ASTM D5819-99

(Guide)Standard Guide for Selecting Test Methods for Experimental Evaluation of Geosynthetic Durability

Standard Guide for Selecting Test Methods for Experimental Evaluation of Geosynthetic Durability

SCOPE

1.1 This guide covers a designer/specifier through a systematic determination of those factors of the appropriate application environment that may affect the post-construction service life of a geosynthetic. Subsequently, test methods are recommended to facilitate an experimental evaluation of the durability of geosynthetics in a specified environment so that the durability can be considered in the design process.

1.2 This guide is not intended to address durability issues associated with the manufacturing, handling, transportation, or installation environments.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5819–99

Standard Guide for

Selecting Test Methods for Experimental Evaluation of

Geosynthetic Durability

This standard is issued under the fixed designation D 5819; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 4886 Test Method forAbrasion Resistance of Geotextiles

(Sand Paper/Sliding Block Method)

1.1 This guide covers a designer/specifier through a system-

D 5101 Test Method for Measuring the Soil-Geotextile

atic determination of those factors of the appropriate applica-

System Clogging Potential by the Gradient Ratio

tion environment that may affect the post-construction service

D 5262 Test Method for Evaluating the UnconfinedTension

life of a geosynthetic. Subsequently, test methods are recom-

Creep Behavior of Geosynthetics

mended to facilitate an experimental evaluation of the durabil-

D 5322 Practice for Immersion Procedures for Evaluating

ity of geosynthetics in a specified environment so that the

the Chemical Resistance of Geosynthetics to Liquids

durability can be considered in the design process.

D 5397 Test Method for Evaluation of Stress Crack Resis-

1.2 This guide is not intended to address durability issues

tance of Polyolefin Geomembranes Using Notched Con-

associated with the manufacturing, handling, transportation, or

stant Tensile Load Test

installation environments.

D 5496 Practice for In Field Immersion Testing of Geosyn-

2. Referenced Documents

thetics

D 5567 Test Method for Hydraulic Conductivity Ratio

2.1 ASTM Standards:

(HCR) Testing of Soil/Geotextile Systems

D 1204 Test Method for Linear Dimensional Changes of

D 5885 Test Method for Oxidative Induction Time of Poly-

Nonrigid Thermoplastic Sheeting or Film at Elevated

olefin Geosynthetics by High Pressure Differential Scan-

Temperature

ning Calorimetry

D 1987 Test Method for Biological Clogging of Geotextiles

D 5970 Test Method for Deterioration of Geotextiles from

or Soil/Geotextile Filters

Outdoor Exposure

D 2990 Test Methods for Tensile, Compressive, and Flex-

G 23 Practice for Operating Light-Exposure Apparatus

ural Creep and Creep-Rupture of Plastics

(Carbon-Arc Type) With and Without Water for Exposure

D 3083 Specification for Flexible Poly(Vinyl Chloride)

of Nonmetallic Materials

Plastic Sheeting for Pond, Canal, and Reservoir Lining

G 53 Practice for Operating Light- and Water-Exposure

D 3895 Test Method for Oxidative-Induction Time of Poly-

Apparatus (Fluorescent UV-Condensation Type) for Expo-

olefins by Differential Scanning Calorimetry

sure of Nonmetallic Materials

D 4355 Test Method for Deterioration of Geotextiles from

G 151 Practice for Exposing Nonmetallic Materials in Ac-

Exposure to Ultraviolet Light and Water (Xenon-Arc Type

celerated Test Devices That Use Laboratory Light

Apparatus)

Sources

D 4594 Test Method for Effects of Temperature on Stability

G 152 PracticeforOperatingOpenFlameCarbonArcLight

of Geotextiles

Apparatus for Exposure of Nonmetallic Materials

D 4716 Test Method for Determining the (In-Plane) Flow

G 153 Practice for Operating Enclosed Carbon Arc Light

Rate Per Unit Width and Hydraulic Transmissivity of a

Apparatus for Exposure of Nonmetallic Materials

Geosynthetic Using a Constant Head

G 154 Practice for Operating Fluorescent Light Apparatus

for UV Exposure of Nonmetallic Materials

This guide is under the jurisdiction ofASTM Committee D-35 on Geosynthet-

3. Summary of Guide

icsandisthedirectresponsibilityofSubcommitteeD35.02onEnduranceProperties.

Current edition approved Dec. 10, 1999. Published March 2000. Originally

3.1 The effects of a given application environment on the

published as D 5819 – 95. Last previous edition D 5819 – 95.

durability of a geosynthetic must be determined through

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 04.13.

Annual Book of ASTM Standards, Vol 08.02.

5 6

Discontinued; see 1997 Annual Book of ASTM Standards, Vol 04.09. Annual Book of ASTM Standards, Vol 14.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5819–99

A B

TABLE 1 Functions and Other Performance Characteristics

B C

Containment (C)—A geosynthetic provides containment when it encapsulates or surrounds materials such as sand, rocks, and fresh concrete.

A

Filtration (F)—A geosynthetic performs the filtration function when the equilibrium geotextile-to-soil system allows for adequate liquid flow with limited soil loss

across the plane of the geotextile over a service lifetime compatible with the application under consideration.

A

Fluid Barrier (FB)—A geosynthetic performs the fluid barrier function when it essentially eliminates the migration of fluids through it.

A

Fluid Transmission (a.k.a. drainage)—A geosynthetic performs the fluid transmission function when the equilibrium geotextile-to-soil system allows for

adequate flow with limited soil loss within the plane of the geotextile over a service lifetime compatible with the application under consideration.

B

Insulation (I)—A geosynthetic provides insulation when it reduces the passage of heat, electricity, or sound.

A

Protection (P)—A geosynthetic, placed between two materials, performs the protection function when it alleviates or distributes stresses and strains

transmitted to the material to be protected.

A

Reinforcement (R)—A geosynthetic performs the reinforcement function when it provides often synergistic improvement of a total system’s strength created by

the introduction of a tensile force into a soil (good in compression but poor in tension) or other disjointed and separated material.

B

Screening (Scr)—A geosynthetic, placed across the path of a flowing fluid (ground water, surface water, wind) carrying particles in suspension, provides

screening when it retains some or all soil fine particles while allowing the fluid to pass through. After some period of time, particles accumulate against the

screen which requires that the screen be able to withstand pressures generated by the accumulated particles and the increasing fluid pressure.

A

Separation (S)—A geosynthetic placed between dissimilar materials so that the integrity and functioning of both materials can remain intact or be improved

performs the separation function.

B

Surface Stabilization (SS)—A geosynthetic, placed on a soil surface, provides surface stabilization when it restricts movement and prevents dispersion of

surface soil particles subjected to erosion actions (rain, wind), often while allowing or promoting vegetative growth.

B

Vegetative Reinforcement (VR)—A geosynthetic provides vegetative reinforcement when it extends the erosion control limits and performance of vegetation.

A

Functions are used in the context of this guide as terms that can be quantitatively described by standard tests or design techniques, or both.

B

Other performance characteristics are qualitative descriptions that are not yet supported by standard tests or generally accepted design techniques.

Note—during the placement of fresh concrete in a geotextile flexible form, the geosynthetic functions temporarily as a filter to allow excess water to escape.

appropriate testing. Selection of appropriate tests requires a 5.1.1 The intended geosynthetic application,

systematic determination of the primary function(s) to be

5.1.2 The end use of the geosynthetic via its primary

performedandtheassociateddegradationprocessesthatshould

function(s) or performance characteristic(s), or both,

be considered. This guide provides a suitable systematic

5.1.3 The specific environment to which the geosynthetic

approach.

will be exposed,

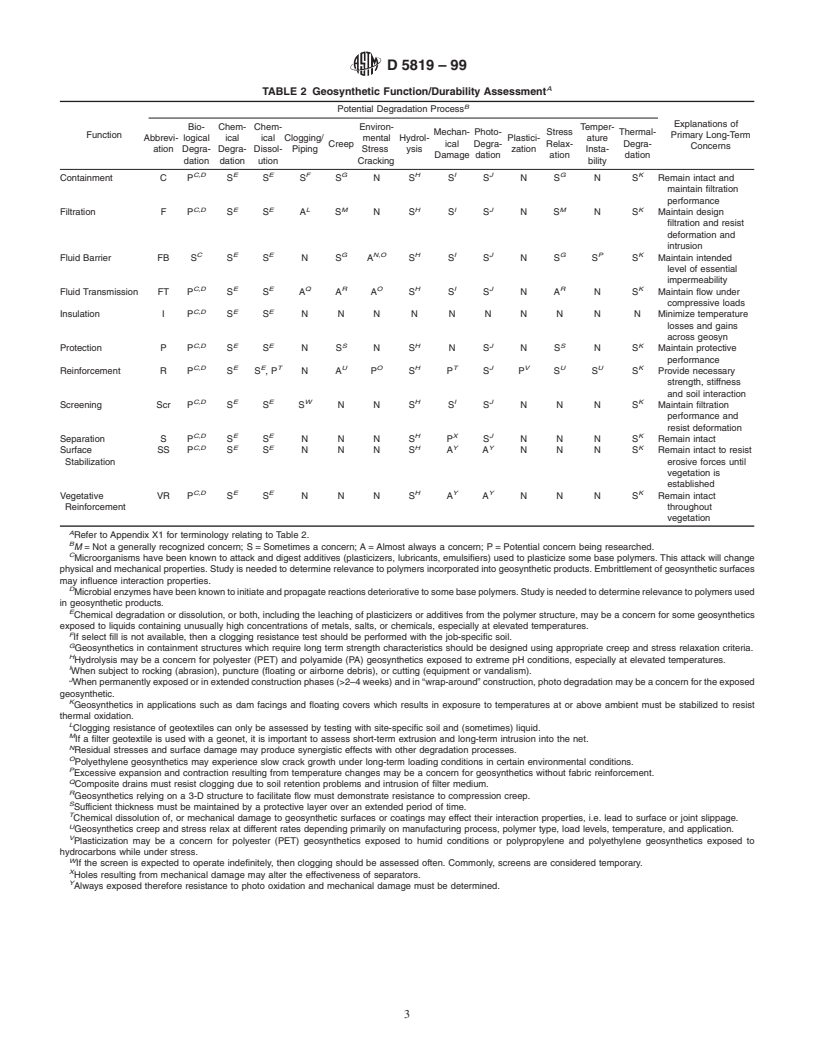

3.2 Primary functions of geosynthetics are listed and de-

5.1.4 The types of geosynthetics that may or will be used,

fined in Table 1. With knowledge of the specific geosynthetic

and

application area and end use, the corresponding primary

function(s) is (are) identified. Table 2 gives degradation con- 5.1.5 The duration or time of use (that is, service life).

cerns as they relate to geosynthetic functions.Table 3 gives the

5.2 With this knowledge, the designer/specifier follows the

environmental elements that relate to the various degradation

following procedure:

processes and the currently available ASTM Committee D-35

5.2.1 Identify the primary function(s) or performance char-

test method for the experimental evaluation of specific types of

acteristic(s),orboth,tobeperformedbythegeosyntheticinthe

geosynthetic degradation. The following appendixes are in-

specific application and end use intended. Functions and

cluded to provide background information:

performance characteristics are defined in Table 1. (Tables for

X1. Terminology

guidance in identifying primary function(s) and performance

X2. Application/End Use/Primary Function Tables

X3. Example of Test Method Selection Procedure

characteristics are given in Appendix X2.)

X4. Design-by-Function Discussion

5.2.2 Using Table 2, identify the potential degradation

X5. Commentary on Geosynthetic Durability

X6. Bibliography

process(es) that will almost always (denoted as “A”) or

sometimes (denoted as “S”) be of concern when a geosynthetic

4. Significance and Use

performs the primary function(s) or provides the performance

4.1 Designers/specifiers of geosynthetics should evaluate

characteristic(s), or both, which were identified in 5.2.1.Annex

geosynthetic durability as an integral part of the geosynthetic

A1 contains associated notes toTable 2 that help to identify the

specification/selection process. This guide is intended to guide

process(es) that is (are) sometimes a concern in the specific

a designer/specifier through a systematic determination of

expected application environment.

degradation concerns based on the intended geosynthetic

5.2.3 Using Table 3, select the test method(s) that applies to

function or performance characteristic. This guide then pro-

the potential degradation process(es) identified in 5.2.2 as a

vides a guide to select available test methods for experimen-

concern(s) in the specific application environment expected.

tally evaluating geosynthetic durability and to identify areas

where no suitable test exists.

NOTE 1—Guidance is given in Table 3 to identify the most important

4.2 This guide does not address the evaluation of degrada-

elements or variables relating to each degradation process.

tion resulting from manufacturing, handling, transporting or

installing the geosynthetic.

6. Keywords

5. Suggested Procedure

6.1 aging; degradation; durability; environment; exposure;

geosynthetic; long-term performance

5.1 To utilize a structured procedure for selecting appropri-

ate test methods, the geosynthetic designer/specifier must have

knowledge of:

D5819–99

A

TABLE 2 Geosynthetic Function/Durability Assessment

B

Potential Degradation Process

Explanations of

Bio- Chem- Chem- Environ- Temper-

Mechan- Photo- Stress Thermal-

Function Primary Long-Term

Abbrevi- logical ical ical Clogging/ mental Hydrol- Plastici- ature

Creep ical Degra- Relax- Degra-

Concerns

ation Degra- Degra- Dissol- Piping Stress ysis zation Insta-

Damage dation ation dation

dation dation ution Cracking bility

C,D E E F G H I J G K

Containment C P S S S S NS S S NS NS Remain intact and

maintain filtration

performance

C,D E E L M H I J M K

Filtration F P S S A S NS S S NS NS Maintain design

filtration and resist

deformation and

intrusion

C E E G N,O H I J G P K

Fluid Barrier FB S S S NS A S S S NS S S Maintain intended

level of essential

impermeability

C,D E E Q R O H I J R K

Fluid Transmission FT P S S A A A S S S NA NS Maintain flow under

compressive loads

C,D E E

Insulation I P S S N N N N NNNN N N Minimizetemperature

losses and gains

across geosyn

C,D E E S H J S K

Protection P P S S NS NS NS NS NS Maintain protective

performance

C,D E E T U O H T J V U U K

Reinforcement R P S S ,P NA P S P S P S S S Provide necessary

strength, stiffness

and soil interaction

C,D E E W H I J K

Screening Scr P S S S NNS S S NN N S Maintain filtration

performance and

resist deformation

C,D E E H X J K

Separation S P S S NN N S P S NN N S Remain intact

C,D E E H Y Y K

Surface SS P S S NN N S A A NN N S Remain intact to resist

Stabilization erosive forces until

vegetation is

established

C,D E E H Y Y K

Vegetative VR P S S NN N S A A NN N S Remain intact

Reinforcement throughout

vegetation

A

Refer to Appendix X1 for terminology relating to Table 2.

B

M = Not a generally recognized concern; S = Sometimes a concern; A = Almost always a concern; P = Potential concern being researched.

C

Microorganisms have been known to attack and digest additives (plasticizers, lubricants, emulsifiers) used to plasticize some base polymers. This attack will change

physical and mechanical properties. Study is needed to determine relevance to polymers incorporated into geosynthetic products. Embrittlement of geosynthetic surfaces

may influence interaction properties.

D

Microbial enzymes have been known to initiate and propagate reactions deteriorative to some base polymers. Study is needed to determine relevance to polymers used

in geosynthetic products.

E

Chemical degradation or dissolution, or both, including the leaching of plasticizers or additives from the polymer structure, may be a concern for some geosynthetics

exposed to liquids containing unusually high concentrations of metals, salts, or chemicals, especially at elevated temperatures.

F

If select fill is not available, then a clogging resistance test should be performed with the job-specific soil.

G

Geosynthetics in containment structures which require long term strength characteristics should be designed using appropriate creep and stress relaxation criteria.

H

Hydrolysis may be a concern for polyester (PET) and polyamide (PA) geosynthetics exposed to extreme pH conditions, especially at elevated temperatures.

I

When subject to rocking (abrasion), puncture (floating or airborne debris), or cutting (equipment or vandalism).

J

When permanently exposed or in extended construction phases (>2–4 weeks) and in “wrap-around” construction, photo degradation may be a concern for the exposed

geosynthetic.

K

Geosynthetics in applications such as dam facings and floating covers which results in exposure to temperatures at or above ambient must be stabilized to resist

thermal oxidation.

L

Clogging resistance of geotextiles can only be assessed by testing with site-specific soil and (sometimes) liquid.

M

If a filter geotextile is used with a geonet, it is important to assess short-term extrusion and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.