ASTM F2005-21

(Terminology)Standard Terminology for Nickel-Titanium Shape Memory Alloys

Standard Terminology for Nickel-Titanium Shape Memory Alloys

SCOPE

1.1 This terminology is a compilation of definitions of terms used in ASTM documents relating to nickel-titanium shape memory alloys used for medical devices. This terminology includes only those terms for which ASTM either has standards or which are used in ASTM standards for nickel-titanium shape memory alloys. It is not intended to be an all-inclusive list of terms related to shape memory alloys.

1.2 Definitions that are similar to those published by another standards body are identified with abbreviations of the name of that organization; for example, ICTAC is the International Confederation for Thermal Analysis and Calorimetry.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2005 − 21

Standard Terminology for

1

Nickel-Titanium Shape Memory Alloys

This standard is issued under the fixed designation F2005; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This terminology is a compilation of definitions of terms

active austenite finish temperature, n—term used to denote

used in ASTM documents relating to nickel-titanium shape

the austenite finish temperature of an aged, shape-set or

memory alloys used for medical devices. This terminology

tempered wire, tube, or component as determined by (1)a

includesonlythosetermsforwhichASTMeitherhasstandards

bend and free recovery (BFR) method pursuant to Test

orwhichareusedinASTMstandardsfornickel-titaniumshape

Method F2082,(2) by a uniform prestrain and free recovery

memory alloys. It is not intended to be an all-inclusive list of

(UPFR) method pursuant to Test Method E3098,or(3)

terms related to shape memory alloys.

another method as agreed upon between purchaser and

supplier rather than by calorimetry (DSC) pursuant to Test

1.2 Definitionsthataresimilartothosepublishedbyanother

standards body are identified with abbreviations of the name of Method F2004.

that organization; for example, ICTAC is the International

age, v—to heat treat at a low to intermediate temperature,

Confederation for Thermal Analysis and Calorimetry.

typically in the range of 300 °C to 575 °C, usually for an

1.3 This international standard was developed in accor-

extended period of time, to form precipitates and/or adjust

dance with internationally recognized principles on standard-

transformation temperatures and thermoelastic properties.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- alloy phase, n—in a shape memory alloy, the crystal structure

mendations issued by the World Trade Organization Technical stable at a particular temperature and stress.

Barriers to Trade (TBT) Committee.

anneal, v—to heat treat at a temperature above the recrystal-

lization temperature, typically in the range of 700 °C to

2. Referenced Documents

950 °C, in order to essentially remove the effects of hot

2

2.1 ASTM Standards:

and/or cold working and dissolve precipitates.

E7 Terminology Relating to Metallography

E473 Terminology Relating to Thermal Analysis and Rhe-

austenite,n—the high temperature parent phase in Ni-Ti shape

ology

memory alloys with a B2 crystal structure. This phase

E3098 Test Method for Mechanical Uniaxial Pre-strain and

transforms to R-phase or martensite on cooling.

Thermal Free Recovery of Shape Memory Alloys

austenite finish temperature (A ), n—the temperature at

f

F2004 Test Method for Transformation Temperature of

which the martensite to austenite transformation is com-

Nickel-Titanium Alloys by Thermal Analysis

pleted on heating in a single-stage transformation (Fig. 1)or

F2082 Test Method for Determination of Transformation

the temperature at which the R-phase to austenite transfor-

Temperature of Nickel-Titanium Shape Memory Alloys

mation is completed on heating in a two-stage transforma-

by Bend and Free Recovery

tion (Fig. 2).

F2516 Test Method for Tension Testing of Nickel-Titanium

Superelastic Materials

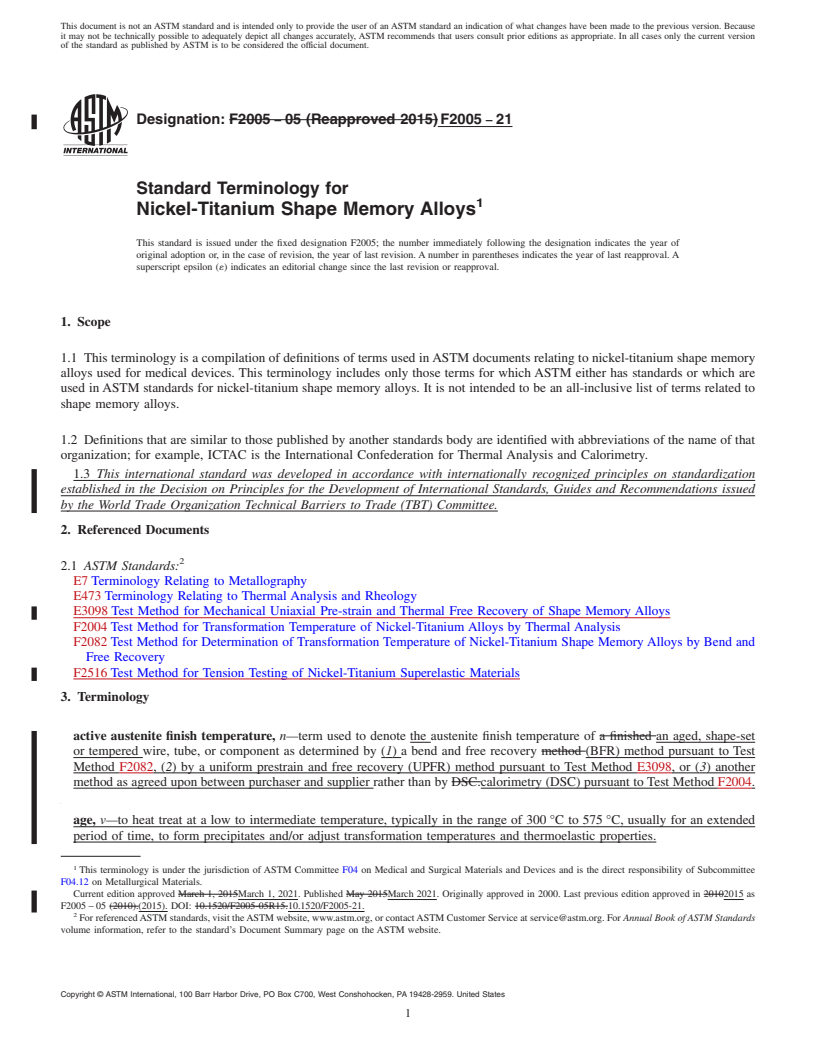

austenite peak temperature (A ), n—the temperature of the

p

endothermic peak position on the differential scanning

calorimeter (DSC) curve upon heating for the martensite to

1

ThisterminologyisunderthejurisdictionofASTMCommittee F04onMedical

austenite transformation in a single-stage transformation

and Surgical Materials and Devices and is the direct responsibility of Subcommittee

(Fig. 1) or the temperature of the endothermic peak position

F04.12 on Metallurgical Materials.

Current edition approved March 1, 2021. Published March 2021. Originally

on the DSC curve upon heating for the R-phase to austenite

approved in 2000. Last previous edition approved in 2015 as F2005 – 05 (2015).

transformation in a two-stage transformation (Fig. 2).

DOI: 10.1520/F2005-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

austenite start temperature (A ),n—the temperature at which

s

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the martensite to austenite transformation begins on heating

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. in a single-stage transformation (Fig. 1) or the temperature at

Copyright

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2005 − 05 (Reapproved 2015) F2005 − 21

Standard Terminology for

1

Nickel-Titanium Shape Memory Alloys

This standard is issued under the fixed designation F2005; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This terminology is a compilation of definitions of terms used in ASTM documents relating to nickel-titanium shape memory

alloys used for medical devices. This terminology includes only those terms for which ASTM either has standards or which are

used in ASTM standards for nickel-titanium shape memory alloys. It is not intended to be an all-inclusive list of terms related to

shape memory alloys.

1.2 Definitions that are similar to those published by another standards body are identified with abbreviations of the name of that

organization; for example, ICTAC is the International Confederation for Thermal Analysis and Calorimetry.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E7 Terminology Relating to Metallography

E473 Terminology Relating to Thermal Analysis and Rheology

E3098 Test Method for Mechanical Uniaxial Pre-strain and Thermal Free Recovery of Shape Memory Alloys

F2004 Test Method for Transformation Temperature of Nickel-Titanium Alloys by Thermal Analysis

F2082 Test Method for Determination of Transformation Temperature of Nickel-Titanium Shape Memory Alloys by Bend and

Free Recovery

F2516 Test Method for Tension Testing of Nickel-Titanium Superelastic Materials

3. Terminology

active austenite finish temperature, n—term used to denote the austenite finish temperature of a finished an aged, shape-set

or tempered wire, tube, or component as determined by (1) a bend and free recovery method (BFR) method pursuant to Test

Method F2082, (2) by a uniform prestrain and free recovery (UPFR) method pursuant to Test Method E3098, or (3) another

method as agreed upon between purchaser and supplier rather than by DSC.calorimetry (DSC) pursuant to Test Method F2004.

age, v—to heat treat at a low to intermediate temperature, typically in the range of 300 °C to 575 °C, usually for an extended

period of time, to form precipitates and/or adjust transformation temperatures and thermoelastic properties.

1

This terminology is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.12 on Metallurgical Materials.

Current edition approved March 1, 2015March 1, 2021. Published May 2015March 2021. Originally approved in 2000. Last previous edition approved in 20102015 as

F2005 – 05 (2010).(2015). DOI: 10.1520/F2005-05R15.10.1520/F2005-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2005 − 21

alloy phase, n—in a shape memory alloy, the crystal structure stable at a particular temperature and stress.

anneal, v—to heat treat in order to remove the effect of cold-working.at a temperature above the recrystallization temperature,

typically in the range of 700 °C to 950 °C, in order to essentially remove the effects of hot and/or cold working and dissolve

precipitates.

austenite, n—the high temperature parent phase in Ni-Ti shape memory alloys with a B2 crystal structure. This phase transforms

to R-phase or martensite on cooling.

austenite finish temperature (A ), n—the temperature at which the martensite to austenite transformation is completed on

f

heating in a single-stage transformation (Fig. 1) or the temperature at which the R-phase to austenite transformation is completed

on heating in a two-stage transformation (Fig. 2).

austenite peak temperature (A ) , ), n—the temperature of the endothermic peak position on the differential scanning

p

ca

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.