutions

NOTE 1—These wavelengths are suggestions and do not represent all

A

contain low concentrations of the analytes (typically less than

possible choices.

1 mg/kg). When concentrations are low, background changes,

Element Wavelength, nm

which can result from variability in the compositions of test

Iron 259.94, 238.20

specimen solutions, can affect the accuracy of the analysis.

Nickel 231.60, 216.56

Vanadium 292.40, 310.22

Background correction minimizes errors due to variable back-

A

Winge, R. K., Fassel, V. A., Peterson, V. J., and Floyd, M. A., Inductively ground intensities.

Coupled Plasma Atomic Emission Spectroscopy: An Atlas of Spectral Information,

Elsevier, NY, 1985.

TEST METHOD B—

ICP AFTER ACID DECOMPOSITION OF SAMPLE

necessary, follow the manufacturer’s operating guide to de-

12. Apparatus

velop and apply correction factors.

12.1 Refer to 7.1-7.4.

10.3.1 Spectral interferences can usually be avoided by

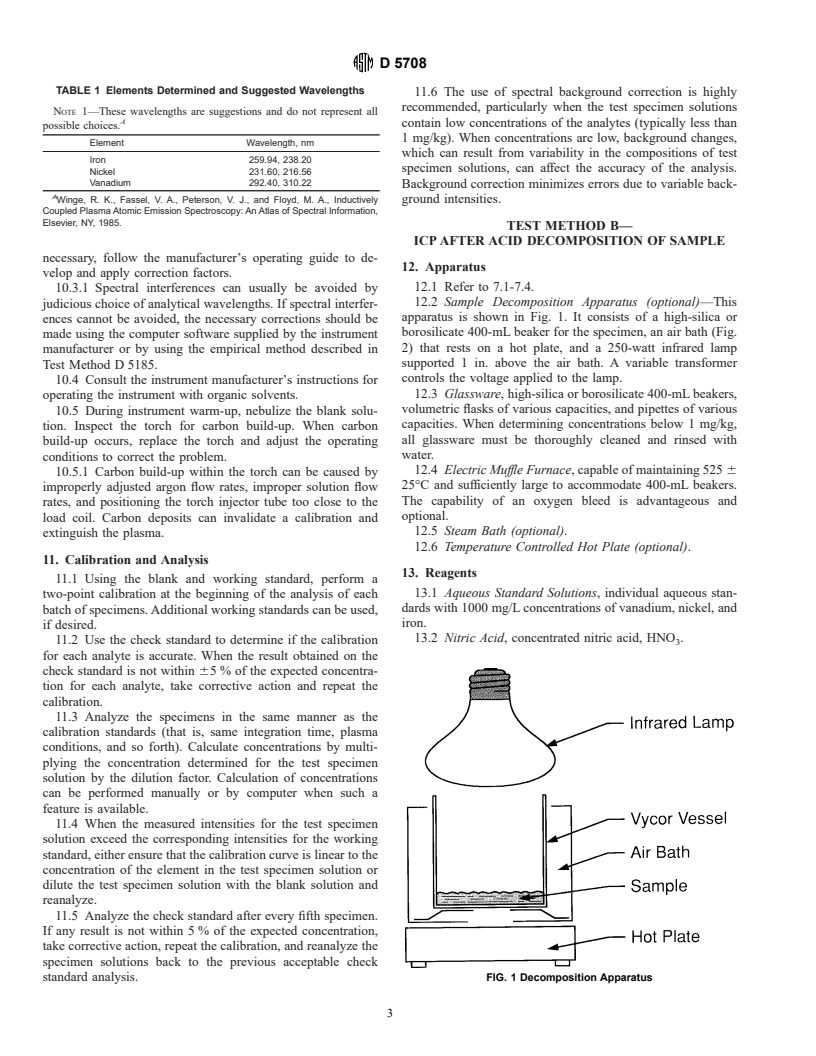

12.2 Sample Decomposition Apparatus (optional)—This

judicious choice of analytical wavelengths. If spectral interfer-

apparatus is shown in Fig. 1. It consists of a high-silica or

ences cannot be avoided, the necessary corrections should be

borosilicate 400-mL beaker for the specimen, an air bath (Fig.

made using the computer software supplied by the instrument

2) that rests on a hot plate, and a 250-watt infrared lamp

manufacturer or by using the empirical method described in

supported 1 in. above the air bath. A variable transformer

Test Method D 5185.

controls the voltage applied to the lamp.

10.4 Consult the instrument manufacturer’s instructions for

12.3 Glassware, high-silica or borosilicate 400-mL beakers,

operating the instrument with organic solvents.

volumetric flasks of various capacities, and pipettes of various

10.5 During instrument warm-up, nebulize the blank solu-

capacities. When determining concentrations below 1 mg/kg,

tion. Inspect the torch for carbon build-up. When carbon

all glassware must be thoroughly cleaned and rinsed with

build-up occurs, replace the torch and adjust the operating

water.

conditions to correct the problem.

12.4 Electric Muffle Furnace, capable of maintaining 525 6

10.5.1 Carbon build-up within the torch can be caused by

25°C and sufficiently large to accommodate 400-mL beakers.

improperly adjusted argon flow rates, improper solution flow

The capability of an oxygen bleed is advantageous and

rates, and positioning the torch injector tube too close to the

optional.

load coil. Carbon deposits can invalidate a calibration and

12.5 Steam Bath (optional).

extinguish the plasma.

12.6 Temperature Controlled Hot Plate (optional).

11. Calibration and Analysis

13. Reagents

11.1 Using the blank and working standard, perform a

13.1 Aqueous Standard Solutions, individual aqueous stan-

two-point calibration at the beginning of the analysis of each

dards with 1000 mg/L concentrations of vanadium, nickel, and

batch of specimens. Additional working standards can be used,

iron.

if desired.

13.2 Nitric Acid, concentrated nitric acid, HNO .

11.2 Use the check standard to determine if the calibration

for each analyte is accurate. When the result obtained on the

check standard is not within 65 % of the expected concentra-

tion for each analyte, take corrective action and repeat the

calibration.

11.3 Analyze the specimens in the same manner as the

calibration standards (that is, same integration time, plasma

conditions, and so forth). Calculate concentrations by multi-

plying the concentration determined for the test specimen

solution by the dilution factor. Calculation of concentrations

can be performed manually or by computer when such a

feature is available.

11.4 When the measured intensities for the test specimen

solution exceed the corresponding intensities for the working

standard, either ensure that the calibration curve is linear to the

concentration of the element in the test specimen solution or

dilute the test specimen solution with the blank solution and

reanalyze.

11.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.