ASTM D7171-05(2016)

(Test Method)Standard Test Method for Hydrogen Content of Middle Distillate Petroleum Products by Low-Resolution Pulsed Nuclear Magnetic Resonance Spectroscopy

Standard Test Method for Hydrogen Content of Middle Distillate Petroleum Products by Low-Resolution Pulsed Nuclear Magnetic Resonance Spectroscopy

SIGNIFICANCE AND USE

5.1 Hydrogen content represents a fundamental quality of a petroleum distillate that has been correlated with many of the performance characteristics of that product. Combustion properties of gas turbine fuels are related primarily to hydrogen content. As hydrogen content of these fuels decreases, soot deposits, exhaust smoke, and thermal radiation increase. Soot deposits and thermal radiation can increase to the point that combustor liner burnout will occur. Hydrogen content is a procurement requirement of the following military fuels: JP-5 specified in MIL-DTL-5624U, JP-8 specified in MIL-DTL-83133E, and Naval Distillate specified in MIL-PRF-16884K.

5.2 This test method provides a simple and precise alternative to existing test methods (D3701, D4808, and D5291) for determining the hydrogen content of petroleum distillate products.

SCOPE

1.1 This test method covers the determination of the hydrogen content of middle distillate petroleum products using a low-resolution pulsed nuclear magnetic resonance (NMR) spectrometer. The boiling range of distillates covered by the test method is 150 °C to 390 °C. While this test method may be applicable to middle distillates outside this boiling range, in such cases the precision statements may not apply. The test method is generally based on Test Methods D3701 and D4808, with a major difference being the use of a pulsed NMR spectrometer instead of a continuous wave NMR spectrometer.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.2.1 The preferred units are mass %.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7171 − 05(Reapproved 2016)

Standard Test Method for

Hydrogen Content of Middle Distillate Petroleum Products

by Low-Resolution Pulsed Nuclear Magnetic Resonance

Spectroscopy

This standard is issued under the fixed designation D7171; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Low-Resolution Nuclear Magnetic Resonance Spectros-

copy

1.1 This test method covers the determination of the hydro-

D5291Test Methods for Instrumental Determination of

gen content of middle distillate petroleum products using a

Carbon, Hydrogen, and Nitrogen in Petroleum Products

low-resolution pulsed nuclear magnetic resonance (NMR)

and Lubricants

spectrometer. The boiling range of distillates covered by the

D6299Practice for Applying Statistical Quality Assurance

testmethodis150°Cto390°C.Whilethistestmethodmaybe

and Control Charting Techniques to Evaluate Analytical

applicable to middle distillates outside this boiling range, in

Measurement System Performance

such cases the precision statements may not apply. The test

D6708Practice for StatisticalAssessment and Improvement

methodisgenerallybasedonTestMethodsD3701andD4808,

of Expected Agreement Between Two Test Methods that

with a major difference being the use of a pulsed NMR

Purport to Measure the Same Property of a Material

spectrometerinsteadofacontinuouswaveNMRspectrometer.

2.2 Other Documents:

1.2 The values stated in SI units are to be regarded as

MIL-DTL-5624U Military Detail Specification, Turbine

standard. No other units of measurement are included in this

Fuel, Aviation, Grades JP-4 and JP-5

standard.

MIL-DTL-83133EMilitary Detail Specification, Turbine

1.2.1 The preferred units are mass%.

Fuels, Aviation, Kerosene Types, NATO F-34, (JP-8),

1.3 This standard does not purport to address all of the

NATO F-35, and JP-8+100

safety concerns, if any, associated with its use. It is the

MIL-PRF-16884K Military Performance Specification,

responsibility of the user of this standard to establish appro-

Fuel, Naval Distillate

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3. Terminology

3.1 Definitions:

2. Referenced Documents

2 3.1.1 calibration, n—the determination of the values of the

2.1 ASTM Standards:

significant parameters by comparison with values indicated by

D3701Test Method for Hydrogen Content of Aviation

a set of calibration standards.

Turbine Fuels by Low Resolution Nuclear Magnetic

Resonance Spectrometry

3.1.2 calibration curve (or calibration line), n—the graphi-

D4057Practice for Manual Sampling of Petroleum and

cal or mathematical representation of a relationship between

Petroleum Products

the assigned (known) values of calibration standards and the

D4808 Test Methods for Hydrogen Content of Light

measured responses from the measurement system.

Distillates, Middle Distillates, Gas Oils, and Residua by

3.1.3 calibration standard, n—a standard having an as-

signed (known) value (reference value) for use in calibrating a

measurementinstrumentorsystem.Thisstandardisnotusedto

This test method is under the jurisdiction of ASTM Committee D02 on

determine the accuracy of the measurement instrument or

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

system (see check standard).

Subcommittee D02.03 on Elemental Analysis.

Current edition approved April 1, 2016. Published May 2016. Originally

approved in 2005. Last previous edition approved in 2011 as D7171–05 (2011).

DOI: 10.1520/D7171-05R16.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from NavalAir Systems Command,AIR-4.4.5, Patuxent River, MD

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 20670.

Standards volume information, refer to the standard’s Document Summary page on Available from ASC/ENSI, Wright-Patterson AFB, OH 45433-7107.

the ASTM website. Available from Naval Sea Systems Command, SEA03R42, Washington, DC.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7171 − 05 (2016)

3.1.4 check standard, n—a material having an assigned procurement requirement of the following military fuels: JP-5

(known) value (reference value) used to determine the accu- specified in MIL-DTL-5624U, JP-8 specified in MIL-DTL-

racyofthemeasurementinstrumentorsystem.Thisstandardis 83133E, and Naval Distillate specified in MIL-PRF-16884K.

not used to calibrate the measurement instrument or system

5.2 This test method provides a simple and precise alterna-

(see calibration standard).

tive to existing test methods (D3701, D4808, and D5291) for

3.1.5 low resolution nuclear magnetic resonance (NMR)

determining the hydrogen content of petroleum distillate prod-

spectroscopy, n—a form of NMR spectroscopy using a simple

ucts.

NMR analyzer that employs a low magnetic field and conse-

quentially low NMR frequency. An example is proton NMR

6. Apparatus

below 60 MHz. Resolution is expressed as time at half height

6.1 Nuclear Magnetic Resonance Spectrometer:

of signal and is typically 1 millisecond (ms) or less.

6.1.1 This test method requires a low-resolution pulsed

3.1.6 nuclear magnetic resonance (NMR) spectroscopy,

instrumentcapableofmeasuringanuclearmagneticresonance

n—that form of spectroscopy concerned with radio-frequency-

signal due to hydrogen atoms in the sample in a linear fashion

induced transitions between magnetic energy levels of atomic

over the filling volume of interest.The instrument includes the

nuclei.

following:

3.1.7 radio frequency, n—the range of frequencies of elec-

6.1.1.1 Permanent magnet to provide the necessary static

tromagnetic radiation between 3 kHz and 300 GHz.

magnetic field for the NMR test,

3.1.8 recycle delay, n—NMR spectrometer parameter set-

6.1.1.2 Sample compartment containing a radio frequency

ting for the time delay that allows magnetization recovery.

(RF) coil for excitation and detection, and

3.1.9 relaxation time constant (T ), n—a numerical value

6.1.1.3 Electronic unit to control and monitor the resonance

which is a measure of magnetization relaxation time following

conditioninvolvingmagnettemperaturecontrolandfieldoffset

an excitation pulse of an NMR spectrometer.

coils.

6.1.2 The test method also requires that the instrument have

4. Summary of Test Method

theabilitytoequilibratesampleswithintheprobeataconstant

4.1 AtestspecimenisanalyzedinapulsedNMRspectrom-

temperature (that is, 35°C or 40°C).

eter calibrated with reference standard materials. The analyzer

6.2 Conditioning Block—Block of aluminum alloy drilled

records in a nondestructive fashion the total NMR signal,

with holes of sufficient size to accommodate the nominal

which arises from the absolute amount of hydrogen atoms in

18mmdiametertestcellstoadepthofatleast42mmandwith

thereferencestandardsandtestsample.Theabsolutehydrogen

a centrally positioned well to house a temperature-sensing

signalintensityreportedbythepulsedNMRinstrumentforthe

device, such as a thermometer or thermocouple.

standard and test specimens is normalized by the correspond-

ing sample mass.The resulting signal-per-gram ratios are used

6.3 Conditioning Apparatus—Bath or other temperature

as a means of comparing theoretical hydrogen contents of the

control device (into which the conditioning block is inserted)

standardswiththatofthesample.Theresultisexpressedasthe

for controlling block temperature to 35°C 6 0.2°C or 40°C

hydrogen content (on a mass% basis) of the sample.

6 0.2°C.

4.2 Toensureanaccuratemeasureoftheabsolutehydrogen

6.4 Test Cell—Glass tube (with a flat or round bottom) with

contentofthereferencestandardsandsample,itisnecessaryto

an outside diameter of 17.6mm to 18.1mm and an inside

ensure that the measured hydrogen signal intensity is always

diameterof15.2mmto16.4mm.Anytubelengththatpermits

directly proportional to the absolute hydrogen content of the

easy insertion into and removal from the NMR sample cham-

standards and sample.

ber may be used.

4.3 Undercounting of the reference standard with respect to

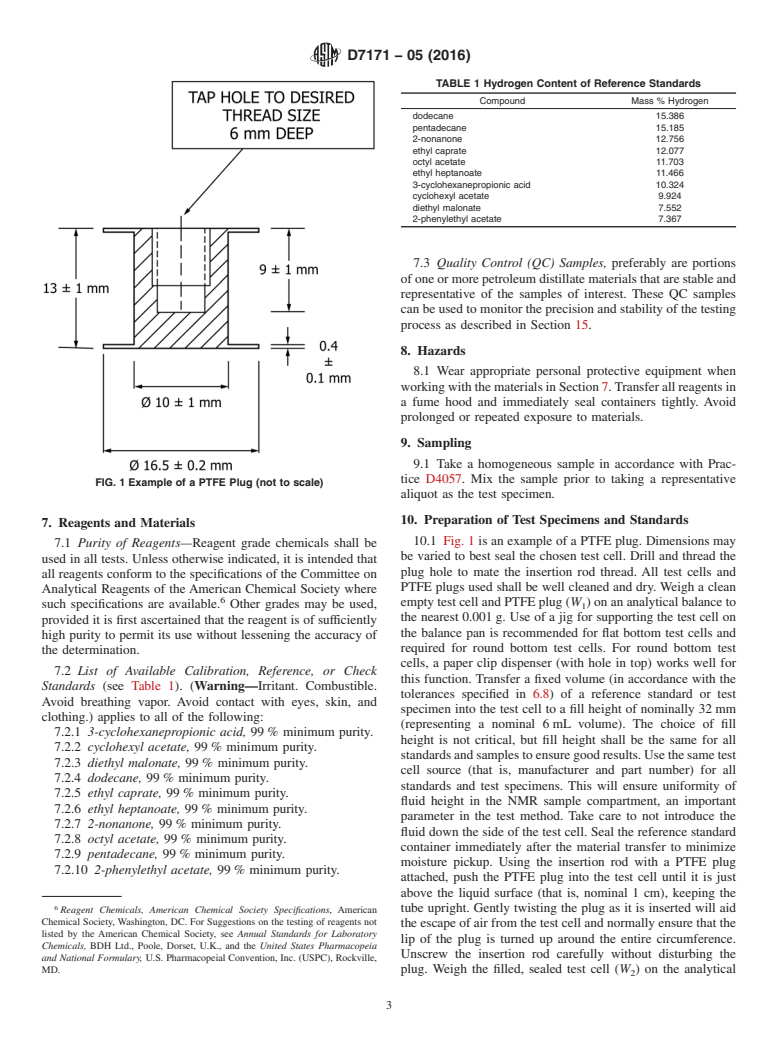

6.5 Polytetrafluorethylene (PTFE) Plug—Device made of

the sample is avoided by a number of strategies, including

PTFE used to tightly fit and close the test cells.An example of

accurate filling into the linear response region of the sample

one type of PTFE plug design is shown in Fig. 1.

compartment so that the mass recorded for the sample repre-

sents the true amount measured by NMR, and use of a recycle 6.6 Insertion Rod—Straight, rigid rod with a threaded end

delay considerably greater than the longest relaxation time (to screw into the PTFE plug) for inserting and removing the

constant (T ) for the sample. PTFE plugs from the test cells. Any diameter and length rod

that facilitates easy plug insertion and removal may be used.

5. Significance and Use

6.7 Analytical Balance—Top loading pan-type balance, ca-

5.1 Hydrogen content represents a fundamental quality of a

pable of weighing the test cells in an upright position to an

petroleum distillate that has been correlated with many of the

accuracy of 0.001g or better.

performance characteristics of that product. Combustion prop-

erties of gas turbine fuels are related primarily to hydrogen 6.8 Volume Transferring Device—Capableofaccuratelyand

content. As hydrogen content of these fuels decreases, soot repeatedly delivering a fixed volume of material within 61%

deposits, exhaust smoke, and thermal radiation increase. Soot or better, for use in preparing test specimens and standards for

deposits and thermal radiation can increase to the point that analysis. A 10mL capacity serological pipet with 0.1mL

combustor liner burnout will occur. Hydrogen content is a marked subdivisions has been found suitable to use.

D7171 − 05 (2016)

TABLE 1 Hydrogen Content of Reference Standards

Compound Mass % Hydrogen

dodecane 15.386

pentadecane 15.185

2-nonanone 12.756

ethyl caprate 12.077

octyl acetate 11.703

ethyl heptanoate 11.466

3-cyclohexanepropionic acid 10.324

cyclohexyl acetate 9.924

diethyl malonate 7.552

2-phenylethyl acetate 7.367

7.3 Quality Control (QC) Samples, preferably are portions

ofoneormorepetroleumdistillatematerialsthatarestableand

representative of the samples of interest. These QC samples

canbeusedtomonitortheprecisionandstabilityofthetesting

process as described in Section 15.

8. Hazards

8.1 Wear appropriate personal protective equipment when

workingwiththematerialsinSection7.Transferallreagentsin

a fume hood and immediately seal containers tightly. Avoid

prolonged or repeated exposure to materials.

9. Sampling

9.1 Take a homogeneous sample in accordance with Prac-

tice D4057. Mix the sample prior to taking a representative

FIG. 1 Example of a PTFE Plug (not to scale)

aliquot as the test specimen.

10. Preparation of Test Specimens and Standards

7. Reagents and Materials

10.1 Fig. 1 is an example of a PTFE plug. Dimensions may

7.1 Purity of Reagents—Reagent grade chemicals shall be

be varied to best seal the chosen test cell. Drill and thread the

used in all tests. Unless otherwise indicated, it is intended that

plug hole to mate the insertion rod thread. All test cells and

all reagents conform to the specifications of the Committee on

PTFE plugs used shall be well cleaned and dry. Weigh a clean

Analytical Reagents of theAmerican Chemical Society where

emptytestcellandPTFEplug(W )onananalyticalbalanceto

such specifications are available. Other grades may be used,

the nearest 0.001g. Use of a jig for supporting the test cell on

provided it is first ascertained that the reagent is of sufficiently

the balance pan is recommended for flat bottom test cells and

high purity to permit its use without lessening the accuracy of

required for round bottom test cells. For round bottom test

the determination.

cells, a paper clip dispenser (with hole in top) works well for

7.2 List of Available Calibration, Reference, or Check

this function. Transfer a fixed volume (in accordance with the

Standards (see Table 1). (Warning—Irritant. Combustible.

tolerances specified in 6.8) of a reference standard or test

Avoid breathing vapor. Avoid contact with eyes, skin, and

specimen into the test cell to a fill height of nominally 32mm

clothing.) applies to all of the following:

(representing a nominal 6mL volume). The choice of fill

7.2.1 3-cyclohexanepropionic acid, 99% minimum purity.

height is not critical, but fill height shall be the same for all

7.2.2 cyclohexyl acetate, 99% minimum purity.

standardsandsamplestoensuregoodresults.Usethesametest

7.2.3 diethyl malonate, 99% minimum purity.

cell source (that is, manufacturer and part number) for all

7.2.4 dodecane, 99% minimum purity.

standards and test specimens. This will ensure uniformity of

7.2.5 ethyl caprate, 99% minimum purity.

fluid height in the NMR sample compartment, an important

7.2.6 ethyl heptanoate, 99% minimum purity.

parameter in the test method. Take care to not introduce the

7.2.7 2-nonanone, 99% minimum purity.

fluid down the side of the test cell. Seal the reference standard

7.2.8 octyl acetate, 99% minimum purity.

container immediately after the material transfer to minimize

7.2.9 pentadecane, 99% minimum purity.

moisture pickup. Using the insertion rod with a PTFE plug

7.2.10 2-phenylethyl acetate, 99% minimum purity.

attached, push the PTFE plug into the test cell until it is just

above the liquid surface (that is, nominal 1 cm), keeping the

tube upright. Gently twisting the plug as it is inserted will aid

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

theescapeofairfromthetestcellandnormallyensurethatthe

listed by the American Chemical Society, see Annual Standards for Laboratory

lip of the plug is turned up around the entire circumference.

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Unscrew the insertion rod carefully without disturbing the

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

MD. plug. Weigh the filled, sealed test cell (W ) on the analytical

D7171 − 05 (2016)

balance to the nearest 0.001g. Determine the sample mass Follow the instrument manufacturer’s instructions for estab-

from the difference (W − W ) of the two weighings. lishing the calibration line. Remove the test cell from the

2 1

instrument. Similarly, run the other calibration standards to

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7171 − 05 (Reapproved 2011) D7171 − 05 (Reapproved 2016)

Standard Test Method for

Hydrogen Content of Middle Distillate Petroleum Products

by Low-Resolution Pulsed Nuclear Magnetic Resonance

Spectroscopy

This standard is issued under the fixed designation D7171; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the hydrogen content of middle distillate petroleum products using a

low-resolution pulsed nuclear magnetic resonance (NMR) spectrometer. The boiling range of distillates covered by the test method

is 150150 °C to 390°C.390 °C. While this test method may be applicable to middle distillates outside this boiling range, in such

cases the precision statements may not apply. The test method is generally based on Test Methods D3701 and D4808, with a major

difference being the use of a pulsed NMR spectrometer instead of a continuous wave NMR spectrometer.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.2.1 The preferred units are mass %.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D3701 Test Method for Hydrogen Content of Aviation Turbine Fuels by Low Resolution Nuclear Magnetic Resonance

Spectrometry

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4808 Test Methods for Hydrogen Content of Light Distillates, Middle Distillates, Gas Oils, and Residua by Low-Resolution

Nuclear Magnetic Resonance Spectroscopy

D5291 Test Methods for Instrumental Determination of Carbon, Hydrogen, and Nitrogen in Petroleum Products and Lubricants

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

D6708 Practice for Statistical Assessment and Improvement of Expected Agreement Between Two Test Methods that Purport

to Measure the Same Property of a Material

2.2 Other Documents:

MIL-DTL-5624U Military Detail Specification, Turbine Fuel, Aviation, Grades JP-4 and JP-5

MIL-DTL-83133E Military Detail Specification, Turbine Fuels, Aviation, Kerosene Types, NATO F-34, (JP-8), NATO F-35, and

JP-8+100

MIL-PRF-16884K Military Performance Specification, Fuel, Naval Distillate

3. Terminology

3.1 Definitions:

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.03 on Elemental Analysis.

Current edition approved May 1, 2011April 1, 2016. Published August 2011 May 2016. Originally approved in 2005. Last previous edition approved in 20052011 as

D7171D7171 – 05 (2011).–05. DOI: 10.1520/D7171-05R11.10.1520/D7171-05R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from Naval Air Systems Command, AIR-4.4.5, Patuxent River, MD 20670.

Available from ASC/ENSI, Wright-Patterson AFB, OH 45433-7107.

Available from Naval Sea Systems Command, SEA03R42, Washington, DC.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7171 − 05 (2016)

3.1.1 calibration, n—the determination of the values of the significant parameters by comparison with values indicated by a set

of calibration standards.

3.1.2 calibration curve (or calibration line), n—the graphical or mathematical representation of a relationship between the

assigned (known) values of calibration standards and the measured responses from the measurement system.

3.1.3 calibration standard, n—a standard having an assigned (known) value (reference value) for use in calibrating a

measurement instrument or system. This standard is not used to determine the accuracy of the measurement instrument or system

(see check standard).

3.1.4 check standard, n—a material having an assigned (known) value (reference value) used to determine the accuracy of the

measurement instrument or system. This standard is not used to calibrate the measurement instrument or system (see calibration

standard).

3.1.5 low resolution nuclear magnetic resonance (NMR) spectroscopy, n—a form of NMR spectroscopy using a simple NMR

analyzer that employs a low magnetic field and consequentially low NMR frequency. An example is proton NMR below 60 MHz.

Resolution is expressed as time at half height of signal and is typically 1 millisecond (ms) or less.

3.1.6 nuclear magnetic resonance (NMR) spectroscopy, n—that form of spectroscopy concerned with radio-frequency-induced

transitions between magnetic energy levels of atomic nuclei.

3.1.7 radio frequency, n—the range of frequencies of electromagnetic radiation between 3 kHz and 300 GHz.

3.1.8 recycle delay, n—NMR spectrometer parameter setting for the time delay that allows magnetization recovery.

3.1.9 relaxation time constant (T ), n—a numerical value which is a measure of magnetization relaxation time following an

excitation pulse of an NMR spectrometer.

4. Summary of Test Method

4.1 A test specimen is analyzed in a pulsed NMR spectrometer calibrated with reference standard materials. The analyzer

records in a nondestructive fashion the total NMR signal, which arises from the absolute amount of hydrogen atoms in the

reference standards and test sample. The absolute hydrogen signal intensity reported by the pulsed NMR instrument for the

standard and test specimens is normalized by the corresponding sample mass. The resulting signal-per-gram ratios are used as a

means of comparing theoretical hydrogen contents of the standards with that of the sample. The result is expressed as the hydrogen

content (on a mass % basis) of the sample.

4.2 To ensure an accurate measure of the absolute hydrogen content of the reference standards and sample, it is necessary to

ensure that the measured hydrogen signal intensity is always directly proportional to the absolute hydrogen content of the standards

and sample.

4.3 Undercounting of the reference standard with respect to the sample is avoided by a number of strategies, including accurate

filling into the linear response region of the sample compartment so that the mass recorded for the sample represents the true

amount measured by NMR, and use of a recycle delay considerably greater than the longest relaxation time constant (T ) for the

sample.

5. Significance and Use

5.1 Hydrogen content represents a fundamental quality of a petroleum distillate that has been correlated with many of the

performance characteristics of that product. Combustion properties of gas turbine fuels are related primarily to hydrogen content.

As hydrogen content of these fuels decreases, soot deposits, exhaust smoke, and thermal radiation increase. Soot deposits and

thermal radiation can increase to the point that combustor liner burnout will occur. Hydrogen content is a procurement requirement

of the following military fuels: JP-5 specified in MIL-DTL-5624U, JP-8 specified in MIL-DTL-83133E, and Naval Distillate

specified in MIL-PRF-16884K.

5.2 This test method provides a simple and precise alternative to existing test methods (D3701, D4808, and D5291) for

determining the hydrogen content of petroleum distillate products.

6. Apparatus

6.1 Nuclear Magnetic Resonance Spectrometer:

6.1.1 This test method requires a low-resolution pulsed instrument capable of measuring a nuclear magnetic resonance signal

due to hydrogen atoms in the sample in a linear fashion over the filling volume of interest. The instrument includes the following:

6.1.1.1 Permanent magnet to provide the necessary static magnetic field for the NMR test,

6.1.1.2 Sample compartment containing a radio frequency (RF) coil for excitation and detection, and

6.1.1.3 Electronic unit to control and monitor the resonance condition involving magnet temperature control and field offset

coils.

6.1.2 The test method also requires that the instrument have the ability to equilibrate samples within the probe at a constant

temperature (that is, 35°C35 °C or 40°C).40 °C).

D7171 − 05 (2016)

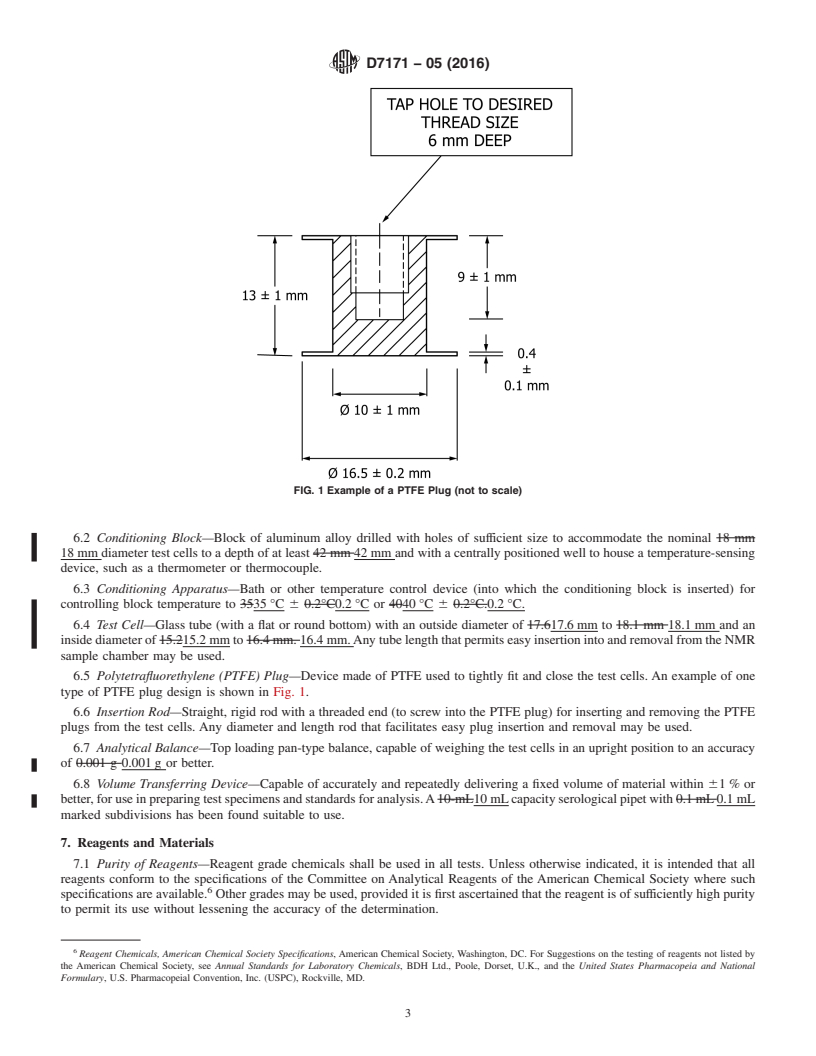

FIG. 1 Example of a PTFE Plug (not to scale)

6.2 Conditioning Block—Block of aluminum alloy drilled with holes of sufficient size to accommodate the nominal 18 mm

18 mm diameter test cells to a depth of at least 42 mm 42 mm and with a centrally positioned well to house a temperature-sensing

device, such as a thermometer or thermocouple.

6.3 Conditioning Apparatus—Bath or other temperature control device (into which the conditioning block is inserted) for

controlling block temperature to 3535 °C 6 0.2°C0.2 °C or 4040 °C 6 0.2°C.0.2 °C.

6.4 Test Cell—Glass tube (with a flat or round bottom) with an outside diameter of 17.617.6 mm to 18.1 mm 18.1 mm and an

inside diameter of 15.215.2 mm to 16.4 mm. 16.4 mm. Any tube length that permits easy insertion into and removal from the NMR

sample chamber may be used.

6.5 Polytetrafluorethylene (PTFE) Plug—Device made of PTFE used to tightly fit and close the test cells. An example of one

type of PTFE plug design is shown in Fig. 1.

6.6 Insertion Rod—Straight, rigid rod with a threaded end (to screw into the PTFE plug) for inserting and removing the PTFE

plugs from the test cells. Any diameter and length rod that facilitates easy plug insertion and removal may be used.

6.7 Analytical Balance—Top loading pan-type balance, capable of weighing the test cells in an upright position to an accuracy

of 0.001 g 0.001 g or better.

6.8 Volume Transferring Device—Capable of accurately and repeatedly delivering a fixed volume of material within 61 % or

better, for use in preparing test specimens and standards for analysis. A 10-mL10 mL capacity serological pipet with 0.1 mL 0.1 mL

marked subdivisions has been found suitable to use.

7. Reagents and Materials

7.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society where such

specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high purity

to permit its use without lessening the accuracy of the determination.

Reagent Chemicals, American Chemical Society Specifications, American Chemical Society, Washington, DC. For Suggestions on the testing of reagents not listed by

the American Chemical Society, see Annual Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

D7171 − 05 (2016)

TABLE 1 Hydrogen Content of Reference Standards

Compound Mass % Hydrogen

dodecane 15.386

pentadecane 15.185

2-nonanone 12.756

ethyl caprate 12.077

octyl acetate 11.703

ethyl heptanoate 11.466

3-cyclohexanepropionic acid 10.324

cyclohexyl acetate 9.924

diethyl malonate 7.552

2-phenylethyl acetate 7.367

7.2 List of Available Calibration, Reference, or Check Standards (see Table 1). (Warning—Irritant. Combustible. Avoid

breathing vapor. Avoid contact with eyes, skin, and clothing.) applies to all of the following:

7.2.1 3-cyclohexanepropionic acid, 99 % minimum purity.

7.2.2 cyclohexyl acetate, 99 % minimum purity.

7.2.3 diethyl malonate, 99 % minimum purity.

7.2.4 dodecane, 99 % minimum purity.

7.2.5 ethyl caprate, 99 % minimum purity.

7.2.6 ethyl heptanoate, 99 % minimum purity.

7.2.7 2-nonanone, 99 % minimum purity.

7.2.8 octyl acetate, 99 % minimum purity.

7.2.9 pentadecane, 99 % minimum purity.

7.2.10 2-phenylethyl acetate, 99 % minimum purity.

7.3 Quality Control (QC) Samples, preferably are portions of one or more petroleum distillate materials that are stable and

representative of the samples of interest. These QC samples can be used to monitor the precision and stability of the testing process

as described in Section 15.

8. Hazards

8.1 Wear appropriate personal protective equipment when working with the materials in Section 7. Transfer all reagents in a

fume hood and immediately seal containers tightly. Avoid prolonged or repeated exposure to materials.

9. Sampling

9.1 Take a homogeneous sample in accordance with Practice D4057. Mix the sample prior to taking a representative aliquot as

the test specimen.

10. Preparation of Test Specimens and Standards

10.1 Fig. 1 is an example of a PTFE plug. Dimensions may be varied to best seal the chosen test cell. Drill and thread the plug

hole to mate the insertion rod thread. All test cells and PTFE plugs used shall be well cleaned and dry. Weigh a clean empty test

cell and PTFE plug (W ) on an analytical balance to the nearest 0.001 g. 0.001 g. Use of a jig for supporting the test cell on the

balance pan is recommended for flat bottom test cells and required for round bottom test cells. For round bottom test cells, a paper

clip dispenser (with hole in top) works well for this function. Transfer a fixed volume (in accordance with the tolerances specified

in 6.8) of a reference standard or test specimen into the test cell to a fill height of nominally 32 mm 32 mm (representing a nominal

6 mL 6 mL volume). The choice of fill height is not critical, but fill height shall be the same for all standards and samples to ensure

good results. Use the same test cell source (that is, manufacturer and part number) for all standards and test specimens. This will

ensure uniformity of fluid height in the NMR sample compartment, an important parameter in the test method. Take care to not

introduce the fluid down the side of the test cell. Seal the reference standard container immediately after the material transfer to

minimize moisture pickup. Using the insertion rod with a PTFE plug attached, push the PTFE plug into the te

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.