ASTM D2622-03

(Test Method)Standard Test Method for Sulfur in Petroleum Products by Wavelength Dispersive X-ray Fluorescence Spectrometry

Standard Test Method for Sulfur in Petroleum Products by Wavelength Dispersive X-ray Fluorescence Spectrometry

SCOPE

1.1 This test method covers the determination of total sulfur in petroleum and petroleum products that are single-phase and either liquid at ambient conditions, liquifiable with moderate heat, or soluble in hydrocarbon solvents. These materials can include diesel fuel, jet fuel, kerosine, other distillate oil, naphtha, residual oil, lubricating base oil, hydraulic oil, crude oil, unleaded gasoline, M-85 and M-100.

1.2 The interlaboratory study on precision covered a variety of materials with sulfur concentrations ranging from approximately 3 mg/kg to 5.3 mass %. For a subset of these samples, with sulfur concentrations below 60 mg/kg, the repeatability standard deviation (Sr) was 1.5 mg/kg. An estimate of the limit of detection is 3 X Sr , and an estimate of the limit of quantitation 2 is 10 X Sr. However, because instrumentation covered by this test method can vary in sensitivity, the applicability of the test method at sulfur concentrations below approximately 20 mg/kg must be determined on an individual basis.

1.3 Samples containing more than 5.0 mass % sulfur can be diluted to bring the sulfur concentration of the diluted material within the scope of this test method.

1.4 Volatile samples (such as high vapor pressure gasolines or light hydrocarbons) may not meet the stated precision because of selective loss of light materials during the analysis.

1.5 A fundamental assumption in this test method is that the standard and sample matrix are well matched. Matrix mismatch can be caused by C/H ratio differences between samples and standards (see Tables 1 and 2) or by the presence of other heteroatoms (see Table 3).

1.6 The values stated in either SI units or angstrom units are to be regarded separately as standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard information, see Note 1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D2622–03

Standard Test Method for

Sulfur in Petroleum Products by Wavelength Dispersive

1

X-ray Fluorescence Spectrometry

This standard is issued under the fixed designation D 2622; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

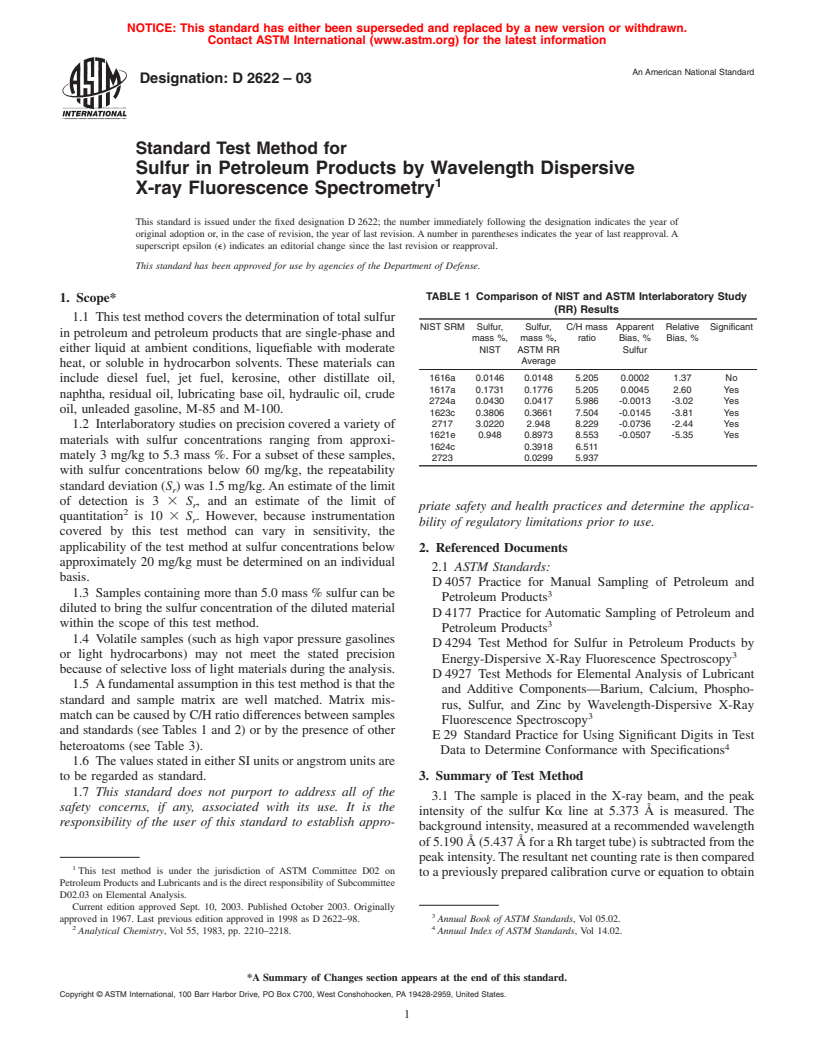

TABLE 1 Comparison of NIST and ASTM Interlaboratory Study

1. Scope*

(RR) Results

1.1 This test method covers the determination of total sulfur

NIST SRM Sulfur, Sulfur, C/H mass Apparent Relative Significant

in petroleum and petroleum products that are single-phase and

mass %, mass %, ratio Bias, % Bias, %

either liquid at ambient conditions, liquefiable with moderate

NIST ASTM RR Sulfur

Average

heat, or soluble in hydrocarbon solvents. These materials can

1616a 0.0146 0.0148 5.205 0.0002 1.37 No

include diesel fuel, jet fuel, kerosine, other distillate oil,

1617a 0.1731 0.1776 5.205 0.0045 2.60 Yes

naphtha, residual oil, lubricating base oil, hydraulic oil, crude

2724a 0.0430 0.0417 5.986 -0.0013 -3.02 Yes

oil, unleaded gasoline, M-85 and M-100.

1623c 0.3806 0.3661 7.504 -0.0145 -3.81 Yes

2717 3.0220 2.948 8.229 -0.0736 -2.44 Yes

1.2 Interlaboratory studies on precision covered a variety of

1621e 0.948 0.8973 8.553 -0.0507 -5.35 Yes

materials with sulfur concentrations ranging from approxi-

1624c 0.3918 6.511

mately 3 mg/kg to 5.3 mass %. For a subset of these samples,

2723 0.0299 5.937

with sulfur concentrations below 60 mg/kg, the repeatability

standard deviation (S ) was 1.5 mg/kg.An estimate of the limit

r

of detection is 3 3 S , and an estimate of the limit of

r

priate safety and health practices and determine the applica-

2

quantitation is 10 3 S . However, because instrumentation

r

bility of regulatory limitations prior to use.

covered by this test method can vary in sensitivity, the

applicability of the test method at sulfur concentrations below 2. Referenced Documents

approximately 20 mg/kg must be determined on an individual

2.1 ASTM Standards:

basis.

D 4057 Practice for Manual Sampling of Petroleum and

1.3 Samples containing more than 5.0 mass % sulfur can be 3

Petroleum Products

diluted to bring the sulfur concentration of the diluted material

D 4177 Practice for Automatic Sampling of Petroleum and

within the scope of this test method. 3

Petroleum Products

1.4 Volatile samples (such as high vapor pressure gasolines

D 4294 Test Method for Sulfur in Petroleum Products by

or light hydrocarbons) may not meet the stated precision 3

Energy-Dispersive X-Ray Fluorescence Spectroscopy

because of selective loss of light materials during the analysis.

D 4927 Test Methods for Elemental Analysis of Lubricant

1.5 Afundamental assumption in this test method is that the

and Additive Components—Barium, Calcium, Phospho-

standard and sample matrix are well matched. Matrix mis-

rus, Sulfur, and Zinc by Wavelength-Dispersive X-Ray

match can be caused by C/H ratio differences between samples 3

Fluorescence Spectroscopy

and standards (see Tables 1 and 2) or by the presence of other

E 29 Standard Practice for Using Significant Digits in Test

heteroatoms (see Table 3). 4

Data to Determine Conformance with Specifications

1.6 The values stated in either SI units or angstrom units are

to be regarded as standard. 3. Summary of Test Method

1.7 This standard does not purport to address all of the

3.1 The sample is placed in the X-ray beam, and the peak

safety concerns, if any, associated with its use. It is the

intensity of the sulfur Ka line at 5.373 Å is measured. The

responsibility of the user of this standard to establish appro-

background intensity, measured at a recommended wavelength

of5.190Å(5.437ÅforaRhtargettube)issubtractedfromthe

peakintensity.Theresultantnetcountingrateisthencompared

1

This test method is under the jurisdiction of ASTM Committee D02 on

to a previously prepared calibration curve or equation to obtain

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.03 on Elemental Analysis.

Current edition approved Sept. 10, 2003. Published October 2003. Originally

3

approved in 1967. Last previous edition approved in 1998 as D 2622–98. Annual Book of ASTM Standards, Vol 05.02.

2 4

Analytical Chemistry, Vol 55, 1983, pp. 2210–2218. Annual Index of ASTM Standards, Vol 14.02.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2622–03

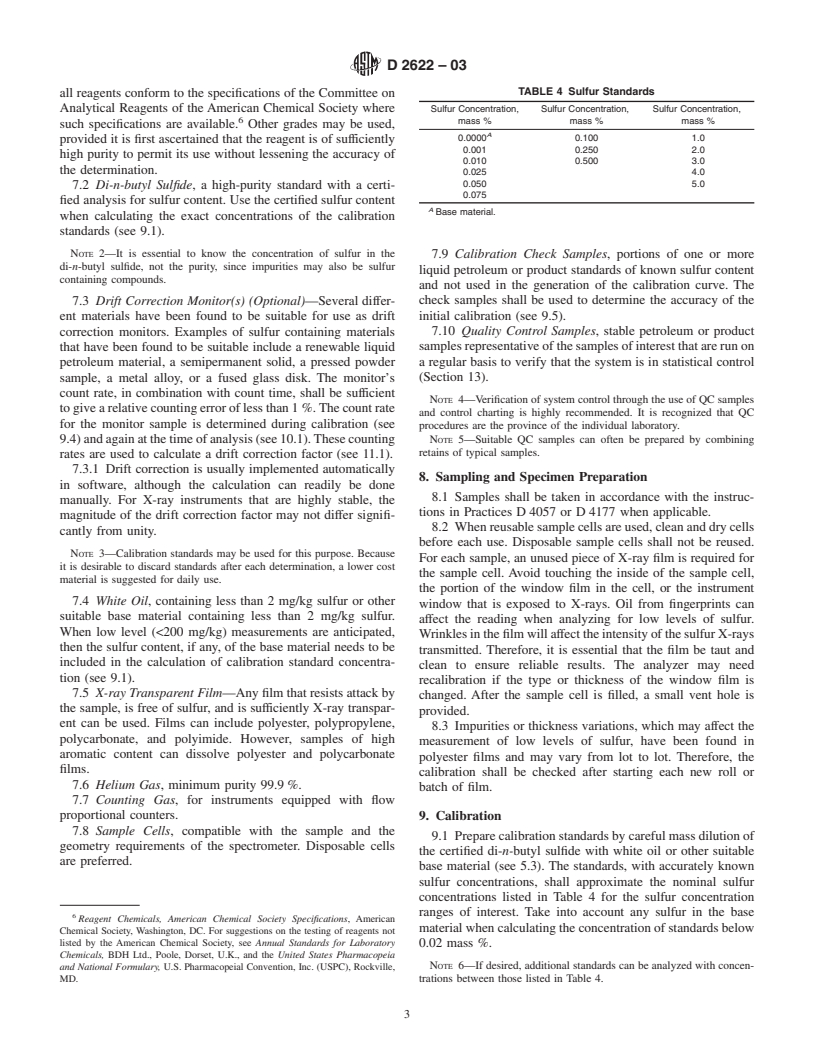

T

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.