ASTM A320/A320M-24

(Specification)Standard Specification for Alloy-Steel and Stainless Steel Bolting for Low-Temperature Service

Standard Specification for Alloy-Steel and Stainless Steel Bolting for Low-Temperature Service

ABSTRACT

This specification covers alloy steel bolting materials for pressure vessels, valves, flanges, and fittings for low-temperature service. Each alloy shall conform to the prescribed chemical composition requirements. The material, as represented by the tension specimens, shall conform to the requirements as to tensile properties such as tensile strength, yield strength, elongation, and hardness. The material shall meet the prescribed impact energy absorption requirements and the recommended test temperature. Mechanical tests shall be conducted on the material, namely: impact testing, tension testing, and hardness testing.

SCOPE

1.1 This specification2 covers alloy and stainless steel bolting materials and bolting components for pressure vessels, valves, flanges, and fittings for low-temperature service. See Specification A962/A962M for the definition of bolting. The bars shall be hot-wrought and may be further processed by centerless grinding or by cold drawing. Austenitic stainless steel may be solution annealed or annealed and strain-hardened. When strain hardened austenitic stainless steel is ordered, the purchaser should take special care to ensure that Appendix X1 is thoroughly understood.

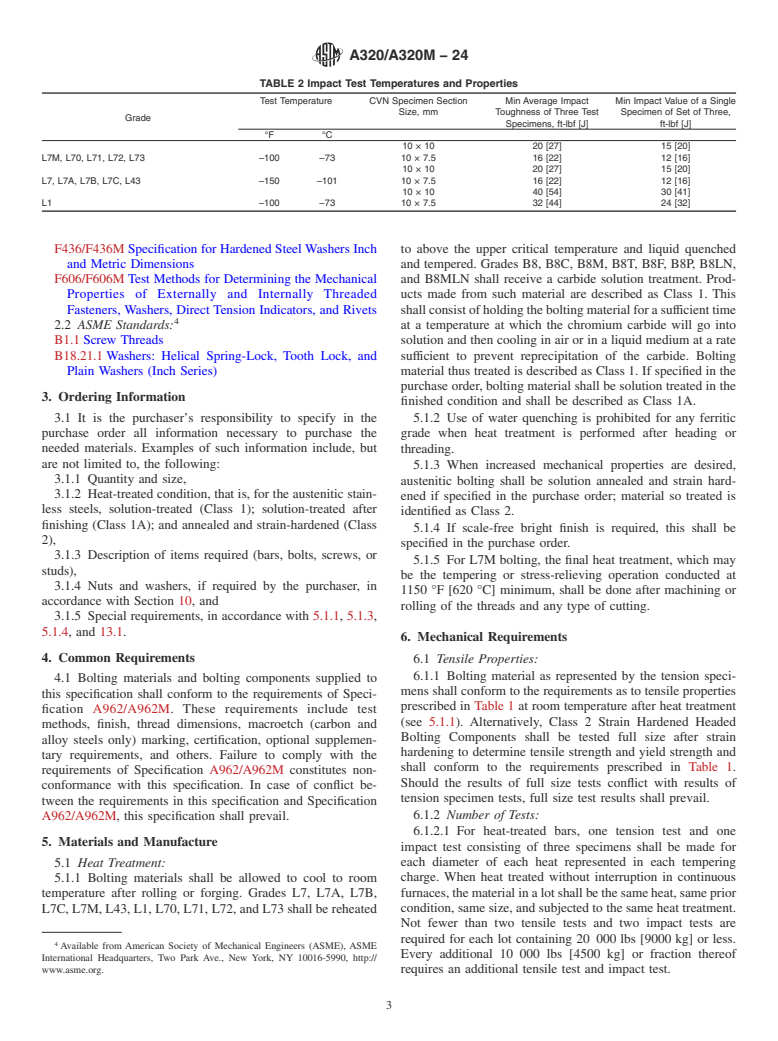

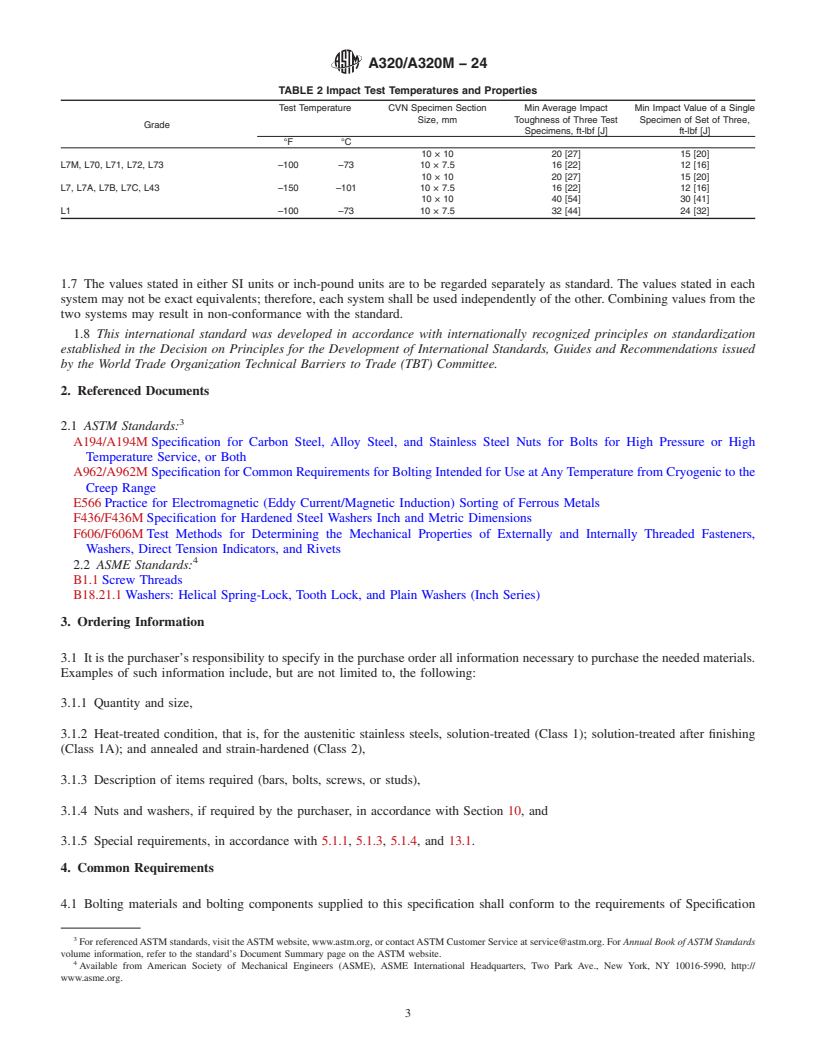

1.2 Several grades are covered, including both ferritic and austenitic steels designated L7, B8, etc. Selection will depend on design, service conditions, mechanical properties, and low-temperature characteristics. The mechanical requirements of Table 1 indicate the diameters for which the minimum mechanical properties apply to the various grades and classes, and Table 2 stipulates the requirements for Charpy impact energy absorption. The manufacturer should determine that the material can conform to these requirements before parts are manufactured. For example, when Grade L43 is specified to meet the Table 2 impact energy values at −150 °F [−101 °C], additional restrictions (such as procuring a steel with lower P and S contents than might normally be supplied) in the chemical composition for AISI 4340 are likely to be required.

Note 1: The committee formulating this specification has included several grades of material that have been rather extensively used for the present purpose. Other compositions will be considered for inclusion by the committee from time to time as the need becomes apparent. Users should note that hardenability of some of the grades mentioned may restrict the maximum size at which the required mechanical properties are obtainable.

1.3 The following referenced general requirements are indispensable for application of this specification: Specification A962/A962M.

1.4 Nuts for use with bolting are covered in Section 10 and the nut material shall be impact tested.

1.5 Supplementary Requirements are provided for use at the option of the purchaser. The supplementary requirements shall apply only when specified in the purchase order or contract.

1.6 This specification is expressed in both inch-pound units and SI units; however, unless the purchase order or contract specifies the applicable M specification designation (SI) units, the inch-pound units shall apply.

1.7 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A320/A320M − 24

Standard Specification for

Alloy-Steel and Stainless Steel Bolting for Low-Temperature

1

Service

This standard is issued under the fixed designation A320/A320M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 1.3 The following referenced general requirements are in-

2 dispensable for application of this specification: Specification

1.1 This specification covers alloy and stainless steel bolt-

A962/A962M.

ing materials and bolting components for pressure vessels,

valves, flanges, and fittings for low-temperature service. See 1.4 Nuts for use with bolting are covered in Section 10 and

Specification A962/A962M for the definition of bolting. The the nut material shall be impact tested.

bars shall be hot-wrought and may be further processed by

1.5 Supplementary Requirements are provided for use at the

centerless grinding or by cold drawing. Austenitic stainless

option of the purchaser. The supplementary requirements shall

steel may be solution annealed or annealed and strain-

apply only when specified in the purchase order or contract.

hardened. When strain hardened austenitic stainless steel is

1.6 This specification is expressed in both inch-pound units

ordered, the purchaser should take special care to ensure that

and SI units; however, unless the purchase order or contract

Appendix X1 is thoroughly understood.

specifies the applicable M specification designation (SI) units,

1.2 Several grades are covered, including both ferritic and

the inch-pound units shall apply.

austenitic steels designated L7, B8, etc. Selection will depend

1.7 The values stated in either SI units or inch-pound units

on design, service conditions, mechanical properties, and

are to be regarded separately as standard. The values stated in

low-temperature characteristics. The mechanical requirements

each system may not be exact equivalents; therefore, each

of Table 1 indicate the diameters for which the minimum

system shall be used independently of the other. Combining

mechanical properties apply to the various grades and classes,

values from the two systems may result in non-conformance

and Table 2 stipulates the requirements for Charpy impact

with the standard.

energy absorption. The manufacturer should determine that the

1.8 This international standard was developed in accor-

material can conform to these requirements before parts are

manufactured. For example, when Grade L43 is specified to dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

meet the Table 2 impact energy values at −150 °F [−101 °C],

additional restrictions (such as procuring a steel with lower P Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

and S contents than might normally be supplied) in the

chemical composition for AISI 4340 are likely to be required. Barriers to Trade (TBT) Committee.

NOTE 1—The committee formulating this specification has included

2. Referenced Documents

several grades of material that have been rather extensively used for the

3

2.1 ASTM Standards:

present purpose. Other compositions will be considered for inclusion by

the committee from time to time as the need becomes apparent. Users

A194/A194M Specification for Carbon Steel, Alloy Steel,

should note that hardenability of some of the grades mentioned may

and Stainless Steel Nuts for Bolts for High Pressure or

restrict the maximum size at which the required mechanical properties are

High Temperature Service, or Both

obtainable.

A962/A962M Specification for Common Requirements for

Bolting Intended for Use at Any Temperature from Cryo-

genic to the Creep Range

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

E566 Practice for Electromagnetic (Eddy Current/Magnetic

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

Induction) Sorting of Ferrous Metals

A01.22 on Steel Forgings and Wrought Fittings for Piping Applications and Bolting

Materials for Piping and Special Purpose Applications.

Current edition approved March 1, 2024. Published April 2024. Originally

3

approved in 1948. Last previous edition approved in 2022 as A320/A320M – 22a. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/A0320_A03

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A320/A320M − 22a A320/A320M − 24

Standard Specification for

Alloy-Steel and Stainless Steel Bolting for Low-Temperature

1

Service

This standard is issued under the fixed designation A320/A320M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

2

1.1 This specification covers alloy and stainless steel bolting materials and bolting components for pressure vessels, valves,

flanges, and fittings for low-temperature service. See Specification A962/A962M for the definition of bolting. The bars shall be

hot-wrought and may be further processed by centerless grinding or by cold drawing. Austenitic stainless steel may be solution

annealed or annealed and strain-hardened. When strain hardened austenitic stainless steel is ordered, the purchaser should take

special care to ensure that Appendix X1 is thoroughly understood.

1.2 Several grades are covered, including both ferritic and austenitic steels designated L7, B8, etc. Selection will depend on

design, service conditions, mechanical properties, and low-temperature characteristics. The mechanical requirements of Table 1

indicate the diameters for which the minimum mechanical properties apply to the various grades and classes, and Table 2 stipulates

the requirements for Charpy impact energy absorption. The manufacturer should determine that the material can conform to these

requirements before parts are manufactured. For example, when Grade L43 is specified to meet the Table 2 impact energy values

at −150 °F [−101 °C], additional restrictions (such as procuring a steel with lower P and S contents than might normally be

supplied) in the chemical composition for AISI 4340 are likely to be required.

NOTE 1—The committee formulating this specification has included several grades of material that have been rather extensively used for the present

purpose. Other compositions will be considered for inclusion by the committee from time to time as the need becomes apparent. Users should note that

hardenability of some of the grades mentioned may restrict the maximum size at which the required mechanical properties are obtainable.

1.3 The following referenced general requirements are indispensable for application of this specification: Specification

A962/A962M.

1.4 Nuts for use with bolting are covered in Section 10 and the nut material shall be impact tested.

1.5 Supplementary Requirements are provided for use at the option of the purchaser. The supplementary requirements shall apply

only when specified in the purchase order or contract.

1.6 This specification is expressed in both inch-pound units and SI units; however, unless the purchase order or contract specifies

the applicable M specification designation (SI) units, the inch-pound units shall apply.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.22

on Steel Forgings and Wrought Fittings for Piping Applications and Bolting Materials for Piping and Special Purpose Applications.

Current edition approved Nov. 1, 2022March 1, 2024. Published November 2022April 2024. Originally approved in 1948. Last previous edition approved in 2022 as

A320/A320M – 22.A320/A320M – 22a. DOI: 10.1520/A0320_A0320M-22A.10.1520/A0320_A0320M-24.

2

For ASME Boiler and Pressure Vessel Code applications, see related Specification SA-320 in Section II of that Code.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A320/A320M − 24

2

TABLE 1 Mechanical Requirements

Minimum Tensile Yield Strength, Elongation

Reduction

Tempering Strength, min, ksi in 2 in. Hardness,

Class and Grade, Diameter, in. [mm] Heat Treatment of Area,

Temperature, min, ksi [MPa] (0.2 % or 50 max

min, %

°F [°C] [MPa] offset) mm, min, %

Ferritic Steels

L7, L7A, L7B, L7C, L70, L71, L72, L73 125 105 16 50 321 HBW or 35

HRC

A

1

2 ⁄2 [65] and under quenched and tempered 1100 [860] [725]

[593]

L43 125 105 16 50 321 HBW or 35

HRC

A

4 [100] and under quenched and tempered 1100 [860] [725]

[593]

B

L7M 100 80 18 50 2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.