ASTM F3372-20

(Practice)Standard Practice for Butt Fusion Joining of PA12 Pipe and Fittings

Standard Practice for Butt Fusion Joining of PA12 Pipe and Fittings

SCOPE

1.1 This practice describes procedures for making butt fusion joints with Polyamide 12 (PA12) pipe and fittings by means of heat fusion joining in, but not limited to, a field environment. Procedure A is for environmental temperatures of 40 °F (4 °C) and higher. Procedure B is for site temperatures below 40 °F (4 °C). Other suitable heat fusion joining procedures are available from various sources including pipe and fitting manufacturers. This standard does not purport to address all possible heat fusion joining procedures, or to preclude the use of qualified procedures developed by other parties that have been proved to produce reliable heat fusion joints.

1.2 The parameters and procedures are applicable only to joining PA12 pipe and fittings and are not applicable to other polyamide types. They are intended only for PA12 fuel gas pipe per Specification F2785 and PA12 butt heat fusion fittings in accordance with Specification F1733. Fusion to other polyamide types (that is, cross-fusion) is not permitted under this practice, and this practice does not not apply to other polyamide types. Consult with the pipe and fittings manufacturers to make sure they recommend this procedure for the pipe and fittings to be joined (also see Appendix X1).

1.3 The procedures in this practice apply to the butt fusion of PA12 pipe and butt fusion fittings in accordance with 1.2 having like diameter and wall thickness.

Note 1: Refer to X1.5 for guidance regarding dissimilar wall thicknesses.

1.4 Other suitable heat joining procedures are available from various sources including pipe and fitting manufacturers. Melt characteristics, average molecular weight and molecular weight distribution of PA12 compounds are influential factors in establishing suitable fusion parameters; therefore, consider the manufacturer’s recommendations in the use or development of a specific fusion procedure.

1.5 The text of this practice references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the practice.

1.6 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6.1 Non-conformance with this specification is possible if values from the two systems are combined. Values in parentheses are conversions that are appropriately rounded for accuracy and precision; that are not exact equivalents, and that are for non-mandatory informational purposes.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3372 − 20 An American National Standard

Standard Practice for

1

Butt Fusion Joining of PA12 Pipe and Fittings

This standard is issued under the fixed designation F3372; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

1.1 This practice describes procedures for making butt

conversions to SI units that are provided for information only

fusion joints with Polyamide 12 (PA12) pipe and fittings by

and are not considered standard.

means of heat fusion joining in, but not limited to, a field

1.6.1 Non-conformance with this specification is possible if

environment.ProcedureAisforenvironmentaltemperaturesof

values from the two systems are combined. Values in paren-

40 °F (4 °C) and higher. Procedure B is for site temperatures

theses are conversions that are appropriately rounded for

below 40 °F (4 °C). Other suitable heat fusion joining proce-

accuracy and precision; that are not exact equivalents, and that

dures are available from various sources including pipe and

are for non-mandatory informational purposes.

fittingmanufacturers.Thisstandarddoesnotpurporttoaddress

1.7 This standard does not purport to address all of the

all possible heat fusion joining procedures, or to preclude the

safety concerns, if any, associated with its use. It is the

use of qualified procedures developed by other parties that

responsibility of the user of this standard to establish appro-

have been proved to produce reliable heat fusion joints.

priate safety, health, and environmental practices and deter-

1.2 The parameters and procedures are applicable only to

mine the applicability of regulatory limitations prior to use.

joining PA12 pipe and fittings and are not applicable to other

1.8 This international standard was developed in accor-

polyamide types. They are intended only for PA12 fuel gas

dance with internationally recognized principles on standard-

pipe per Specification F2785 and PA12 butt heat fusion fittings

ization established in the Decision on Principles for the

in accordance with Specification F1733. Fusion to other

Development of International Standards, Guides and Recom-

polyamide types (that is, cross-fusion) is not permitted under

mendations issued by the World Trade Organization Technical

this practice, and this practice does not not apply to other

Barriers to Trade (TBT) Committee.

polyamide types. Consult with the pipe and fittings manufac-

turerstomakesuretheyrecommendthisprocedureforthepipe

2. Referenced Documents

and fittings to be joined (also see Appendix X1).

2

2.1 ASTM Standards:

1.3 The procedures in this practice apply to the butt fusion

F412 Terminology Relating to Plastic Piping Systems

of PA12 pipe and butt fusion fittings in accordance with 1.2

F1733 Specification for Butt Heat Fusion Polyamide(PA)

having like diameter and wall thickness.

Plastic Fitting for Polyamide(PA) Plastic Pipe and Tubing

NOTE 1—Refer to X1.5 for guidance regarding dissimilar wall thick- F2785 Specification for Polyamide 12 Gas Pressure Pipe,

nesses.

Tubing, and Fittings

1.4 Other suitable heat joining procedures are available

3. Terminology

from various sources including pipe and fitting manufacturers.

Melt characteristics, average molecular weight and molecular

3.1 General—Definitions and abbreviations are in accor-

weight distribution of PA12 compounds are influential factors

dance with Terminology F412, unless otherwise specified.

in establishing suitable fusion parameters; therefore, consider

3.2 Definitions of Terms Specific to This Standard:

the manufacturer’s recommendations in the use or develop-

3.2.1 drag force, n—the force required to overcome the

ment of a specific fusion procedure.

static and dynamic resistance to motion of the movable

1.5 The text of this practice references notes, footnotes, and

carriage.

appendixes which provide explanatory material. These notes

3.2.2 fusion force, n—the force applied between the melted

and footnotes (excluding those in tables and figures) shall not

polymer pipe ends.

be considered as requirements of the practice.

1 2

This test method is under the jurisdiction of ASTM Committee F17 on Plastic For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining. contact ASTM Customer Service at service@astm.org. F

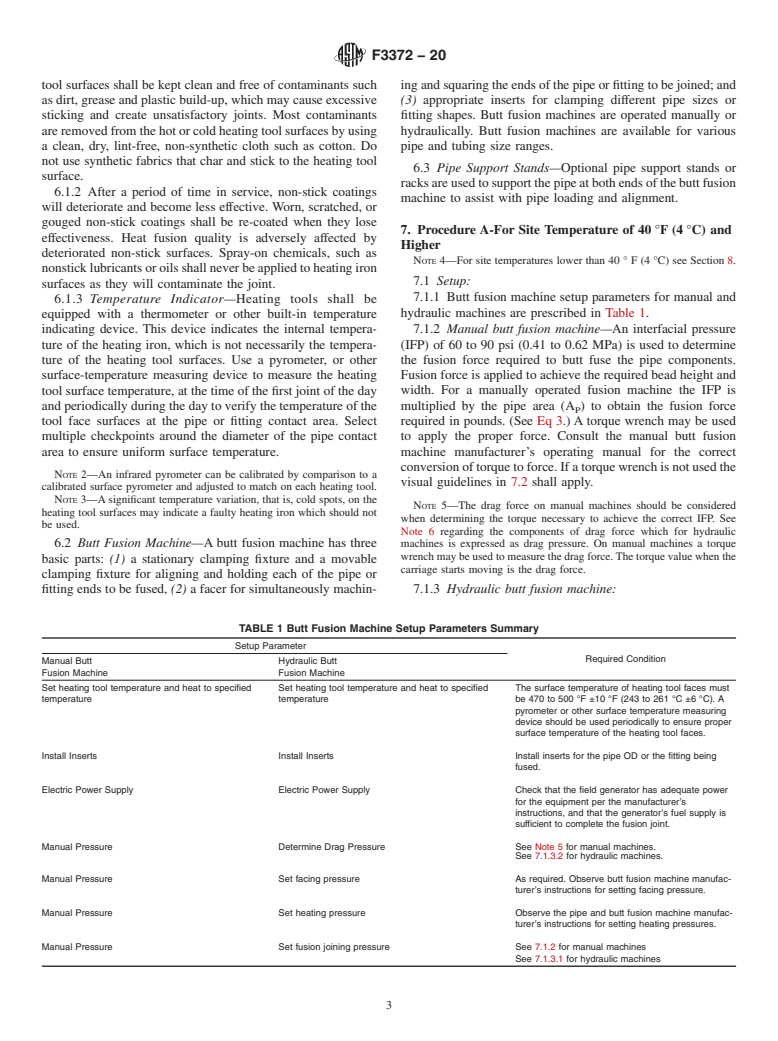

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.