ASTM E439-98

(Test Method)Standard Test Methods for Chemical Analysis of Beryllium

Standard Test Methods for Chemical Analysis of Beryllium

SCOPE

1.1 These test methods cover the chemical analysis of beryllium having chemical compositions within the following limits: Concentration Element Range, % Aluminum 0.05 to 0.30 Beryllium 97.5 to 100 Beryllium Oxide 0.3 to 3 Carbon 0.05 to 0.30 Copper 0.005 to 0.10 Chromium 0.005 to 0.10 Iron 0.05 to 0.30 Magnesium 0.02 to 0.15 Nickel 0.005 to 0.10 Silicon 0.02 to 0.15

1.2 The test methods in this standard are contained in the sections indicated below. Sections Chromium by the Diphenylcarbazide Photometric Test Method 9 to 18 Iron by the 1,10-Phenanthroline Photometric Test Method 19 to 28 Manganese by the Periodate Photometric Test Method 29 to 38 Nickel by the Dimethylglyoxime Photometric Test Method 39 to 48

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 439 – 98

Standard Test Methods for

Chemical Analysis of Beryllium

This standard is issued under the fixed designation E 439; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 55 Practice for Sampling Wrought Nonferrous Metals and

Alloys for Determination of Chemical Composition

1.1 These test methods cover the chemical analysis of

E 60 Practice for Photometric and Spectrophotometric

beryllium having chemical compositions within the following

Methods for Chemical Analysis of Metals

limits:

E 88 Practice for Sampling Nonferrous Metals and Alloys

Concentration

in Cast Form for Determination of Chemical Composition

Element Range, %

Aluminum 0.05 to 0.30

E 173 Practice for Conducting Interlaboratory Studies of

Beryllium 97.5 to 100

Methods for Chemical Analysis of Metals

Beryllium Oxide 0.3 to 3

Carbon 0.05 to 0.30

3. Significance and Use

Copper 0.005 to 0.10

Chromium 0.005 to 0.10

3.1 These test methods for the chemical analysis of beryl-

Iron 0.05 to 0.30

lium metal are primarily intended as referee methods to test

Magnesium 0.02 to 0.15

Nickel 0.005 to 0.10

such materials for compliance with compositional specifica-

Silicon 0.02 to 0.15

tions. It is assumed that all who use these test methods will be

1.2 The test methods in this standard are contained in the trained analysts capable of performing common laboratory

sections indicated below.

procedures skillfully and safely. It is expected that work will be

performed in a properly equipped laboratory.

Sections

Chromium by the Diphenylcarbazide Photometric Test Method 9-18

Iron by the 1,10-Phenanthroline Photometric Test Method 19-28

4. Apparatus, Reagents, and Photometric Practice

Manganese by the Periodate Photometric Test Method 29-38

4.1 Apparatus and reagents required for each determination

Nickel by the Dimethylglyoxime Photometric Test Method 39-48

are listed in separate sections preceding the procedure unless

1.3 This standard does not purport to address all of the

otherwise specified. The apparatus, standard solutions, and

safety problems, if any, associated with its use. It is the

reagents shall conform to the requirements prescribed in

responsibility of the user of this standard to establish appro-

Practices E 50. Photometers shall conform to the requirements

priate safety and health practices and determine the applica-

prescribed in Practice E 60.

bility of regulatory limitations prior to use.

4.2 Photometric and spectrophotometric practice prescribed

in these test methods shall conform to Practice E 60.

2. Referenced Documents

2.1 ASTM Standards:

5. Hazards

D 1193 Specification for Reagent Water

5.1 For precautions to be observed in these test methods,

E 29 Practice for Using Significant Digits in Test Data to

reference shall be made to Practices E 50. Both beryllium

Determine Conformance with Specifications

metal and its compounds may be toxic. Care should be

E 50 Practices for Apparatus, Reagents, and Safety Precau-

exercised to prevent contact of beryllium-containing materials

tions for Chemical Analysis of Metals

with the skin. The inhalation of any beryllium-containing

substance, either as a volatile compound or as finely divided

powder, should be especially avoided. Beryllium-containing

These test methods are under the jurisdiction of ASTM Committee E-1 on

residues (especially ignited oxide) should be carefully disposed

Analytical Chemistry for Metals, Ores, and Related Materials and are the direct

of.

responsibility of Subcommittee E01.05 on Zinc, Tin, Lead, Cadmium, Beryllium,

and Other Metals.

6. Sampling

Current edition approved May 10, 1998. Published July 1998. Originally

e1

published as E 439 – 71 T. Last previous edition E 439 – 88 (1993) .

6.1 Wrought products shall be sampled in accordance with

Annual Book of ASTM Standards, Vol 03.05.

3 Practice E 55. Cast products shall be sampled in accordance

Annual Book of ASTM Standards, Vol 11.01.

Annual Book of ASTM Standards, Vol 14.02. with Practice E 88. However, these test methods do not

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 439

supersede any sampling requirements specified in a specific 14.5 Phosphoric Acid (1 + 1)—Mix 1 volume of concen-

ASTM material specification. trated phosphoric acid (H PO , sp gr 1.69) with 1 volume of

3 4

water.

7. Rounding Calculated Values

14.6 Silver Nitrate Solution (2.5 g/L)—Dissolve 0.25 g of

silver nitrate (AgNO ) in water and dilute to 100 mL.

7.1 Calculated values shall be rounded to the desired num-

14.7 Sodium Hydroxide Solution (500 g/L—Dissolve 50 g

ber of places as directed in 3.4 to 3.6 of Practice E 29.

of sodium hydroxide (NaOH) in water, and dilute to 100 mL.

8. Interlaboratory Studies

14.8 Sulfuric Acid (1 + 1)—Mix carefully and with stirring

1 volume of concentrated sulfuric acid (H SO , sp gr 1.84) into

8.1 These test methods have been evaluated in accordance 2 4

1 volume of water.

with Practices E 173, unless otherwise noted under the preci-

sion section.

15. Preparation of Calibration Curve

CHROMIUM BY THE DIPHENYLCARBAZIDE

15.1 Calibration Solutions:

(PHOTOMETRIC) TEST METHOD

15.1.1 Using pipets, transfer 5, 10, 15, and 20 mL of

chromium solution (1 mL 5 0.005 mg Cr) to five 400-mL

9. Scope

beakers. Add 1 mL of H PO (1 + 1) and dilute to approxi-

3 4

9.1 This test method covers the determination of chromium

mately 250 mL with water.

in concentrations from 0.004 to 0.04 %.

15.1.2 Adjust the pH to 0.95 6 0.05 with NaOH solution or

H SO (1 + 1). Add 10 mL of AgNO solution, 10 mL of

2 4 3

10. Summary of Test Method

(NH ) S O solution, and a few glass beads. Cover the beaker

4 2 2 8

10.1 Chromium is oxidized by peroxydisulfate in the pres-

with a ribbed cover glass, and boil for at least 25 min. During

ence of silver nitrate, and the chromium diphenylcarbazide

this period, add water as required to maintain a volume not less

complex is then developed. Photometric measurement is made

than 150 mL. Cool, and transfer to a 250-mL volumetric flask.

at approximately 540 nm.

Proceed as directed in 15.3.

15.2 Reference Solution—Add1mLofH PO (1 + 1) to 250

3 4

11. Concentration Range

mL of water in a 400-mL beaker. Proceed as directed in 15.1.2.

11.1 The recommended concentration range is from 0.02 to

15.3 Color Development—Add 2.0 mL of diphenylcarba-

0.10 mg of chromium per 250 mL of solution, using a 2-cm zide solution. Dilute to volume, and mix.

cell.

15.3.1 Prepare only that number of solutions which can be

measured 5 min after color development.

NOTE 1—This test method has been written for cells having a 2-cm

15.4 Photometry:

light path. Cells having other dimensions may be used, provided suitable

15.4.1 Multiple-Cell Photometer—Measure the cell correc-

adjustments can be made in the amounts of sample and reagents used.

tion, using absorption cells with a 2-cm light path and a light

12. Stability of Color

band centered at approximately 540 nm. Using the test cell,

12.1 The color of the chromium complex develops almost take the photometric readings of the calibration solutions.

immediately but starts to fade after about 10 min. Photometric 15.4.2 Single-Cell Photometer—Transfer a suitable portion

measurements should be made within 5 min after developing

of the reference solution to an absorption cell with a 2-cm light

the color. path and adjust the photometer to the initial setting using a light

band centered at approximately 540 nm. While maintaining

13. Interferences

this adjustment, take the photometric readings of the calibra-

tion solutions.

13.1 The elements ordinarily present do not interfere if their

15.5 Calibration Curve—Plot the net photometric readings

concentrations are under the maximum limits shown in 1.1.

of the calibration solutions against milligrams of chromium per

14. Reagents

250 mL of solution.

14.1 Acetone (CH COCH ).

3 3

16. Procedure

14.2 Ammonium Peroxydisulfate Solution (100 g/L)—

Dissolve 10 g of ammonium peroxydisulfate ((NH ) S O )in

4 2 2 8 16.1 Test Solution:

water and dilute to 100 mL. Do not use a solution that has

16.1.1 Transfer a 0.50-g sample, weighed to the nearest 0.1

stood more than 12 h.

mg, to a 250-mL beaker (Note 3). Add 100 mL of water and,

14.3 Chromium, Standard Solution (1 mL 5 0.005 mg

in small increments, add 15 mL of H SO (1 + 1). When

2 4

Cr)—Dissolve 0.2830 g of potassium dichromate (K Cr O )in

2 2 7 apparent reaction has ceased, warm until all action stops.

water in a 1-L volumetric flask, dilute to volume, and mix.

NOTE 2—If the chromium content of the sample is between 0.02 and

Using a pipet, transfer 5 mL to a 100-mL volumetric flask,

0.04 %, use a 0.25-g sample.

dilute to volume, and mix.

14.4 Diphenylcarbazide Solution (5 g/L)—Dissolve 0.50 g 16.1.2 Filter through an 11-cm fine filter paper into a

of diphenylcarbazide (1,5-diphenylcarbohydrazide) in 100 mL 400-mL beaker. Wash the paper five or six times with hot

of acetone. Do not use a solution that has stood for more than water. Reserve the filtrate. Transfer the paper to a platinum

1h. crucible, dry, and ignite at 700°C.

E 439

NOTE 3—This test method has been written for cells having a 2-cm

16.1.3 Treat the residue with 1 drop of H SO (1+1),3or4

2 4

light path. Cells having other dimensions may be used, provided suitable

drops of HNO , and 3 or 4 mL of HF. Evaporate to complete

adjustments can be made in the amounts of sample and reagents used.

dryness, and ignite for 3 to 4 min at 900°C. Fuse the residue

with about1gof potassium pyrosulfate (K S O ). Cool, leach

2 2 7

22. Stability of Color

in 25 mL of water, add this solution to the reserved filtrate

22.1 The color develops within 10 min and is stable for at

(16.1.2), and dilute to 250 mL. Proceed as directed in 15.1.2.

least 2 h.

16.2 Reference Solution—Carry a reagent blank through the

entire procedure, using the same amounts of all reagents with

23. Interferences

the sample omitted for use as the reference solution.

23.1 Nickel forms a complex with and consumes 1,10-

16.3 Color Development—Proceed as directed in 15.3.

phenanthroline. However, an amount of nickel equivalent to

16.4 Photometry—Take the photometric reading of the test

four times the amount of iron does not affect the iron

solution as directed in 15.4.

determination. Other elements ordinarily present in beryllium

do not interfere if their concentrations are under the maximum

17. Calculation

limits shown in 1.1.

17.1 Convert the net photometric reading of the test solution

24. Reagents

to milligrams of chromium by means of the calibration curve.

Calculate the percentage of chromium as follows: 24.1 Ammonium Acetate Solution (230/L)—Dissolve 115 g

of ammonium acetate in water and dilute to 500 mL.

Chromium, % 5 A/~B 3 10! (1)

24.2 Hydroxylamine Hydrochloride Solution (100 g/L)—

where:

Reagent No. 131.

A 5 chromium found in 250 mL of the final test solution,

24.3 Iron, Standard Solution (1 mL 5 0.01 mg Fe)—

mg, and

Dissolve 0.7020 g of ferrous ammonium sulfate

B 5 sample represented in 250 mL of the final test solution,

(Fe(NH ) (SO ) ·6H O) in 10 mL of water, and add 1 mL of

4 2 4 2 2

g.

H SO (1 + 1). Transfer to a 100-mL volumetric flask, dilute to

2 4

volume, and mix.

18. Precision and Bias

24.4 1,10-Phenanthroline Solution (1 g/L)—Dissolve 0.1 g

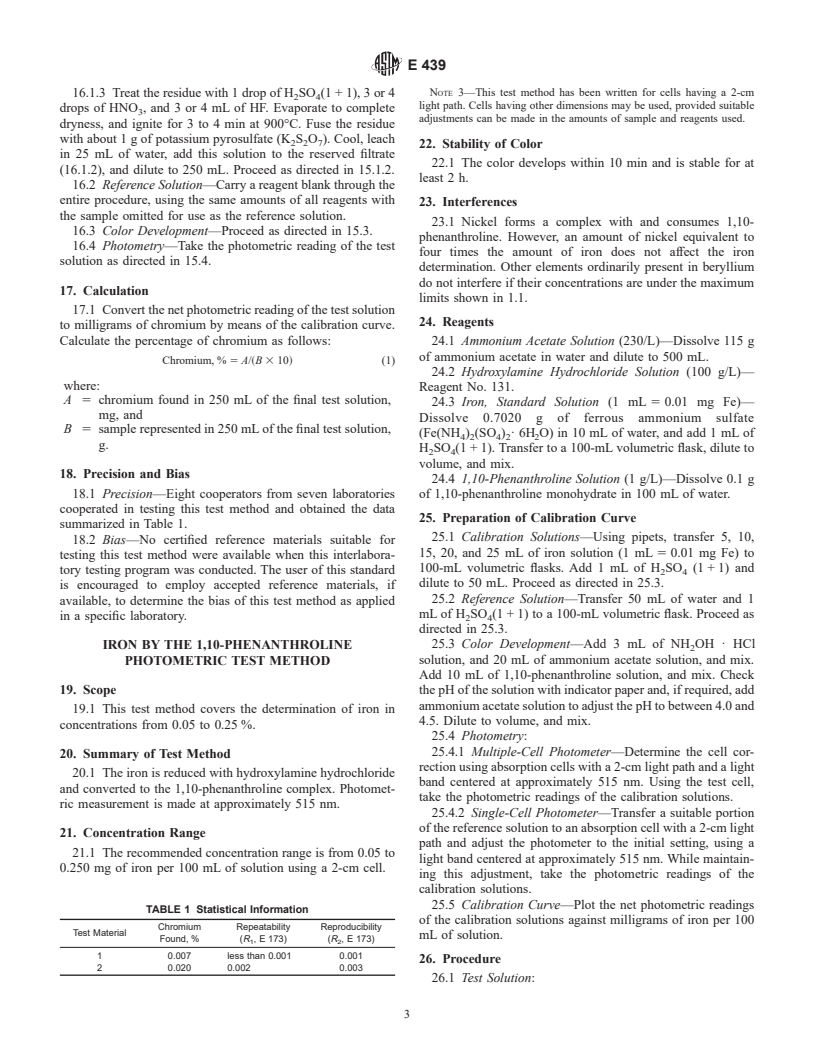

18.1 Precision—Eight cooperators from seven laboratories of 1,10-phenanthroline monohydrate in 100 mL of water.

cooperated in testing this test method and obtained the data

25. Preparation of Calibration Curve

summarized in Table 1.

25.1 Calibration Solutions—Using pipets, transfer 5, 10,

18.2 Bias—No certified reference materials suitable for

15, 20, and 25 mL of iron solution (1 mL 5 0.01 mg Fe) to

testing this test method were available when this interlabora-

100-mL volumetric flasks. Add 1 mL of H SO (1 + 1) and

tory testing program was conducted. The user of this standard

2 4

dilute to 50 mL. Proceed as directed in 25.3.

is encouraged to employ accepted reference materials, if

25.2 Reference Solution—Transfer 50 mL of water and 1

available, to determine the bias of this test method as applied

mL of H SO (1 + 1) to a 100-mL volumetric flask. Proceed as

in a specific laboratory. 2 4

directed in 25.3.

IRON BY THE 1,10-PHENANTHROLINE 25.3 Color Development—Add3mL ofNH OH · HCl

solution, and 20 mL of ammonium acetate solution, and mix.

PHOTOMETRIC TEST METHOD

Add 10 mL of 1,10-phenanthroline solution, and mix. Check

19. Scope the pH of the solution with indicator paper and, if required, add

ammonium acetate solution to adjust the pH to between 4.0 and

19.1 This test method covers the determination of iron in

4.5. Dilute to volume, and mix.

concentrations from 0.05 to 0.25 %.

25.4 Photometry:

25.4.1 Multiple-Cell Photometer—Determine the cell cor-

20. Summary of Test Method

rection using absorption cells with a 2-cm light path and a light

20.1 The iron is reduced with hydroxylamine hydrochloride

band centered at approximately 515 nm. Using the test cell,

and converted to the 1,10-phenanthroline complex. Photomet-

take the photometric readings of the calibration solutions.

ric measurement is made at approximately 515 nm.

25.4.2 Single-Cell Photometer—Transfer a suitable portion

of the reference solution to an absorption cell with a 2-cm light

21. Concentration Range

path and adjust the photometer to the initial setting, using a

21.1 The recommended concentration range is from 0.05 to

light band centered at approximately 515 nm. While maintain-

0.250 mg of iron per 100 mL of solution using a 2-cm cell.

ing this adjustment, take the photometric readings of the

calibration solutions.

25.5 Calibration Curve—Plot the net photometric readings

TABLE 1 Statistical Information

of the calibration solutions against milligrams of iron per 100

Chromium Repeatability Reproducibility

Test Material

mL of solution.

Found, % (R , E 173) (R , E 173)

1 2

1 0.007 less than 0.001 0.001

26. Procedure

2 0.020 0.002 0.003

26.1 Test Solution:

E 439

26.1.1 Transfer a 1.0-g sample, weighed to the nearest 1 mg 30. Summary of Test Method

to a 250-mL beaker. Add 100 mL of water and, in small

30.1 Manganese is oxidized to permanganate with potas-

increments, add 25 mL of H SO (1 + 1). When the apparent

2 4 sium periodate in a nitric-sulfuric-phosphoric acid medium.

reaction has ceased, warm until all action stops.

Photometric measurement is made at approximately 525 nm.

26.1.2 Filter using an 11-cm fine paper into a 500-mL

vo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.