ASTM D8133-23

(Test Method)Standard Test Method for Determination of Low Level Phthalates in Poly(Vinyl Chloride) Plastics by Solvent Extraction-Gas Chromatography/Mass Spectrometry

Standard Test Method for Determination of Low Level Phthalates in Poly(Vinyl Chloride) Plastics by Solvent Extraction-Gas Chromatography/Mass Spectrometry

SIGNIFICANCE AND USE

5.1 Identification and Quantification of Phthalates-DBP, BBP, DEHP, DNOP, DINP and DIDP are representative of the phthalates either banned or being monitored by a variety of regulations. Regulations include: EU-Directive 2005/84/EC, US-Consumer Product Safety Improvement Act of 2008 – section 108, Japan-Health, Labor and Welfare Ministry guideline No. 336 (2010) and IEC 62321-8:2017. These test methods provide a procedure to identify and quantify phthalates in PVC.

5.2 Other techniques successfully used to separate and identify phthalates in PVC include TD-GC/MS (ASTM D7823), GC/MS, HPLC/UV, HPLC/MS, FTIR, and GC/FID (flame ionization detector).

SCOPE

1.1 This test method provides a procedure to quantify six phthalates by solvent extraction of plasticized PVC articles followed by analysis of the extract by gas chromatography/mass spectrometry. Six phthalates, BBP, DBP, DEHP, DNOP, DINP, and DIDP, are used to illustrate how to implement the method.

Note 1: The method can be extended to other phthalates in a wide range of polymeric substrates.

1.2 Within the context of this method, “low level” is defined as 1000 ppm.

1.3 The values in SI units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 2: There is no known ISO equivalent to this standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Frequently Asked Questions

ASTM D8133-23 is a standard published by ASTM International. Its full title is "Standard Test Method for Determination of Low Level Phthalates in Poly(Vinyl Chloride) Plastics by Solvent Extraction-Gas Chromatography/Mass Spectrometry". This standard covers: SIGNIFICANCE AND USE 5.1 Identification and Quantification of Phthalates-DBP, BBP, DEHP, DNOP, DINP and DIDP are representative of the phthalates either banned or being monitored by a variety of regulations. Regulations include: EU-Directive 2005/84/EC, US-Consumer Product Safety Improvement Act of 2008 – section 108, Japan-Health, Labor and Welfare Ministry guideline No. 336 (2010) and IEC 62321-8:2017. These test methods provide a procedure to identify and quantify phthalates in PVC. 5.2 Other techniques successfully used to separate and identify phthalates in PVC include TD-GC/MS (ASTM D7823), GC/MS, HPLC/UV, HPLC/MS, FTIR, and GC/FID (flame ionization detector). SCOPE 1.1 This test method provides a procedure to quantify six phthalates by solvent extraction of plasticized PVC articles followed by analysis of the extract by gas chromatography/mass spectrometry. Six phthalates, BBP, DBP, DEHP, DNOP, DINP, and DIDP, are used to illustrate how to implement the method. Note 1: The method can be extended to other phthalates in a wide range of polymeric substrates. 1.2 Within the context of this method, “low level” is defined as 1000 ppm. 1.3 The values in SI units are to be regarded as standard. 1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Note 2: There is no known ISO equivalent to this standard. 1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

SIGNIFICANCE AND USE 5.1 Identification and Quantification of Phthalates-DBP, BBP, DEHP, DNOP, DINP and DIDP are representative of the phthalates either banned or being monitored by a variety of regulations. Regulations include: EU-Directive 2005/84/EC, US-Consumer Product Safety Improvement Act of 2008 – section 108, Japan-Health, Labor and Welfare Ministry guideline No. 336 (2010) and IEC 62321-8:2017. These test methods provide a procedure to identify and quantify phthalates in PVC. 5.2 Other techniques successfully used to separate and identify phthalates in PVC include TD-GC/MS (ASTM D7823), GC/MS, HPLC/UV, HPLC/MS, FTIR, and GC/FID (flame ionization detector). SCOPE 1.1 This test method provides a procedure to quantify six phthalates by solvent extraction of plasticized PVC articles followed by analysis of the extract by gas chromatography/mass spectrometry. Six phthalates, BBP, DBP, DEHP, DNOP, DINP, and DIDP, are used to illustrate how to implement the method. Note 1: The method can be extended to other phthalates in a wide range of polymeric substrates. 1.2 Within the context of this method, “low level” is defined as 1000 ppm. 1.3 The values in SI units are to be regarded as standard. 1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Note 2: There is no known ISO equivalent to this standard. 1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ASTM D8133-23 is classified under the following ICS (International Classification for Standards) categories: 83.080.20 - Thermoplastic materials. The ICS classification helps identify the subject area and facilitates finding related standards.

ASTM D8133-23 has the following relationships with other standards: It is inter standard links to ASTM D883-24, ASTM D883-23, ASTM D7823-20, ASTM D883-20, ASTM E594-96(2019), ASTM D883-19c, ASTM D7993-15(2019), ASTM D883-19a, ASTM D883-19, ASTM D883-18a, ASTM D7823-18, ASTM D883-18, ASTM D1600-18, ASTM D883-17, ASTM D7823-16. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ASTM D8133-23 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ASTM standards.

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8133 − 23

Standard Test Method for

Determination of Low Level Phthalates in Poly(Vinyl

Chloride) Plastics by Solvent Extraction—Gas

Chromatography/Mass Spectrometry

This standard is issued under the fixed designation D8133; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D3465 Guide for Purity of Monomeric Plasticizers by Gas

Chromatography

1.1 This test method provides a procedure to quantify six

D7083 Practice for Determination of Monomeric Plasticiz-

phthalates by solvent extraction of plasticized PVC articles

ers in Poly (Vinyl Chloride) (PVC) by Gas Chromatogra-

followed by analysis of the extract by gas chromatography/

phy

mass spectrometry. Six phthalates, BBP, DBP, DEHP, DNOP,

D7823 Test Method for Determination of Low Level Phtha-

DINP, and DIDP, are used to illustrate how to implement the

lates in Poly (Vinyl Chloride) Plastics by Thermal

method.

Desorption—Gas Chromatography/Mass Spectrometry

NOTE 1—The method can be extended to other phthalates in a wide

D7993 Guide for Analyzing Complex Phthalates

range of polymeric substrates.

E177 Practice for Use of the Terms Precision and Bias in

1.2 Within the context of this method, “low level” is defined

ASTM Test Methods

as 1000 ppm.

E355 Practice for Gas Chromatography Terms and Relation-

ships

1.3 The values in SI units are to be regarded as standard.

E594 Practice for Testing Flame Ionization Detectors Used

1.4 This standard does not purport to address all of the

in Gas or Supercritical Fluid Chromatography

safety concerns, if any, associated with its use. It is the

E691 Practice for Conducting an Interlaboratory Study to

responsibility of the user of this standard to establish appro-

Determine the Precision of a Test Method

priate safety, health, and environmental practices and deter-

IEEE/ASTM SI-10 Practice for Use of the International

mine the applicability of regulatory limitations prior to use.

System of Units (SI), the Modernized Metric System

NOTE 2—There is no known ISO equivalent to this standard.

2.2 ASTM Adjuncts:ADJD7823-EA

Vinyl Plasticizer Library—Total Ion Chromatograms and

1.5 This international standard was developed in accor-

Mass Spectra

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

2.3 CPSC Standard:

Development of International Standards, Guides and Recom- CPSC-CH-C1001–09.3 Standard Operating Procedure for

mendations issued by the World Trade Organization Technical

Determination of Phthalates

Barriers to Trade (TBT) Committee.

3. Terminology

2. Referenced Documents

3.1 Definitions:

2.1 ASTM Standards: 3.1.1 For definition of plastic terms used in this standard,

see Terminologies D883 and D1600.

D883 Terminology Relating to Plastics

D1600 Terminology for Abbreviated Terms Relating to Plas-

3.2 For units, symbols, and abbreviations used in this

tics

standard refer to Practices E594, E355, or IEEE/ASTM SI-10.

3.3 Compounds and Instrumentation:

3.3.1 (DOA) Hexanedioic acid, 1,6-bis(2-ethylhexyl) ester

This test method is under the jurisdiction of ASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.70 on Analytical Methods. CAS #103-23-1

Current edition approved March 15, 2023. Published April 2023. Originally

3.3.2 (DINCH) 1,2-Cyclohexanedicarboxylic acid, dinonyl

approved in 2017. Last previous edition approved in 2021 as D8133 – 21. DOI:

ester, branched and linear CAS #474919-59-0

10.1520/D8133-23.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from U.S. Consumer Product Safety Commission (CPSC), 4330 East

the ASTM website. West Hwy., Bethesda, MD 20814, http://www.cpsc.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D8133 − 23

3.3.3 (DBP) 1,2-Benzenedicarboxylic acid, 1,2-di-n-butyl 5. Significance and Use

ester CAS #84-74-2

5.1 Identification and Quantification of Phthalates—DBP,

3.3.4 (BBP) Benzyl butyl phthalate CAS #85-68-7

BBP, DEHP, DNOP, DINP and DIDP are representative of the

3.3.5 (DEHP) Bis(2-ethyhexyl) phthalate CAS #117-81-7

phthalates either banned or being monitored by a variety of

3.3.6 (DNOP) Di(n-octyl) phthalate CAS #117-84-0

regulations. Regulations include: EU—Directive 2005/84/EC,

3.3.7 (DINP) 1,2-Benzenedicarboxylic acid, di-C8-10-

US—Consumer Product Safety Improvement Act of 2008 –

branched alkyl esters, C9-rich (Jayflex) CAS #68515-48-0

section 108, Japan—Health, Labor and Welfare Ministry

3.3.8 (DINP) 1,2-Benzenedicarboxylic acid, 1,2-diisononyl

guideline No. 336 (2010) and IEC 62321-8:2017. These test

(Palatinol) CAS #28553-12-0

methods provide a procedure to identify and quantify phtha-

3.3.9 (DIDP) 1,2-Benzenedicarboxylic acid, di-C9-11-

lates in PVC.

branched alkyl esters, C10-rich (Jayflex) CAS #68515-49-1

5.2 Other techniques successfully used to separate and

3.3.10 (DIDP) 1,2-Benzenedicarboxylic acid, 1,2-

identify phthalates in PVC include TD-GC/MS (ASTM

diisodecyl CAS #26761-40-0

D7823), GC/MS, HPLC/UV, HPLC/MS, FTIR, and GC/FID

3.3.11 GC Gas Chromatography

(flame ionization detector).

3.3.12 GC/MS Gas Chromatography/Mass Spectrometry

3.3.13 TD-GC/MS Thermal Desorption—Gas

6. Interferences

Chromatography/Mass Spectrometry

3.3.14 PVC Poly(vinyl chloride)

6.1 Retention times for GC are dependent on several vari-

3.3.15 Heptane GC grade or higher

ables and it is possible to have two or more components with

3.3.16 FTIR Fourier Transform Infrared Spectroscopy

identical retention times. The analyst shall take the necessary

3.3.17 TIC Total ion chromatogram

steps to ensure that adequate separation of the plasticizer

3.3.18 DQO Data quality objectives

components is achieved and or the ions used to monitor for a

target phthalate are free of interference. This includes, but is

4. Summary of Test Method

not limited to changing the selectivity of the chromatographic

4.1 Test Method A—100 mg of the plasticized PVC sample

column or the heating profile of the GC column. Calibration by

along with 10 mL of heptane is extracted for 2 hours with the

standard addition offers the advantage of correcting for matrix

aid of sonication. One milliliter of the heptane solution is

affects.

placed in a GC vial and analyzed by GC/MS. Phthalates are

6.2 When running the GC/MS method, care must be taken

identified by their retention times and their mass spectra/SIM

to ensure that the vials, septa, and containers are free of any

ions. Quantification is based on the area of a designated

phthalate contamination. Also, all solvents used to prepare

quantitative ion (SIM or full scan) (see Table 1). The amount

standards and sample solutions must be free of contamination.

of each component is determined using a standard addition

calibration method. 6.3 The presence or absence of each phthalate is based upon

three criteria:

4.2 Test Method B—100 mg of the plasticized PVC sample

(1) the relative retention time of the peak,

are dissolved in THF. After the polymer is precipitated by

(2) the presence or absence of the Quant Ion and the two

adding 20 mL of hexane, 1.3 mL of the supernatant is filtered

Confirm Ions, and

and placed in a GC vial and analyzed by GC/MS. Quantifica-

(3) the ratio of the Quant Ion and the Confirm Ion 1 in

tion is based on the area of a designated quantitative ion (SIM

Table 1 must satisfy the established guideline.

or full scan) (see Table 1). The amount of each component is

determined using an internal calibration method.

6.4 Calculating the phthalate concentrations using the areas

of compound specific ions significantly reduces interference

NOTE 3—Standard addition calibration will correct for matrix affects

from non-target compounds, additionally using standard addi-

(that is, response of the phthalates being different in solvent versus the

solvent and sample matrix). tion corrects for matrix affects.

TABLE 1 Ions and Ion Ratios Used to Identify Each Phthalate

NOTE 1—When DINP and DIDP are both present in a sample or standard, m/z 127 is used as a qualifying ion for DINP and m/z 289 for DIDP. This

is because DINP and DIDP partially co-elute and both produce m/z 149 and 167. If 149 qualifier ion ratios are set when DINP and DIDP are at equal

concentrations, then any samples with different ratios will produce substantially different 149/167 ratios, potentially leading to a false negative.

DBP BBP DEHP DNOP DINP DIDP

Quant ion 223 206 279 279 293 307

Confirm ion 1 149 149 149 149 149 149

Area ratio (±10%) <0.04 <0.23 <0.08 <0.06 <0.20 <0.12

(Quant/Confirm 1)

Confirm ion 2 167 167 167 167 167 167

D8133 − 23

7. Safety and Precautions solutions. To test system performance and verify retention

times a 10 μL aliquot of Standard Solution #1 is added to 1 mL

7.1 Use organic solvents in a well-ventilated space.

of heptane and analyzed.

TEST METHOD A—HEPTANE EXTRACTION

10.4 Sample Solution—Cut each plasticized component part

PROCEDURE

into small pieces (no dimension larger than 2 mm), or

milled/ground into a representative powder. Each cut/milled

8. Apparatus

plasticized component part will be considered a sample for

8.1 Gas chromatograph/mass spectrometer capable of op- testing as described below.

erating in the 100-260°C temperature range and equipped with 10.4.1 Weigh 100 mg (0.10 g) of the sample in a vial and

autosampler and injector. add 10 mL heptane with a 10-mL volumetric pipet (100 mg/10

mL). The vial with the sample and heptane is placed in a

8.2 GC vials, glass pipets, 4, and 20-mL vials.

sonication bath and extracted for two hours at room tempera-

8.3 Optional Recommended Equipment—10-mL volumetric

ture. Into a GC vial, place 1.0 mL of the extracted sample

flask.

solution (this is conveniently done with a 1 mL volumetric

8.4 GC Capillary Column—Carbowax capillary column, 30 pipet). See Fig. 1 and Fig. 2 for example chromatograms.

m by 0.25 mm ID with a 0.25 μm film thickness, or equivalent.

10.5 Spiked Sample Solution—Place 1.0 mL of the sample

8.5 Integrator or data handling system, capable of measur- solution (10.4) into a GC vial. Add 10 μL of the phthalate

Standard Solution #1 (10.3) to the sample solution with a GC

ing peak areas and retention times.

syringe.

8.6 Analytical balance, capable of weighing to 60.00001 g.

NOTE 5—A critical step in the accurate determination of phthalates is

8.7 Pressure regulators, for all required gas cylinders.

sample homogeneity. This is discussed in more detail in Appendix X1.

8.8 Flow meter, or other means of measuring gas flow rates

11. Procedure

60.1 mL/min.

11.1 Establish that the analytical system has an acceptable

9. Reagents and Materials

background of phthalate contamination by analyzing a heptane

9.1 Helium carrier gas, chromatographic grade.

solvent blank. Acceptable background contamination will be

determined by the data quality specific objectives.

9.2 Heptane for preparing the phthalate standard solution

(Stock Standard Solution, Standard Solution #1, 10.2 and 10.3;

11.2 Establish the relative retention time and mass

Sample Solution, 10.4), spectral quality or chromatographic

spectrum/SIM ions of each phthalate by analyzing a solution of

grade.

10 μL of Standard Solution #1 (10.1(3)) added to 1.0 mL of

heptane. The conditions in Table 2 were used to obtain the

9.3 Standards of the appropriate phthalates for use when

example chromatograms shown in Figs. 1 and 2.

preparing the Stock Standard Solution (10.2) and Standard

TABLE 2 Gas Chromatography/Mass Spectrometry Analysis

Solution #1 (10.3) used for standard addition. See Note 4.

Conditions

NOTE 4—DINP and DIDP, when used in various PVC formulations are

Column: Carbowax (Polyethylene glycol) stationary phase, 30 m

technical mixtures. Here is specific information on DINP and DIDP. For

× 0.25 mm i.d, 0.25 μm film thickness

more information, please refer to Appendix X3.

Carrier Gas: Helium or other acceptable gas

Jayflex DIDP: 1,2-Benzenedicarboxylic acid, di-C9-11-branched alkyl

Carrier 1.0 mL/min

Flow Rate:

esters, C10-rich: CAS# 68515-49-1.

Oven 150°C (0 min hold) to 250°C (at 10°C/min) (45 min hold)

Jayflex DINP: 1,2-Benzenedicarboxylic acid, di-C8-10-branched alkyl

Temperature

esters, C9-rich: CAS# 68515-48-0.

Program:

Injector 250°C

10. Preparation of the Analytical Samples

Temperature:

Injection Split or splitless injection depending on the sensitivity of

10.1 Four solutions shall be prepared:

Conditions: the instrument. 20:1 split is recommended as a starting

(1) a Stock Standard Solution of the target phthalate

point for those wishing to run split.

Injection 1 μL

standards,

Volume:

(2) a Standard Solution of the target phthalate standards

MSD Transfer 250°C

used to spike the sample,

Line Temp.:

Ion Source 230°C

(3) a solution of the sample, and

(EI) Temp.:

(4) the sample solution spiked with the standard stock

MS Mode: SIM (scan mode is employed if sufficient detection

solution. sensitivity is met)

10.2 Stock Standard Solution—Prepare a stock standard 11.2.1 The mass spectrometer is run in scan mode for

solution of the phthalates by dissolving 0.10 g of each general identification of phthalates and other sample compo-

phthalate in 10 mL of heptane (0.10 g/10 mL; this is conve- nents.

niently performed by weighing the phthalates into a 10 mL

11.3 Analyze the sample (Sample Solution – 10.4) and

volumetric flask and diluting to the mark).

Spiked Sample (Spiked Sample Solution – 10.5) using the

10.3 Standard Solution #1A—Prepare a diluted (1:10) solu- conditions outlined in 11.2. A typical chromatogram is shown

tion of the Stock Standard Solution to spike the sample in Fig. 1 and Fig. 2.

D8133 − 23

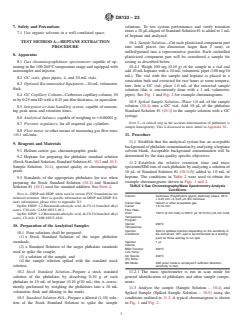

FIG. 1 Sample Solution—Ion Extracted Chromatogram of DINCH Plasticizer with About 1000 ppm of Each Phthalate (see 10.4 and 11.3)

D8133 − 23

FIG. 2 Sample Solution—Ion Extracted Chromatogram of DINCH Plasticizer with About 1000 ppm of Each Phthalate (see 10.4 and

11.3)—Expanded TIC

D8133 − 23

11.4 Peak identifications are based on relative retention y = 12202.3x + 116113.0 = 0

data, Scan mode (extracted ion) or single ion monitoring (SIM)

x (μg of analyte in sample solution) = 116113.0 / 12202.3 =

mode of the quant and confirming ions and the ion area ratios

9.52

as indicated in Table 1. Phthalate quantification is based upon

Amount of analyte in sample (ppm) = μg of analyte in

the peak areas of the quant ions listed in Table 1. The

sample solution / weight of sample in spiked sample

assumption being made is that the sole source of the quant ion

Weight of spiked sample = weight of sample / 10 =

at a predetermined retention time is the phthalate. Use the peak

0.1002 / 10 = 0.01002

area of the quant ion to accurately determine the amount of the

Amount of BBP in sample (ppm) = 9.52 / 0.01002 = 947

phthalate.

11.4.1 Peak identification is based solely on the presence or

13. Quality Control

absence of the quant ion and the two confirming ions at a

13.1 Perform the quality checks outlined in Table 3.

predetermined retention time. Quantification is based on the

area of the quant ion.

13.2 Ensure that the system is free of phthalate contamina-

NOTE 6—A typical ion extracted chromatogram obtained using the tion before analyzing samples. Prior to sample analysis the

conditions specific in 11.2 is shown in Fig. 1. Because the absolute

ability of the system to perform properly shall be verified.

retention times are dependent upon the entirety of the GC system; relative

retention times are used to identify each phthalate.

14. Report

11.5 Quantification is done using standard addition. Analyze

14.1 The amount of each target phthalate in ppm.

a Sample Solution. A typical ion extracted chromatogram is

14.1.1 Analyze 10 % of the samples in triplicate, report the

shown in Fig. 1 and Fig. 2. Standard addition is very useful to

standard deviation for each target compound. If the sample

correct for difference in response of the analyte in the sample

batch is less than 10 samples, then analyze one sample in

matrix. This is often the case when analyzing PVC where

triplicate and report the standard deviation. The standard

DINCH, Mesamoll or both are present.

deviation must be calculated using N-1 (2 rather than 3). No

NOTE 7—A good overview of standard addition is found on page 476,

outlier detection is allowed.

LCGC North America, Volume 27, number 6, June 2009.

14.1.2 If a sample batch is analyzed over more than two

days, the percent difference between the first and last Labora-

12. Example Calculations

tory control sample must be less than 10. Use the average in the

12.1 The amount of each phthalate in the samples are

denominator for calculating the % difference.

determined by a single-point standard addition method. The

amount of the analyte spiked into the sample (in μg) is plotted 14.2 R

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D8133 − 21 D8133 − 23

Standard Test Method for

Determination of Low Level Phthalates in Poly(Vinyl

Chloride) Plastics by Solvent Extraction—Gas

Chromatography/Mass Spectrometry

This standard is issued under the fixed designation D8133; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method provides a procedure to quantify six phthalates by solvent extraction of plasticized PVC articles followed by

analysis of the extract by gas chromatography/mass spectrometry. Six phthalates, BBP, DBP, DEHP, DNOP, DINP, and DIDP, are

used to illustrate how to implement the method.

NOTE 1—The method can be extended to other phthalates in a wide range of polymeric substrates.

1.2 Within the context of this method, “low level” is defined as 1000 ppm.

1.3 The values in SI units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

NOTE 2—There is no known ISO equivalent to this standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

D1600 Terminology for Abbreviated Terms Relating to Plastics

D3465 Guide for Purity of Monomeric Plasticizers by Gas Chromatography

D7083 Practice for Determination of Monomeric Plasticizers in Poly (Vinyl Chloride) (PVC) by Gas Chromatography

D7823 Test Method for Determination of Low Level Phthalates in Poly (Vinyl Chloride) Plastics by Thermal Desorption—Gas

Chromatography/Mass Spectrometry

D7993 Guide for Analyzing Complex Phthalates

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.70 on Analytical Methods.

Current edition approved Jan. 15, 2021March 15, 2023. Published February 2021April 2023. Originally approved in 2017. Last previous edition approved in 20202021

as D8133 – 20.D8133 – 21. DOI: 10.1520/D8133-21.10.1520/D8133-23.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D8133 − 23

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E355 Practice for Gas Chromatography Terms and Relationships

E594 Practice for Testing Flame Ionization Detectors Used in Gas or Supercritical Fluid Chromatography

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

IEEE/ASTM SI-10 Practice for Use of the International System of Units (SI), the Modernized Metric System

2.2 ASTM Adjuncts:ADJD7823-EA

Vinyl Plasticizer Library—Total Ion Chromatograms and Mass Spectra

2.3 CPSC Standard:

CPSC-CH-C1001–09.3 Standard Operating Procedure for Determination of Phthalates

3. Terminology

3.1 Definitions:

3.1.1 For definition of plastic terms used in this standard, see Terminologies D883 and D1600.

3.2 For units, symbols, and abbreviations used in this standard refer to Practices E594, E355, or IEEE/ASTM SI-10.

3.3 Compounds and Instrumentation:

3.3.1 (DOA) Hexanedioic acid, 1,6-bis(2-ethylhexyl) ester CAS #103-23-1

3.3.2 (DINCH) 1,2-Cyclohexanedicarboxylic acid, dinonyl ester, branched and linear CAS #474919-59-0

3.3.3 (DBP) 1,2-Benzenedicarboxylic acid, 1,2-di-n-butyl ester CAS #84-74-2

3.3.4 (BBP) Benzyl butyl phthalate CAS #85-68-7

3.3.5 (DEHP) Bis(2-ethyhexyl) phthalate CAS #117-81-7

3.3.6 (DNOP) Di(n-octyl) phthalate CAS #117-84-0

3.3.7 (DINP) 1,2-Benzenedicarboxylic acid, di-C8-10-branched alkyl esters, C9-rich (Jayflex) CAS #68515-48-0

3.3.8 (DINP) 1,2-Benzenedicarboxylic acid, 1,2-diisononyl (Palatinol) CAS #28553-12-0

3.3.9 (DIDP) 1,2-Benzenedicarboxylic acid, di-C9-11-branched alkyl esters, C10-rich (Jayflex) CAS #68515-49-1

3.3.10 (DIDP) 1,2-Benzenedicarboxylic acid, 1,2-diisodecyl CAS #26761-40-0

3.3.11 GC Gas Chromatography

3.3.12 GC/MS Gas Chromatography/Mass Spectrometry

3.3.13 TD-GC/MS Thermal Desorption—Gas Chromatography/Mass Spectrometry

3.3.14 PVC Poly(vinyl chloride)

3.3.15 Heptane GC grade or higher

3.3.16 FTIR Fourier Transform Infrared Spectroscopy

3.3.17 TIC Total ion chromatogram

3.3.18 DQO Data quality objectives

Available from U.S. Consumer Product Safety Commission (CPSC), 4330 East West Hwy., Bethesda, MD 20814, http://www.cpsc.gov.

D8133 − 23

4. Summary of Test Method

4.1 Test Method A—100 mg of the plasticized PVC sample along with 10 mL of heptane is extracted for 2 hours with the aid of

sonication. One milliliter of the heptane solution is placed in a GC vial and analyzed by GC/MS. Phthalates are identified by their

retention times and their mass spectra/SIM ions. Quantification is based on the area of a designated quantitative ion (SIM or full

scan) (see Table 1). The amount of each component is determined using a standard addition calibration method.

4.2 Test Method B—100 mg of the plasticized PVC sample are dissolved in THF. After the polymer is precipitated by adding 20

mL of hexane, 1.3 mL of the supernatant is filtered and placed in a GC vial and analyzed by GC/MS. Quantification is based on

the area of a designated quantitative ion (SIM or full scan) (see Table 1). The amount of each component is determined using an

internal calibration method.

NOTE 3—Standard addition calibration will correct for matrix affects (that is, response of the phthalates being different in solvent versus the solvent and

sample matrix).

5. Significance and Use

5.1 Identification and Quantification of Phthalates—DBP, BBP, DEHP, DNOP, DINP and DIDP are representative of the

phthalates either banned or being monitored by a variety of regulations. Regulations include: EU—Directive 2005/84/EC,

US—Consumer Product Safety Improvement Act of 2008 – section 108, Japan—Health, Labor and Welfare Ministry guideline No.

336 (2010) and IEC 62321-8:2017. These test methods provide a procedure to identify and quantify phthalates in PVC.

5.2 Other techniques successfully used to separate and identify phthalates in PVC include TD-GC/MS (ASTM D7823), GC/MS,

HPLC/UV, HPLC/MS, FTIR, and GC/FID (flame ionization detector).

6. Interferences

6.1 Retention times for GC are dependent on several variables and it is possible to have two or more components with identical

retention times. The analyst shall take the necessary steps to ensure that adequate separation of the plasticizer components is

achieved and or the ions used to monitor for a target phthalate are free of interference. This includes, but is not limited to changing

the selectivity of the chromatographic column or the heating profile of the GC column. Calibration by standard addition offers the

advantage of correcting for matrix affects.

6.2 When running the GC/MS method, care must be taken to ensure that the vials, septa, and containers are free of any phthalate

contamination. Also, all solvents used to prepare standards and sample solutions must be free of contamination.

6.3 The presence or absence of each phthalate is based upon three criteria:

(1) the relative retention time of the peak,

(2) the presence or absence of the Quant Ion and the two Confirm Ions, and

(3) the ratio of the Quant Ion and the Confirm Ion 1 in Table 1 must satisfy the established guideline.

6.4 Calculating the phthalate concentrations using the areas of compound specific ions significantly reduces interference from

non-target compounds, additionally using standard addition corrects for matrix affects.

TABLE 1 Ions and Ion Ratios Used to Identify Each Phthalate

NOTE 1—When DINP and DIDP are both present in a sample or standard, m/z 127 is used as a qualifying ion for DINP and m/z 289 for DIDP. This

is because DINP and DIDP partially co-elute and both produce m/z 149 and 167. If 149 qualifier ion ratios are set when DINP and DIDP are at equal

concentrations, then any samples with different ratios will produce substantially different 149/167 ratios, potentially leading to a false negative.

DBP BBP DEHP DNOP DINP DIDP

Quant ion 223 206 279 279 293 307

Confirm ion 1 149 149 149 149 149 149

Area ratio (±10%) <0.04 <0.23 <0.08 <0.06 <0.20 <0.12

(Quant/Confirm 1)

Confirm ion 2 167 167 167 167 167 167

D8133 − 23

7. Safety and Precautions

7.1 Use organic solvents in a well-ventilated space.

TEST METHOD A—HEPTANE EXTRACTION PROCEDURE

8. Apparatus

8.1 Gas chromatograph/mass spectrometer capable of operating in the 100-260°C temperature range and equipped with

autosampler and injector.

8.2 GC vials, glass pipets, 4, and 20-mL vials.

8.3 Optional Recommended Equipment—10-mL volumetric flask.

8.4 GC Capillary Column—Carbowax capillary column, 30 m by 0.25 mm ID with a 0.25 μm film thickness, or equivalent.

8.5 Integrator or data handling system, capable of measuring peak areas and retention times.

8.6 Analytical balance, capable of weighing to 60.00001 g.

8.7 Pressure regulators, for all required gas cylinders.

8.8 Flow meter, or other means of measuring gas flow rates 60.1 mL/min.

9. Reagents and Materials

9.1 Helium carrier gas, chromatographic grade.

9.2 Heptane for preparing the phthalate standard solution (Stock Standard Solution, Standard Solution #1, 10.2 and 10.3; Sample

Solution, 10.4), spectral quality or chromatographic grade.

9.3 Standards of the appropriate phthalates for use when preparing the Stock Standard Solution (10.2) and Standard Solution #1

(10.3) used for standard addition. See Note 4.

NOTE 4—DINP and DIDP, when used in various PVC formulations are technical mixtures. Here is specific information on DINP and DIDP. For more

information, please refer to Appendix X3.

Jayflex DIDP: 1,2-Benzenedicarboxylic acid, di-C9-11-branched alkyl esters, C10-rich: CAS# 68515-49-1.

Jayflex DINP: 1,2-Benzenedicarboxylic acid, di-C8-10-branched alkyl esters, C9-rich: CAS# 68515-48-0.

10. Preparation of the Analytical Samples

10.1 Four solutions shall be prepared:

(1) a Stock Standard Solution of the target phthalate standards,

(2) a Standard Solution of the target phthalate standards used to spike the sample,

(3) a solution of the sample, and

(4) the sample solution spiked with the standard stock solution.

10.2 Stock Standard Solution—Prepare a stock standard solution of the phthalates by dissolving 0.10 g of each phthalate in 10 mL

of heptane (0.10 g/10 mL; this is conveniently performed by weighing the phthalates into a 10 mL volumetric flask and diluting

to the mark).

D8133 − 23

10.3 Standard Solution #1A—Prepare a diluted (1:10) solution of the Stock Standard Solution to spike the sample solutions. To

test system performance and verify retention times a 10 μL aliquot of Standard Solution #1 is added to 1 mL of heptane and

analyzed.

10.4 Sample Solution—Cut each plasticized component part into small pieces (no dimension larger than 2 mm), or milled/ground

into a representative powder. Each cut/milled plasticized component part will be considered a sample for testing as described

below.

10.4.1 Weigh 100 mg (0.10 g) of the sample in a vial and add 10 mL heptane with a 10-mL volumetric pipet (100 mg/10 mL).

The vial with the sample and heptane is placed in a sonication bath and extracted for two hours at room temperature. Into a GC

vial, place 1.0 mL of the extracted sample solution (this is conveniently done with a 1 mL volumetric pipet). See Fig. 1 and Fig.

2 for example chromatograms.

10.5 Spiked Sample Solution—Place 1.0 mL of the sample solution (10.4) into a GC vial. Add 10 μL of the phthalate Standard

Solution #1 (10.3) to the sample solution with a GC syringe.

NOTE 5—A critical step in the accurate determination of phthalates is sample homogeneity. This is discussed in more detail in Appendix X1.

11. Procedure

11.1 Establish that the analytical system has an acceptable background of phthalate contamination by analyzing a heptane solvent

blank. Acceptable background contamination will be determined by the data quality specific objectives.

11.2 Establish the relative retention time and mass spectrum/SIM ions of each phthalate by analyzing a solution of 10 μL of

Standard Solution #1 (10.1(3)) added to 1.0 mL of heptane. The conditions in Table 2 were used to obtain the example

chromatograms shown in Figs. 1 and 2.

TABLE 2 Gas Chromatography/Mass Spectrometry Analysis Conditions

Column: Carbowax (Polyethylene glycol) stationary phase, 30 m × 0.25 mm i.d, 0.25 μm film thickness

Carrier Gas: Helium or other acceptable gas

Carrier 1.0 mL/min

Flow Rate:

Oven 150°C (0 min hold) to 250°C (at 10°C/min) (45 min hold)

Temperature

Program:

Injector 250°C

Temperature:

Injection Splitless injection

Conditions:

Injection Split or splitless injection depending on the sensitivity of the instrument. 20:1 split is recommended as a starting point

Conditions: for those wishing to run split.

Injection 1 μL

Volume:

MSD Transfer 250°C

Line Temp.:

Ion Source 230°C

(EI) Temp.:

MS Mode: SIM (scan mode is employed if sufficient detection sensitivity is met)

11.2.1 The mass spectrometer is run in scan mode for general identification of phthalates and other sample components.

11.3 Analyze the sample (Sample Solution – 10.4) and Spiked Sample (Spiked Sample Solution – 10.5) using the conditions

outlined in 11.2. A typical chromatogram is shown in Fig. 1 and Fig. 2.

11.4 Peak identifications are based on relative retention data, Scan mode (extracted ion) or single ion monitoring (SIM) mode of

the quant and confirming ions and the ion area ratios as indicated in Table 1. Phthalate quantification is based upon the peak areas

of the quant ions listed in Table 1. The assumption being made is that the sole source of the quant ion at a predetermined retention

time is the phthalate. Use the peak area of the quant ion to accurately determine the amount of the phthalate.

D8133 − 23

FIG. 1 Sample Solution—Ion Extracted Chromatogram of DINCH Plasticizer with About 1000 ppm of Each Phthalate (see 10.4 and 11.3)

D8133 − 23

FIG. 2 Sample Solution—Ion Extracted Chromatogram of DINCH Plasticizer with About 1000 ppm of Each Phthalate (see 10.4 and

11.3)—Expanded TIC

D8133 − 23

11.4.1 Peak identification is based solely on the presence or absence of the quant ion and the two confirming ions at a

predetermined retention time. Quantification is based on the area of the quant ion.

NOTE 6—A typical ion extracted chromatogram obtained using the conditions specific in 11.2 is shown in Fig. 1. Because the absolute retention times

are dependent upon the entirety of the GC system; relative retention times are used to identify each phthalate.

11.5 Quantification is done using standard addition. Analyze a Sample Solution. A typical ion extracted chromatogram is shown

in Fig. 1 and Fig. 2. Standard addition is very useful to correct for difference in response of the analyte in the sample matrix. This

is often the case when analyzing PVC where DINCH, Mesamoll or both are present.

NOTE 7—A good overview of standard addition is found on page 476, LCGC North America, Volume 27, number 6, June 2009.

12. Example Calculations

12.1 The amount of each phthalate in the samples are determined by a single-point standard addition method. The amount of the

analyte spiked into the sample (in μg) is plotted versus the peak area (see Fig. 3). The line is used to calculate the amount of

phthalate in the sample. As only one-tenth of the sample solution is spiked (the weight of sample is about 0.100 g / 10 = 0.01 g).

12.1.1 To determine the amount of the analyte in the sample, determine the point where the line crosses the x-axis (this is the

amount of the analyte in the sample solution, DBP in this case).

y = 12202.3x + 116113.0 = 0

x (μg of analyte in sample solution) = 116113.0 / 12202.3 = 9.52

Amount of analyte in sample (ppm) = μg of analyte in sample solution / weight of sample in spiked sample

Weight of spiked sample = weight of sample / 10 =

0.1002 / 10 = 0.01002

Amount of BBP in sample (ppm) = 9.52 / 0.01002 = 947

13. Quality Control

13.1 Perform the quality checks outlined in Table 3.

13.2 Ensure that the system is free of phthalate contamination before analyzing samples. Prior to sample analysis the ability of

the system to perform properly shall be verified.

14. Report

14.1 The amount of each target phthalate in ppm.

FIG. 3 Plot of Micrograms of Phthalate Added to the Sample Solution Versus Phthalate Peak Area

D8133 − 23

TABLE 3 System Performance Verificatio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...