ASTM D7691-23

(Test Method)Standard Test Method for Multielement Analysis of Crude Oils Using Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES)

Standard Test Method for Multielement Analysis of Crude Oils Using Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES)

SIGNIFICANCE AND USE

5.1 Most often determined trace elements in crude oils are nickel and vanadium, which are usually the most abundant; however, as many as 45 elements in crude oils have been reported. Knowledge of trace elements in crude oil is important because they can have an adverse effect on petroleum refining and product quality. These effects can include catalyst poisoning in the refinery and excessive atmospheric emission in combustion of fuels. Trace element concentrations are also useful in correlating production from different wells and horizons in a field. Elements such as iron, arsenic, and lead are catalyst poisons. Vanadium compounds can cause refractory damage in furnaces, and sodium compounds have been found to cause superficial fusion on fire brick. Some organometallic compounds are volatile which can lead to the contamination of distillate fractions, and a reduction in their stability or malfunctions of equipment when they are combusted.

5.2 The value of crude oil can be determined, in part, by the concentrations of nickel, vanadium, and iron.

5.3 Inductively coupled plasma-atomic emission spectrometry (ICP-AES) is a widely used technique in the oil industry. Its advantages over traditional atomic absorption spectrometry (AAS) include greater sensitivity, freedom from molecular interferences, wide dynamic range, and multi-element capability. See Practice D7260.

SCOPE

1.1 This test method covers the determination of several elements (including iron, nickel, sulfur, and vanadium) occurring in crude oils.

1.2 For analysis of any element using wavelengths below 190 nm, a vacuum or inert gas optical path is required.

1.3 Analysis for elements such as arsenic, selenium, or sulfur in whole crude oil may be difficult by this test method due to the presence of their volatile compounds of these elements in crude oil; but this test method should work for resid samples.

1.4 Because of the particulates present in crude oil samples, if they do not dissolve in the organic solvents used or if they do not get aspirated in the nebulizer, low elemental values may result, particularly for iron and sodium. This can also occur if the elements are associated with water which can drop out of the solution when diluted with solvent.

1.4.1 An alternative in such cases is using Test Method D5708, Procedure B, which involves wet decomposition of the oil sample and measurement by ICP-AES for nickel, vanadium, and iron, or Test Method D5863, Procedure A, which also uses wet acid decomposition and determines vanadium, nickel, iron, and sodium using atomic absorption spectrometry.

1.4.2 From ASTM Interlaboratory Crosscheck Programs (ILCP) on crude oils data available so far, it is not clear that organic solvent dilution techniques would necessarily give lower results than those obtained using acid decomposition techniques.2

1.4.3 It is also possible that, particularly in the case of silicon, low results may be obtained irrespective of whether organic dilution or acid decomposition is utilized. Silicones are present as oil field additives and can be lost in ashing. Silicates should be retained but unless hydrofluoric acid or alkali fusion is used for sample dissolution, they may not be accounted for.

1.5 This test method uses oil-soluble metals for calibration and does not purport to quantitatively determine insoluble particulates. Analytical results are particle size dependent and low results may be obtained for particles larger than a few micrometers.

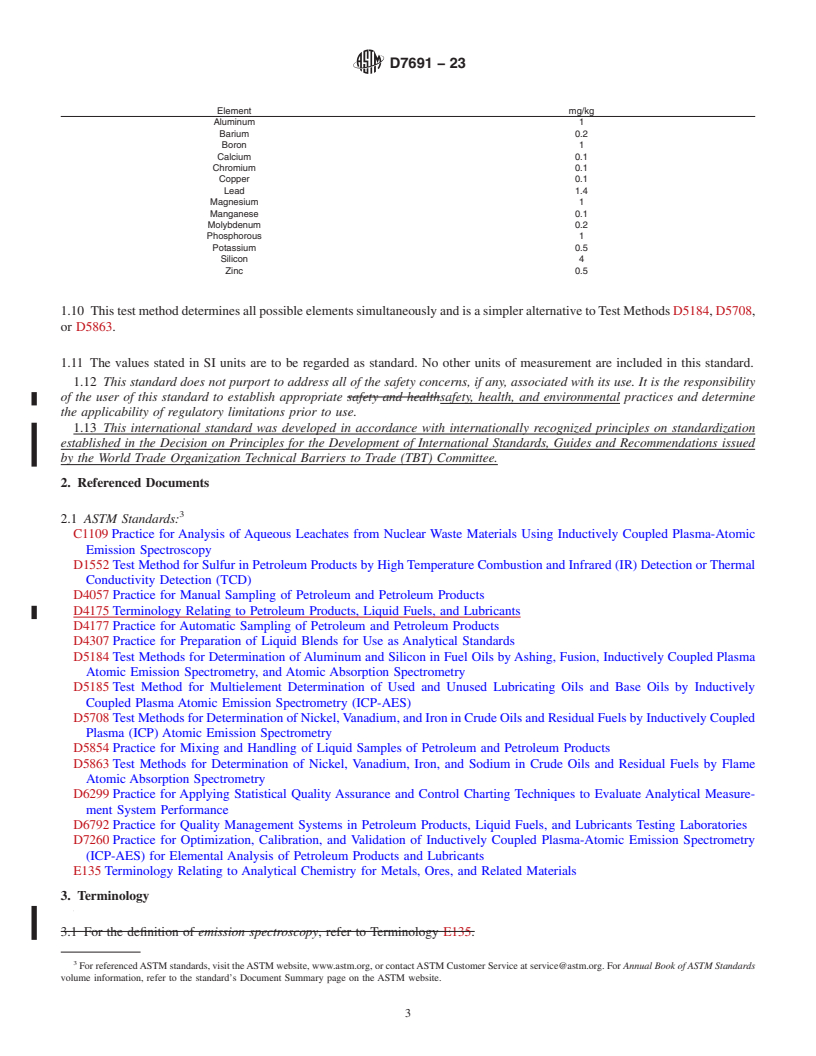

1.6 The precision in Section 18 defines the concentration ranges covered in the interlaboratory study. However, lower and particularly higher concentrations can be determined by this test method. The low concentration limits are dependent on the sensitivity of the ICP instrument and the dilution factor used. The high concentration limits are determined by the product of the maximum concentration defined by the calibration curve and the sample di...

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7691 − 23

Standard Test Method for

Multielement Analysis of Crude Oils Using Inductively

1

Coupled Plasma Atomic Emission Spectrometry (ICP-AES)

This standard is issued under the fixed designation D7691; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* present as oil field additives and can be lost in ashing. Silicates

should be retained but unless hydrofluoric acid or alkali fusion

1.1 This test method covers the determination of several

is used for sample dissolution, they may not be accounted for.

elements (including iron, nickel, sulfur, and vanadium) occur-

ring in crude oils. 1.5 This test method uses oil-soluble metals for calibration

and does not purport to quantitatively determine insoluble

1.2 For analysis of any element using wavelengths below

particulates. Analytical results are particle size dependent and

190 nm, a vacuum or inert gas optical path is required.

low results may be obtained for particles larger than a few

1.3 Analysis for elements such as arsenic, selenium, or

micrometers.

sulfur in whole crude oil may be difficult by this test method

1.6 The precision in Section 18 defines the concentration

due to the presence of their volatile compounds of these

ranges covered in the interlaboratory study. However, lower

elements in crude oil; but this test method should work for

and particularly higher concentrations can be determined by

resid samples.

this test method. The low concentration limits are dependent on

1.4 Because of the particulates present in crude oil samples,

the sensitivity of the ICP instrument and the dilution factor

if they do not dissolve in the organic solvents used or if they do

used. The high concentration limits are determined by the

not get aspirated in the nebulizer, low elemental values may

product of the maximum concentration defined by the calibra-

result, particularly for iron and sodium. This can also occur if

tion curve and the sample dilution factor.

the elements are associated with water which can drop out of

1.7 Elements present at concentrations above the upper limit

the solution when diluted with solvent.

of the calibration curves can be determined with additional

1.4.1 An alternative in such cases is using Test Method

appropriate dilutions and with no degradation of precision.

D5708, Procedure B, which involves wet decomposition of the

oil sample and measurement by ICP-AES for nickel, 1.8 As a generality based on this interlaboratory study (see

vanadium, and iron, or Test Method D5863, Procedure A, 18.1), the trace elements identifiable in crude oils can be

which also uses wet acid decomposition and determines divided into three categories:

vanadium, nickel, iron, and sodium using atomic absorption 1.8.1 Element levels that are too low for valid detection by

spectrometry. ICP-AES and hence, cannot be determined: aluminum, barium,

1.4.2 From ASTM Interlaboratory Crosscheck Programs lead, magnesium, manganese, and silicon.

(ILCP) on crude oils data available so far, it is not clear that 1.8.2 Elements that are just at the detection levels of the

organic solvent dilution techniques would necessarily give ICP-AES method and hence, cannot be determined with a great

lower results than those obtained using acid decomposition deal of confidence: boron, calcium, chromium, copper,

2

techniques. molybdenum, phosphorus, potassium, sodium, and zinc. Per-

1.4.3 It is also possible that, particularly in the case of haps the determination of these elements can be considered as

silicon, low results may be obtained irrespective of whether semi-quantitative.

organic dilution or acid decomposition is utilized. Silicones are 1.8.3 Elements that are at higher levels of concentration and

can be determined with good precision: iron, nickel, sulfur, and

vanadium.

1

This test method is under the jurisdiction of ASTM Committee D02 on

1.9 The detection limits for elements not determined by this

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

test method follow. This information should serve as an

Subcommittee D02.03 on Elemental Analysis.

indication as to what elements are not present above the

Current edition approved May 1, 2023. Published June 2023. Originally

approved in 2011. Last previous edition approved in 2016 as D7961 – 16. DOI: detection limits typically obtainable by ICP-AES instruments.

10.1520/D7691-23.

2

Nadkarni, R. A., Hwang, J. D., and Young, L., “M

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7691 − 16 D7691 − 23

Standard Test Method for

Multielement Analysis of Crude Oils Using Inductively

1

Coupled Plasma Atomic Emission Spectrometry (ICP-AES)

This standard is issued under the fixed designation D7691; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of several elements (including iron, nickel, sulfur, and vanadium) occurring in crude

oils.

1.2 For analysis of any element using wavelengths below 190 nm, a vacuum or inert gas optical path is required.

1.3 Analysis for elements such as arsenic, selenium, or sulfur in whole crude oil may be difficult by this test method due to the

presence of their volatile compounds of these elements in crude oil; but this test method should work for resid samples.

1.4 Because of the particulates present in crude oil samples, if they do not dissolve in the organic solvents used or if they do not

get aspirated in the nebulizer, low elemental values may result, particularly for iron and sodium. This can also occur if the elements

are associated with water which can drop out of the solution when diluted with solvent.

1.4.1 An alternative in such cases is using Test Method D5708, Procedure B, which involves wet decomposition of the oil sample

and measurement by ICP-AES for nickel, vanadium, and iron, or Test Method D5863, Procedure A, which also uses wet acid

decomposition and determines vanadium, nickel, iron, and sodium using atomic absorption spectrometry.

1.4.2 From ASTM Interlaboratory Crosscheck Programs (ILCP) on crude oils data available so far, it is not clear that organic

2

solvent dilution techniques would necessarily give lower results than those obtained using acid decomposition techniques.

1.4.3 It is also possible that, particularly in the case of silicon, low results may be obtained irrespective of whether organic dilution

or acid decomposition is utilized. Silicones are present as oil field additives and can be lost in ashing. Silicates should be retained

but unless hydrofluoric acid or alkali fusion is used for sample dissolution, they may not be accounted for.

1.5 This test method uses oil-soluble metals for calibration and does not purport to quantitatively determine insoluble particulates.

Analytical results are particle size dependent and low results may be obtained for particles larger than a few micrometers.

1.6 The precision in Section 18 defines the concentration ranges covered in the interlaboratory study. However, lower and

particularly higher concentrations can be determined by this test method. The low concentration limits are dependent on the

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.03 on Elemental Analysis.

Current edition approved June 1, 2016May 1, 2023. Published June 2016June 2023. Originally approved in 2011. Last previous edition approved in 20112016 as

ɛ1

D7961 – 11D7961 – 16. . DOI: 10.1520/D7691-16.10.1520/D7691-23.

2

Nadkarni, R. A., Hwang, J. D., and Young, L., “Multielement Analysis of Crude Oils Using Inductively Coupled Plasma Atomic Emission Spectrometry,” J. ASTM

International, Vol 8, No. 10, 2011, pp. 103837.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7691 − 23

sensitivity of the ICP instrument and the dilution factor used. The high concentration limits are determined by the product of the

maximum concentration defined by the calibration curve and the sample dilution factor.

1.7 Elements present at concentrations above the upper limit of the calibration curves can be determined with additional

appropriate dilutions and with no degradation of precision.

1.8 As a generality based on this interlaboratory study (see 18.1), the trace elements identifiable in crude oils can be divided into

three categories:

1.8.1 Element levels that are too low for valid detection by ICP-AES and hence, cannot be determined: aluminum, barium, lead,

magnesium, manganese, and silicon.

1.8.2 Elements that are just at the detection levels of the ICP-AES method and hence, canno

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.